Deviation rectifying, speed adjusting and roller interval adjusting system for producing boards

A technology for plate production and adjustment system, applied in the fields of roll spacing adjustment system, speed regulation, and deviation correction, can solve problems such as affecting the normal operation of the unit, decline in production capacity, damage to production equipment, etc., achieve simple structure, low cost, and increase the pass rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

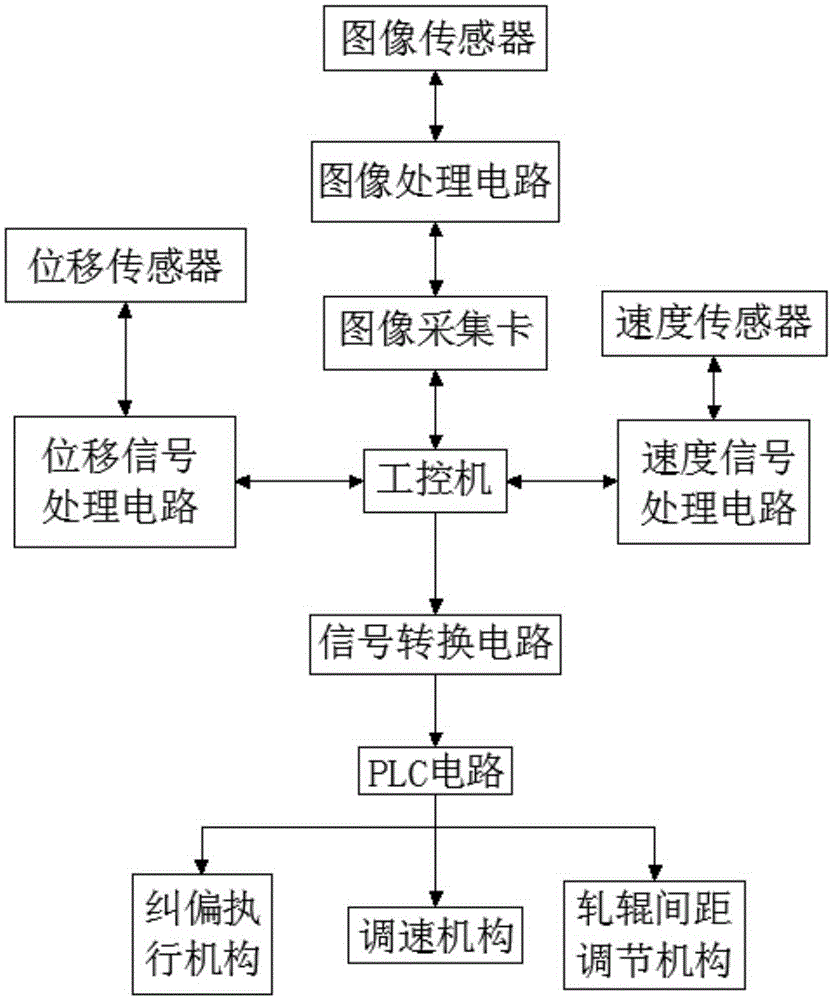

[0018] A deviation correction, speed regulation, and roller spacing adjustment system for plate production, which can effectively correct the deviation of the strip, and can effectively control the quality of the strip in production by combining the technology of speed regulation and roller spacing adjustment, thereby improving The quality of the entire strip increases the qualified rate of the product. It has the characteristics of simple structure, low cost, high detection accuracy, strong real-time performance, and strong anti-interference ability, such as figure 1 As shown, the following structure is specially set up: including an image processing system, a displacement sensing system, an industrial computer, a speed sensing system and an adjustment circuit, and the industrial computer is respectively connected to the image processing system, the displacement sensing system, and the speed sensing system and an adjustment circuit, the adjustment circuit is provided with a si...

Embodiment 2

[0020] This embodiment is further optimized on the basis of the above-mentioned embodiments. Further, in order to better realize the present invention, fast scanning is realized according to the conveying speed of the strip steel, and the direction of the dot matrix image of the edge of the laser line strip steel is reconstructed in real time, and according to The double-edge form visualizes the shape change form of the strip during the running process, such as figure 1 As shown, the following structure is particularly provided: the image processing system is provided with an image sensor, an image processing circuit and an image acquisition card, the industrial computer is connected to the image acquisition card, the image acquisition card is connected to the image processing circuit, and the The image processing circuit is connected with the image sensor.

Embodiment 3

[0022] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, the displacement value of the strip steel can be monitored in real time, and real-time data basis is provided for the correction operation, such as figure 1 As shown, the following structure is particularly provided: the displacement sensor system is provided with a displacement sensor and a displacement signal processing circuit, the displacement sensor is connected to the displacement signal processing circuit, and the displacement signal processing circuit is connected to the industrial computer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com