Bottle bottom defect detection system and method

A technology for defect detection and detection, which is applied in the direction of optical testing of flaws/defects, measuring devices, and material analysis through optical means, which can solve the problems of slow bottom detection and error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

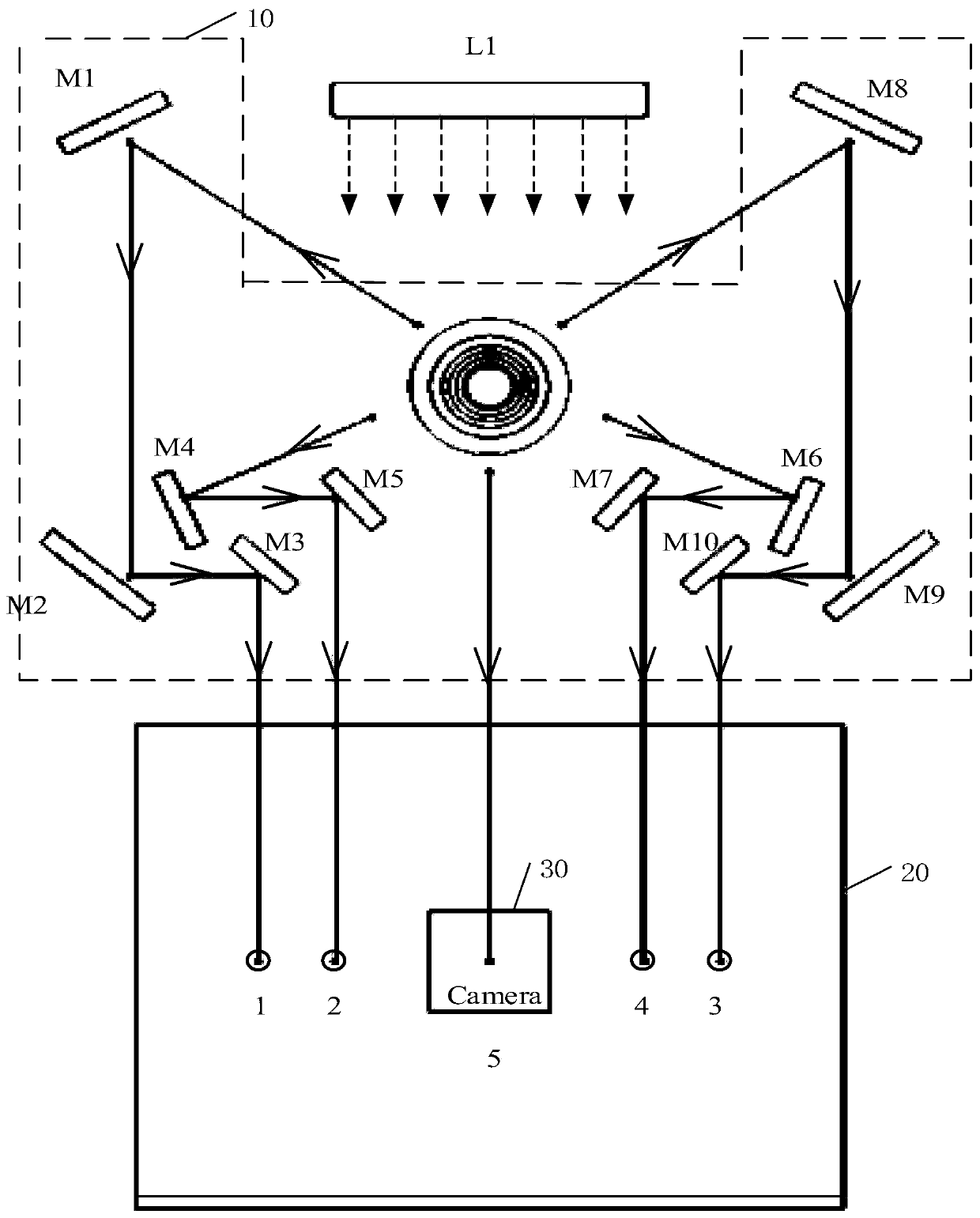

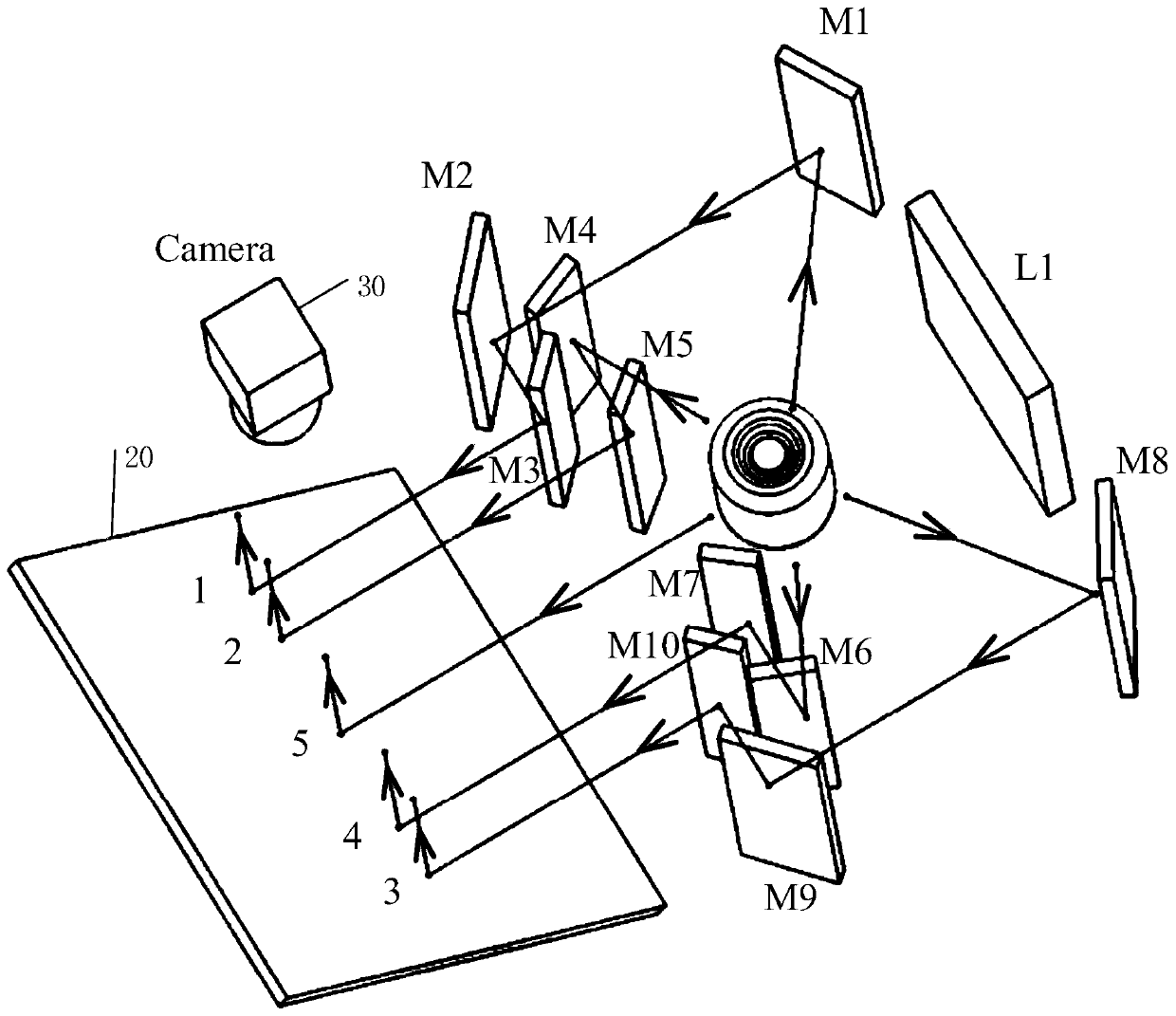

[0041] Such as figure 1 As shown, it is a schematic top view of the optical path structure of the bottle bottom defect detection system provided by Embodiment 1 of the present invention. The bottle bottom defect detection system may include: a light source L1, a mirror array 10, a light collecting device 20, a photographing device 30 and a control device 40;

[0042] Wherein, the system is provided with the light source L1 to irradiate the bottom of the product to be inspected at the detection position (i.e. the C surface of the product to be inspected); Beams of return light carrying bottom information, and respectively transmit the return light reflected by each of the equally divided areas to the light collection device 20; the light collection device 20 reflects the several beams of return light to the within the field of view of the photographing device 30.

[0043]Specifically, since the bottom defect of the product is easy to be ignored during the production process, ...

Embodiment 2

[0060] Such as Figure 4 Shown is a schematic flow chart of the bottle bottom defect detection method provided in Embodiment 2 of the present invention. This embodiment is applicable to the scene where the bottle bottom defect detection system in Embodiment 1 performs defect detection on the bottom (bottom) of the product to be inspected. This method can be executed by the control device 40, which can be an intelligent terminal, tablet or PC, etc. In the embodiment of the present invention, the control device 40 in the bottle bottom defect detection system is used as the execution subject for description, and the method specifically includes the following steps:

[0061] S210. Receive a detection signal sent by a photoelectric sensor disposed at the detection position;

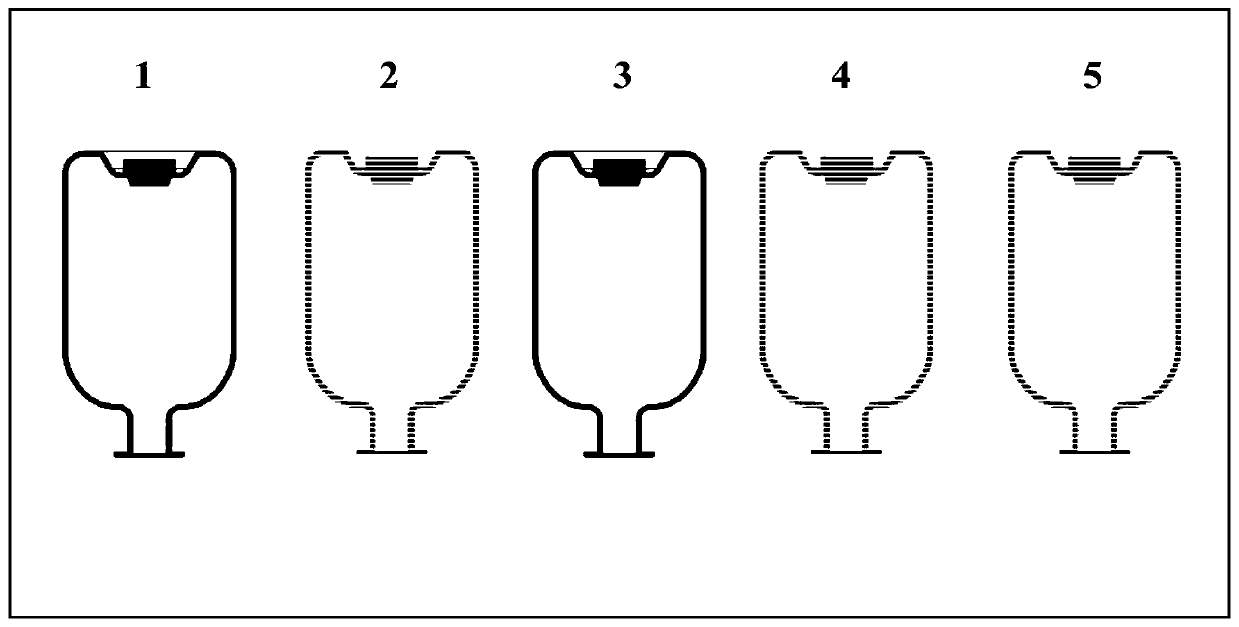

[0062]The bottom of the product to be inspected can be divided into several equal parts according to the requirements. When the product transmission device installed on the assembly line transports the produc...

Embodiment 3

[0075] Figure 7 It is a structural schematic diagram of the control device of the bottle bottom defect detection system provided by the third embodiment of the present invention. The control device includes: a processor 70, a memory 71, and a computer program 72 stored in the memory 71 and operable on the processor 70, such as a program of a method for detecting defects at the bottom of a bottle. When the processor 70 executes the computer program 72, it implements the steps in the above working mode switching method embodiment, for example image 3 Steps S210 to S230 are shown.

[0076] Exemplarily, the computer program 72 can be divided into one or more modules, and the one or more modules are stored in the memory 71 and executed by the processor 70 to complete the present application. The one or more modules may be a series of computer program instruction segments capable of accomplishing specific functions, and the instruction segments are used to describe the execution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com