Fibreboard packaging rack

A fiberboard and frame technology, which is applied in the field of packing racks, can solve the problems of uneven top and bottom stacking, time-consuming and labor-intensive, manual sorting, etc., and achieves the effect of convenient bundling and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

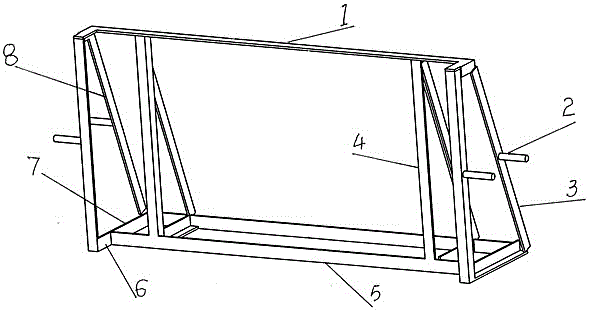

[0009] In the technical proposal, the length of the fiberboard and the height when stacked are limited by the limit right angle and the height limit bar. Specific examples figure 1 As shown, the packing rack is composed of a height limit rod 1, a handle 2, an outer support rod 3, an inner support rod 4, a base 5 and a limit right angle 6, and the outer support is composed of a horizontal rod 7 and two oblique rods 8 Further, the oblique bar 8 is welded to the two ends of the cross bar 7, the two ends of the base 5 are aligned with the rear end of the cross bar on the bottom surface of the outer support and welded to form a frame, and the front ends of the two ends of the base and the cross bar It is a 90° limit right angle, and this 90° angle is just the limit angle that limits the easy dislocation of the fiberboards when they are stacked. There is an inner support 4 on the base of the inner frame of the frame, and the shape of the inner support is "herringbone". A height-lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com