Material conveying device with material arranging function

A technology for conveying devices and materials, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high manufacturing and maintenance costs, manual packaging, and high labor costs, and achieve simple and practical structure and low manufacturing and maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0020] It should be noted that when an element is referred to as "connecting" or "installing" another element, it can be directly connected or installed to another element, or indirectly connected and installed through a central element. Additionally, the terms "front", "rear" and similar expressions used herein are for the purpose of illustration only and do not represent the only embodiments.

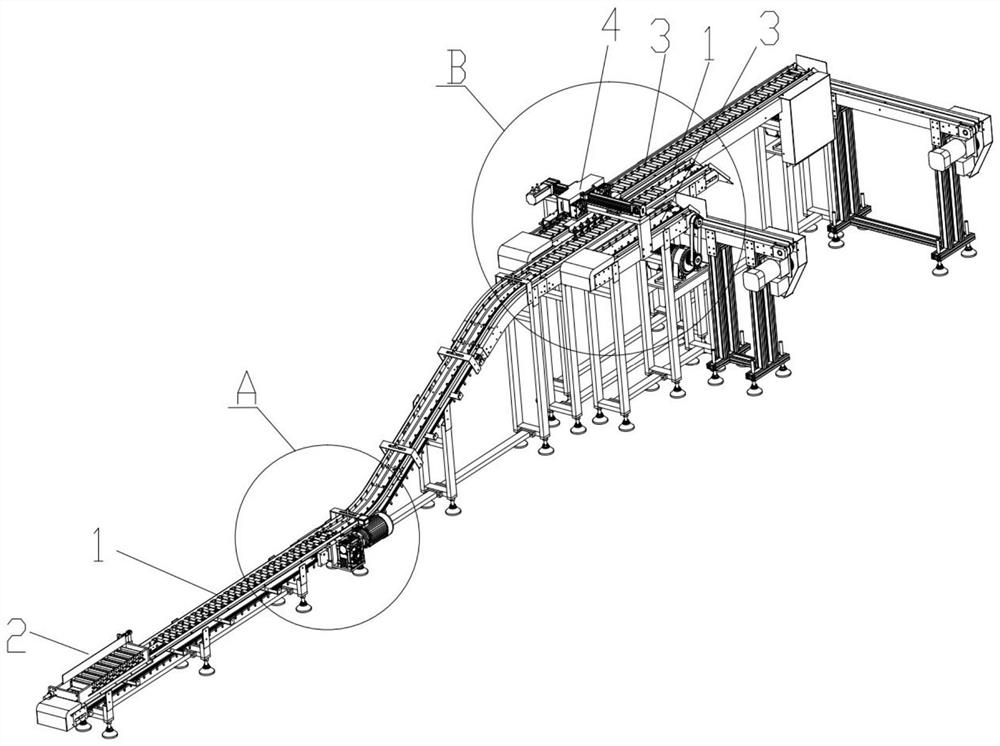

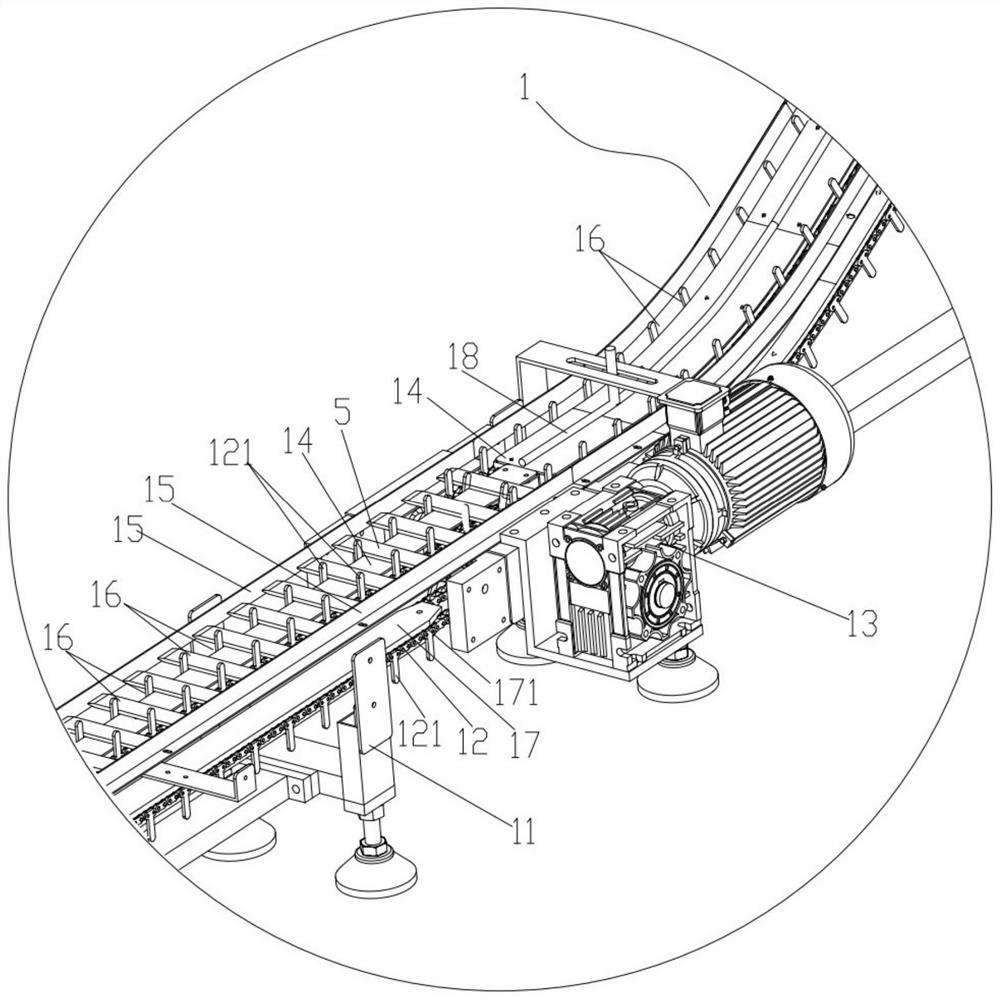

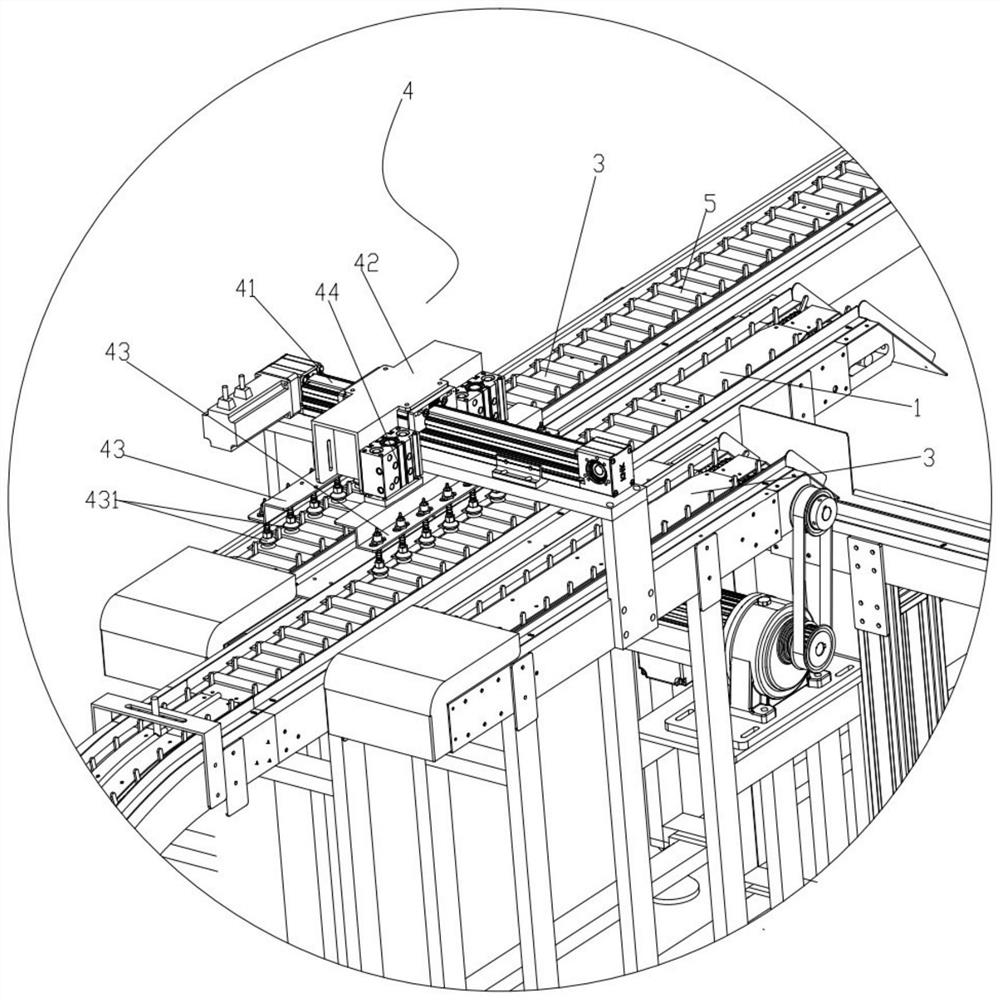

[0021] like Figure 1-5As shown in the figure, a material conveying device with a material sorting function of the present invention includes a feeding conveyor belt 1 and a feeding mechanism 2 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com