Roller blind piece

A technology of rolling shutters and curtains, which is applied in door/window protection devices, shutters/movable grilles, windows/doors, etc., and can solve the problems of inconvenient production, construction, installation and maintenance, and the lack of modularization of rolling shutters. Wind resistance performance can not be guaranteed and other problems, to achieve the effect of improving wind resistance performance, smooth retractable operation, and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

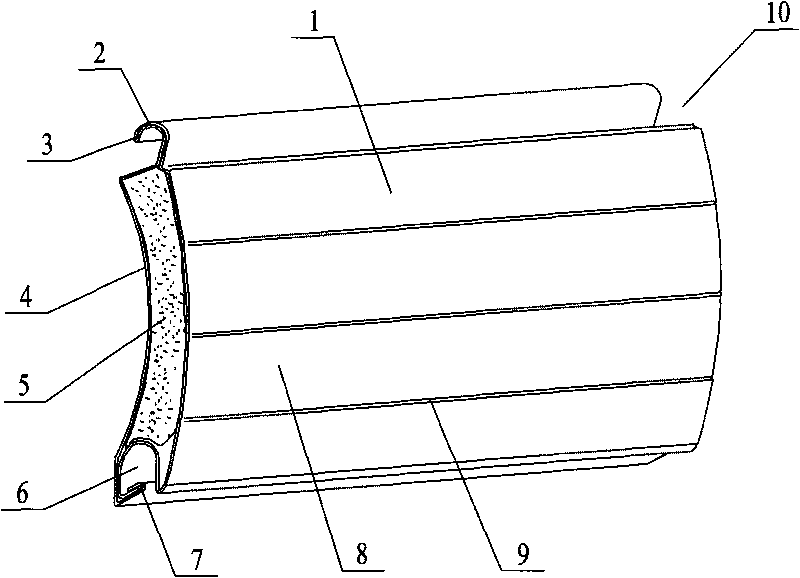

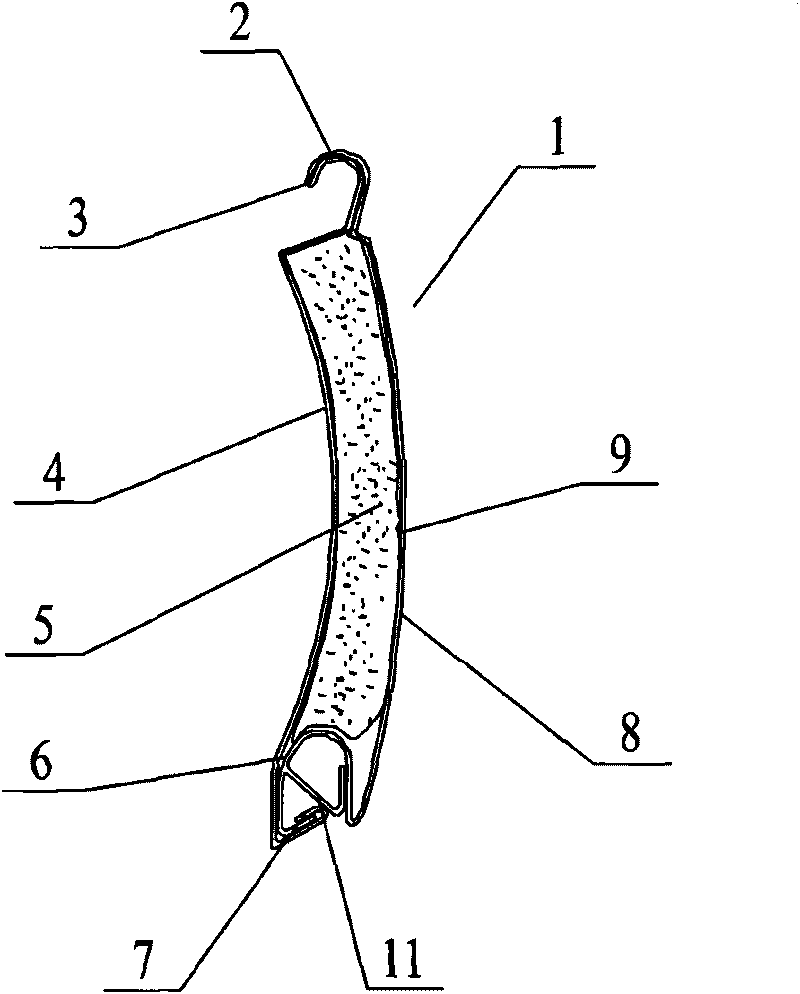

[0013] As shown in the figure, the present invention includes a curtain body 1, the curtain body 1 protrudes upwards with an upper hook 2, and the lower part is recessed to form a lower hook 6, and the upper hook 2 can be buckled with the lower hook 6 of the adjacent curtain The upper hook 2 and the lower hook 6 are a large circular arc structure that cooperates with each other. The large circular arc structure can increase the contact area of the connection between the curtains, so that when rolling or unwinding, the distance between the curtains Small friction and low noise; in order to make the curtain more compact when rolling up, run smoothly, reduce friction, avoid extrusion and deformation between the curtains, and run without impact, the upper hook 2, the lower hook 6 and the curtain body 1 The concave arc surface 4 is located on the same arc surface.

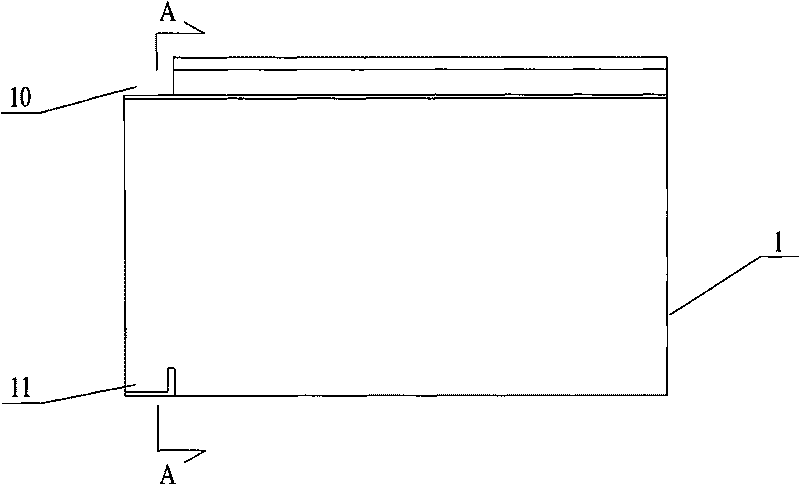

[0014] Such as image 3 As shown, one end of the upper hook 2 on the curtain body 1 is provided with a notch 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com