Textile bobbin sorting collector

A collection device and wire reel technology, which is applied in the directions of packaging, transportation and packaging, individual objects, etc., can solve the problems of low space utilization rate of the wire reel collection frame, reduction of the number of wire reels, and low carding efficiency, etc. Achieve high degree of automation, improve utilization, reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

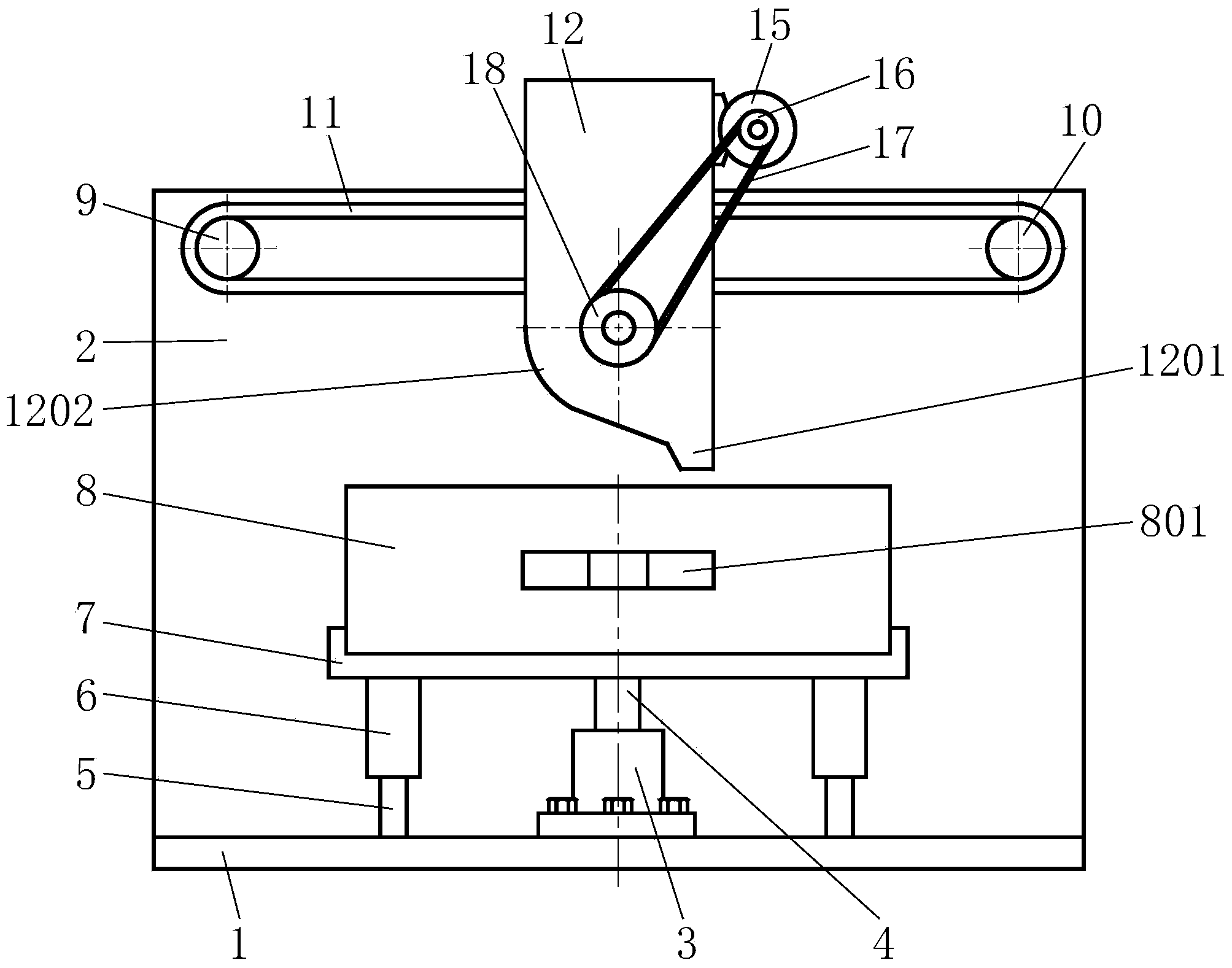

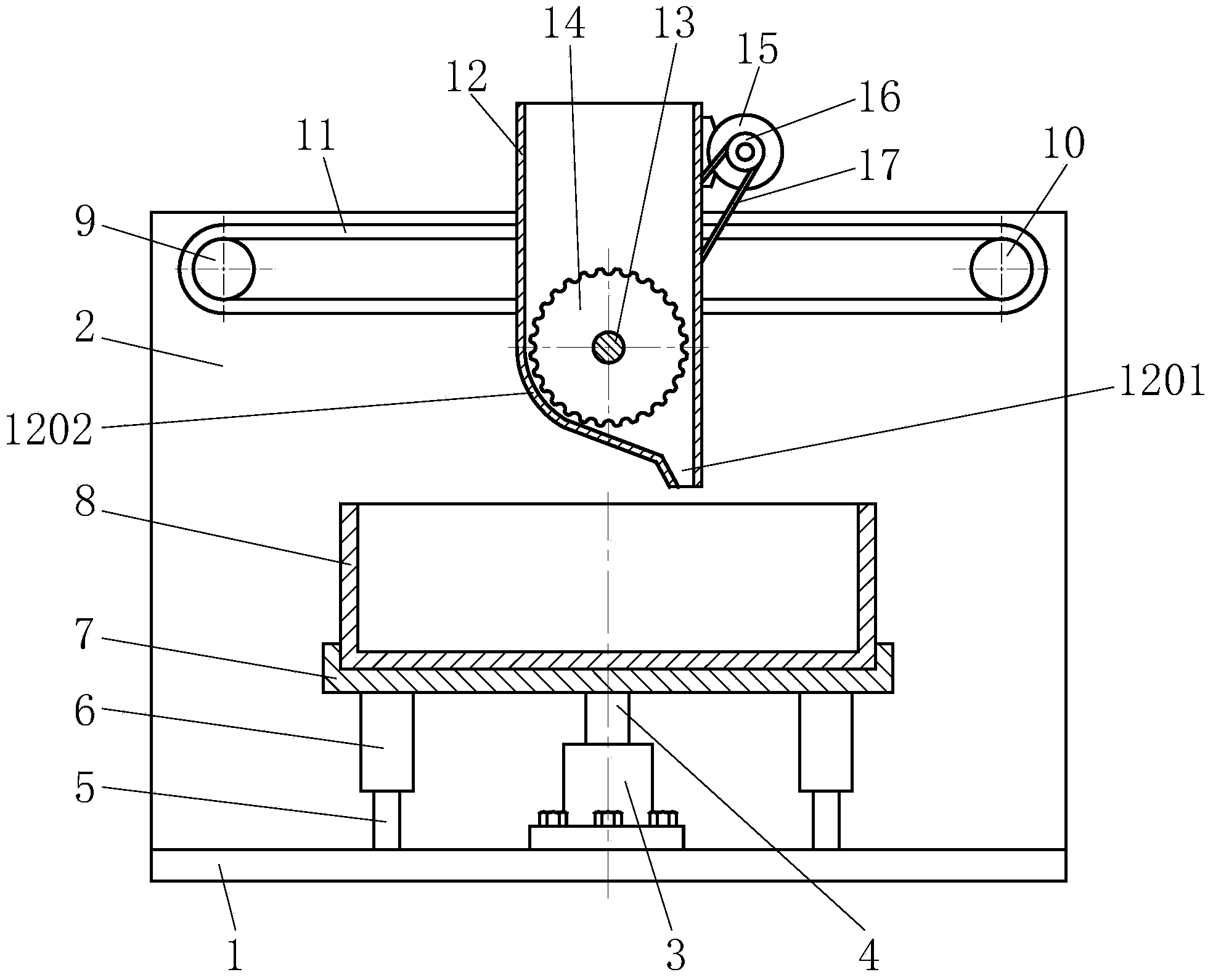

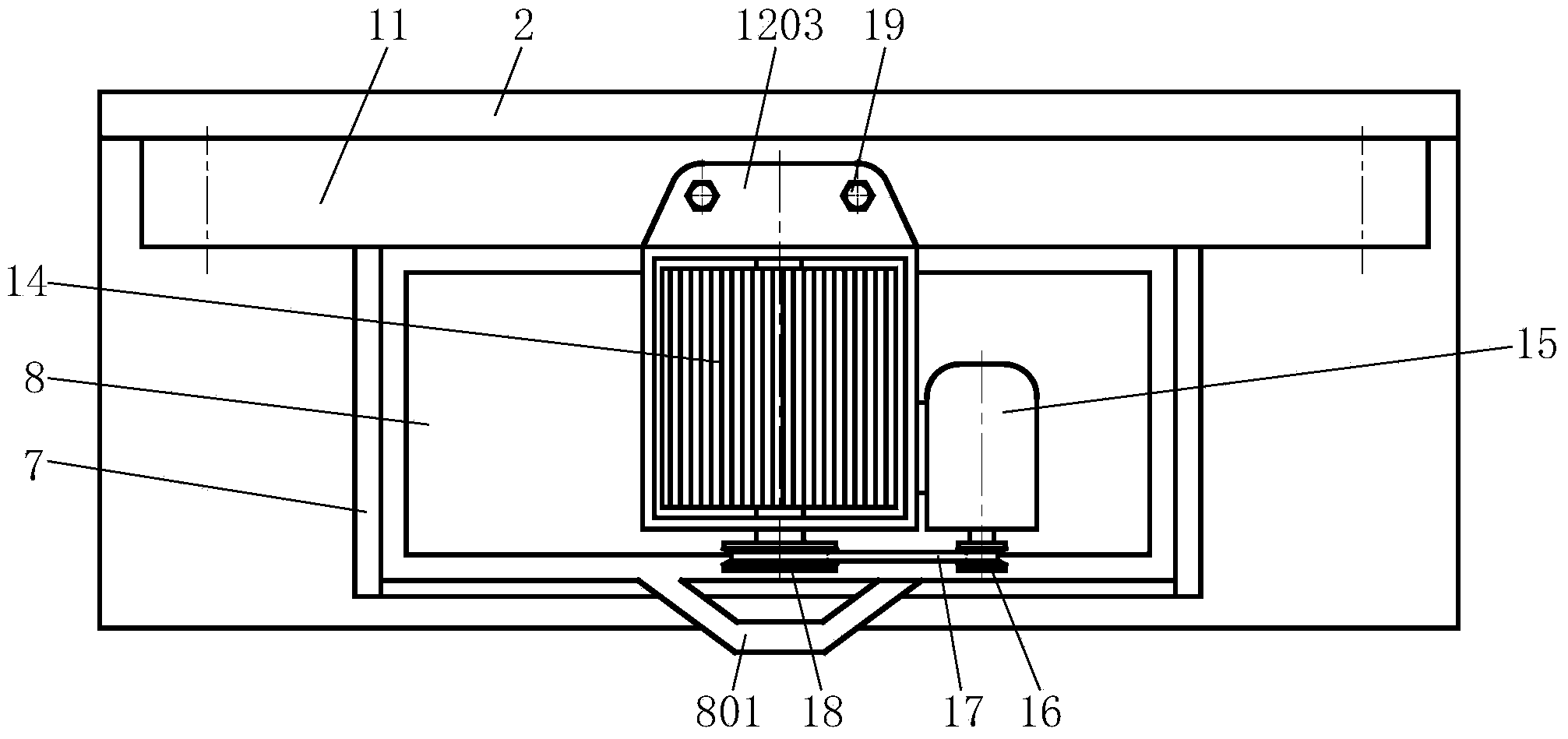

[0019] like Figure 1 to Figure 5 Shown, a kind of spinning rod comb rod collection device for weaving comprises bottom plate 1 and side vertical plate 2, and described bottom plate 1 is connected with side vertical plate 2, and the middle part of the upper end surface of described bottom plate 1 is connected with lifting device, The upper part of the lifting device is connected with a material holding frame 8; the upper part of the side vertical plate 2 is connected with a lateral movement device, and the middle part of the lateral movement device is connected with a comb device. Use the comb device to comb the winding rods, and drive the comb device to move left and right through the horizontal moving device, and then use the lifting device and the horizontal moving device to cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com