Ultrasonic detection method for defect automatic identification auxiliary electric melting joint smart phased array

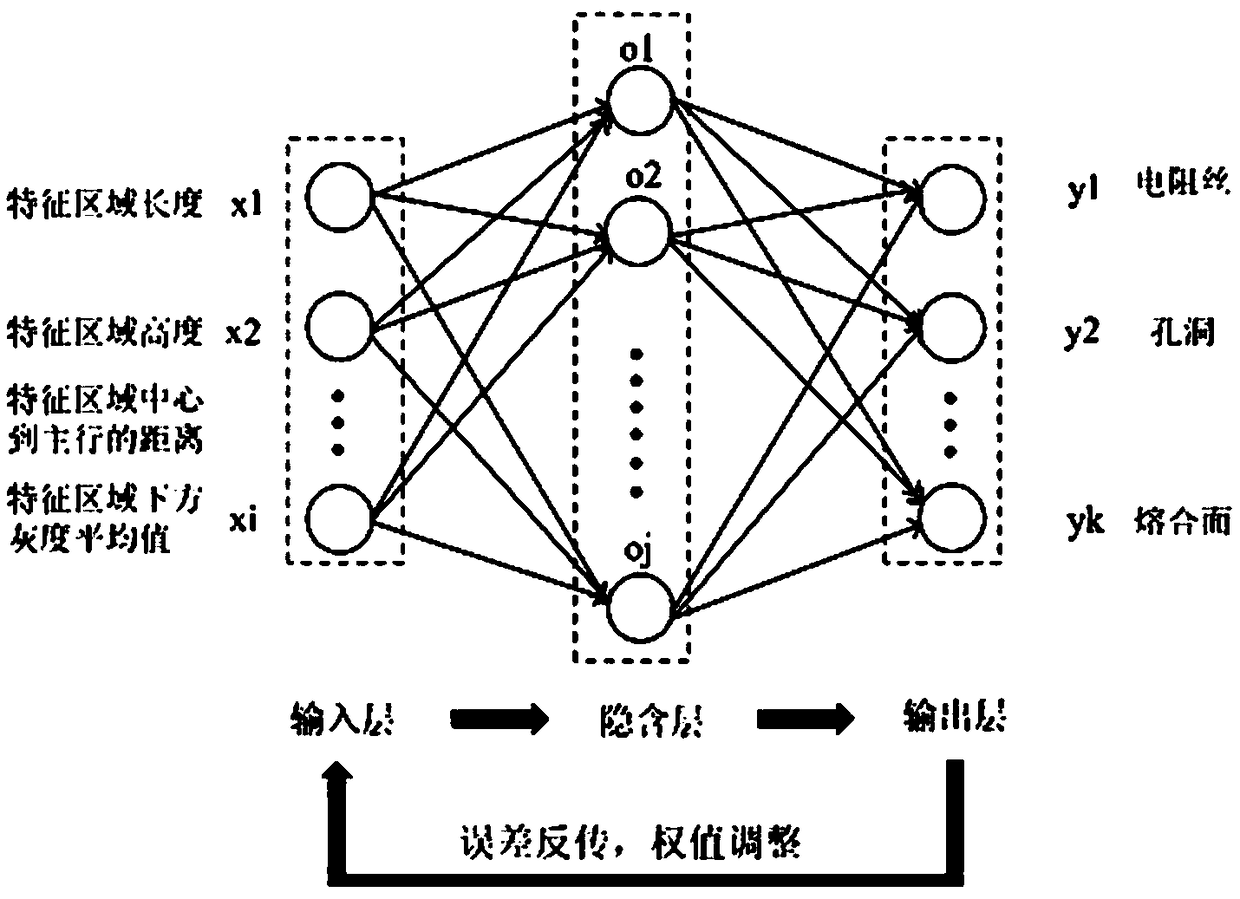

A technology for automatic identification and electrofusion joints, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. Problems such as slow running speed, to avoid missing defects, overcome the dependence on the qualifications of testing personnel, and achieve the effect of fast running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

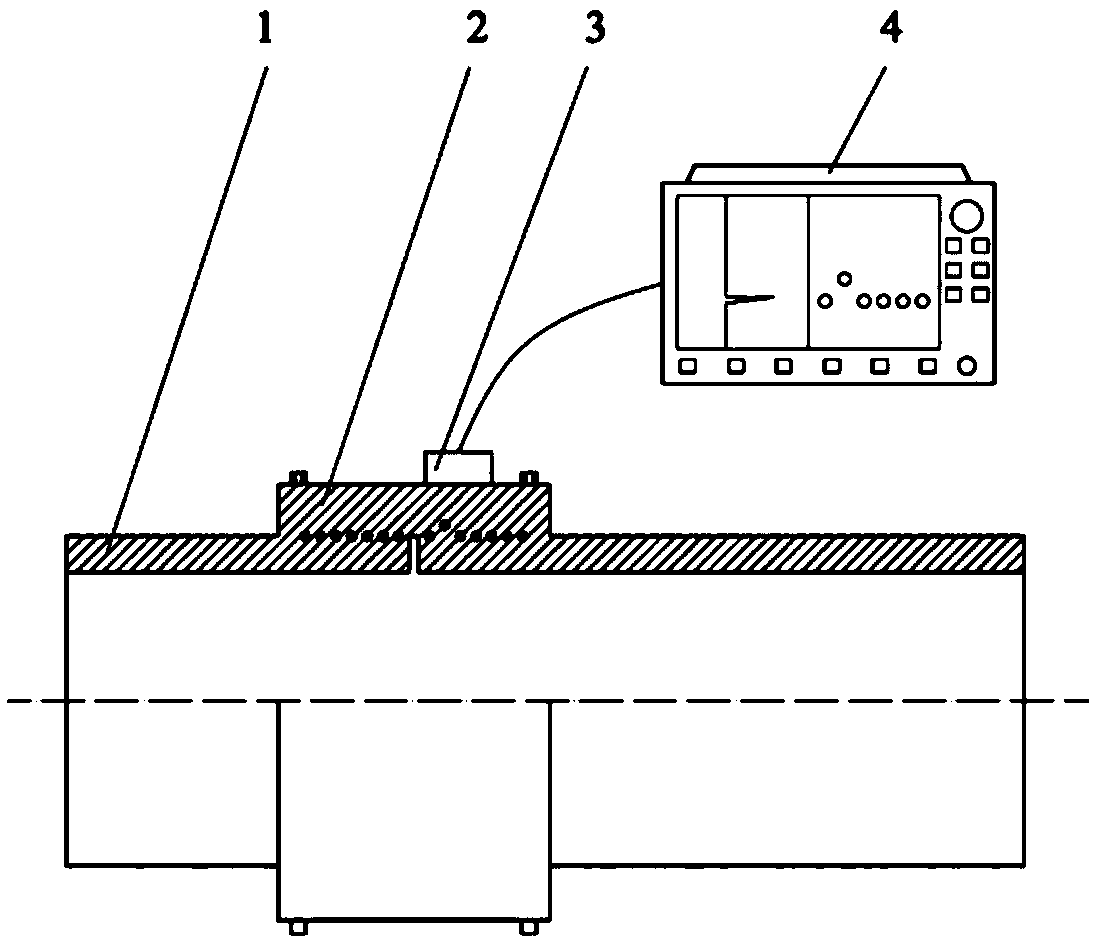

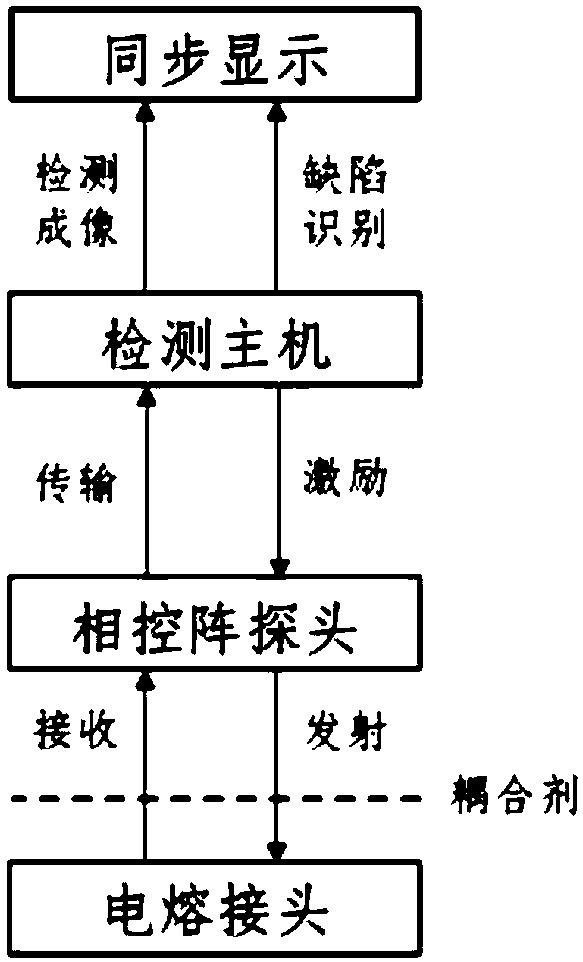

[0055] According to the automatic defect identification technology provided by the present invention, the intelligent phased array ultrasonic detection method for plastic pipe electrofusion joints is assisted to detect plastic pipe electrofusion joints, and the defects are identified and displayed in real time to assist inspectors in detection. Take the electrofusion joint of PE pipe in a city's water supply system as an example. The specifications of this section of PE pipe are DN110 and SDR11, and the electrofusion joint is used to connect the pipeline. The detection depth is about 25mm, and the melting zone depth is about 12mm. The phased array ultrasonic detector produced by a certain company has two modes of linear scanning and sectoral scanning; it can realize 32-channel reception and independent 128-channel transmission, and can support a phased array probe with a maximum of 128 array elements. The phased array probe has a center frequency of 7.5MHz, 64 array elements, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com