Hot rolling process for producing electrical steel free of metal flow stacking defect

An electrical steel, metal-free technology, applied in metal rolling, temperature control and other directions, can solve problems such as affecting product benefits, increasing manufacturing costs, insufficient quality control stability, etc., to facilitate the hot rolling process and improve the quality of steel strips , The effect of improving the production qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

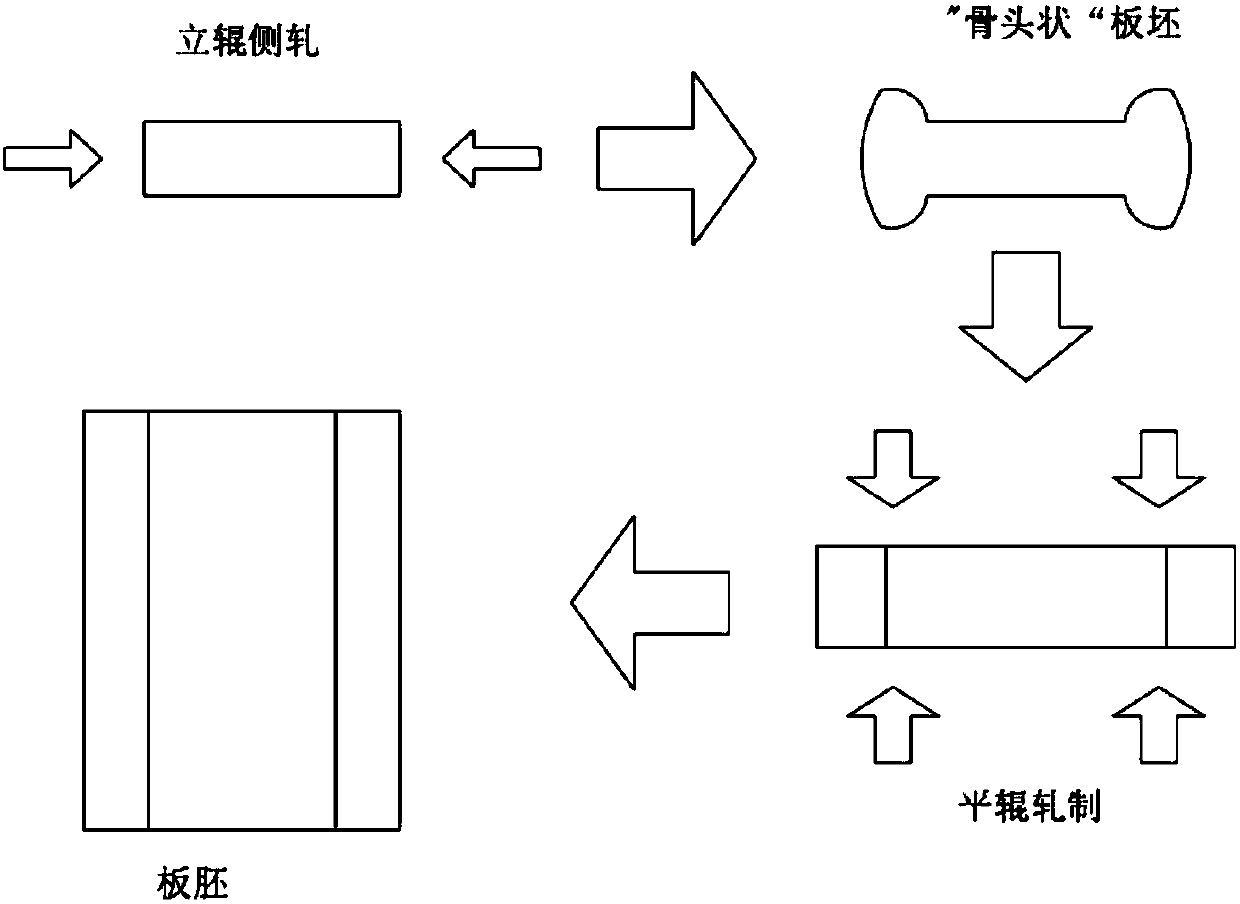

Method used

Image

Examples

Embodiment 1

[0027] In the actual production process, the chemical composition weight percentage of electrical steel is: C≤0.0025%, Si: 0.38%, Mn: 0.31%, P: 0.07%, S: 0.006%, Als: 0.004%, N: 0.004%, and the rest For iron and unavoidable impurity elements.

[0028] The present invention implements production method and comprises the following processing steps:

[0029] Converter smelting, argon blowing at Ar station, RH vacuum refining treatment, molten steel components treated according to the above requirements, and continuous casting into a slab with a thickness of 230mm and a width of 1250mm.

[0030] Specifications of hot rolling orders: thickness 2.5mm, width 1244mm steel strip, side pressure from slab to finished product 6mm.

[0031] In the hot rolling process, the slab is heated to 1140°C, the final rolling temperature is 890°C, and the coiling temperature is 570°C.

[0032] Implementation effect of the present invention

[0033] Finished product inspection Product quality: elec...

Embodiment 2

[0035] In the actual production process, the chemical composition weight percentage of electrical steel is: C≤0.0035%, Si: 0.43%, Mn: 0.25%, P: 0.065%, S: 0.007%, Als: 0.0035%, N: 0.0045%, and the rest For iron and unavoidable impurity elements.

[0036] The present invention implements production method and comprises the following processing steps:

[0037] Converter smelting, argon blowing at Ar station, RH vacuum refining treatment, molten steel components treated according to the above requirements, and continuous casting into a slab with a thickness of 230mm and a width of 1300mm.

[0038] Specifications of hot rolling orders: thickness 2.5mm, width 1274mm steel strip, side pressure from slab to finished product 26mm.

[0039] In the hot rolling process, the slab is heated to 1150°C, the final rolling temperature is 880°C, and the coiling temperature is 580°C.

[0040] Implementation effect of the present invention

[0041] Finished product inspection Product quality: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com