High-speed peeling and recycling device for seat ring heater cable

A technology for recycling equipment and heaters, which is applied in dismantling/armoring cable equipment, recycling technology, electronic waste recycling, etc. It can solve problems such as low efficiency, manual cleaning of cable skins, and inability to segment and cut to length. Achieve the effect of improving efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those of ordinary skill in the art to which the invention pertains can easily implement the embodiments. However, the present invention can also be implemented in various forms, so the present invention is not limited to the embodiments described hereinafter, and in addition, in order to describe the present invention more clearly, components not connected with the present invention will be omitted from the drawings.

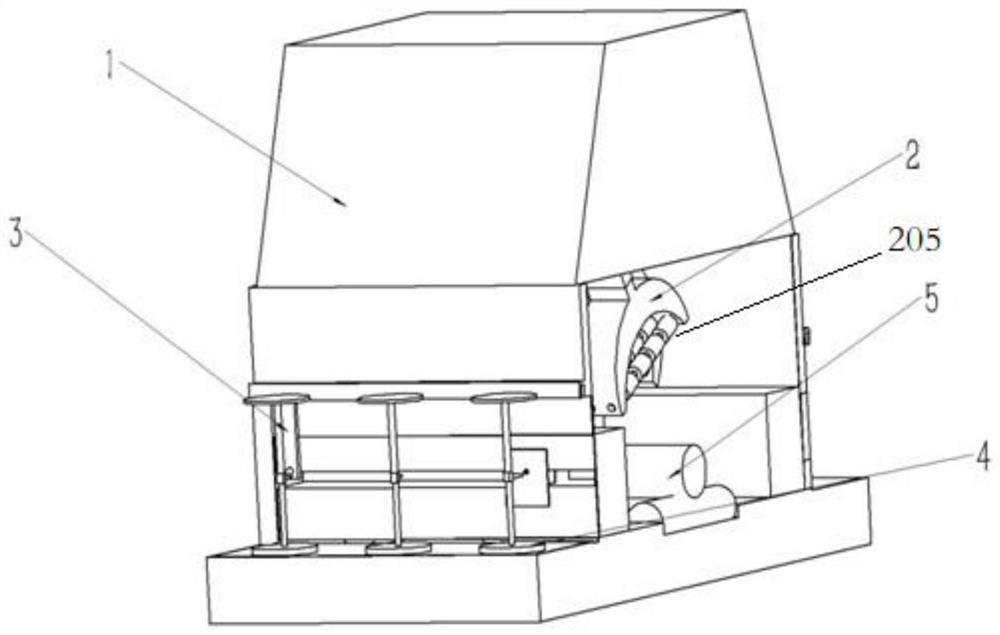

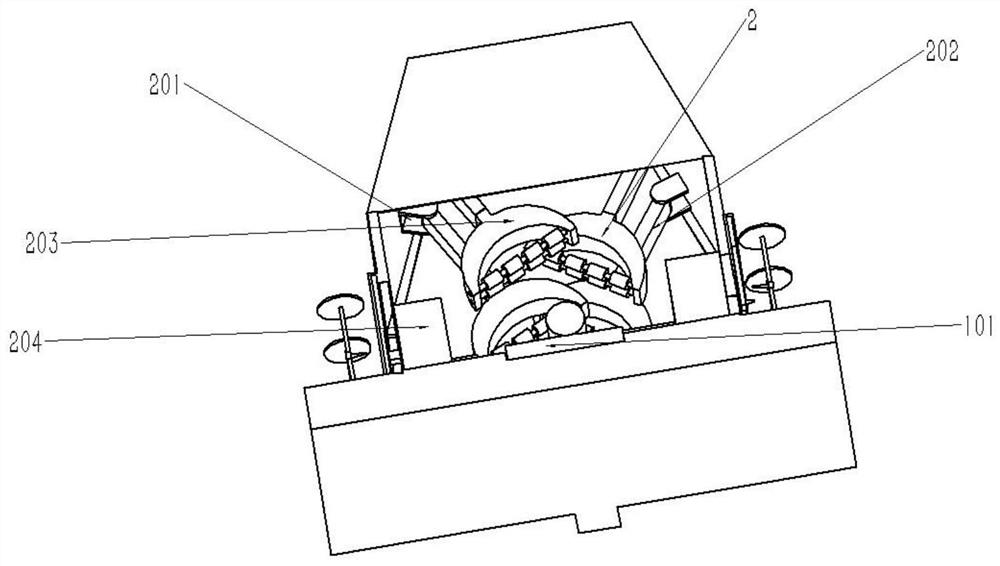

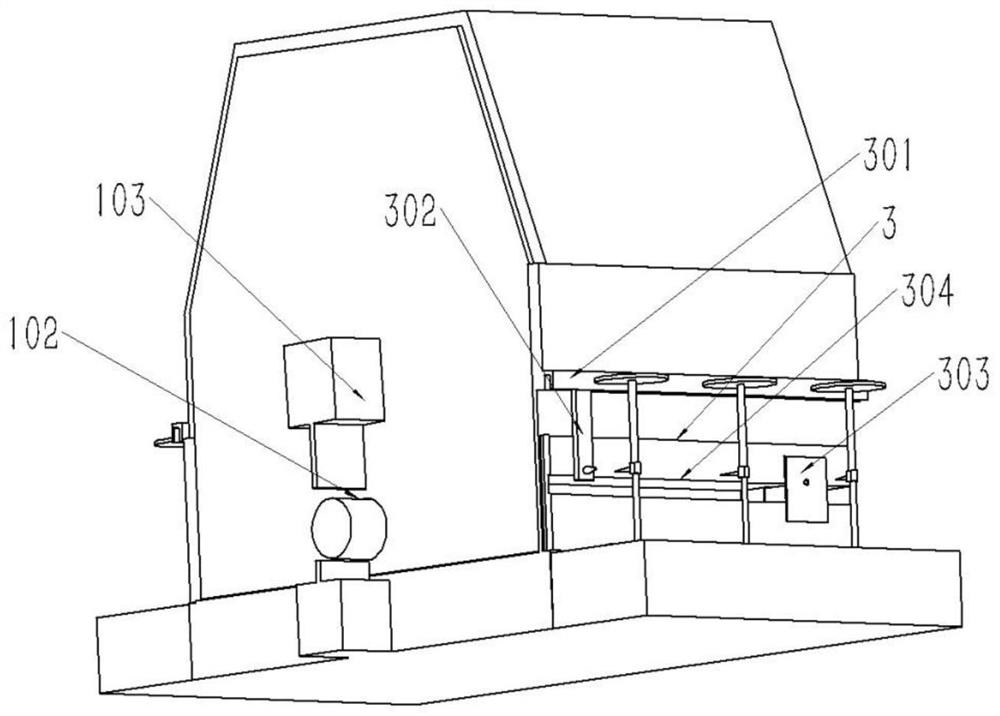

[0022] like Figure 1-5 As shown, a high-speed stripping and recycling equipment for seat heater cables includes: a work room 1, the device is located on the side and inside of the work room 1, and a telescopic device that can be adjusted according to the size of the wire is installed in the front of the work room 1 The blade 103 and the wire hole 102, the bottom roller 101 is installed on the inner bottom side, the auxiliary wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com