Ultrasonic time-of-flight diffraction method by cylinder focusing wedge

A diffraction time difference method and wedge block technology, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve problems such as the need to improve the detection sensitivity and the low energy level of the diffraction signal, and achieve the effect of improving the identification ability and avoiding the missed detection of defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

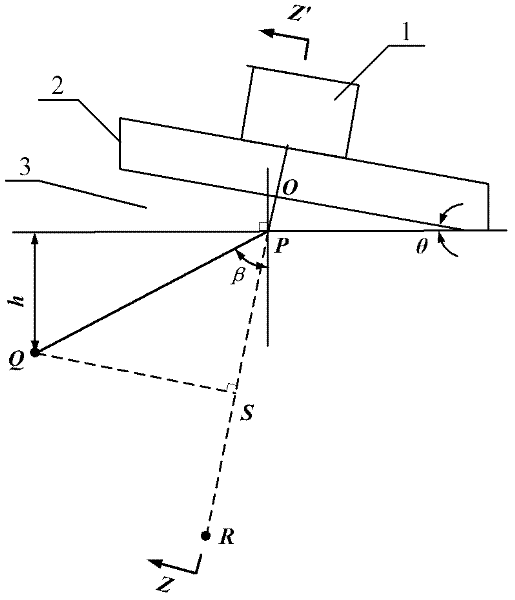

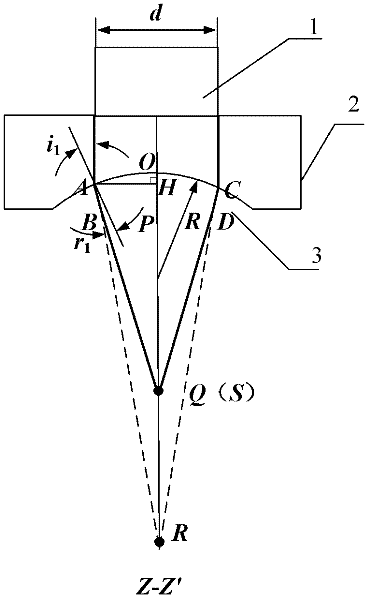

[0042] Specific implementation mode 1: Combination figure 1 with figure 2 To describe this embodiment, the specific steps included in this embodiment are as follows:

[0043] Step 1. Determine the known conditions: the diameter of the probe wafer, the longitudinal wave speed of the wedge, the longitudinal wave sound speed of the tested workpiece, and the longitudinal wave sound speed in water;

[0044] Step 2. Set the required conditions: the water path of the spindle sound beam, the refraction angle of the longitudinal wave in the tested workpiece, and the vertical depth of focus of the spindle sound beam in the workpiece;

[0045] Step 3: Calculate the radius of curvature of the wedge cylinder according to the above conditions:

[0046] The incident angle of the sound beam emitted by the probe on the curved surface is i 1 , The refraction angle after curved surface refraction is r 1 , Stipulating the refraction angle β of the sound beam at the interface between the water and the te...

specific Embodiment approach 2

[0077] Specific embodiment 2: This embodiment adopts the technical scheme of specific embodiment 1, and experiments are carried out in combination with a specific environment to illustrate the effect of the present invention. The aluminum alloy plate with a thickness of 10.5 mm is used as the detection object, and the wedge is made of organic glass:

[0078] Step 1. Determine the known conditions: probe wafer diameter d=6mm, plexiglass longitudinal wave sound velocity v Plexiglass =2730m / s, the longitudinal wave sound velocity of the tested workpiece v aluminum =6260m / s, longitudinal wave sound velocity in water v water =1480m / s;

[0079] Step two, set the required conditions: the spindle sound beam water path OP=1.5mm, the longitudinal wave refraction angle θ=60° in the inspected workpiece, and the focal depth of the spindle sound beam in the workpiece h=5.3mm;

[0080] Step 3: Calculate the radius of curvature of the wedge:

[0081] The incident angle of the sound beam emitted by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com