Zinc liquid pump for hot galvanizing

A technology of hot-dip galvanizing and zinc liquid, which is applied in the field of pumping devices or systems, and can solve problems such as threatening the normal production process of strip steel, affecting the surface quality of strip steel, and sticking zinc dross to strip steel, achieving simple structure and thorough removal of dross , the effect of high strip quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

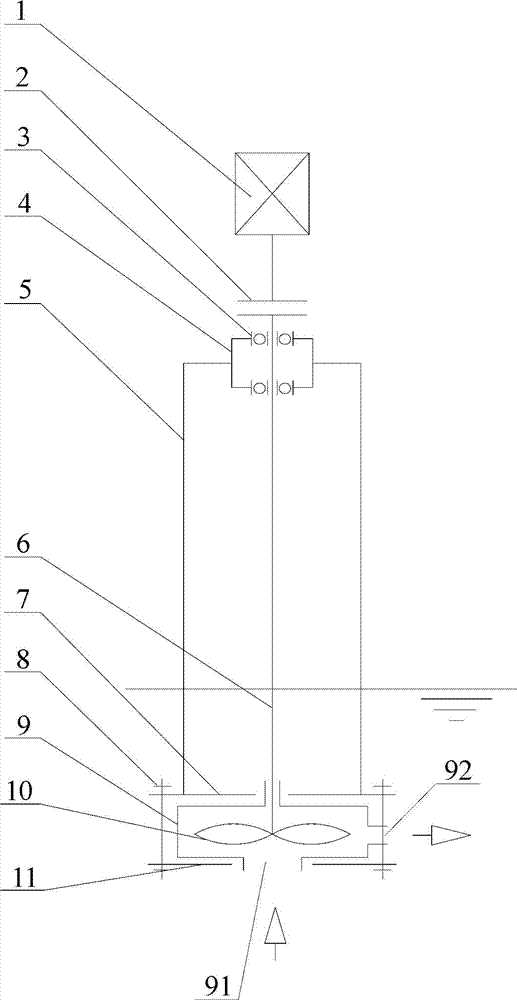

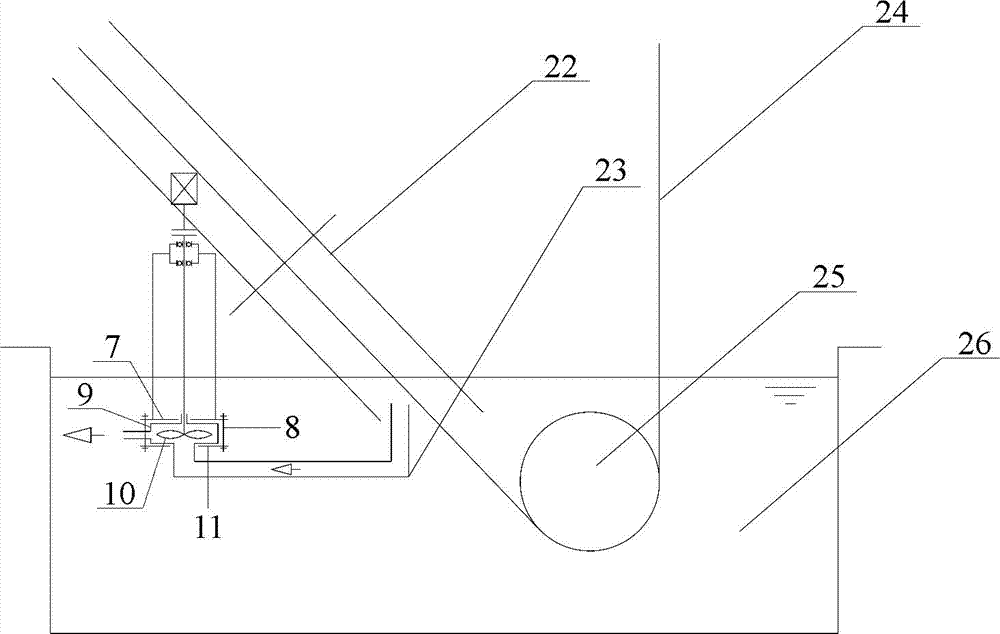

[0018] A liquid zinc pump for hot-dip galvanizing, including a driving motor 1, a coupling 2, a bearing 3, a bearing seat 4, a connecting rod 5, a pump shaft 6, a pump upper flange 7, connecting bolts 8, and a pump casing 9 , impeller 10 and pump lower flange 11, such as figure 1 As shown, the specific structure is:

[0019] The rotating shaft of the drive motor 1 is connected to the input shaft of the coupling 2;

[0020] The output shaft of the coupling 2 is connected to the top of the pump shaft 6, the driving motor 1 is set above the coupling 2, the pump shaft 6 is set below the coupling 2, the impeller 10 is set in the pump casing 9, and the pump casing 9 is provided with a liquid inlet 91 and a liquid outlet 92, and the bottom end of the pump shaft 6 penetrates the pump casing 9 and connects with the impeller 10;

[0021] The top of the pump casing 9 is provided with the pump upper flange 7, the bottom of the pump shaft 6 passes through the flange neck of the pump uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com