Method and device for detecting fruit defects based on multi-sensor information fusion

A multi-sensor, defect detection technology, applied in the direction of optical test defect/defect, color/spectral characteristic measurement, etc., can solve the problem of not considering the influence of environmental temperature and humidity of fruit, unable to realize simultaneous detection of fruit, etc., to improve stability and detection accuracy, and the effect of preventing defects from being missed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples.

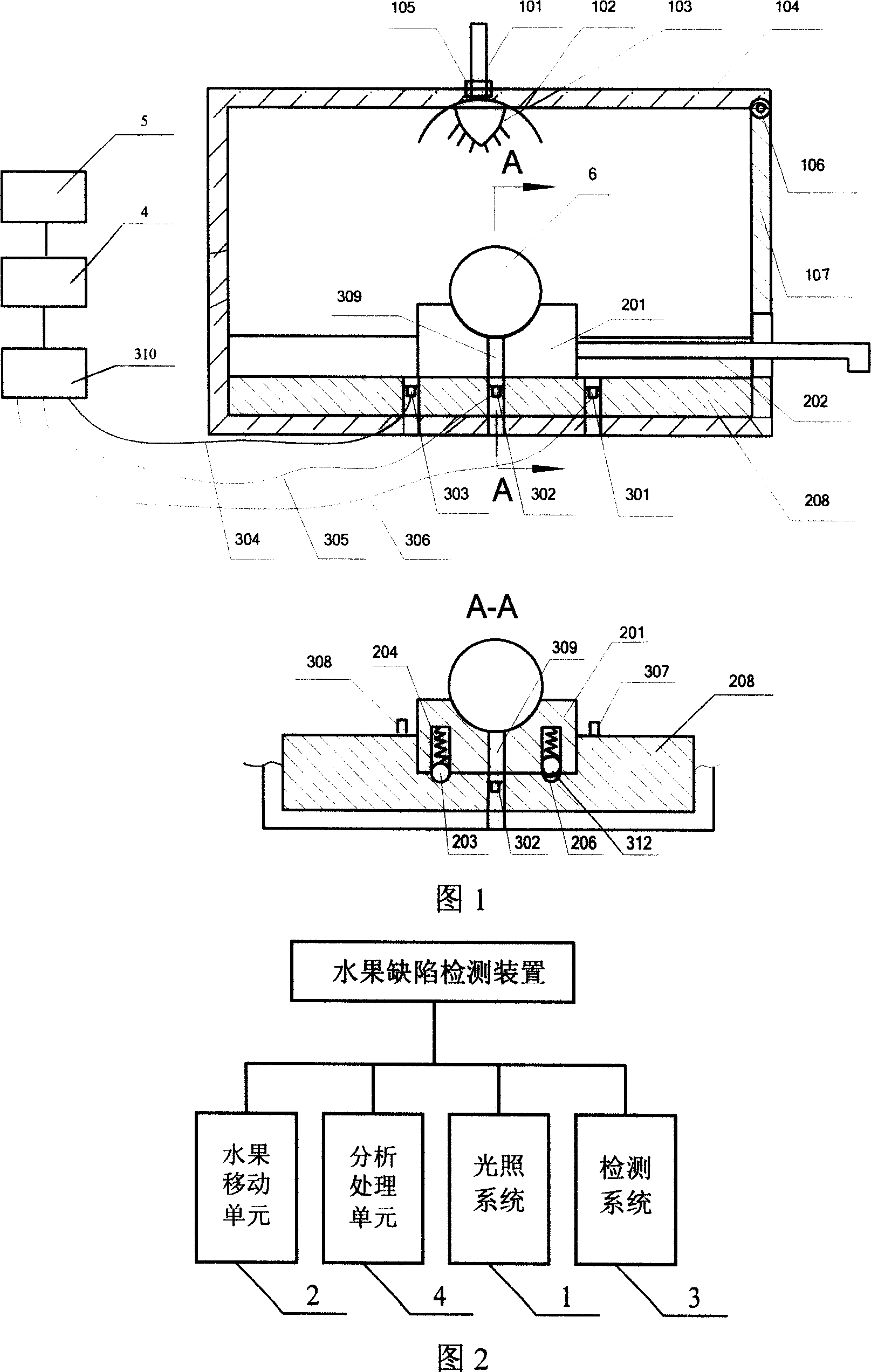

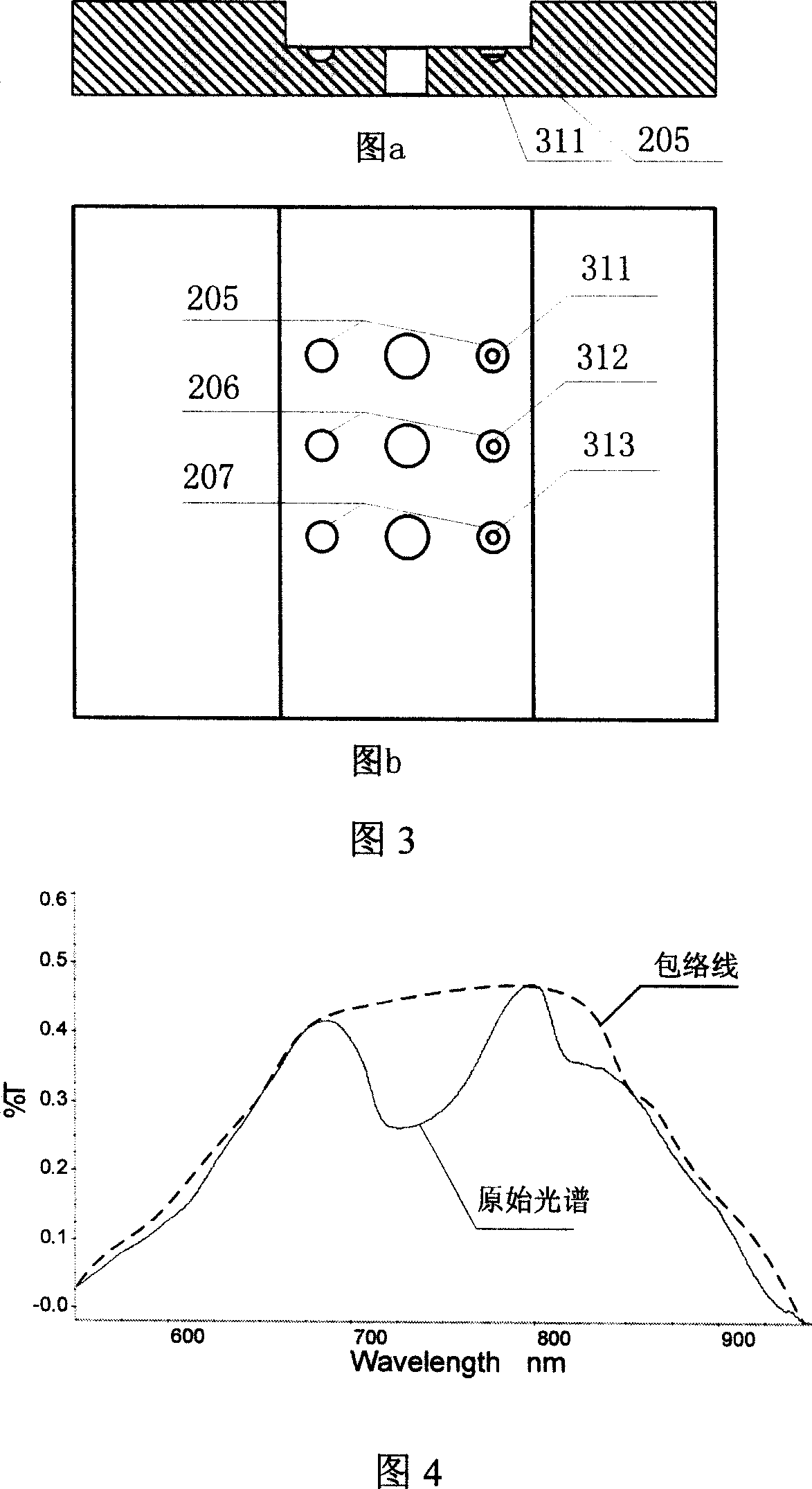

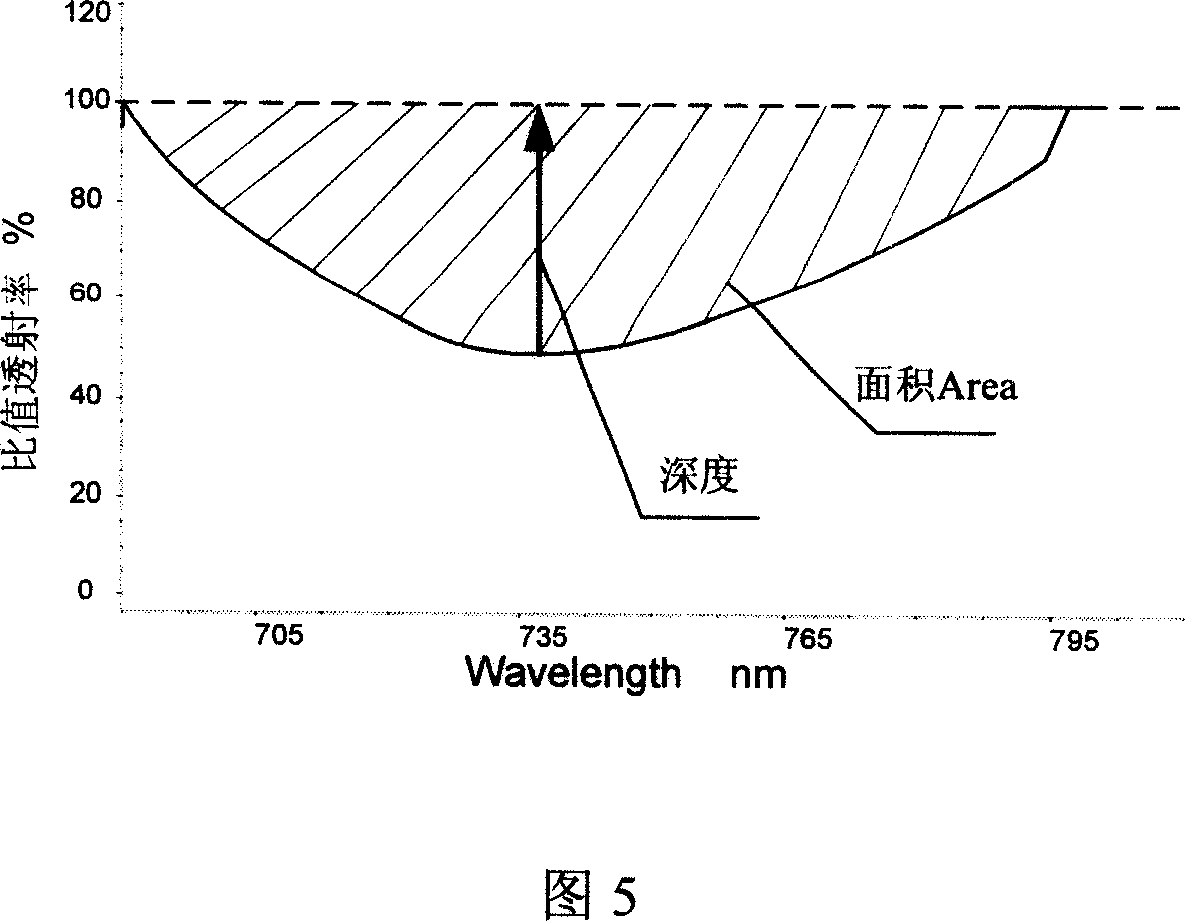

[0033] As shown in Fig. 1, Fig. 2 and Fig. 3, the present invention mainly is made up of illumination system 1, fruit moving unit 2, detection system 3 and analysis processing unit 4; Wherein:

[0034] 1) Illumination system 1 as shown in Figure 1, comprises light box 104, halogen tungsten lamp 103, hemispherical reflector 102, adjusting screw rod 101, nut 105, hinge 106, movable plate 107; Halogen tungsten lamp 103 is installed on hemispherical reflector In the center of the plate 102, the hemispherical reflector 102 is fixedly connected with the adjusting screw 101, and the adjusting screw 101 is fixed on the light box 104 through the nut 105, and the height of the halogen tungsten lamp 103 can be adjusted by adjusting the screw 101; the halogen tungsten lamp 103 is the light source power Adjustable, different light sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com