Winding equipment for lampblack separator network disc and winding method of winding equipment

A technology of oil fume separator and winding equipment, applied in the field of equipment processing and manufacturing, can solve the problems of large human injury, slow winding process, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

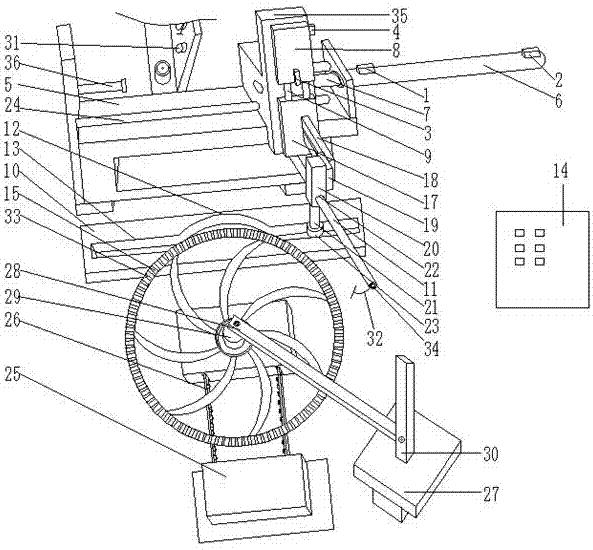

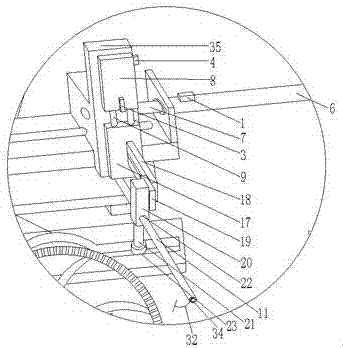

[0047] See figure 1 In this embodiment, the left and right transmission mechanism is the first cylinder 6, the upper and lower transmission mechanism is the second cylinder 8. Both ends of the base 5 are provided with vertical ears (not shown in the figure), and the vertical ears are provided with connecting holes (not marked in the figure). Out), the first cylinder 6 is horizontally arranged in the connecting hole, the second cylinder 8 is vertically arranged at the end of the first piston rod 7 of the first cylinder 6; the first cylinder 6 is provided with a first sensor 1, the first A second sensor 2 is provided at the end of the cylinder 6, a third sensor 3 is provided at the opening of the second cylinder 8, a fourth sensor 4 is provided at the end of the second cylinder 8, a first sensor 1, a second sensor 2, a third sensor 3 and The fourth sensors 4 are electrically connected to the control system 14; the second piston rod 9 of the second cylinder 8 is provided with an ou...

Embodiment 2

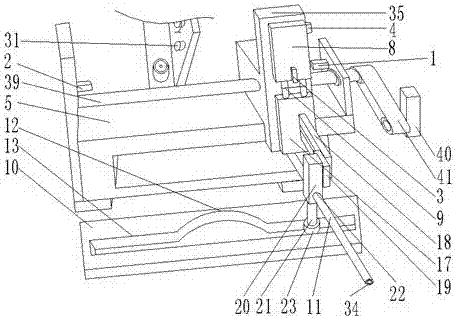

[0052] The working principle of the winding device of this embodiment is basically the same as that of the first embodiment, except that: figure 2 The left and right transmission mechanisms of this embodiment are the screw guide rail 39 and the second servo motor 40. The screw guide rail 39 and the second servo motor 40 are connected by a second toothed belt 41. The second servo motor 40 is connected to the control system 14 Electrical connection; the screw guide rail 39 is arranged on the base 5, the first slider 35 and the screw guide rail 39 are connected in a transmission type for connecting the second cylinder 8; the second sensor 2 moves left and right relative to the screw guide 39, the first sensor 1 is installed at one end of the screw guide 39. In the dual-cylinder structure, the movement force of the piston rod is fixed, and in practical applications, the stopper 36 is needed to limit the extension length of the piston rod, and the outlet pipe 11 is passively stopped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com