Patents

Literature

127 results about "Torsion strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torsional Yield Strength is the stress state causing material to twist or rotate which it can withstand before any twisting failure. The formula for computing the Torsional yield strength in a rod is: Torsional strength = rotational force / cross sectional area.

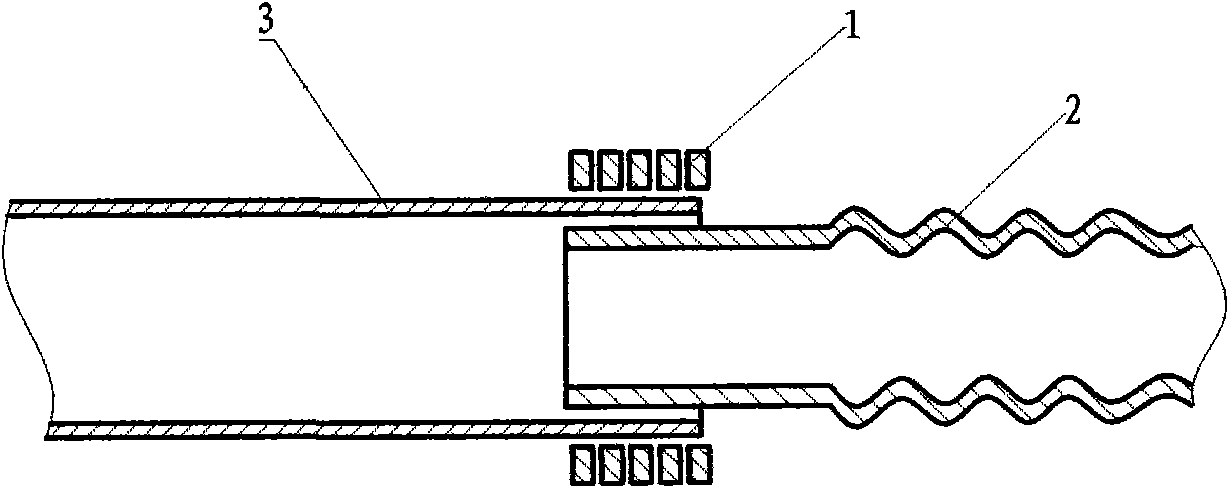

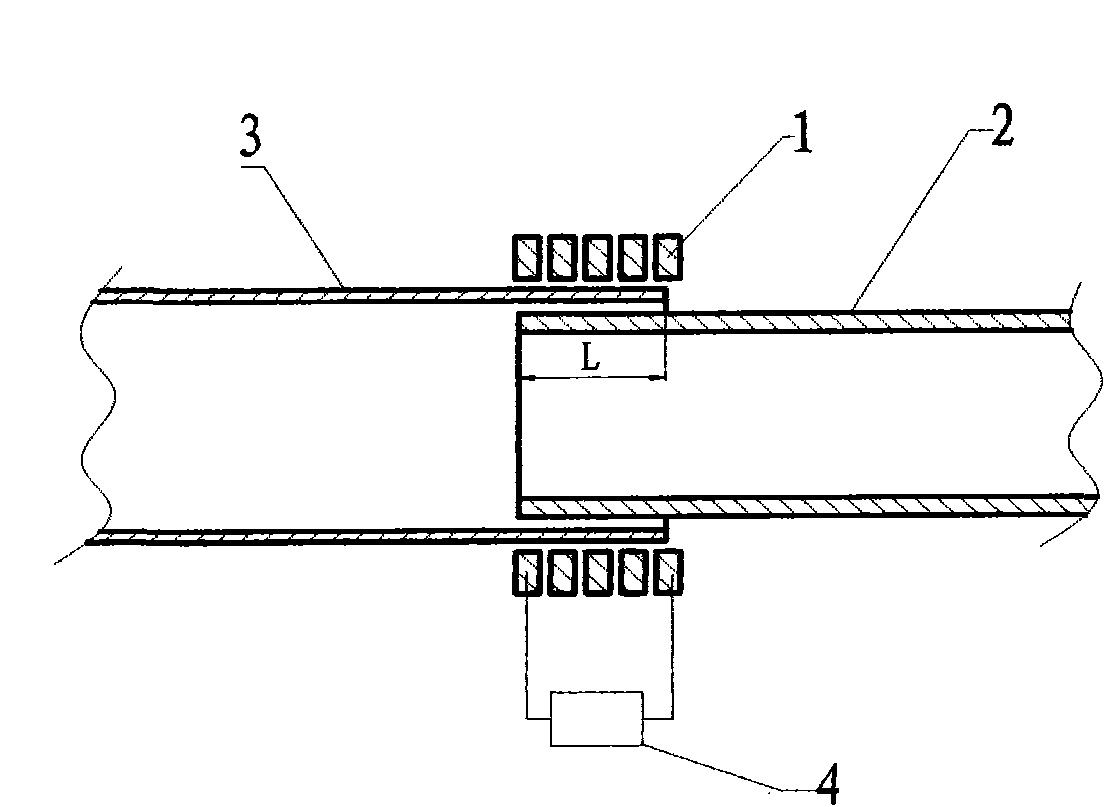

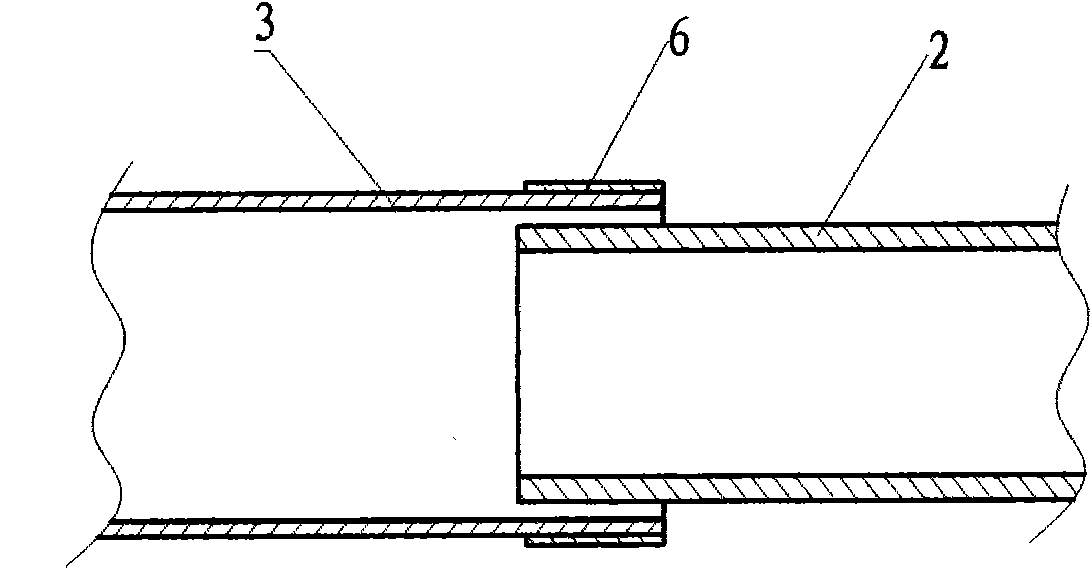

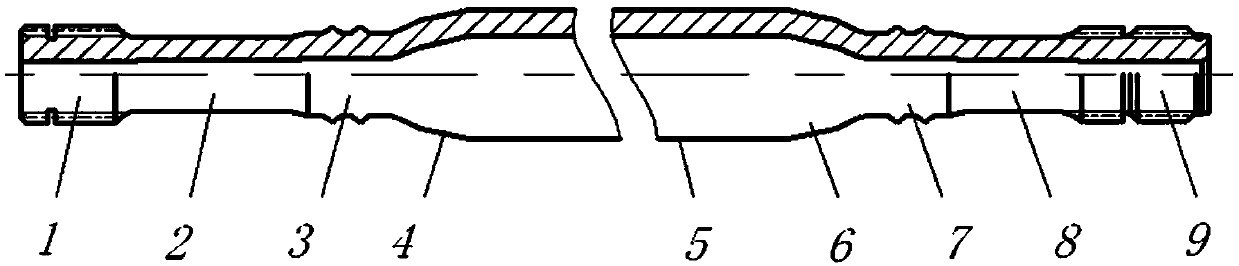

Magnetic pulse connecting method and joint structure for thin-wall metal pipelines

InactiveCN101905375AIncreased processing flexibilityHigh strengthNon-electric welding apparatusHeat-affected zoneEngineering

The invention discloses a magnetic pulse connecting method and a joint structure for thin-wall metal pipelines and provides a safe and high-efficiency magnetic pulse connecting method and a magnetic pulse connecting joint structure for similar and dissimilar thin-wall metal pipelines. A coil-magnetic concentrator composite inductor or a coil inductor is connected with electromagnetic pulse forming equipment so that the pipelines of various metal materials or various structure shapes can be connected in a magnetic pulse way. The transition area of the joint connecting interface is small, the brittle phase or intermetallic compound almost cannot be generated, and the joint almost has no heat affected area and torsion deformation and has high strength and corrosion-resistance property; the tension strength and torsion strength of the joint are respectively higher than those of weak base metal; the subsequent cleaning procedure and post-weld heat treatment are not needed; and the connected pipeline satisfies certain rigidity requirement, cannot be subjected to the plastic deformation in the magnetic pulse connecting process and has high process flexibility.

Owner:HARBIN INST OF TECH

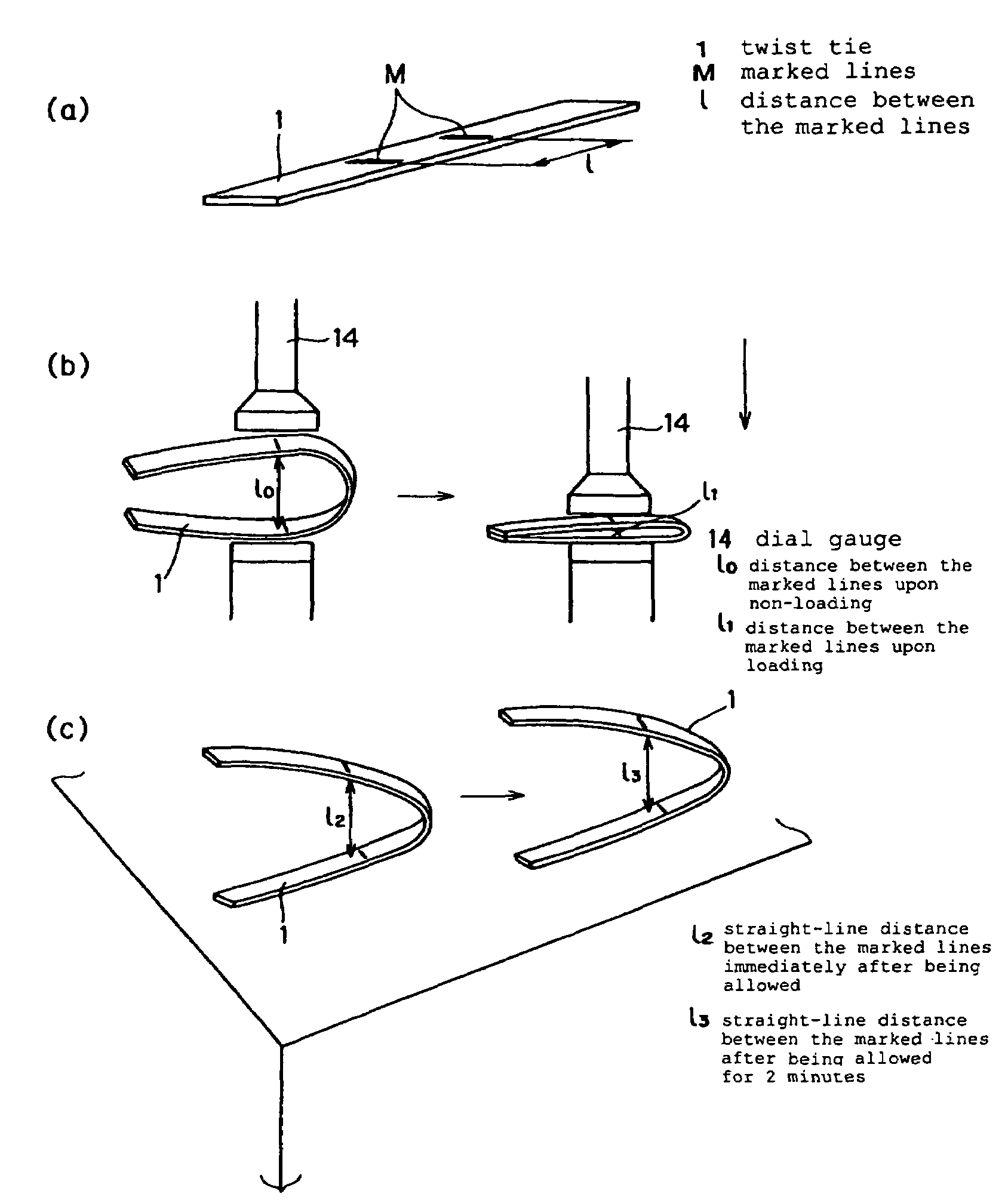

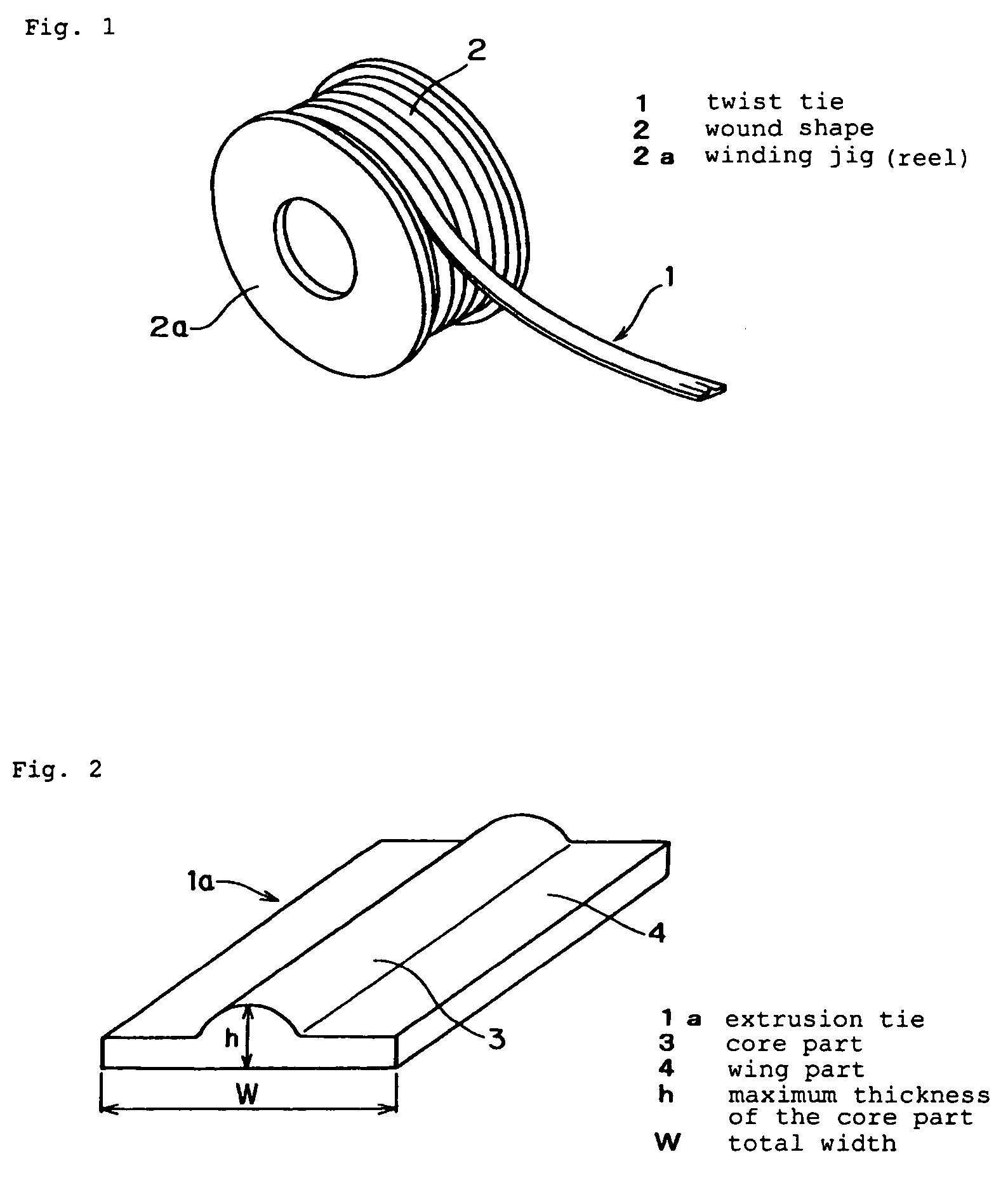

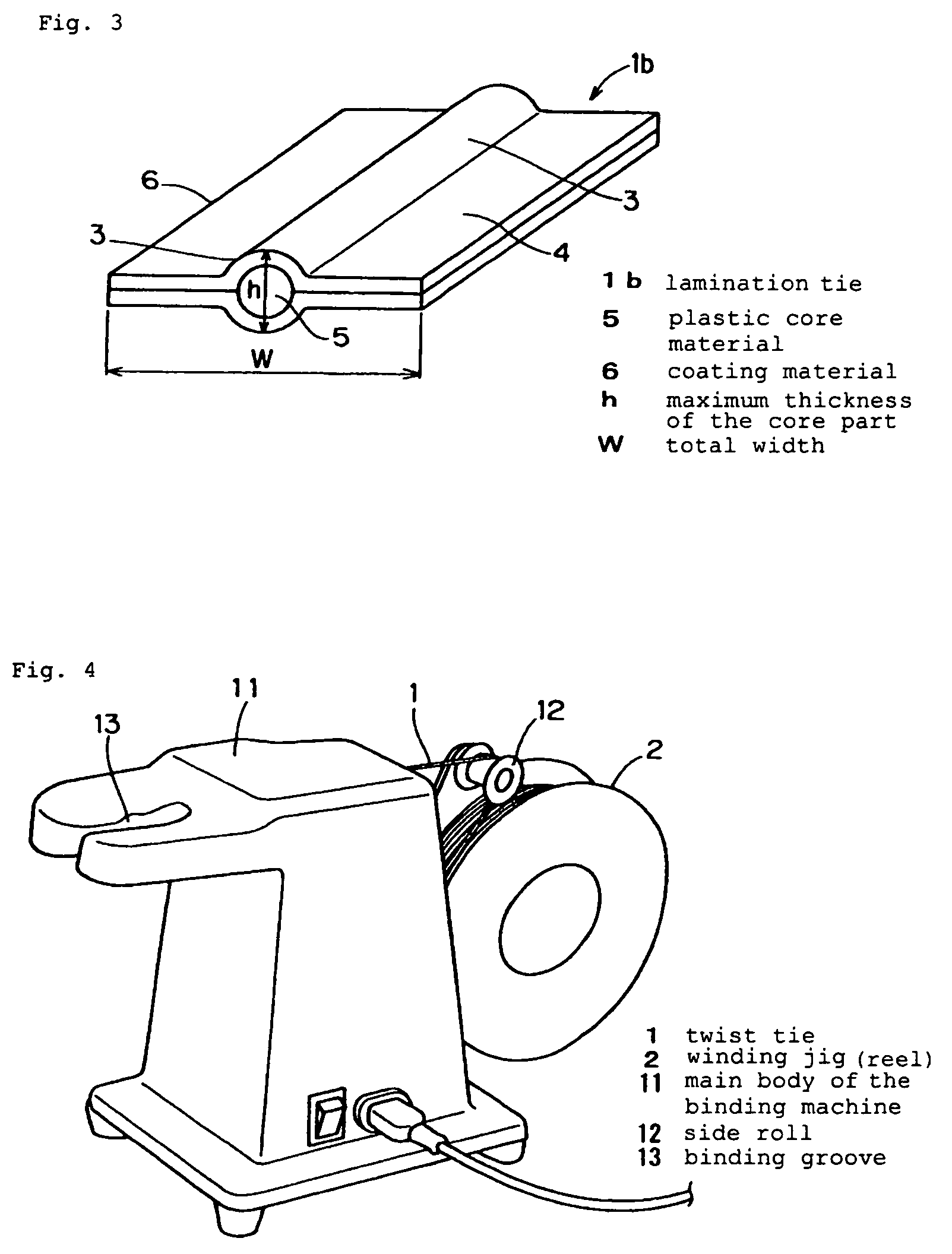

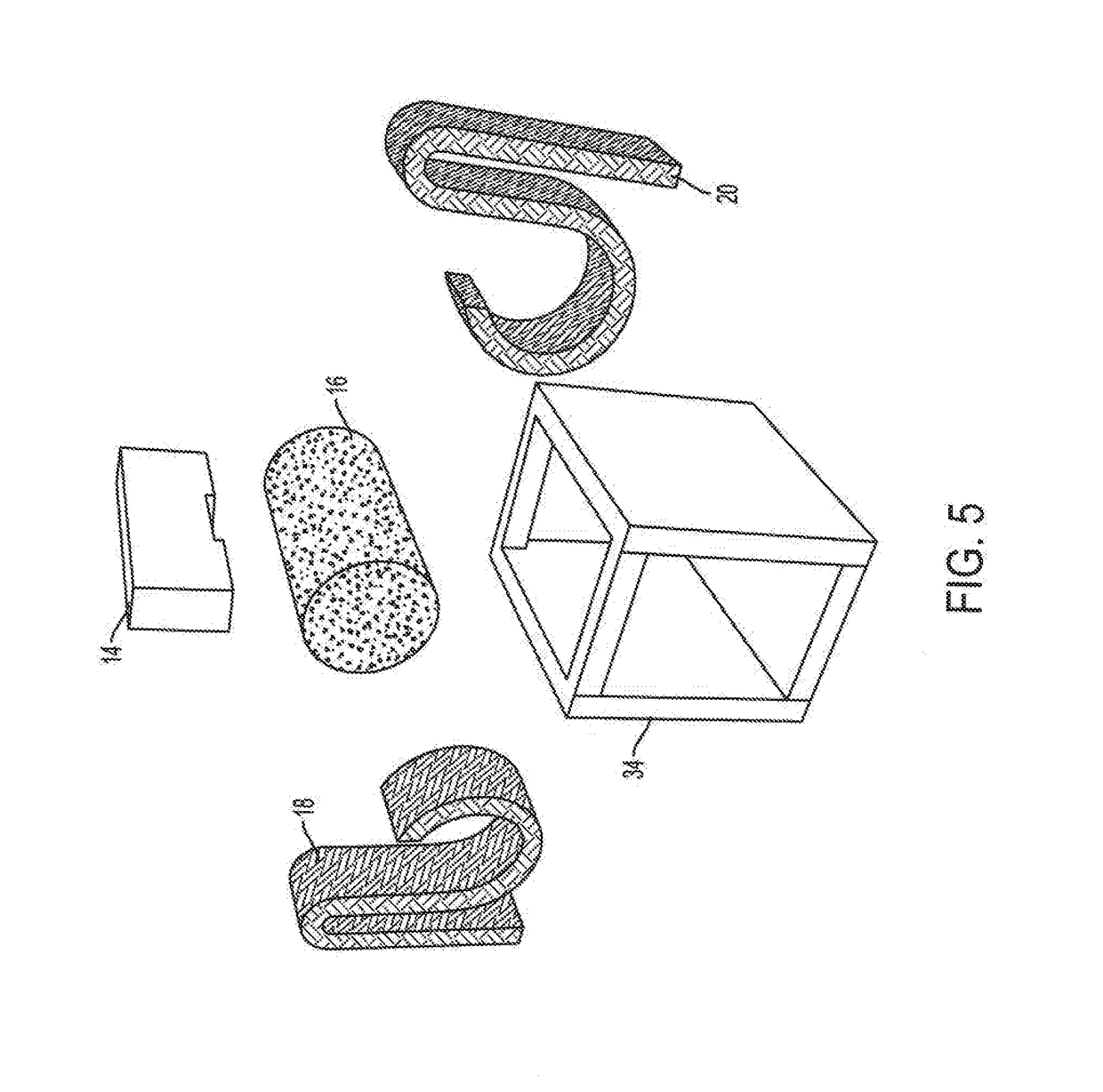

Non-metallic twist tie

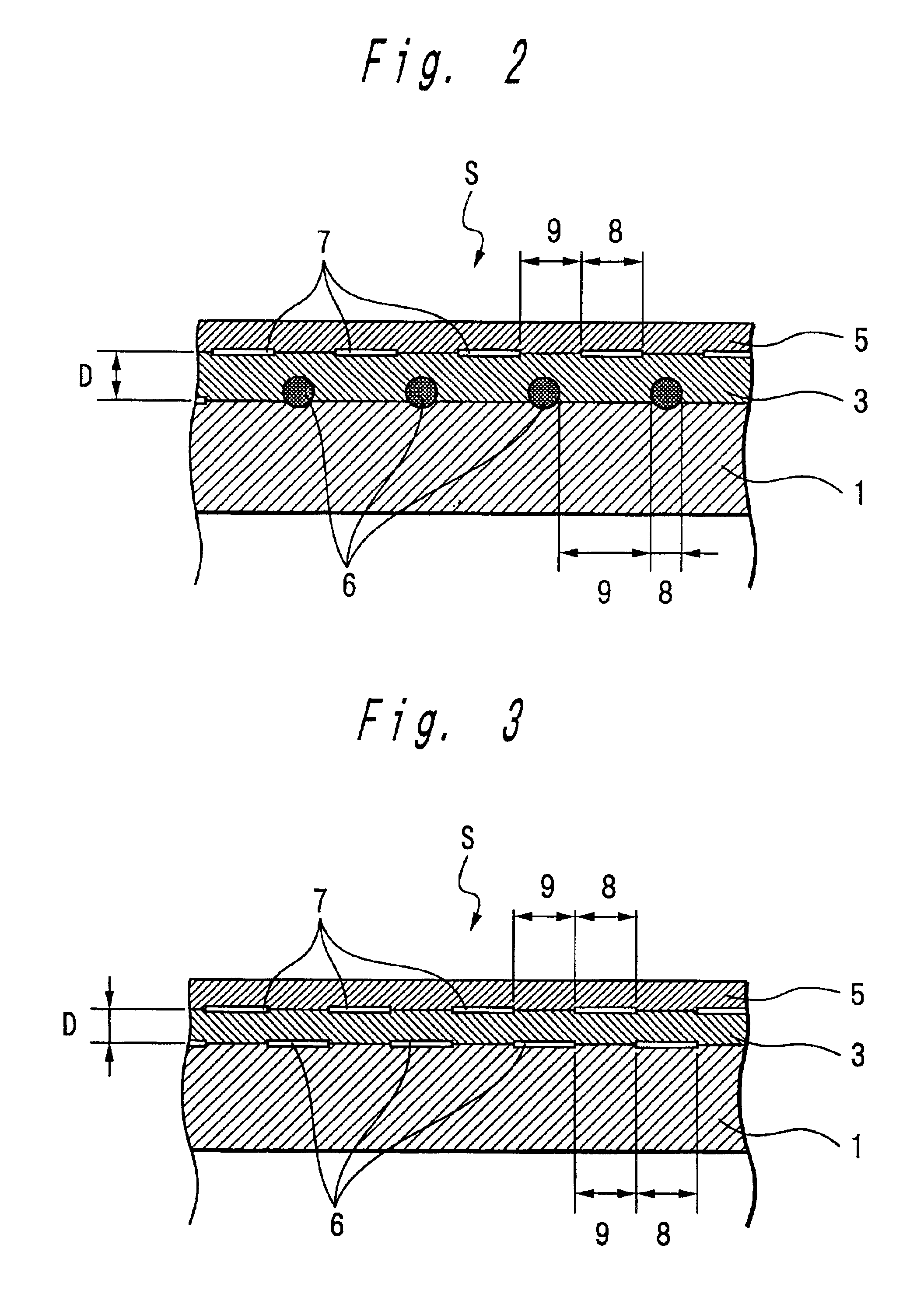

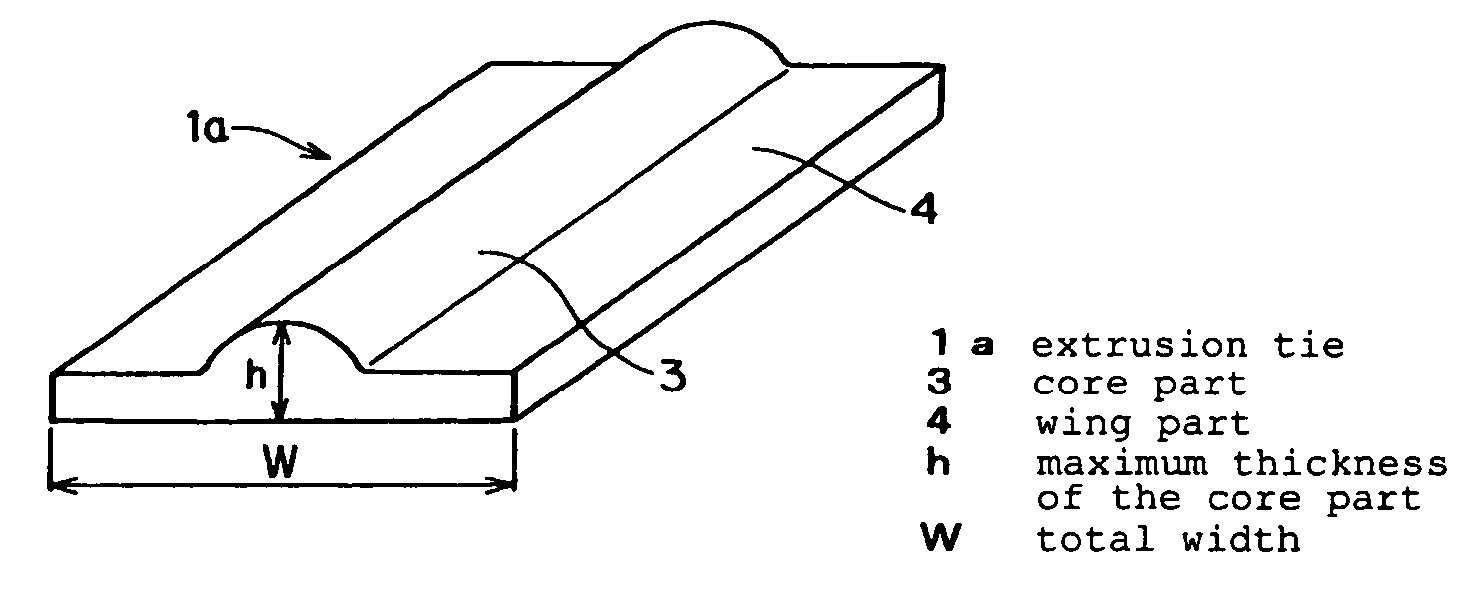

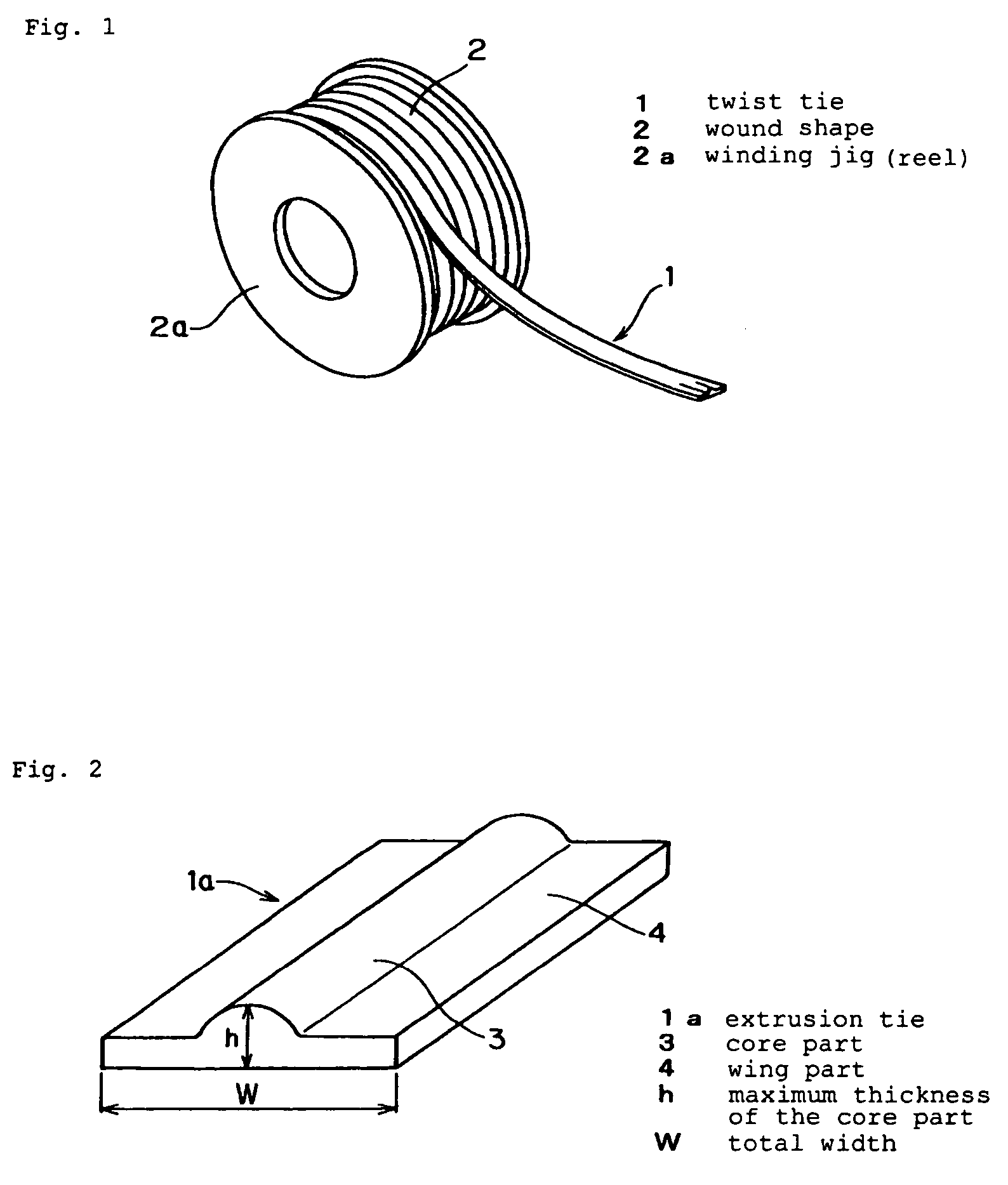

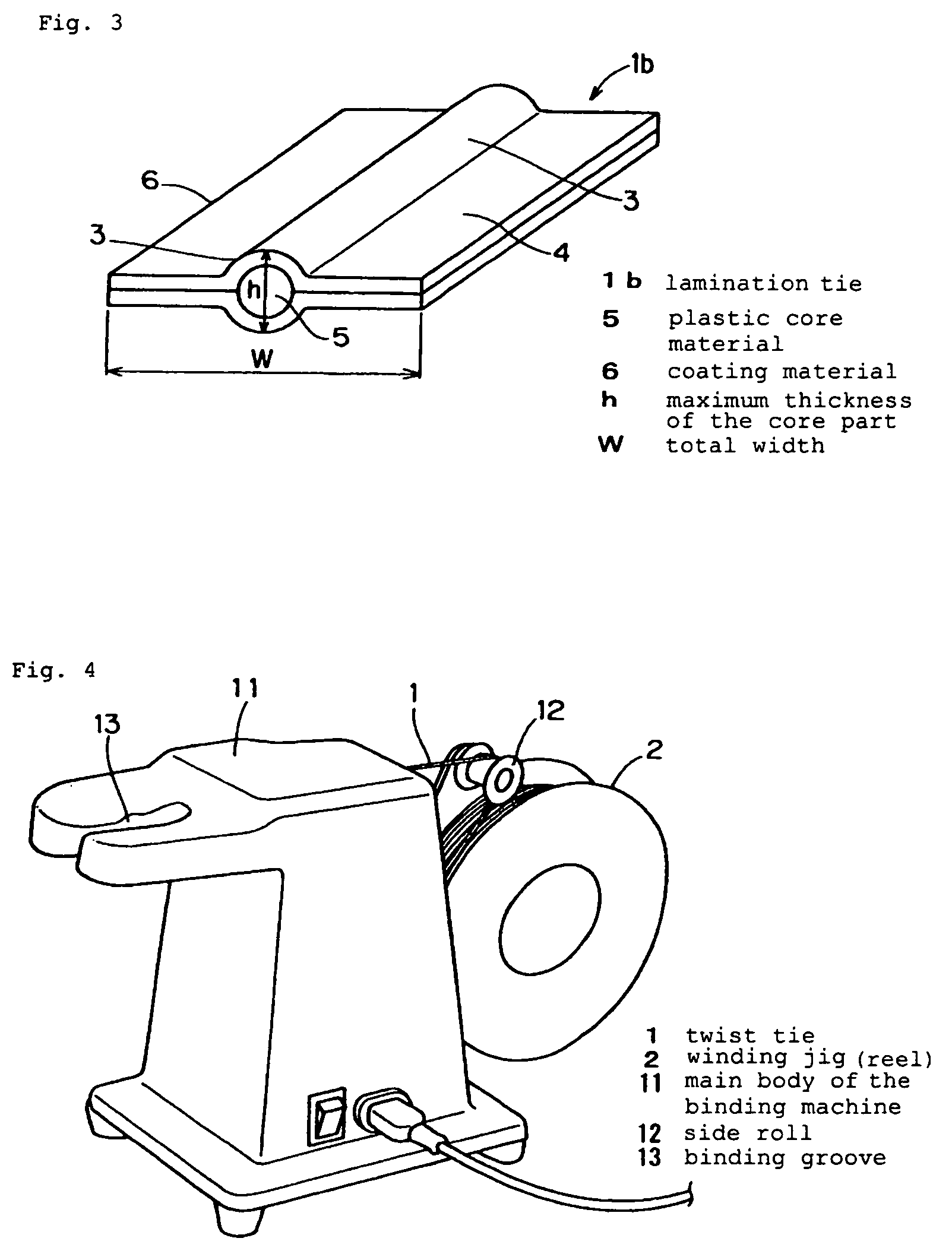

The present invention provides a nonmetallic twist tie in which the function inherent to the twist tie is of course available and the twist tie is easily made into a shape of being wound in a bundle with no slipping down of the tie into gap, no torsion of the tie itself, no curl, no twining and tangling of ties and no loosening or disjoining from a reel whereby its drawing-out from the wound shape is able to be carried out smoothly. The nonmetallic twist tie having a core part and a wing part constituted from a non-halogenous material is characterized in that (1) a shape having a total width is 1.5 to 20.0 mm, the average thickness of the wing part is 0.02 to 0.20 mm and the maximum thickness of the core part is 0.04- to 0.30-fold of the total width, (2) a binding property where a torsion strength is 5.0 to 15 N, (3) a rigidity where a tensile elasticity is 5,000 to 30,000 Mpa, (4) a property of forming a fixed shape where the property is 90% or more and a property of retaining a fixed shape where the rate of retaining the fixed shape is 70 to 95%, and (5) a drawing-out property where a degree of curving to the drawing-out direction is 10° or less and a curl radius to the winding direction retains the range of 50 to 200 mm.

Owner:KYOWA LTD

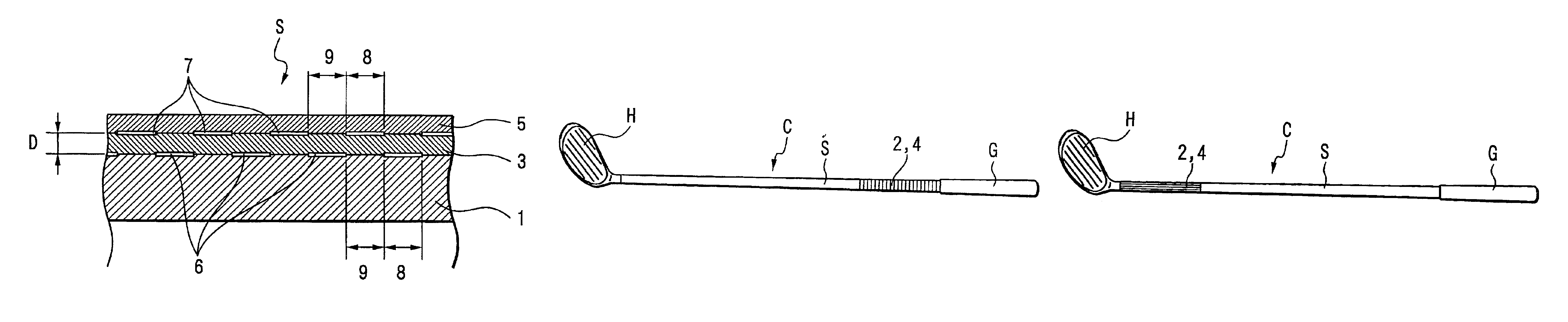

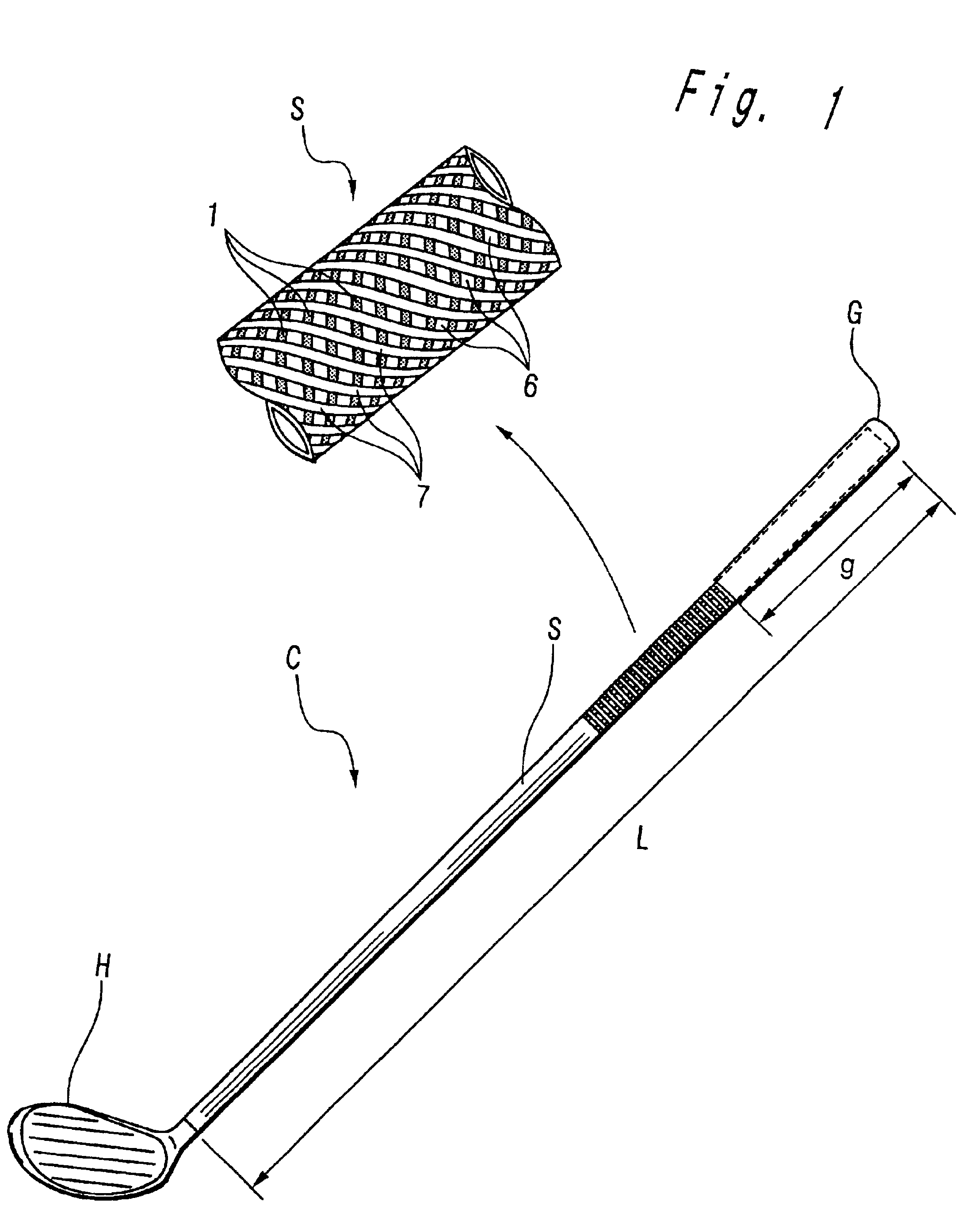

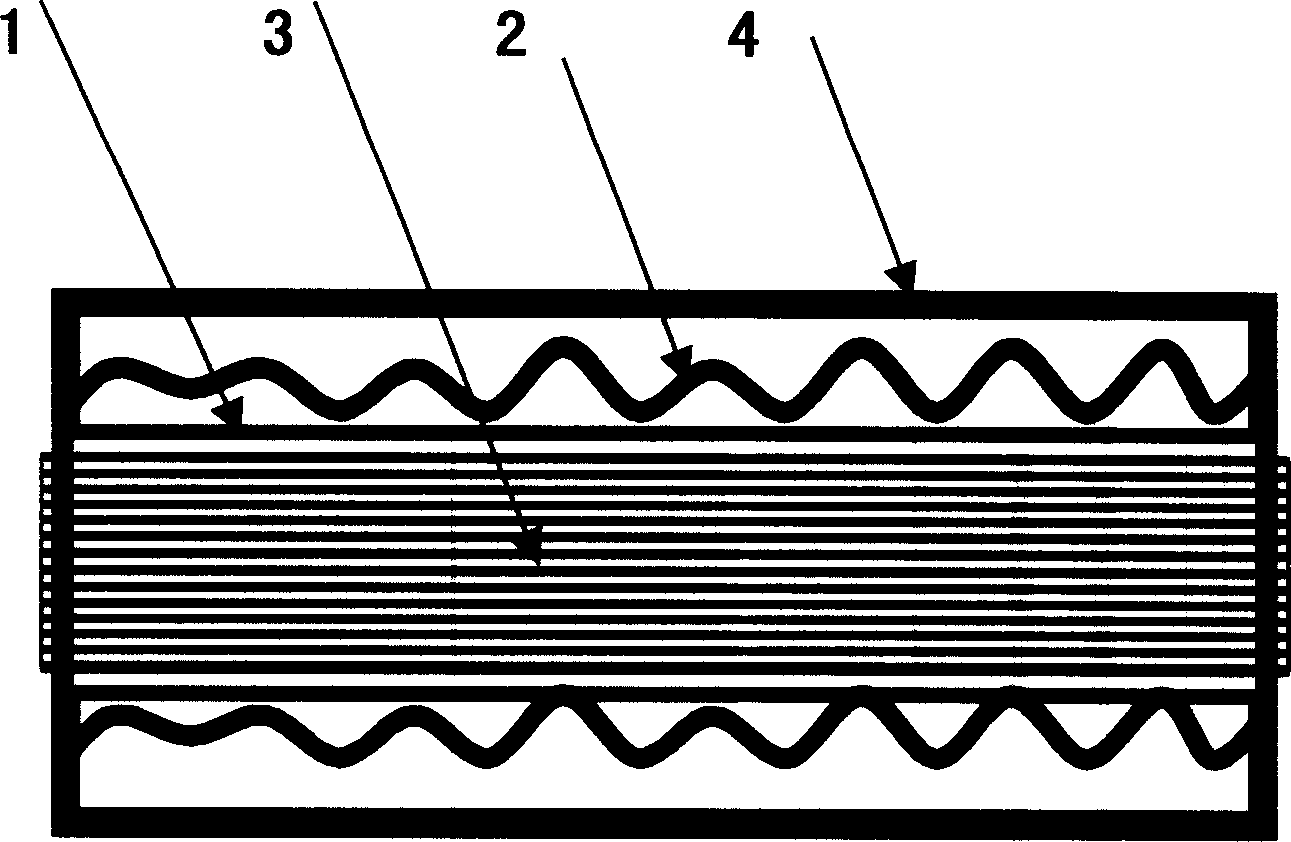

Golf shaft, forming method therefor and golf club

InactiveUS6860821B2High compressive strengthIncreased torsional strengthGolf clubsRacket sportsFiberEngineering

A golf shaft which features lightness, high crushing strength and high torsion strength with no interlayer peeling, as well as an excellent aesthetic design with a three-dimensional effect which gives the user a sense of depth, and a method for forming the same and a golf club using the same. The golf shaft is produced by baking a plurality of fiber prepreg layers. The shaft is a laminate comprising: a main layer of resin-impregnated high-strength high-elasticity fiber; a metal wire layer laid over the main layer; and a layer of low-elasticity fiber, laid over the metal wire layer, impregnated with resin through which the underlying metal wire layer can be seen.

Owner:MAMIYA

Non-metallic twist tie

ActiveUS20070006426A1Simple processWind evenlyFlexible elementsHaberdasheryBound propertyEngineering

The present invention provides a nonmetallic twist tie in which the function inherent to the twist tie is of course available and the twist tie is easily made into a shape of being wound in a bundle with no slipping down of the tie into gap, no torsion of the tie itself, no curl, no twining and tangling of ties and no loosening or disjoining from a reel whereby its drawing-out from the wound shape is able to be carried out smoothly. The nonmetallic twist tie having a core part and a wing part constituted from a non-halogenous material is characterized in that (1) a shape having a total width is 1.5 to 20.0 mm, the average thickness of the wing part is 0.02 to 0.20 mm and the maximum thickness of the core part is 0.04- to 0.30-fold of the total width, (2) a binding property where a torsion strength is 5.0 to 15 N, (3) a rigidity where a tensile elasticity is 5,000 to 30,000 Mpa, (4) a property of forming a fixed shape where the property is 90% or more and a property of retaining a fixed shape where the rate of retaining the fixed shape is 70 to 95%, and (5) a drawing-out property where a degree of curving to the drawing-out direction is 10° or less and a curl radius to the winding direction retains the range of 50 to 200 mm.

Owner:KYOWA LTD

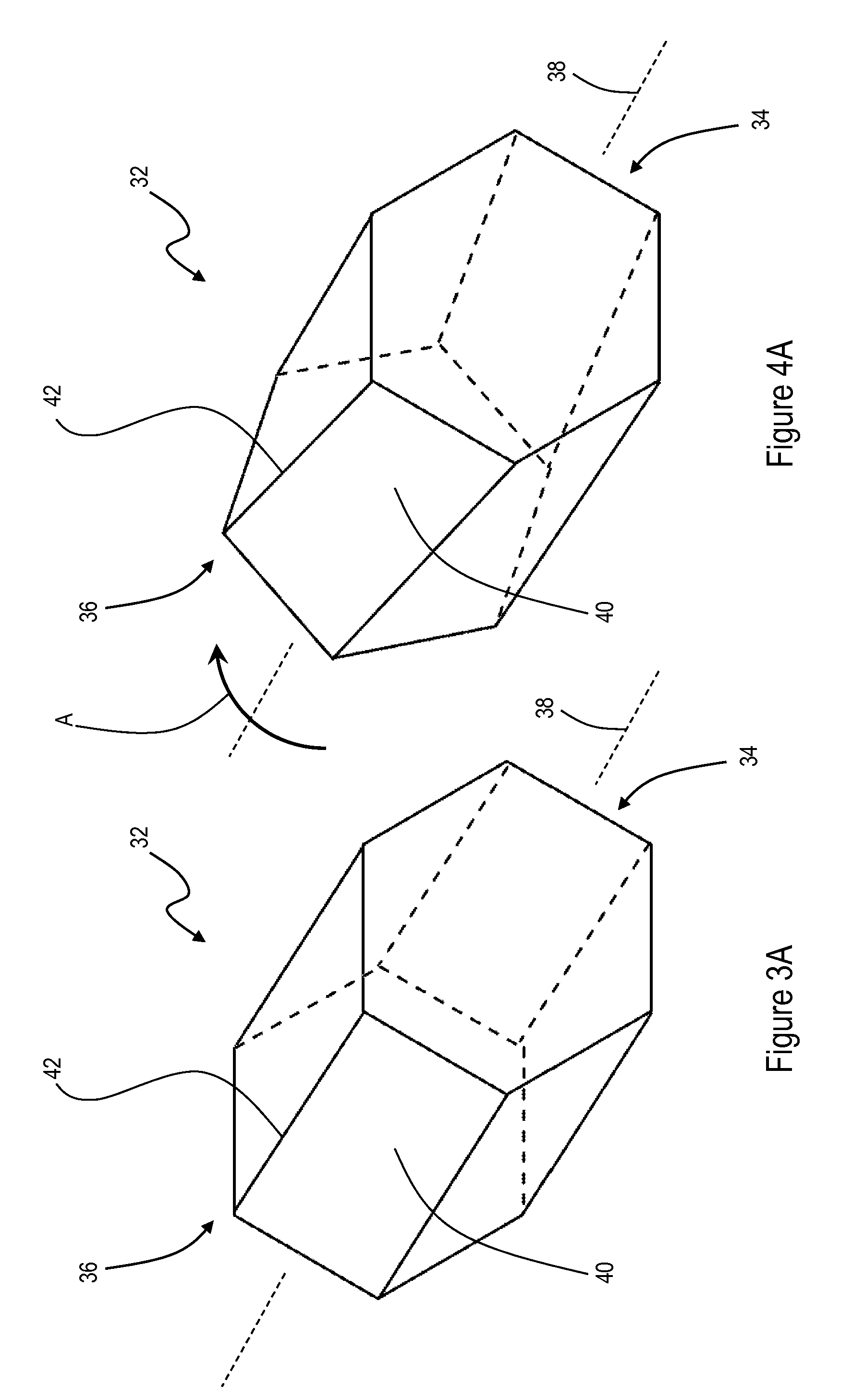

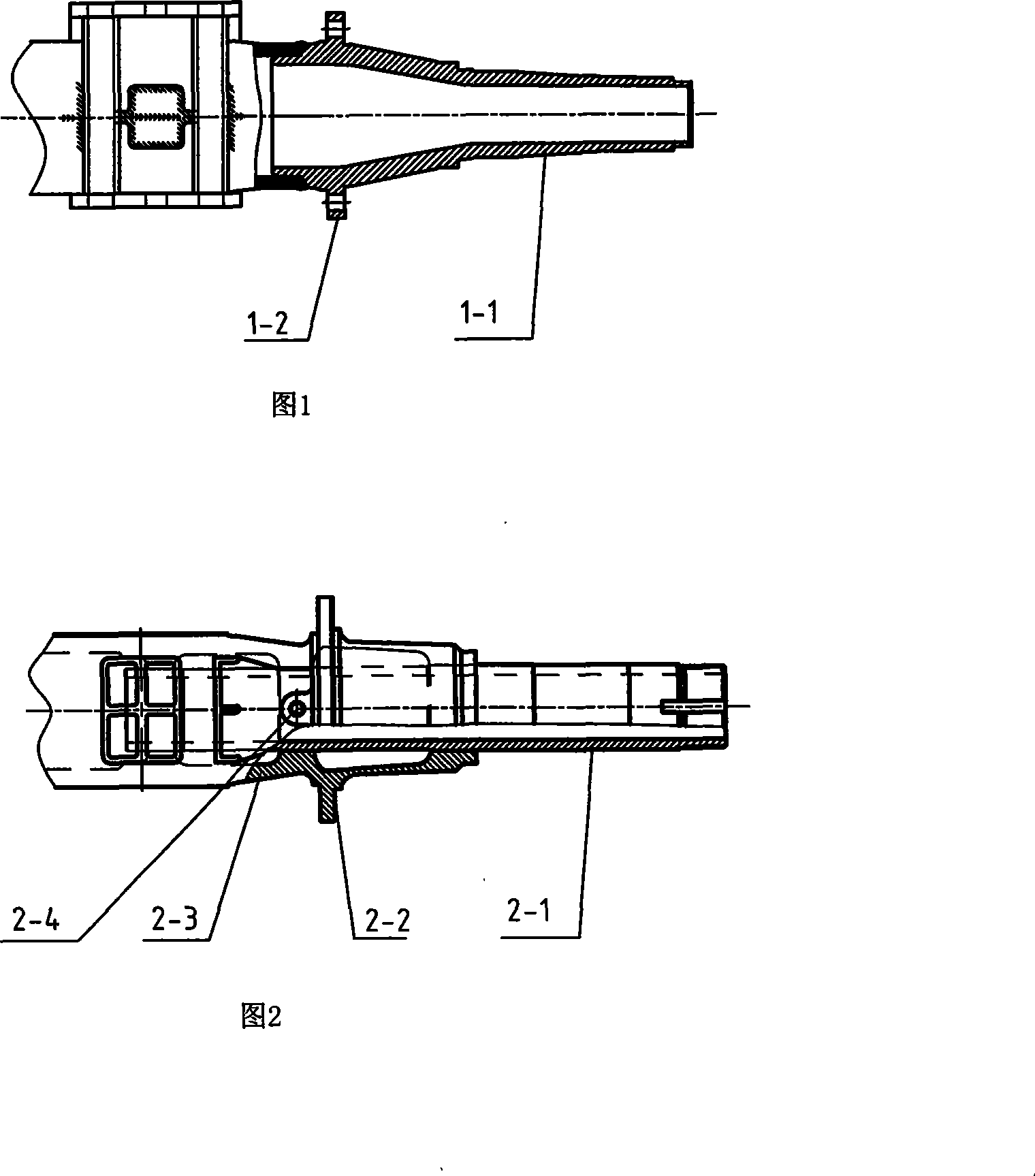

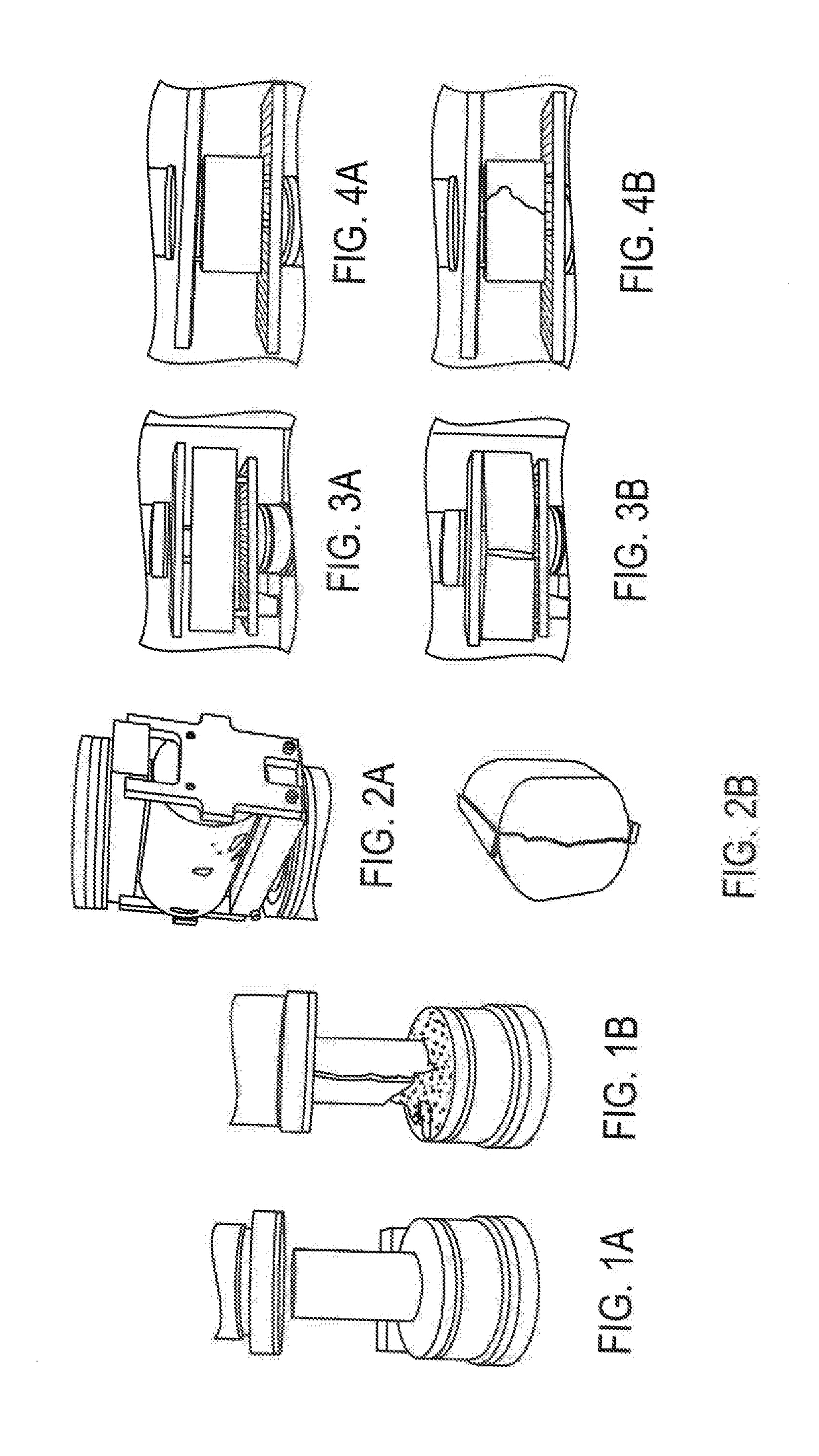

Locking screw driver with increased torsional strength

InactiveUS20110245839A1Increased torsional strengthMetal working apparatusProsthesisEngineeringTorsional strength

An orthopedic tool for implanting a bone screw and a method of manufacturing the same. The orthopedic tool includes a head that is shaped to lock onto the bone screw and that has improved torsional strength.

Owner:ZIMMER INC

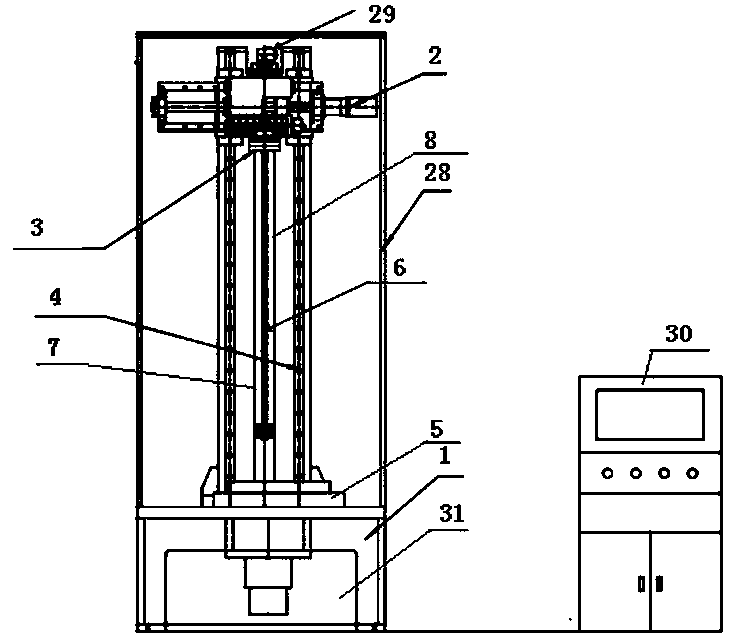

Power transformation material bending and fatigue testing machine

InactiveCN109540693AImplement Performance EvaluationCompact and reasonable structureMaterial strength using steady bending forcesMaterial strength using steady torsional forcesTransformerFlexural strength

The invention relates to the technical field of power transformation material performance test equipment, and provides a power transformation material bending and fatigue testing machine. The power transformation material bending and fatigue testing machine comprises a base, a loading device and a torsion head. The machine is reasonable and compact in structure and convenient to use. Based on thecooperative usage of the loading device, a first screw-nut mechanism, a rotating disc, a first driving mechanism, a tension load sensor and a torque sensor, the rotating disc is rotated or the torsionhead is horizontally moved on the same testing machine. As a result, the testing machine can be used for carrying out conventional bending strength and torsion strength tests on transformer substation insulators and hardware tools with various sizes. The testing machine can also be used for carrying out the fatigue test and simulating the working states of the transformer substation insulators and the hardware tools. Therefore, the performances of the transformer substation insulators and the hardware tools can be evaluated. The testing machine is especially important for evaluating the performances of transformer substation materials.

Owner:ELECTRIC POWER SCI RES INST OF STATE GRID XINJIANG ELECTRIC POWER +1

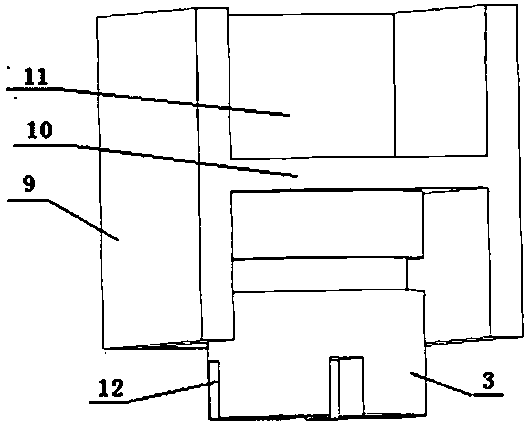

Medium-sized car drive axle housing semi-axis sleeve welding process

InactiveCN101186165AMeet load requirementsSolve problems such as torsional strengthAxle unitsGas flame welding apparatusCar drivingFlexural strength

The invention belongs to the automobile driving axle housing processing field, relating to a welding process of a half-shaft sleeve of medium automobile driving axle housing. An installation flange of a brake is separated from the half-shaft sleeve; the flange is welded on an axle housing body; the circumference of the welded seam of an external ring is fully welded, the circumference of the welded seam of an internal ring is welded by 3 / 4, and 1 / 4 range (88 to 92 DEG) of the lower edge is not welded. The invention can lead the circular welded seam of the half-shaft sleeve to outwards move by 60mm; by calculation, the stress born by the circular welded seam is reduced by 29.7%, thus meeting the bearing capability of a rear axle. Meanwhile, the invention solves the problems of the bending strength of the half-shaft sleeve circular welded seam and the torsion strength of the welded seam of the installation flange of the brake, etc.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

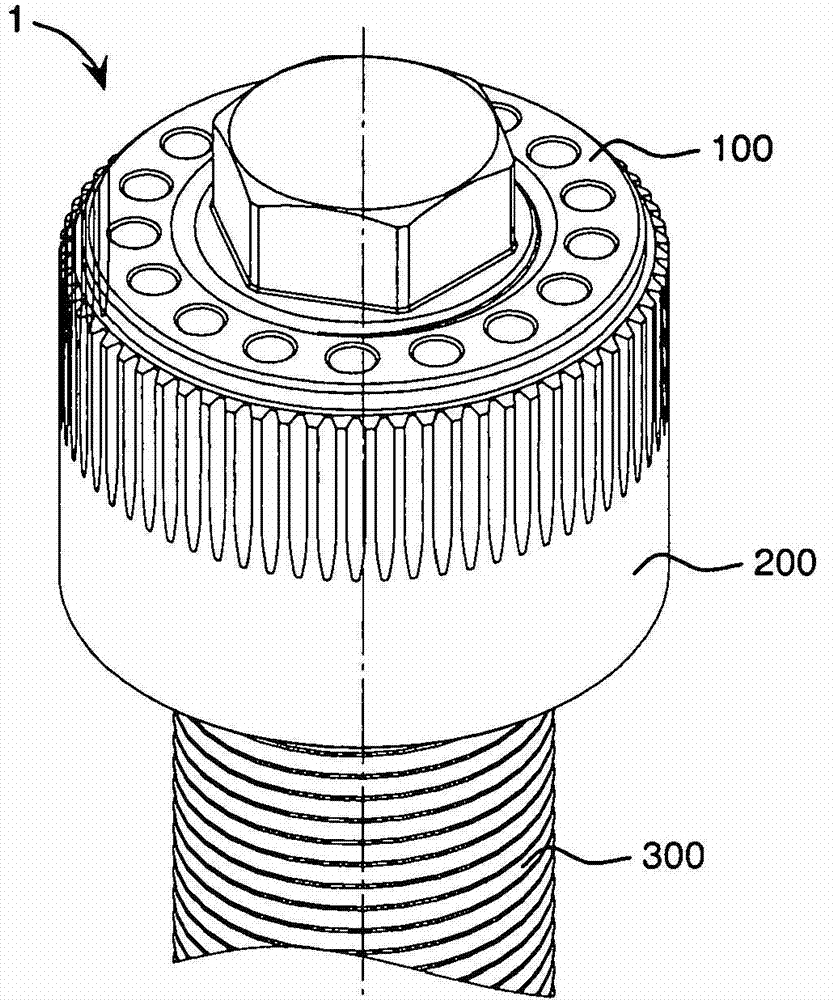

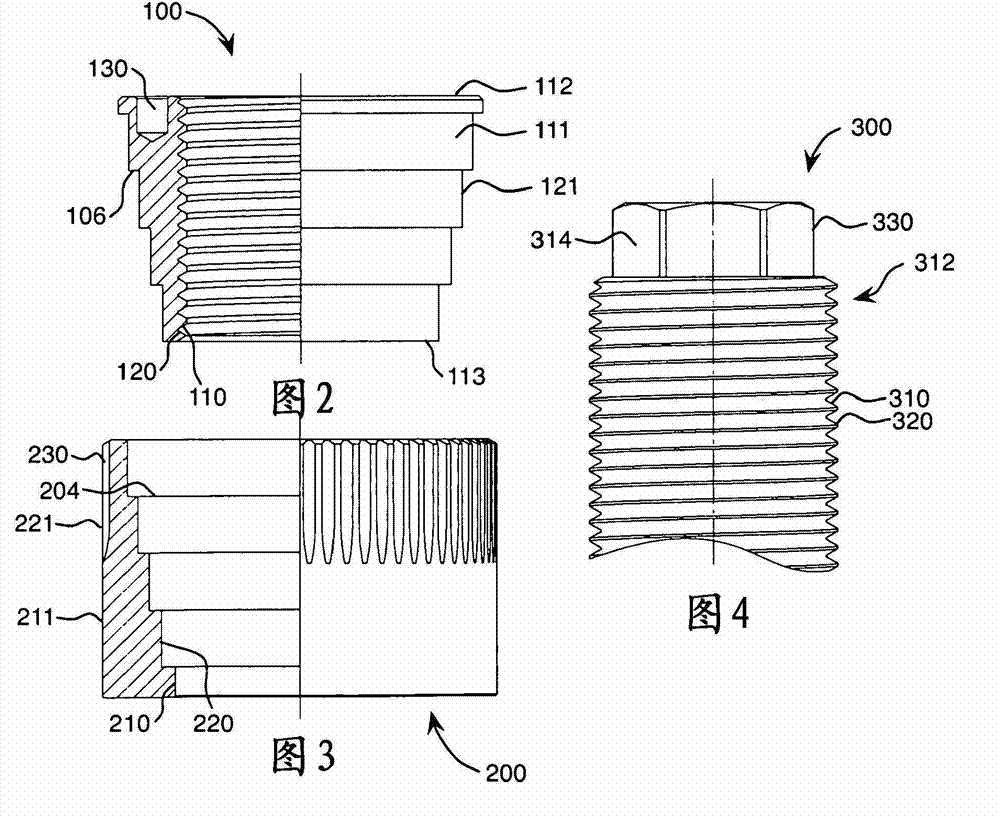

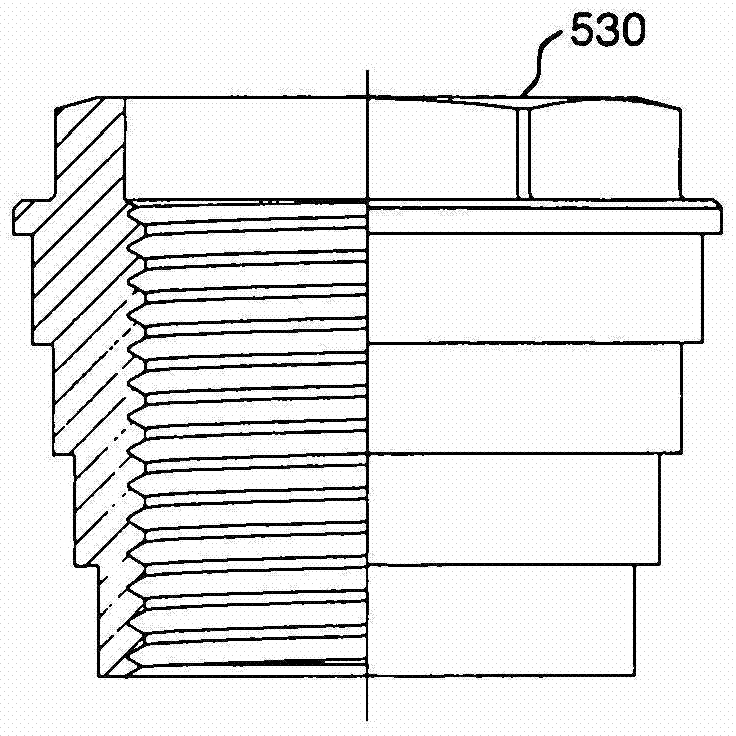

Apparatus for tightening threaded fasteners

ActiveCN103119309AIncreased load bearing surface areaIncreased torsional strengthNutsLoad modified fastenersStress distributionUltimate tensile strength

According to a first aspect of the invention we provide an apparatus (1) for use with a threaded fastener including: -an inner sleeve member (100) having an internal surface threadedly engagable with the fastener and a tapered external surface; and an outer sleeve member (200) having an inversely tapered internal surface rotatably engagable with the tapered external surface of the inner sleeve member. Advantageously, the invention allows for an increased load bearing surface area between the inner sleeve member (100), which is clamped, and the outer sleeve members (200) without increasing the overall diameter of the apparatus (1) 6; a three dimensional load bearing surface area rather than a conventional two dimensional plane; more efficiently and evenly distributed load stress distribution over the load bearing surface area; higher torsion strength; and apparatus with lower mass, dimensions and volume.

Owner:JETYD CORP

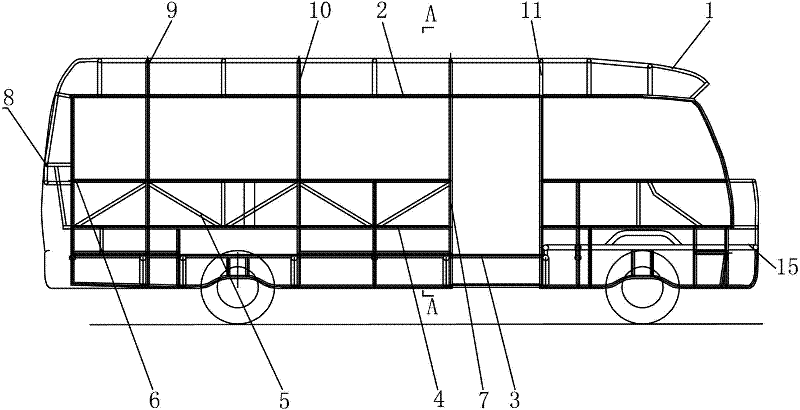

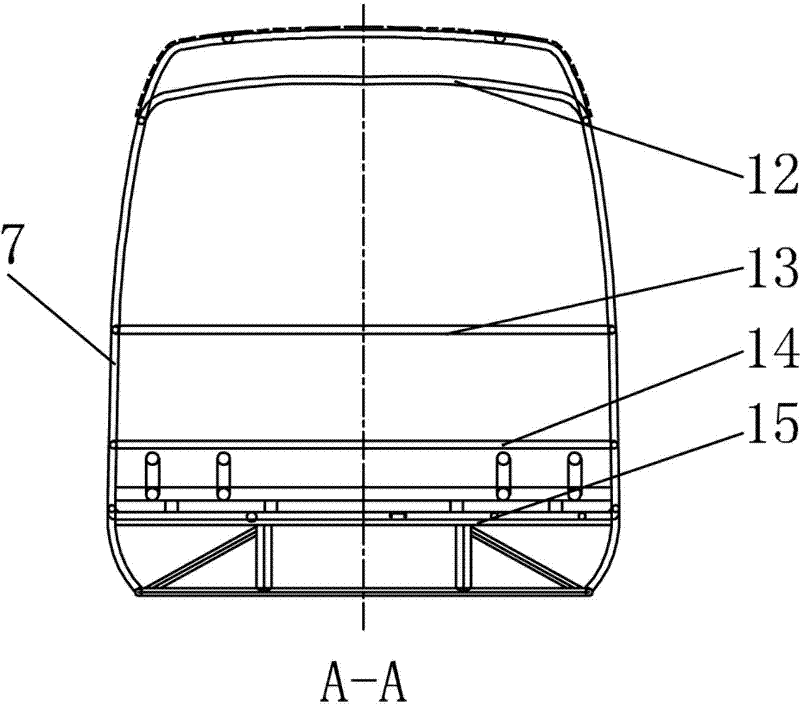

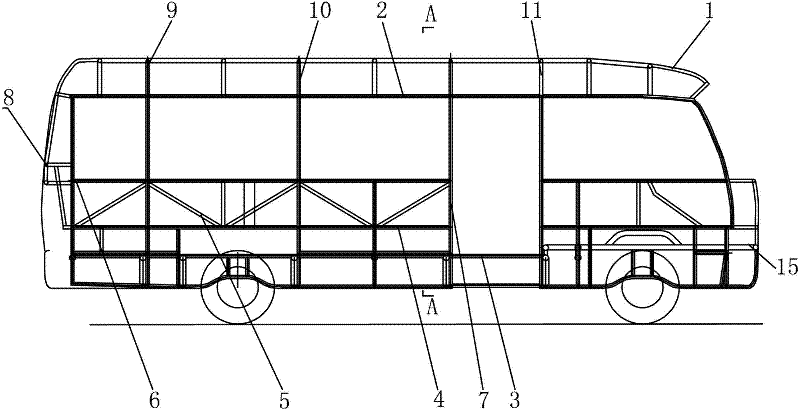

Round steel pipe fully-bearing type vehicular framework

InactiveCN102442351AIncrease profitImprove securityMonocoque constructionsManufacturing technologyUltimate tensile strength

A round steel pipe fully-bearing type vehicular body relates to the vehicular body manufacturing technology. A framework of the vehicular body is in a fully-bearing round steel pipe combined structure, the upper portion and the lower portion of the framework are in an integral structure by means of round pipe closed rings, and a passenger door front closed ring, a passenger door rear closed ring, a rear wheel front closed ring and a rear wheel rear closed ring are arranged on the upper side, the lower side and two lateral sides of the framework. Each closed ring is in a closed annular structure made by a whole round steel pipe, and the closed rings is welded with a vehicular body longitudinal framework and a reinforcing support to form the round steel pipe fully-bearing type vehicular body. Manufacturing process is simplified, weld joints and welding deformation are reduced, materials are saved, processing time is shortened, and operation efficiency is improved. Rigidity, strength of the framework and torsional rigidity of the vehicular body are enhanced by means of the fully-bearing round steel pipe combined structure, the anti-torsion strength of the framework is higher than that of a conventional vehicular frame by three to six times, a passenger vehicle is uniform in stress of each portion, and thereby the whole vehicular body is involved in bearing, and safety factor is greatly increased.

Owner:SHANDONG QILU AUTOMOBILE MFG

Lightweight design method of high-torsional-rigidity drive shaft

ActiveCN103807281AImprove comfortIncreased torsional stiffnessYielding couplingShaftsDrive shaftTorsional vibration

The invention provides a lightweight design method of a high-torsional-rigidity drive shaft. The lightweight design method of the high-torsional-rigidity drive shaft comprises the following steps: designing a drive shaft into a hollow rotary forging shaft, calculating the maximal outer diameters of two performance constraint sections of the drive shaft, and simplifying the drive shaft into a three-section-type stepped shaft, wherein the relatively small maximal outer diameter of two performance constraint sections as the two-end-section outer diameter; designing the intermediate section outer diameter with the aim that the outer diameter of the intermediate section is maximized by combining the outer peripheral rotation space of the intermediate section of the drive shaft according to the constraint condition that the outer diameter of the intermediate section of the drive shaft is not greater than twice of the outer diameter of the sections at two ends; and designing the inner diameter and the weight losing ratio of each section of the three-section-type stepped shaft according to the allowable torque intensity value of raw materials of the rotary forging shaft and the required torque intensity improvement ratio. Compared with a solid shaft in the prior art, according to the method, the torque rigidity of the drive shaft can be improved by 60% approximately, and meanwhile the weight can be lost by 20%, so that the horizontal finished automobile control stability is improved with the minimum cost; the torque vibration of a drive system is improved; the vehicle comfort is improved.

Owner:SHANGHAI GKN DRIVE SYST

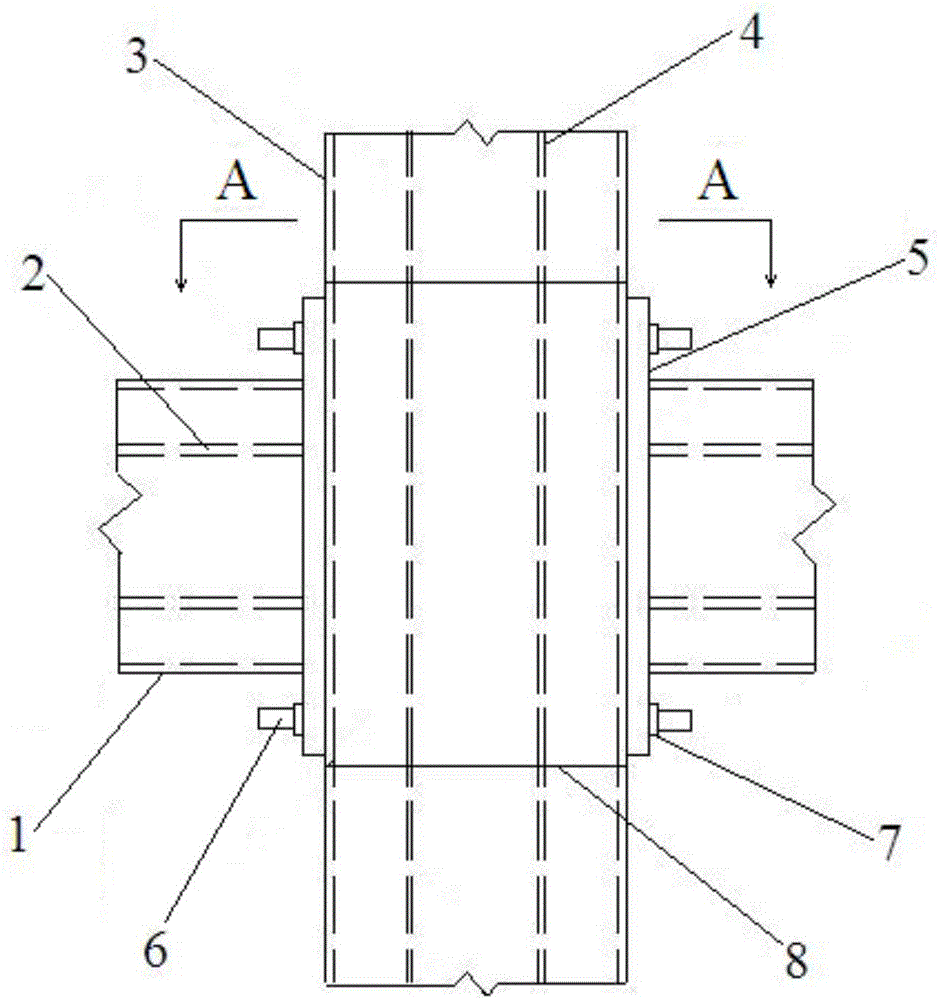

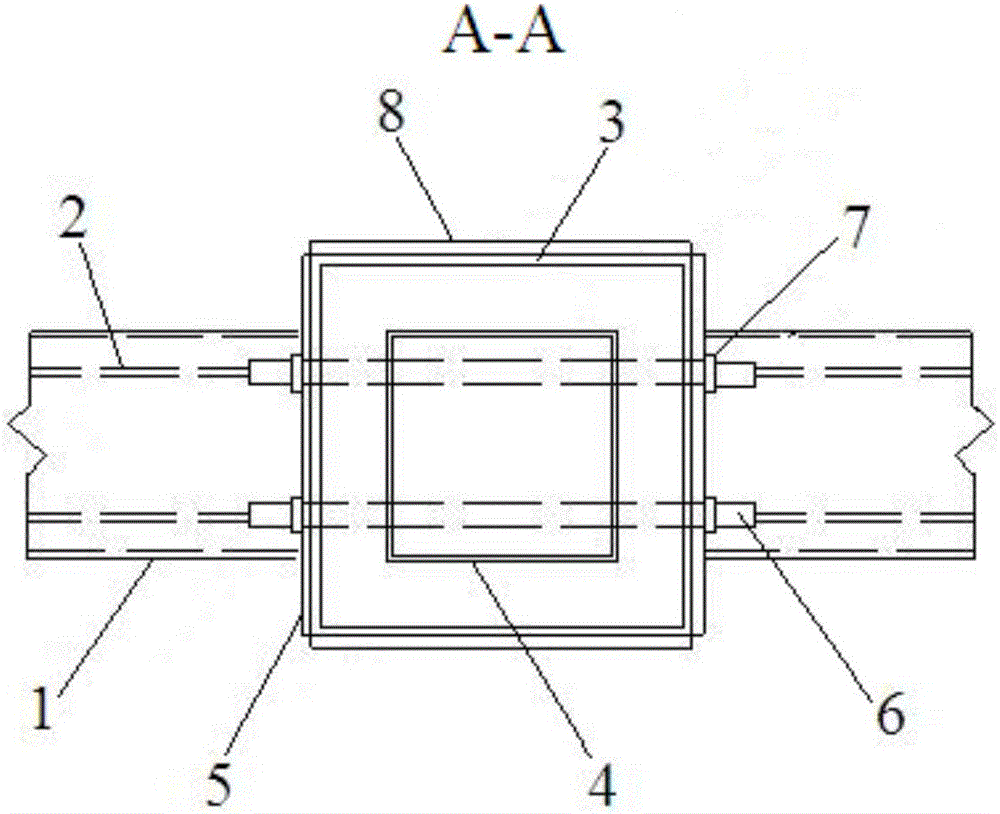

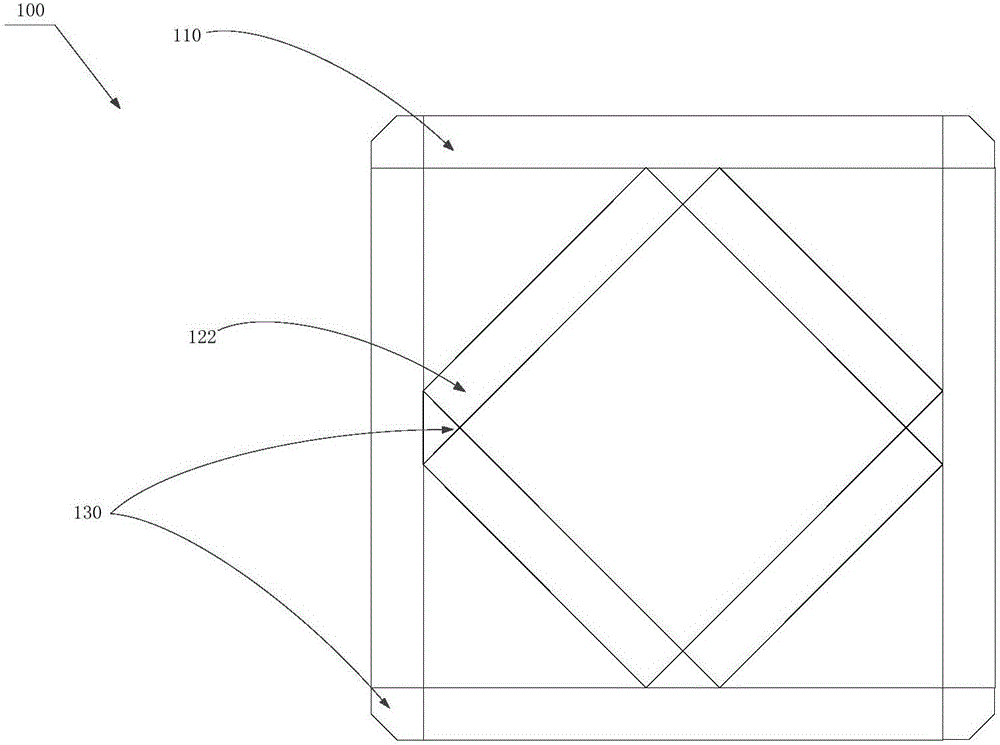

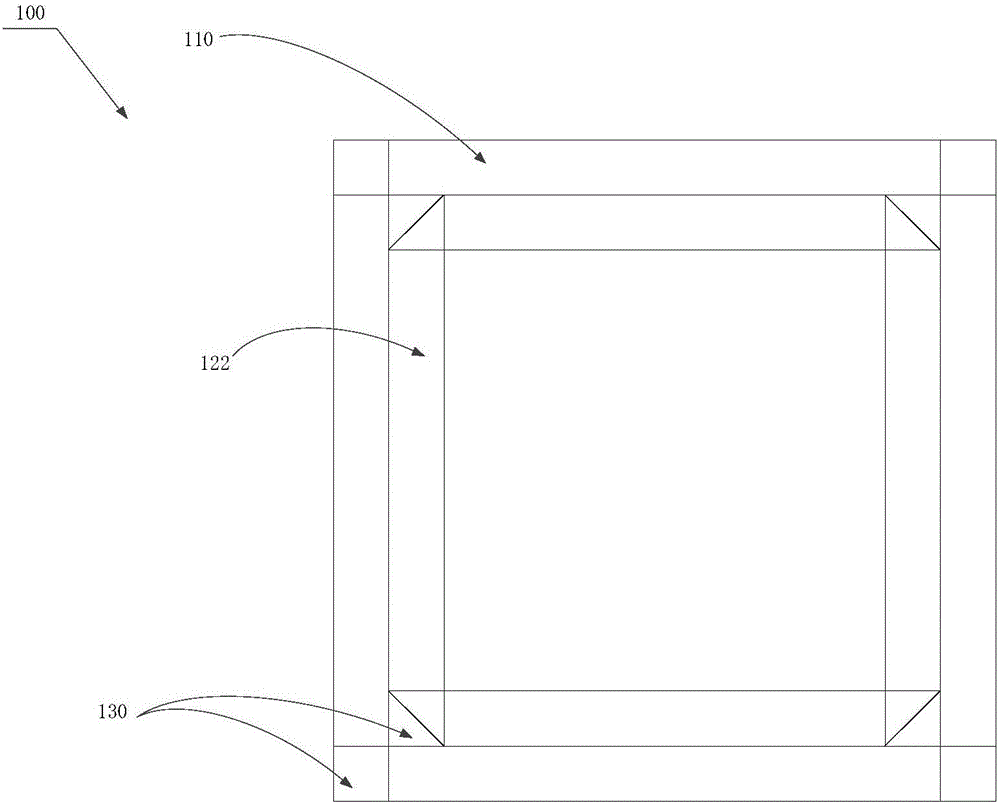

High-strength concrete-filled steel tube column-beam joint structure and construction method thereof

InactiveCN106836491AFirmly connectedIncreased torsional strengthBuilding constructionsHigh strength concreteUltimate tensile strength

The invention discloses a high-strength concrete-filled steel tube column-beam joint structure and a construction method thereof. The high-strength concrete-filled steel tube column-beam joint structure comprises a tube column and a tube beam, wherein a first column square steel tube and a second column square steel tube are arranged on the outer side wall and inner side wall of the tube column, and the part between the first column square steel tube and the second column square steel tube is filled with concrete; a first beam rectangle steel tube and a second beam rectangle steel tube are arranged on the outer side wall and inner side wall of the tube beam separately, the part between the first beam rectangle steel tube and the second beam rectangle steel tube is filled with concrete, and beam end plates are welded at two ends of the tube beam; two beam end plates on the tube beam are fixedly connected to the left side and right side of the tube column through nuts and bolts; reinforced steel plates are arranged at the front side and back side of the tube column separately; and two edges of the reinforced steel plates are welded with the edges of the two beam end plates separately. According to the high-strength concrete-filled steel tube column-beam joint structure, the torsion strength and connection strength of the connection joint of the tube column and the tube beam are improved separately. The construction method of the high-strength concrete-filled steel tube column-beam joint structure is used for building the high-strength concrete-filled steel tube column-beam joint structure.

Owner:CHANGAN UNIV

Optical cable having metal corrugated pipe protective sheath

InactiveCN1430081AIncreased traction resistanceTwist upFibre mechanical structuresMetallic materialsEngineering

An optical cable with corrugated metallic protection sheath is composed of bundle of optical fibrs, a corrugated metallic protection sheath, and a sleeve tube made of plastics. Its advantages are high torsion strength and high corrosion resistance.

Owner:上海科星自动化技术有限公司

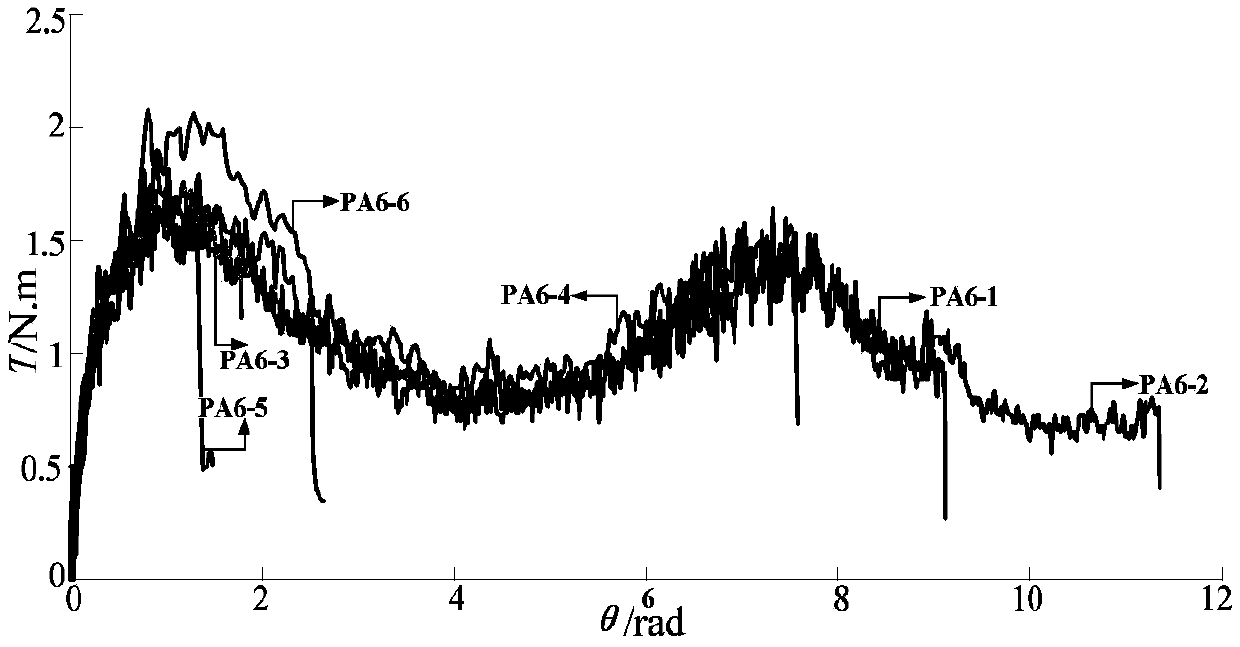

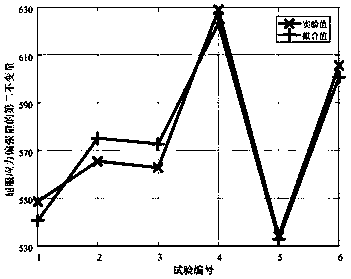

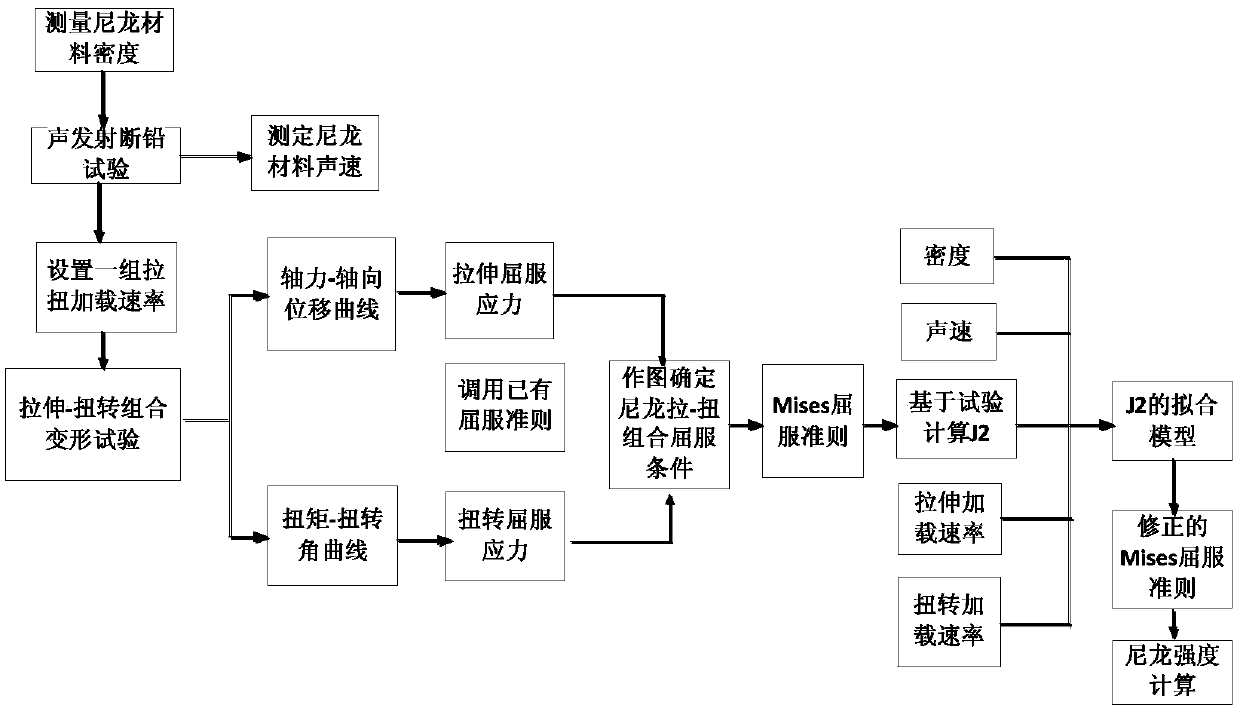

Nylon material tension and torsion combination yield criterion and establishing method thereof

ActiveCN108956265AIncrease flexibilityImprove general performanceStrength propertiesRelational modelAcoustic emission

The invention relates to a nylon material tension and torsion combination yield criterion and an establishing method thereof. The establishing method comprises the following steps: firstly measuring the density of a nylon material, performing acoustic emission lead breakage test on the processed tension and torsion standard test piece to obtain sound velocity values of each test piece, testing thetest pieces according to the set tension and torsion loading scheme and acquiring a mechanical signal, analyzing and calculating each yield stress of tension and torsion, drawing according to experimental data and verifying to obtain Mises yield criterion as a yield criterion in nylon tension and torsion combination, and fitting based on the experiment data to obtain a relationship model of second invariants (relates to density, sound velocity, tension and torsion loading rate) of stress deviator tension in the Mises yield criterion, thus obtaining the corrected nylon tension and torsion Mises yield criterion. The equivalent stress can be obtained in tension and torsion yield by the criterion through sound velocity, density, tension and torsion loading velocity determined before loading,and the strength conditions are established to calculate the corresponding tension and torsion strength.

Owner:XUZHOU NORMAL UNIVERSITY

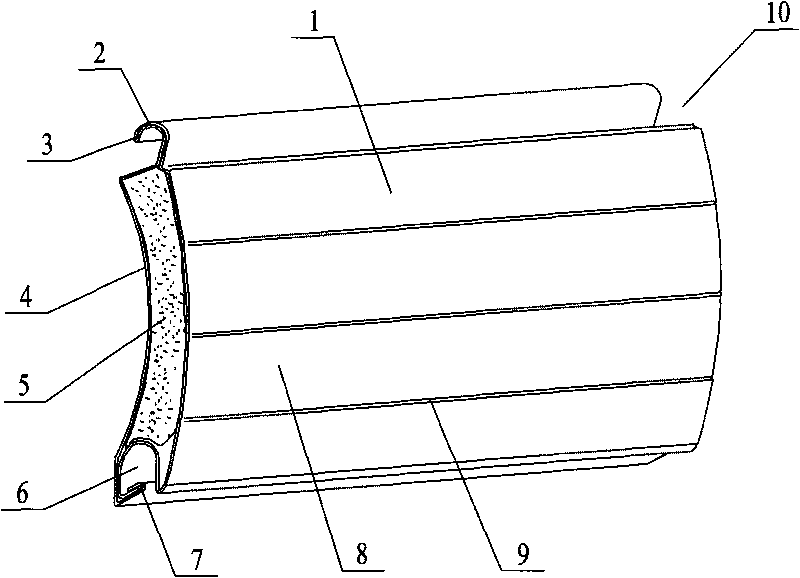

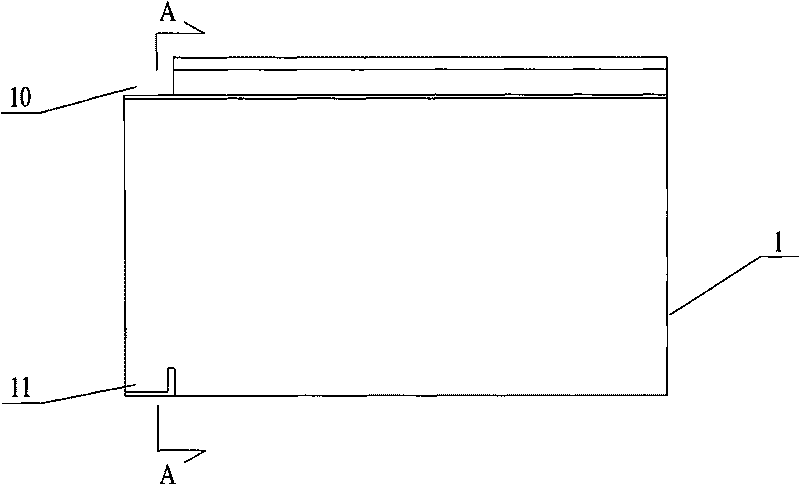

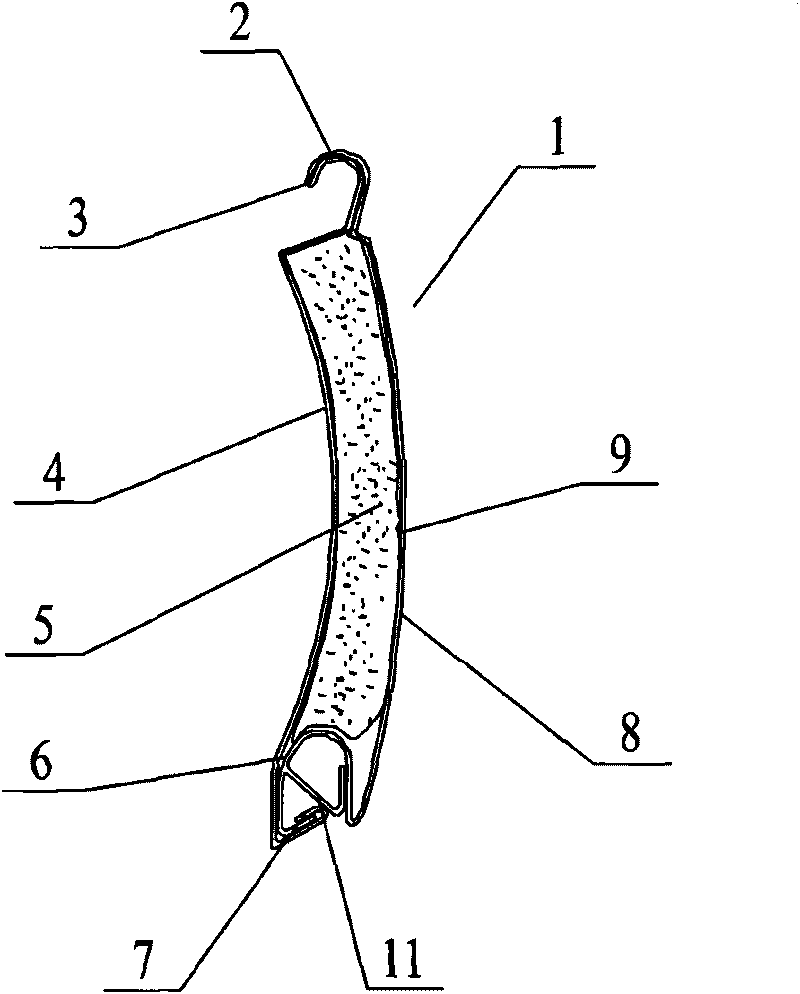

Roller blind piece

ActiveCN101736997AExtended service lifePrevent slippingShutters/ movable grillesFireproof doorsLow noiseThermal insulation

The invention relates to a roller blind piece applied to roller blind doors or windows. The roller blind piece comprises a piece body. An upper hook is formed through upward convex extension of the piece body and a lower hook is formed through depression of the lower part of the piece body. The upper hook can be connected with the adjacent lower hook of the piece body by buckling. The roller blind piece is characterized in that one end of the upper hook on the piece body is provided with a nick and the lower hook is provided with a retaining groove corresponding to the nick; the nick and the retaining groove are arranged at the same end of the same piece body; and when the upper hook on one roller blind piece is connected with the lower hook on the other roller blind piece by buckling, one end of the upper hook, which is provided with the nick, is blocked by the retaining groove. The roller blind piece has compact and reasonable structure, small friction when rolling or unrolling and low noise, is smooth in rolling and unrolling operations and safe and reliable in connection, and simultaneously has good compression strength, anti-bending property, anti-torsion strength and thermal insulation property.

Owner:WUXI JIEYANG ENERGY SAVING TECH

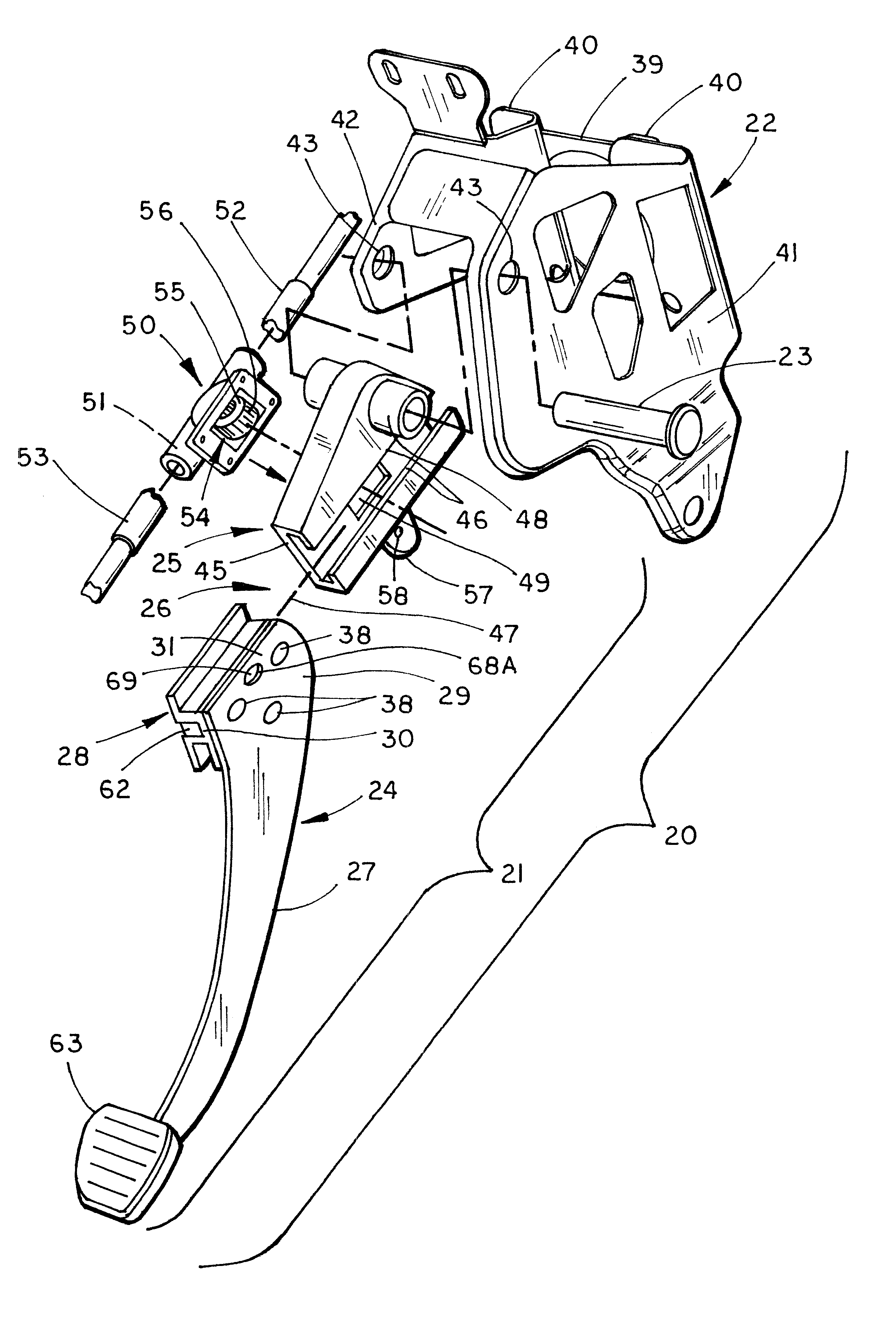

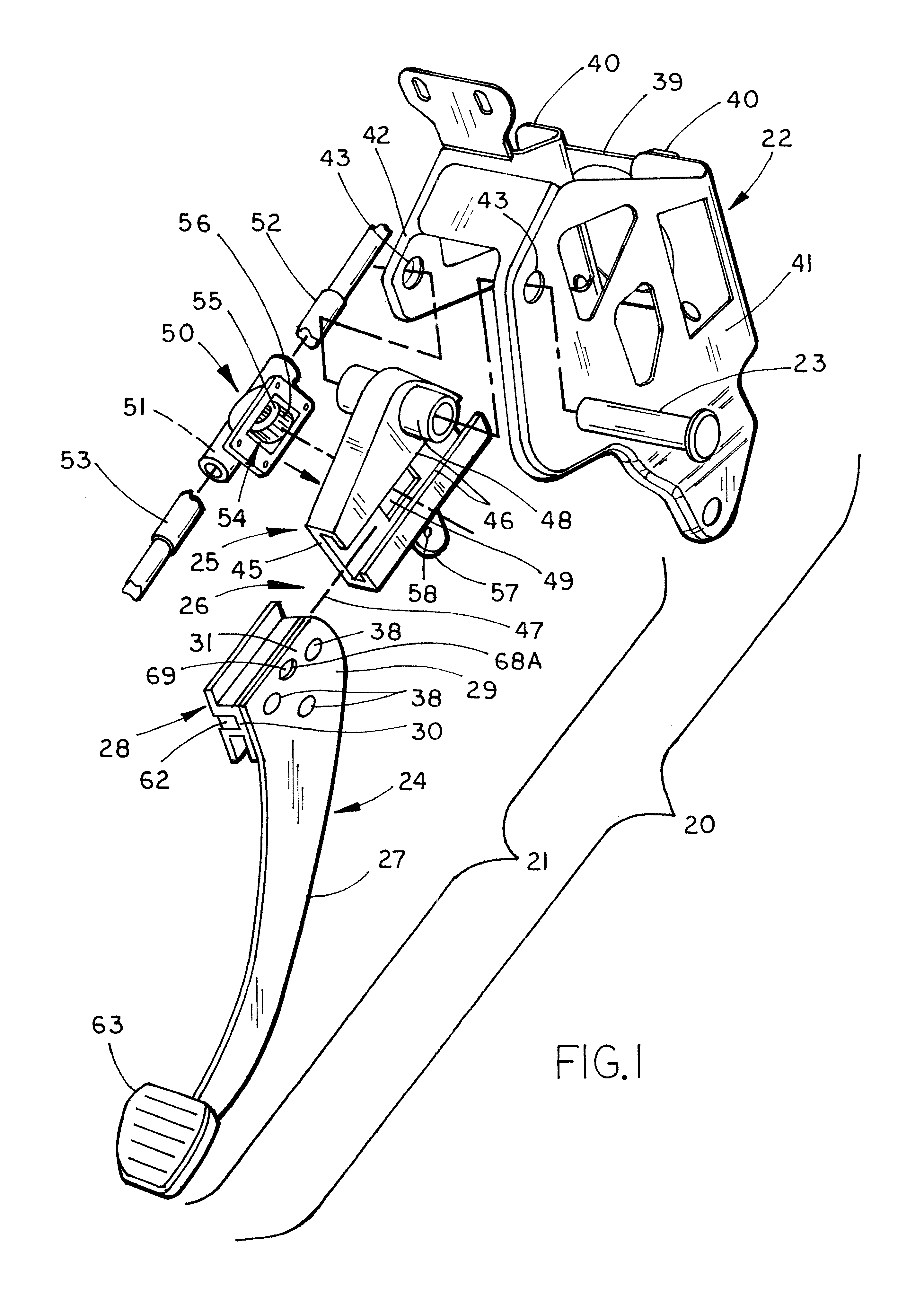

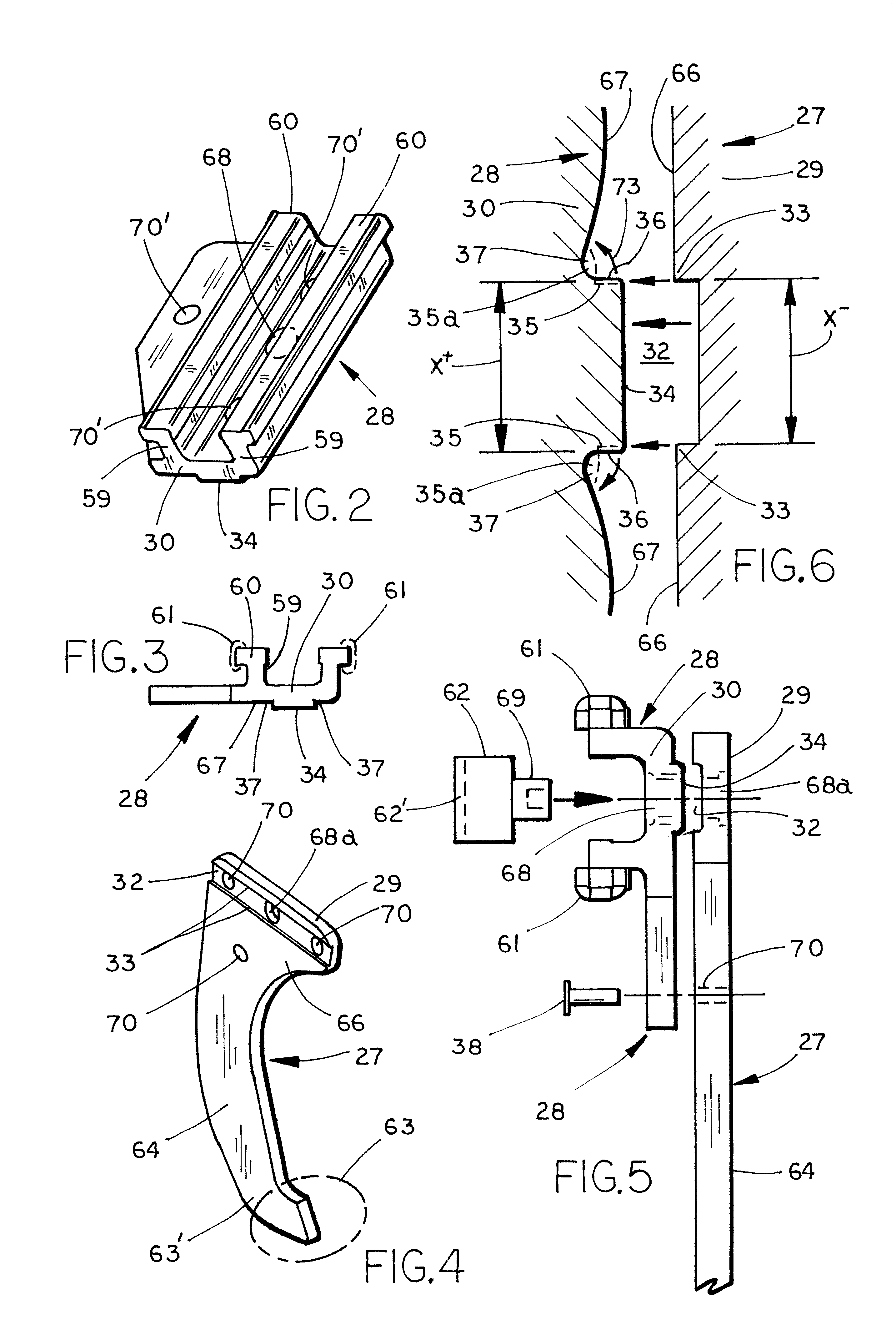

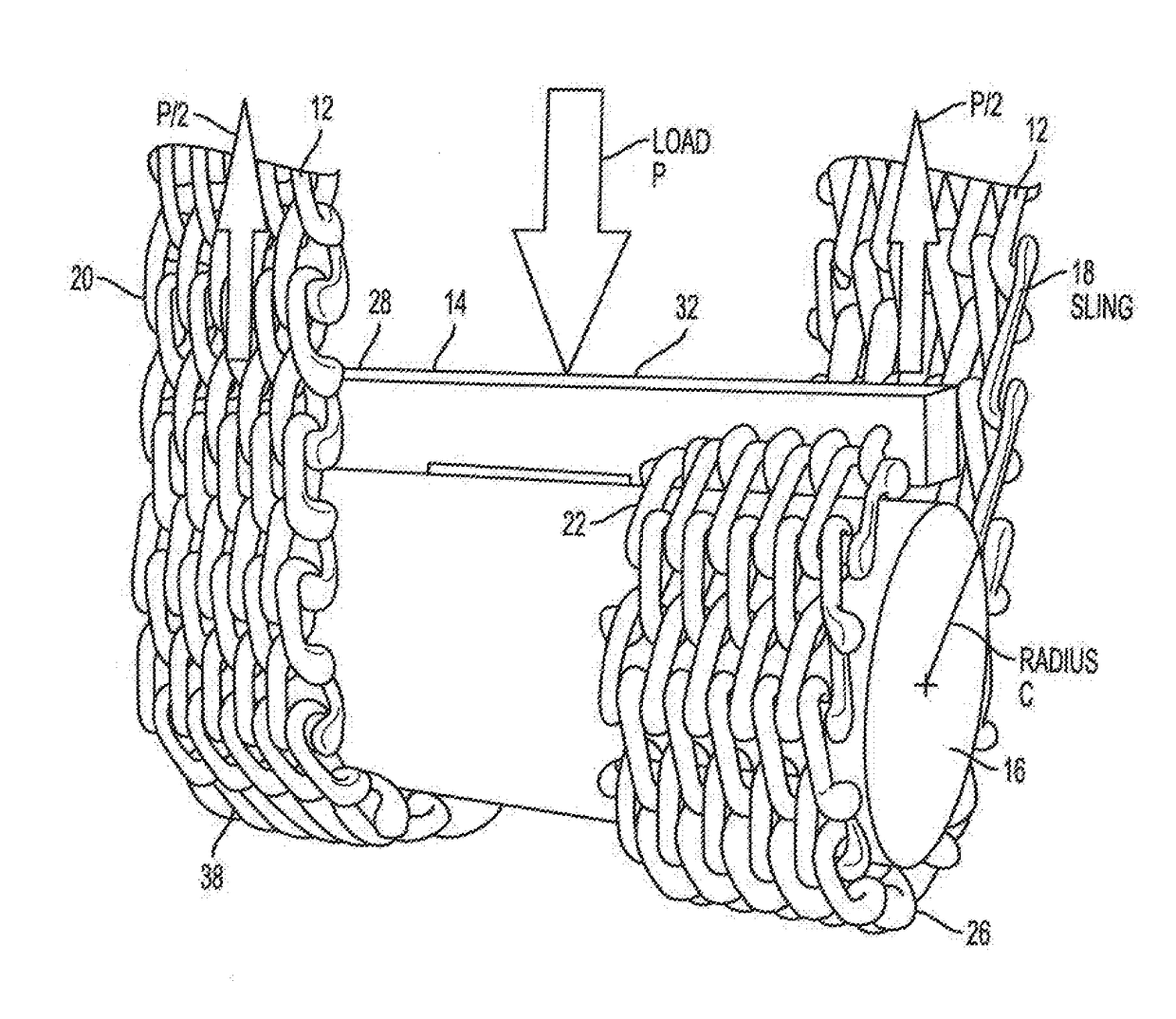

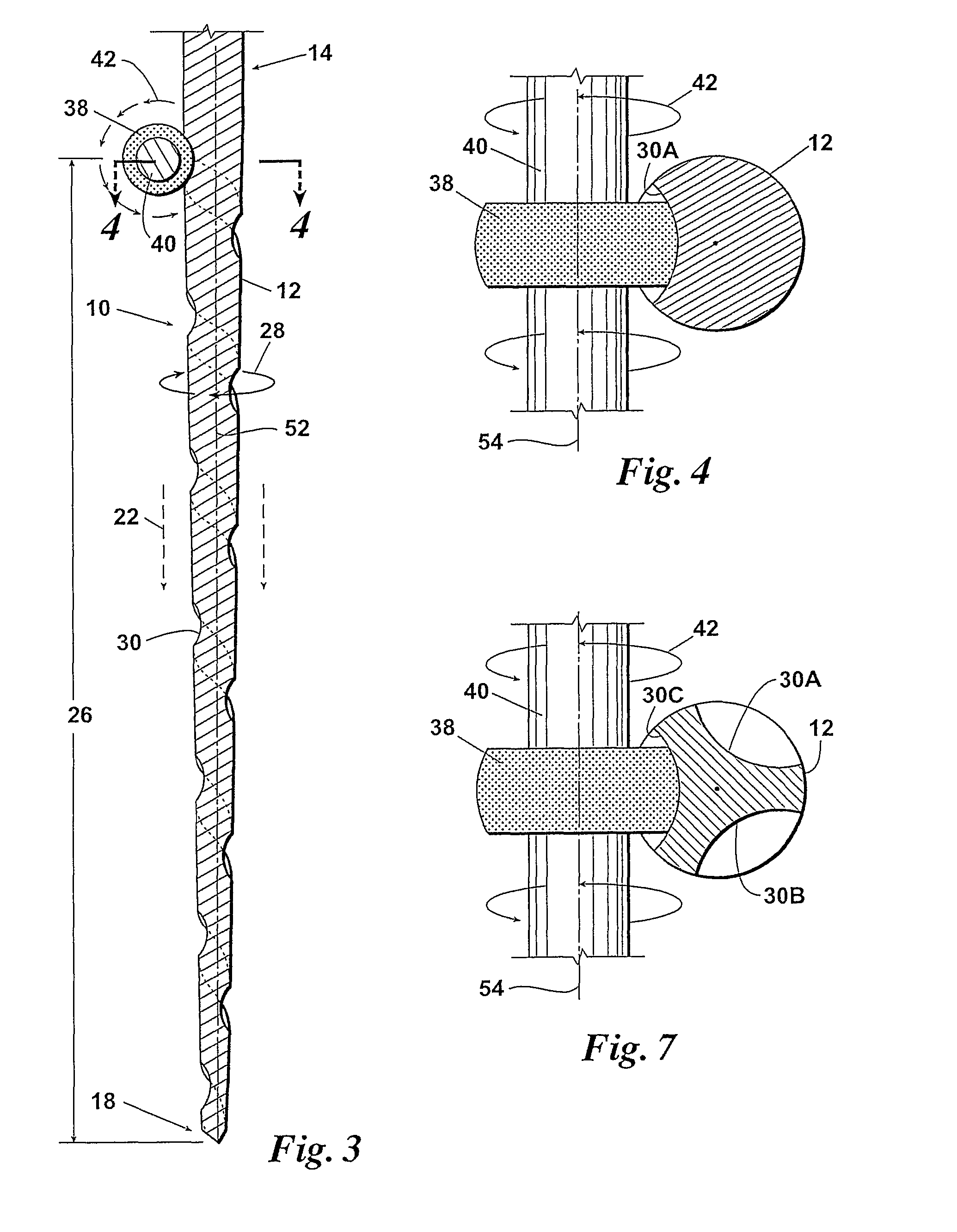

Pedal with tongued connection for improved torsional strength

A pedal construction includes an adjustable pedal subassembly having a lower pedal member adjustably supported on an upper pedal member by an adjustment device. The lower pedal member includes a pedal lever and a lever mount including abutting mounting sections forming a fixed joint. The mounting section of the lever mount has a channel with sharp edges and the mounting section of the lever has a ridge interference fit into the channel. The sharp edges shave marginal material from sides of the ridge when the ridge is forced into the channel, but the ridge has depressions adjacent its bottom that receive the shaved marginal material when the ridge is forced into the channel. Fasteners extend through the ridge and channel to hold the assembly together, with the ridge and channel interface forming a primary mechanical structure providing torsional strength to the joint.

Owner:GRAND HAVEN STAMPED PRODS DIV OF JSJ

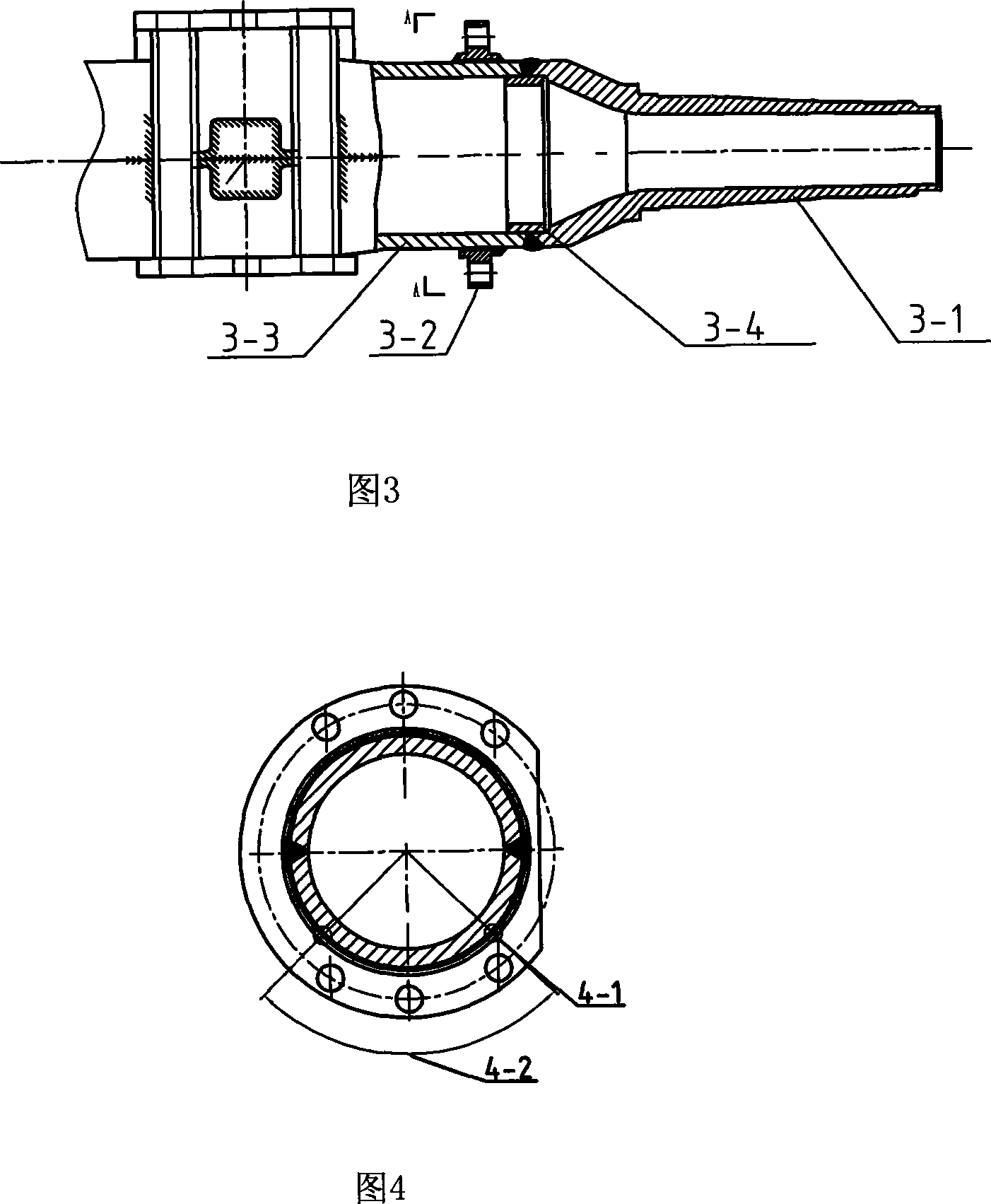

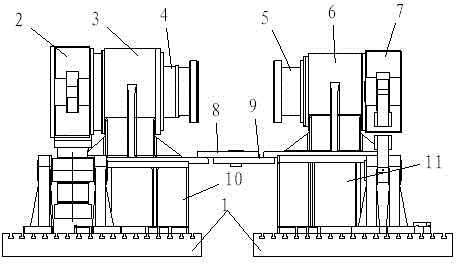

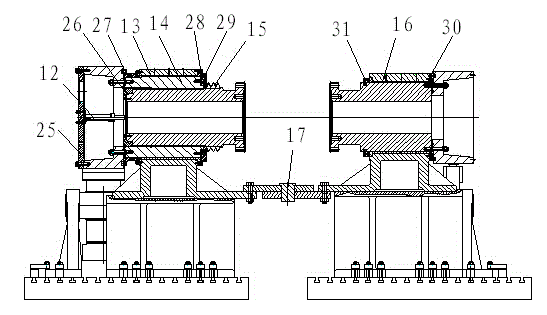

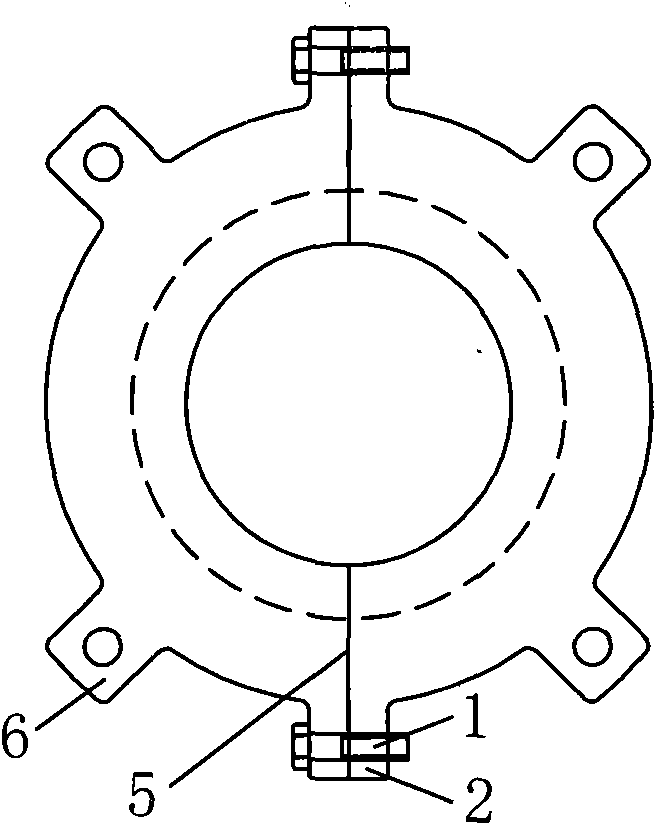

Static load test bench of overload couplers

ActiveCN104406790AEasy to adjustImprove test efficiencyMachine gearing/transmission testingHydraulic cylinderDrive shaft

The invention discloses a static load test bench of overload couplers. The static load test bench of the overload couplers comprises a drive mechanism, a test mechanism and a work piece placement mechanism, wherein the drive mechanism is connected with the test mechanism through the work piece placement mechanism, the drive mechanism comprises a flat plate, a drive force arm, two hydraulic cylinder components, a drive end bottom seat and a drive shaft component, the two hydraulic cylinder components are both fixed on the flat plate, and connected with the drive force arm, the drive shaft component is fixed on the drive end bottom seat and connected with the drive force arm, the drive end bottom seat is fixed on a bottom plate, the test mechanism comprises a flat board, a test force arm, two force sensor components, a test end bottom seat and a rotation shaft component, the two force sensor components are both fixed on the flat board, and connected with the test force arm, the rotation shaft component is fixed on the test end bottom seat, and connected with the test force arm, and the test end bottom seat is fixed on the bottom plate. The static load test bench of the overload couplers is suitable for the couplers of various weights, and particularly suitable for a torque test and tests of parameters of static torsion strength and the like of heavy load couplers and the overload couplers.

Owner:TAIER HEAVY IND +1

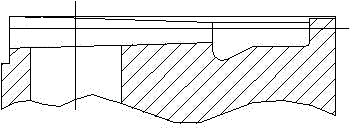

Anti-torsion cable with fireproof function

PendingCN106158104AAct as a hindrancePrevent rotationInsulated cablesInsulated conductorsThermal insulationEngineering

The invention discloses an anti-torsion cable with fireproof function, comprising an outer sheath (1), an inner sheath (3) arranged in the outer sheath (1), a plurality of cable sheaths (4) arranged in the inner sheath (3) and a cable core (5) arranged in the cable sheaths (4); the inner surface of the outer sheath (1) is provided with a plurality of grooves A, the outer surface of the inner sheath (3) is provided with a plurality of grooves B that are in one-to-one correspondence with the grooves A, the grooves A and the grooves B cooperate to form cavities, a stiffener (2) is mounted in each cavity, and a fireproof layer (6) is provided outside the outer sheath (1). The anti-torsion cable has the advantages that relative rotation between the outer sheath and the inner sheath can be prevented by using the stiffeners so as to improve torsion strength and avoid abrasions between the inner sheath and the outer sheath, the stiffeners can be arranged to provide enhanced mechanical strength for the cable, and the fireproof layer can be arranged to impart good thermal insulation and fireproof property to the cable.

Owner:成都云士达科技有限公司

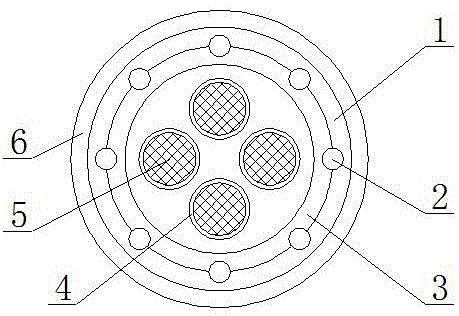

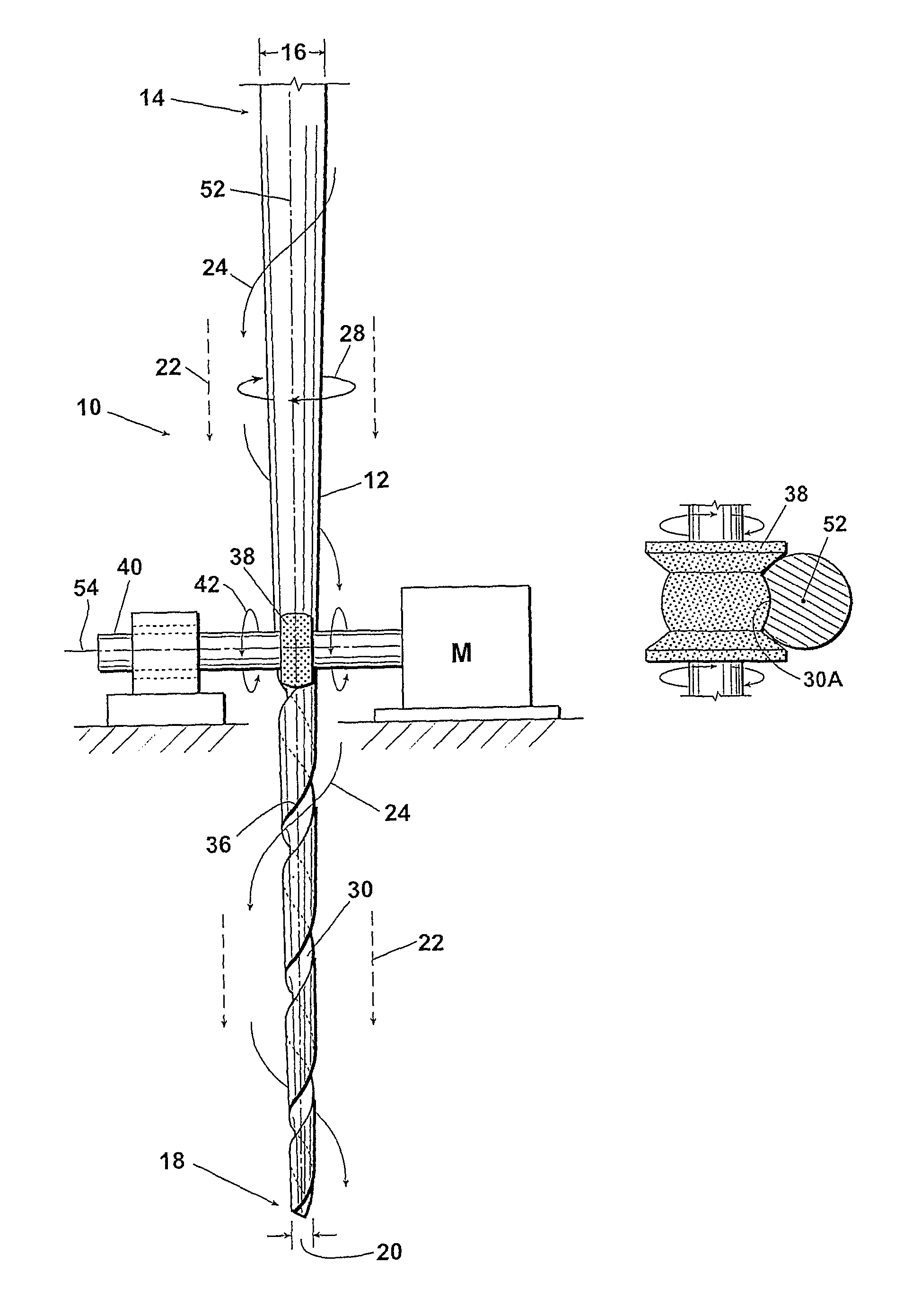

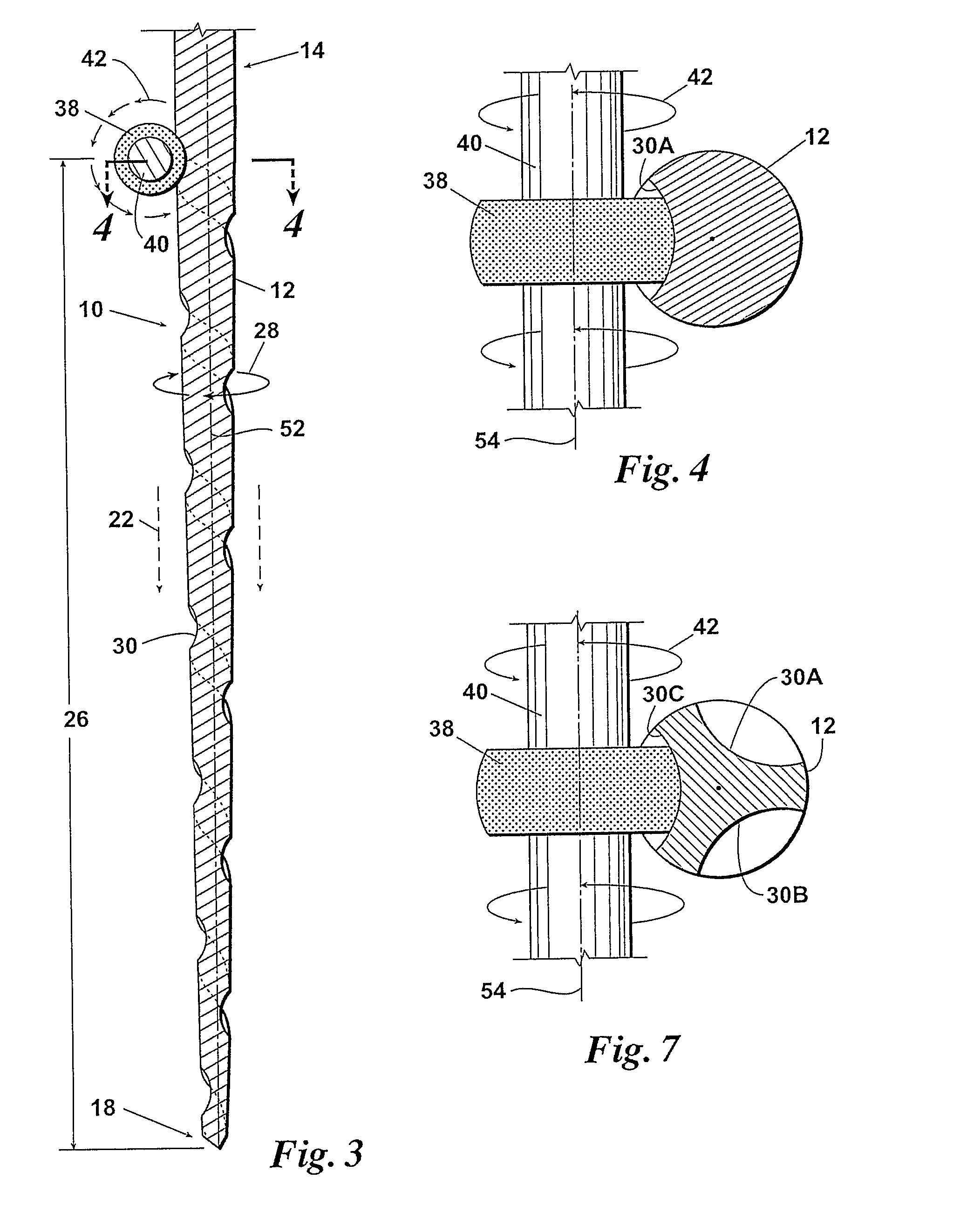

Torsion Testing Devices and Methods

ActiveUS20180149567A1Easy to insertEasy to removeMaterial strength using steady torsional forcesMaterial strength using steady shearing forcesEngineeringTorsional strength

A torsional testing device for testing helical tensile strength, shear strength, and interface bond shear strength using an apparatus to apply torsional loads on a cylindrical specimen is provided. A plurality of slings is wrapped in opposed circular directions around the specimen. A connecting bar is coupled to a first end of each of the slings. A second end of each of the slings is coupled to a frame. A conventional compression load testing machine applies a compressive load to the connecting member causing the slings to apply rotational forces to the specimen in opposite senses creating torsional stresses. Rotational forces are transmitted to the cylindrical specimen due to friction between the slings and the surface of the specimen being tested. The amount of force applied to the specimen is measured so that the torsional strength of different specimens can be compared.

Owner:UNIV OF COLORADO THE REGENTS OF

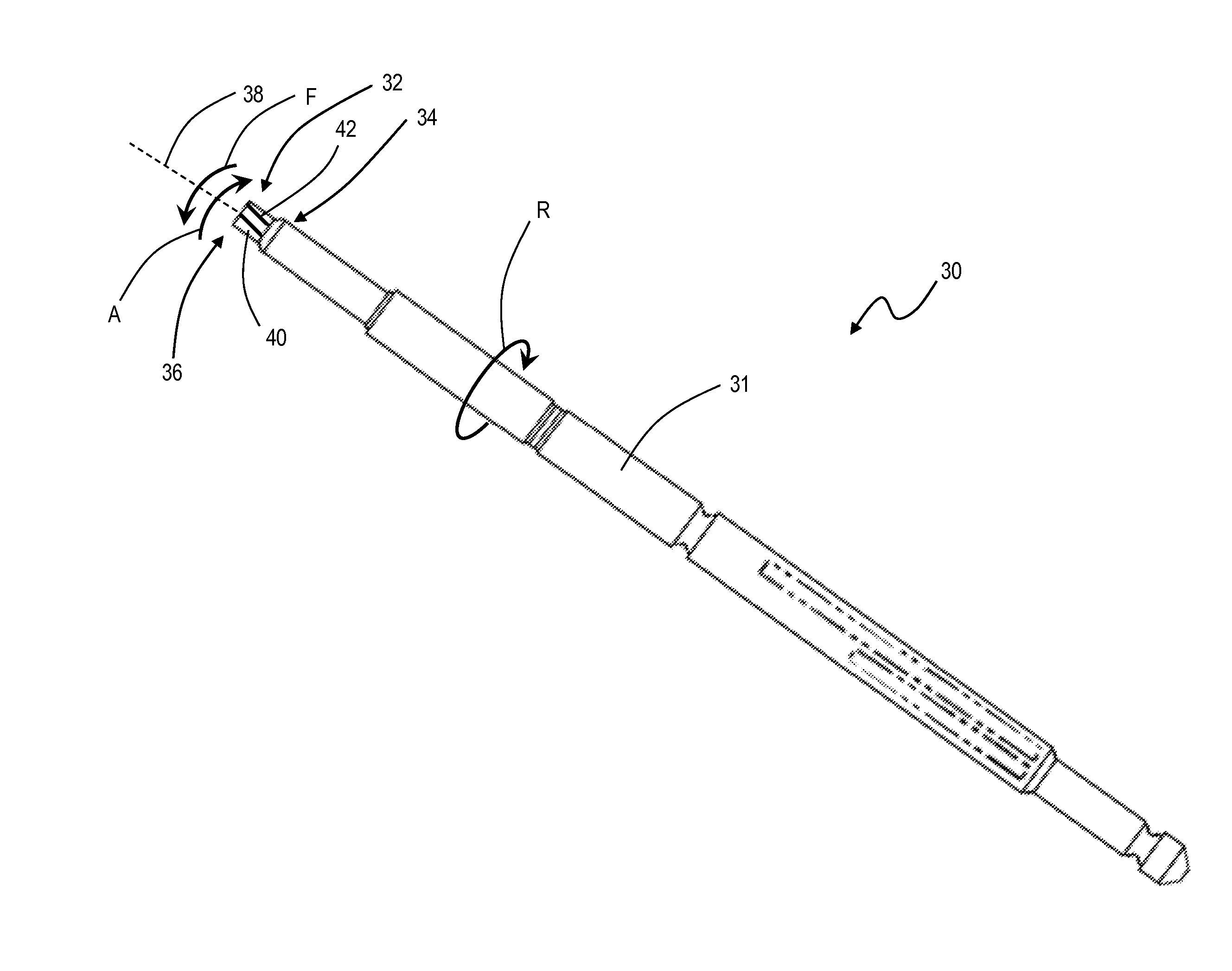

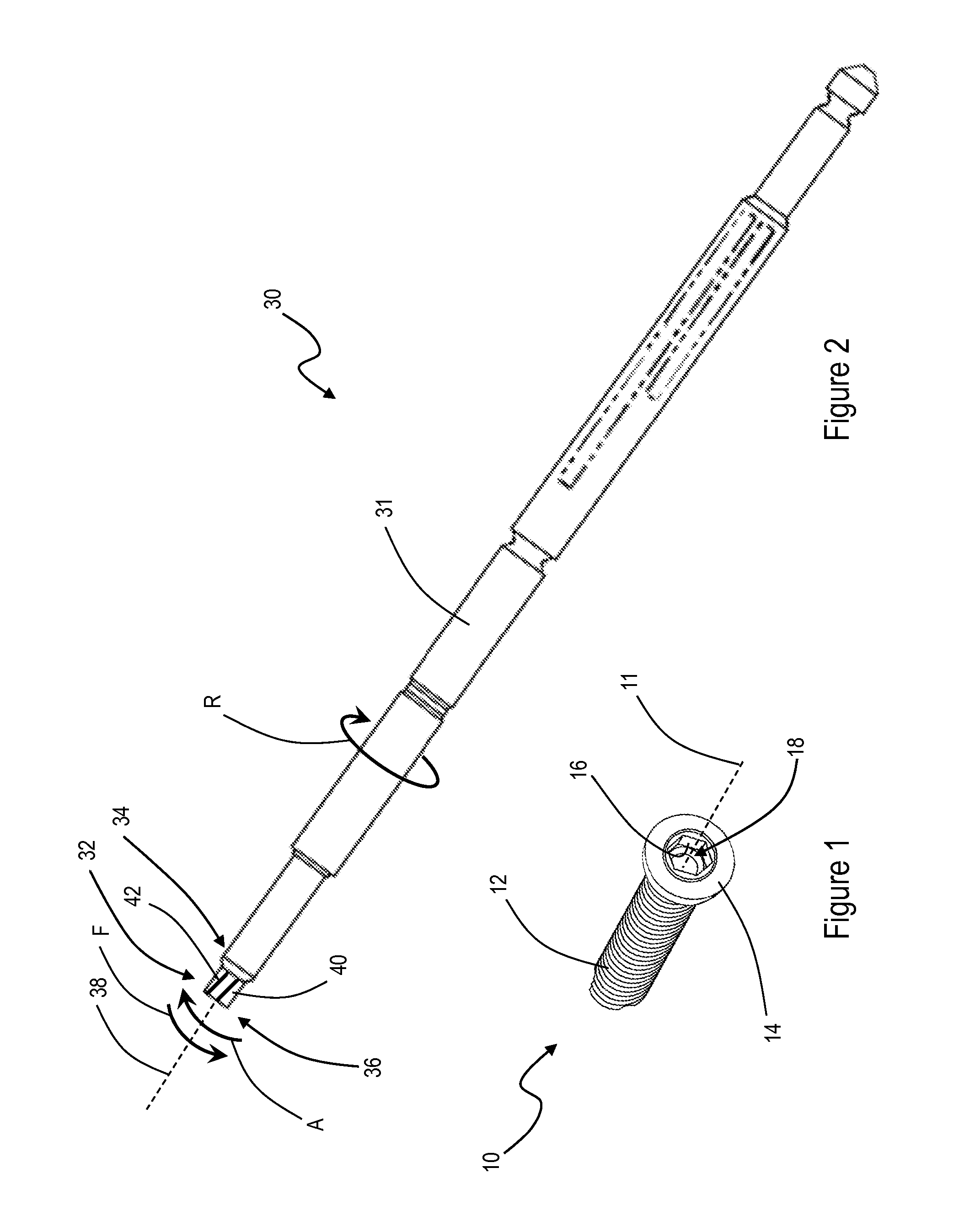

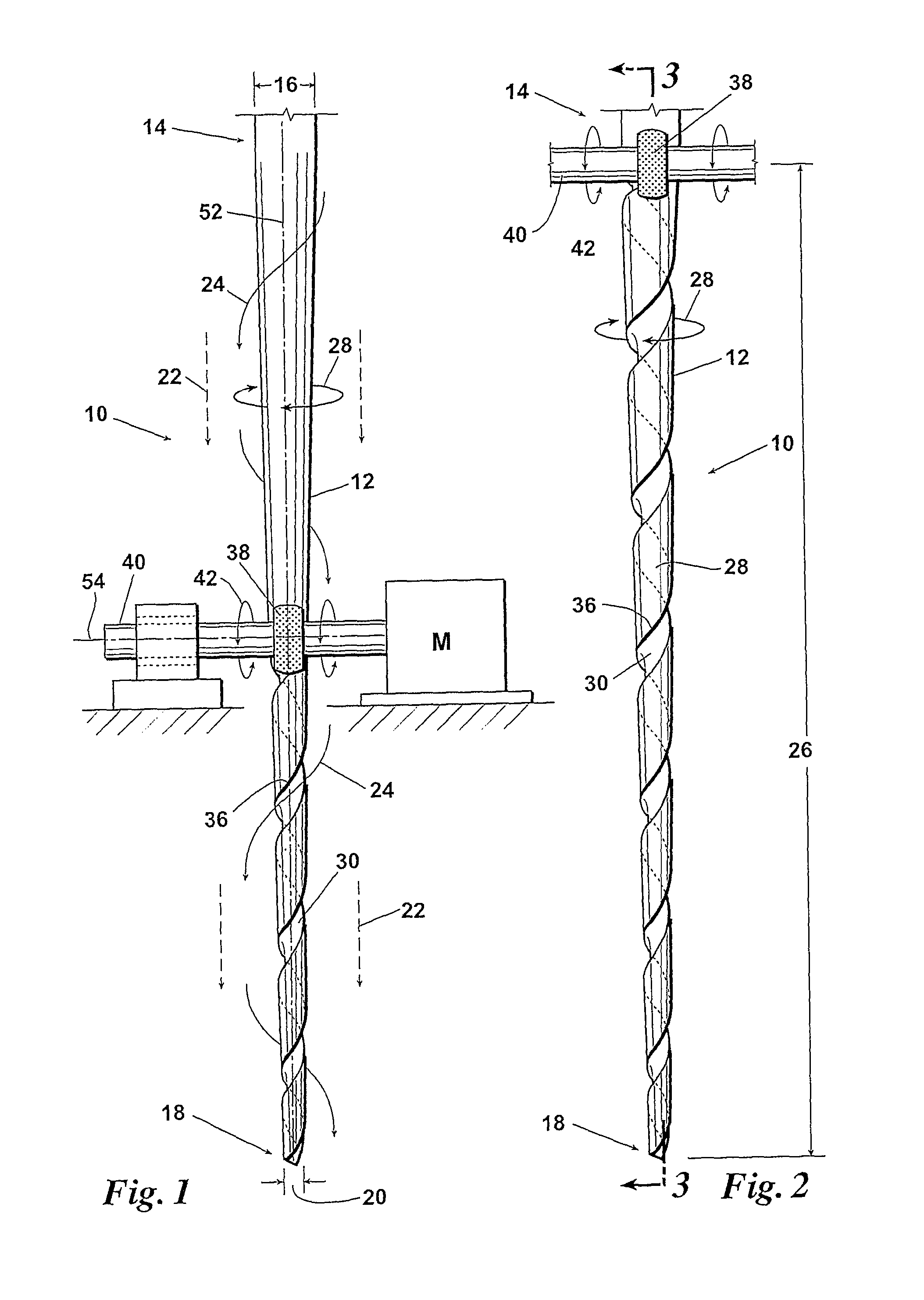

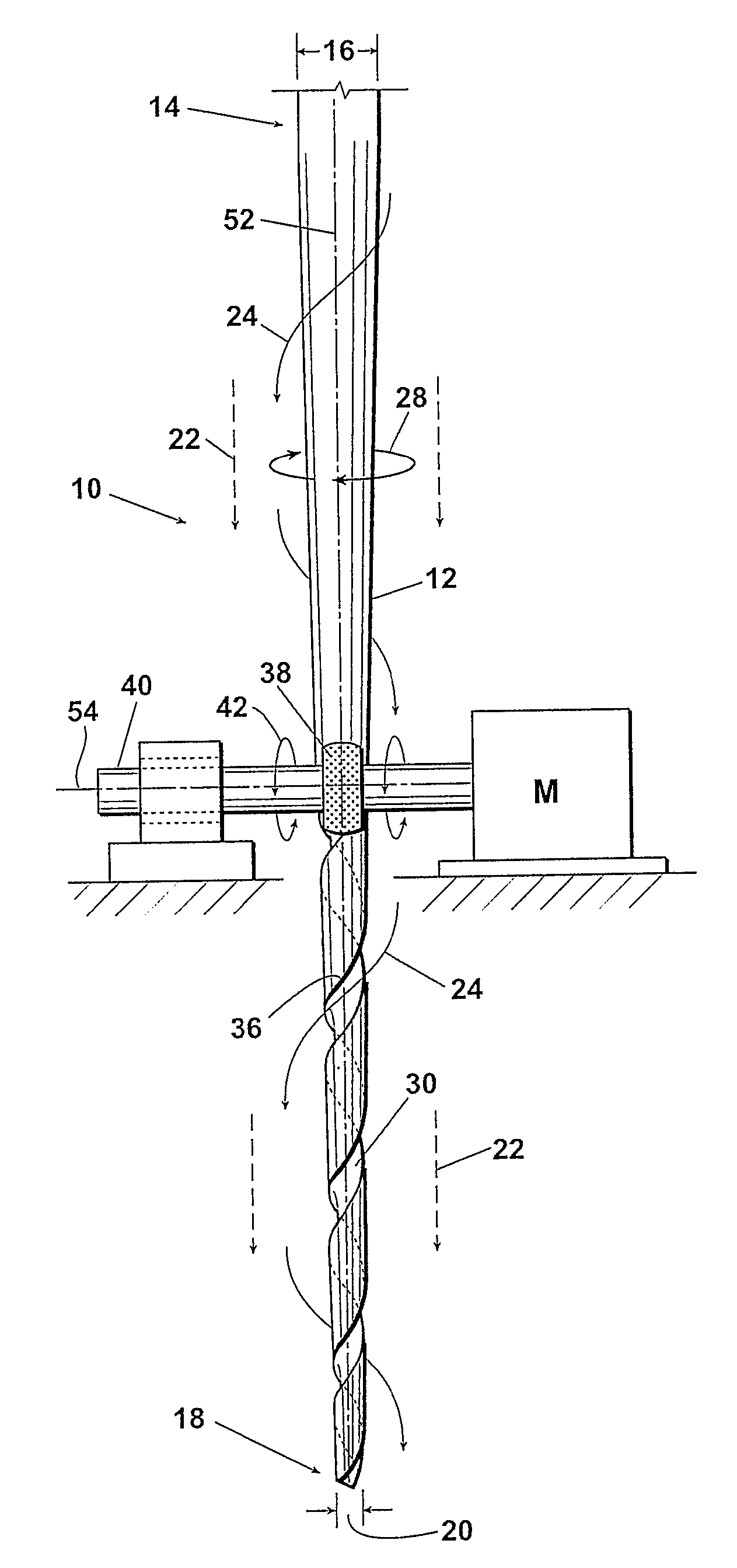

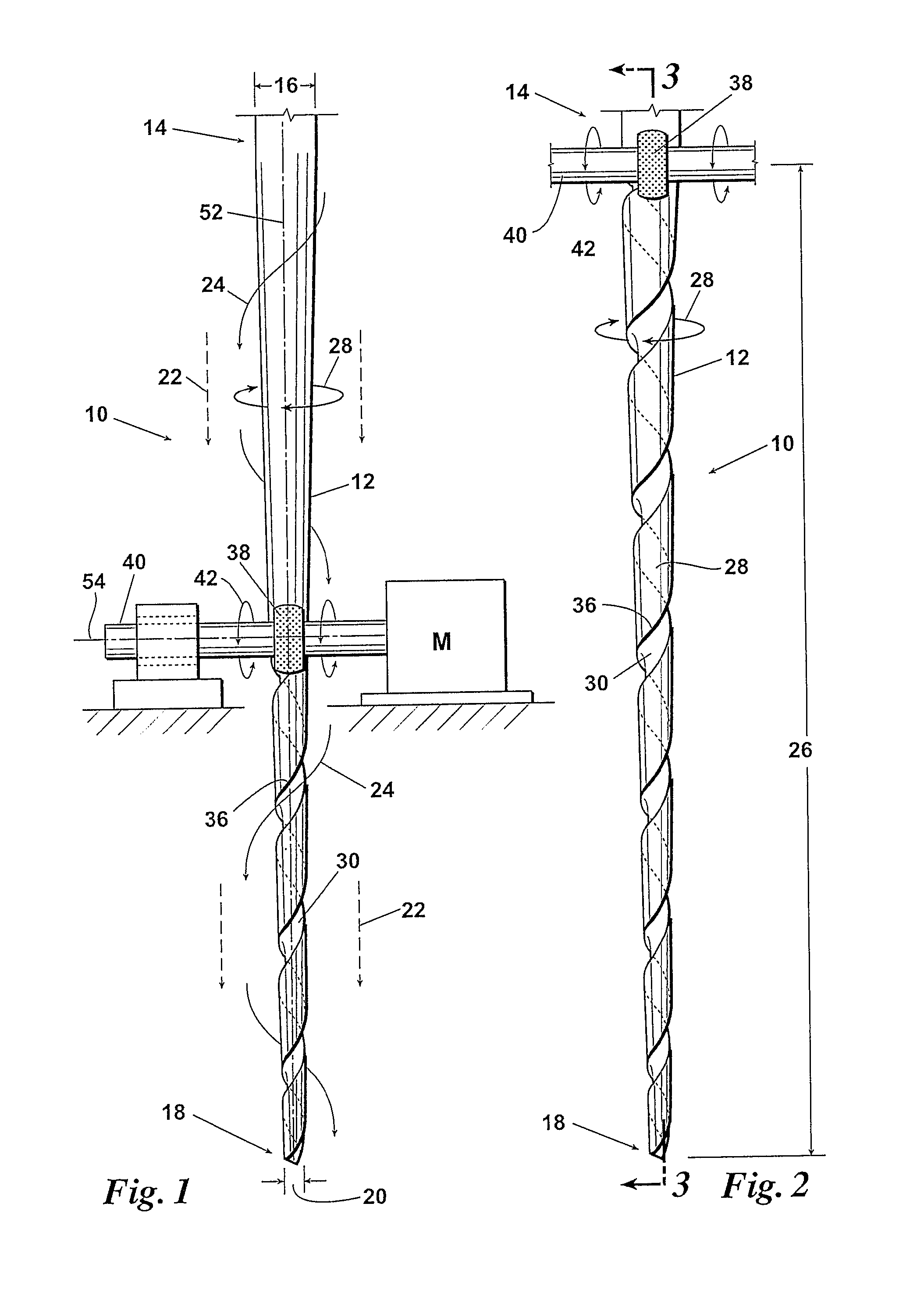

Longitudinally ground file having increased resistance to torsional and cyclic fatigue failure

A method of producing an endodontic file that involves grinding in a plane substantially parallel to the longitudinal axis of a rotating dental instrument blank. By grinding the dental instrument blank in this manner, the torsional strength of the resulting endodontic file is not eroded during its production, thereby providing a file that is less susceptible to breakage during its use.

Owner:DENTSPLY SIRONA INC

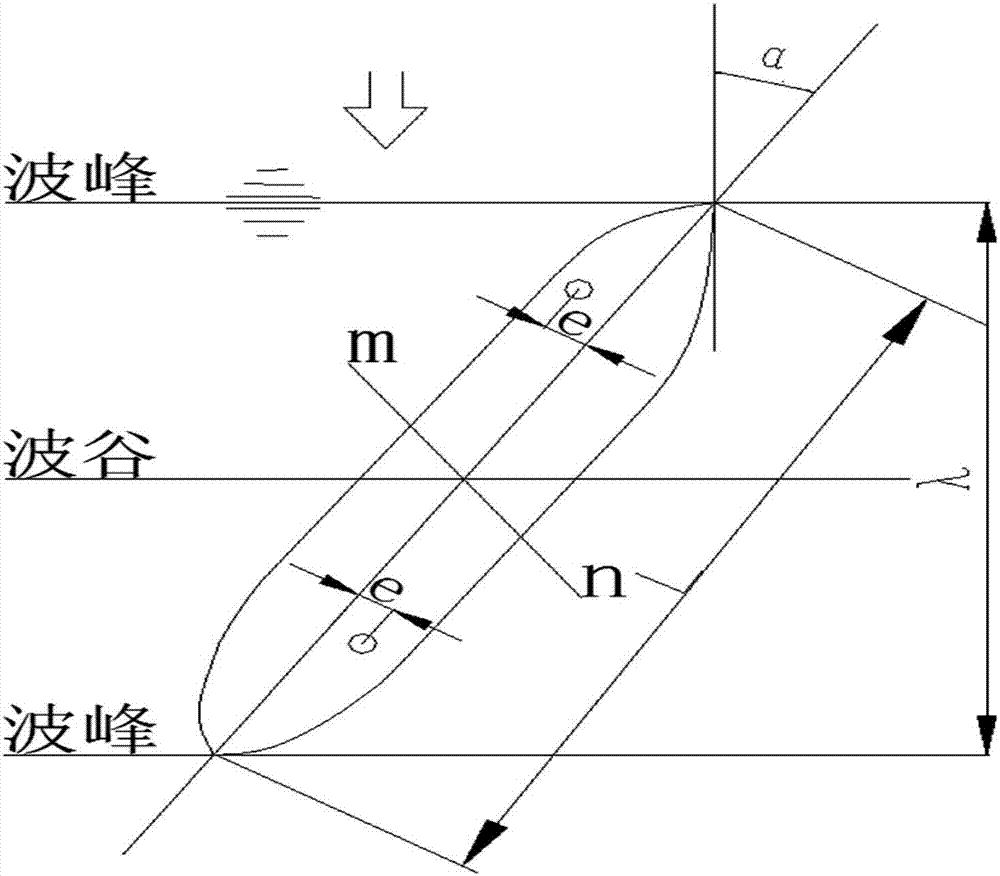

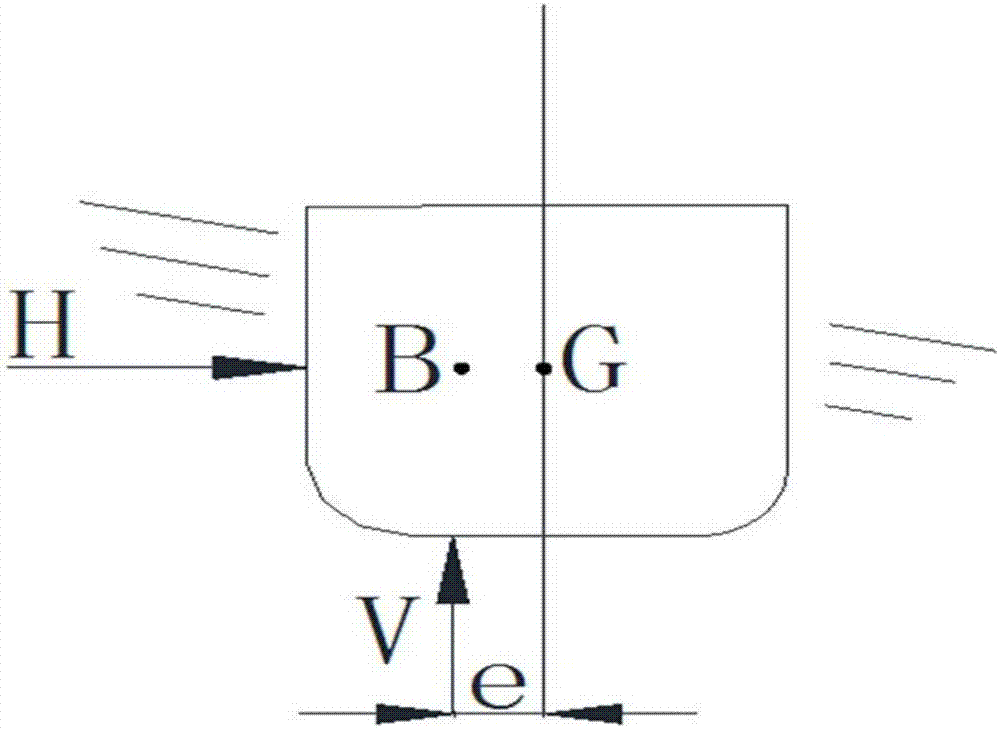

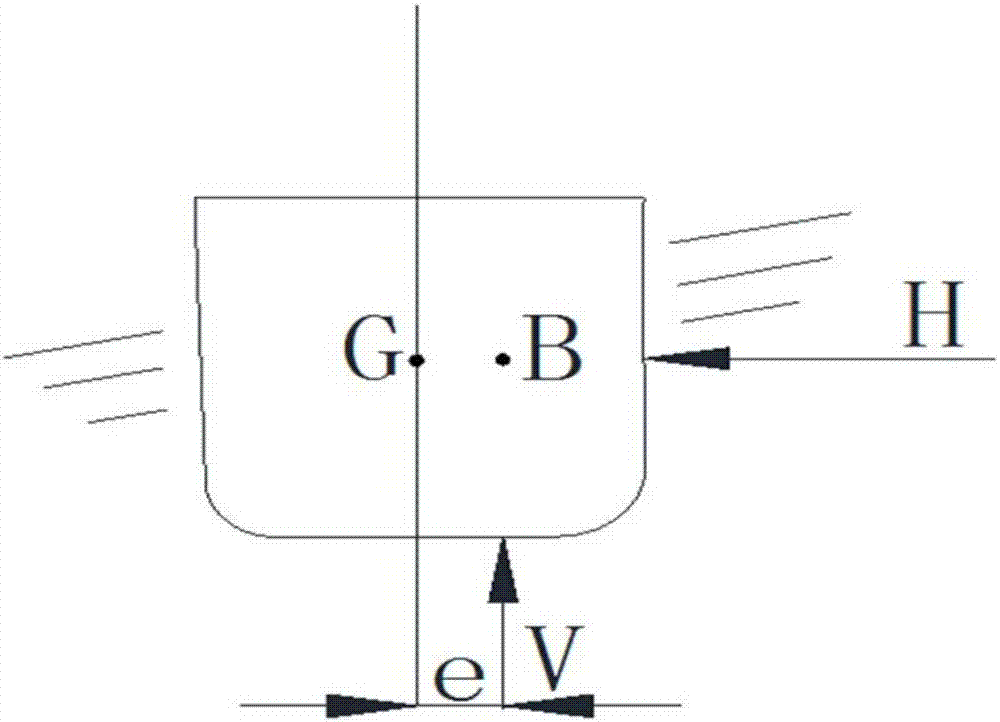

Experimental device and experimental method for measuring torsion strength of large container ship

ActiveCN107067933AExperimental realEasy to observeWork measurementEducational modelsMaximum torqueAudio power amplifier

The invention discloses an experimental device for measuring the torsion strength of a large container ship. The experimental device comprises a loading water tank in which a ship model is placed. The ship model and the loading water tank are connected by partition boards. The partition boards divide the loading water tank into a plurality of independent spaces. A plurality of T profiles and a plurality of counterweights are mounted on the ship model. A plurality of strain gauges are also mounted on the ship model. The strain gauges are connected with a charge amplifier. The charge amplifier is sequentially connected with a multi-channel information collection instrument and a computer. The experimental device enables students to have an understanding of the basic causes of maximum torque produced by a ship and the basic principle of formation of maximum torque. The ship model produces a torque in the experiment, which enables students to have an intuitive understanding of the torque problem of a container ship.

Owner:江苏新扬子造船有限公司

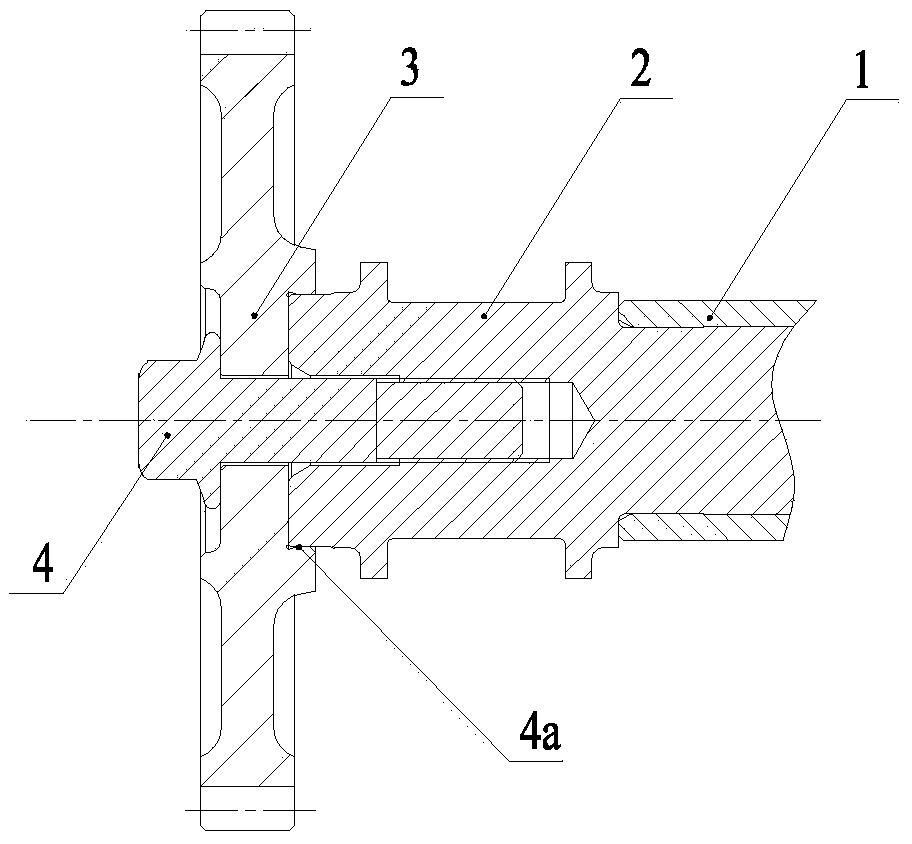

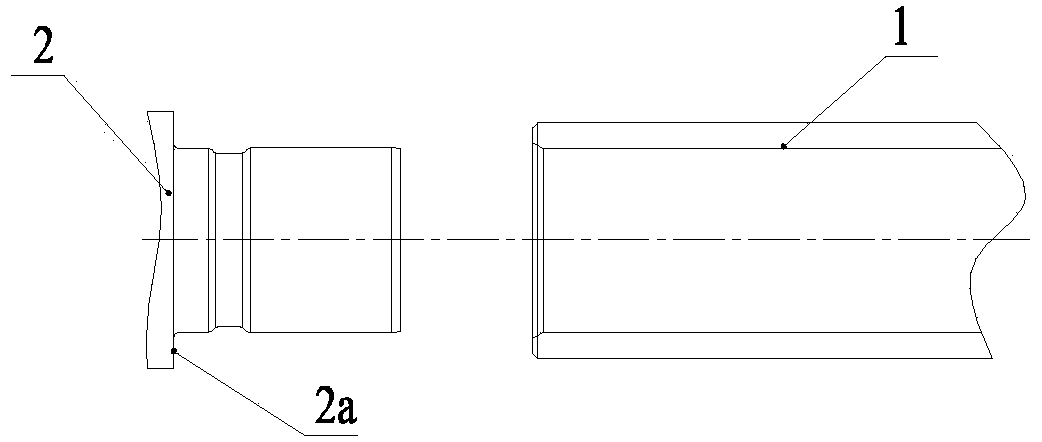

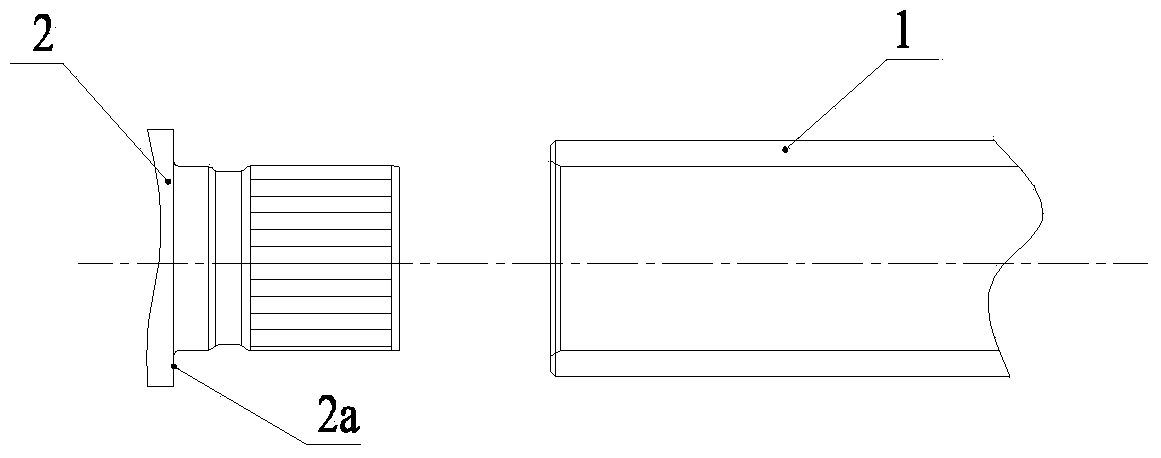

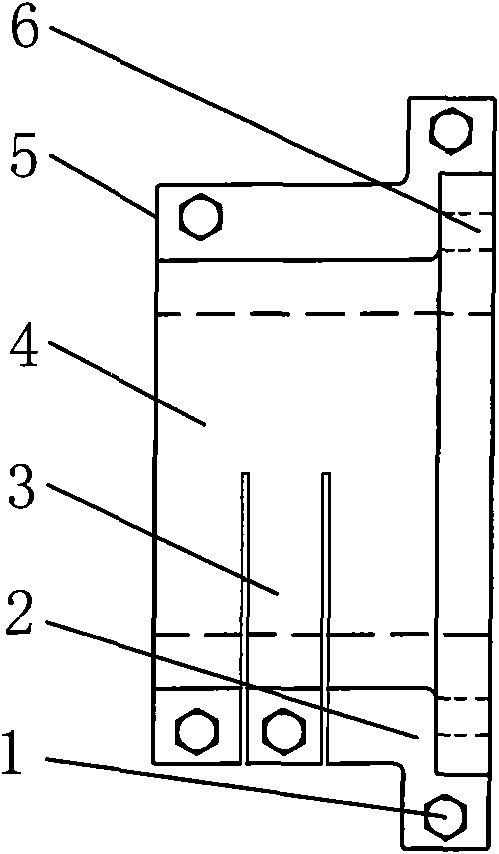

Cam shaft and timing gear connection structure

InactiveCN103967952AReduce quality problemsMeet lightweight requirementsValve arrangementsCouplings for rigid shaftsGear wheelControl engineering

The invention relates to a cam shaft and timing gear connection structure which comprises a cam shaft and a timing gear. The cam shaft and timing gear connection structure is characterized by further comprising a shaft head, wherein the cam shaft is hollow, the hollow cam shaft is connected with the timing gear through the shaft head, and the timing gear can be detached and replaced separately. The cam shaft and timing gear connection structure is simple in structure; the hollow cam shaft is connected with the timing gear through the shaft head, so that torsional strength is reliable; the cam shaft and timing gear connection structure has remarkable advantages with respect to light weight, energy conversation, cost reduction, material optimization and matching and the like; meanwhile, it can be guaranteed that the connecting mode of the timing gear and the cam shaft is consistent with an existing integrated cam shaft.

Owner:CHINA FIRST AUTOMOBILE

Actuating device, manufacturing method therefor, and underwater acoustic transducer

ActiveCN106205582AExtended service lifeIncreased bending and torsional strengthImpedence networksMechanical vibrations separationTransducerSingle crystal

The invention provides an actuating device, a manufacturing method therefor, and an underwater acoustic transducer. The actuating device and the manufacturing method therefor aim at a technical problem of breakage under the action of bending and torsion because an actuator in the prior art employs a longer thin single crystal wafer and the thin single crystal wafer is liable to be damaged because of the low anti-torsion strength. The interior of a first actuator which is formed by a plurality of first single crystal wafers is provided with a supporting part, and the axial length of the supporting part is consistent with the axial length of the first actuator. The anti-torsion strength of the first single crystal wafers of the first actuator is improved through the supporting part, thereby prolonging the service life of the actuating device and the service life of the underwater acoustic transducer employed by the same.

Owner:BEIJING SUPERSONIC TECH CO LTD

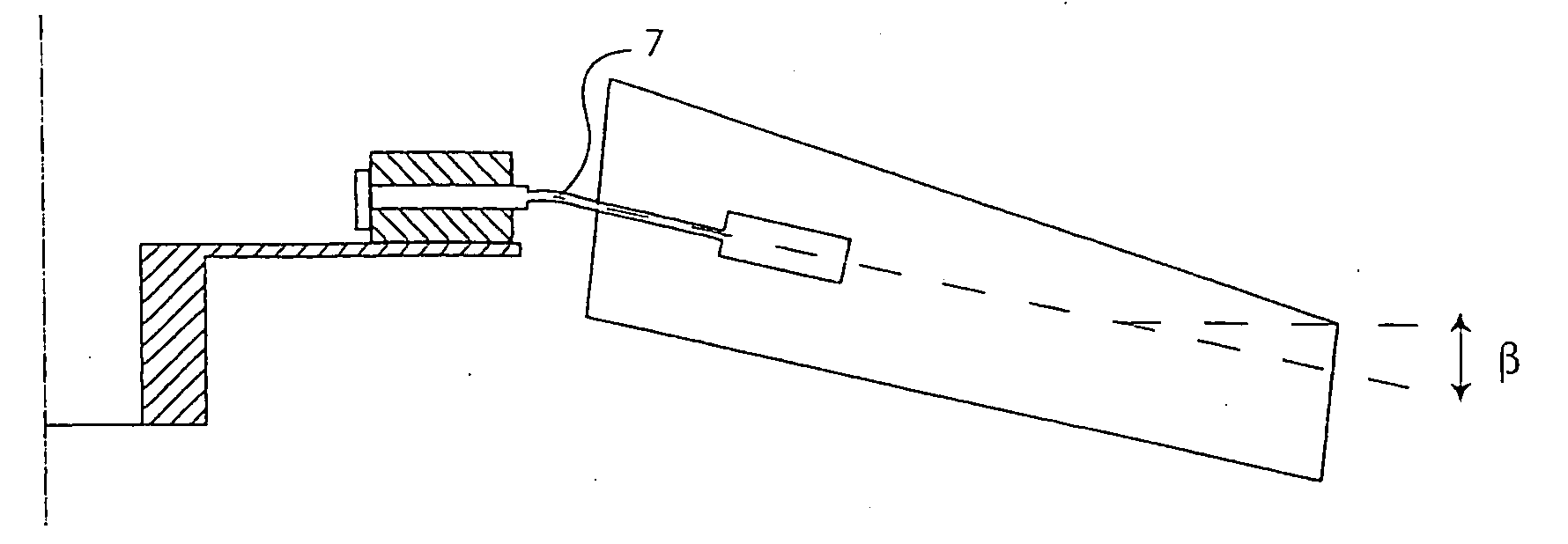

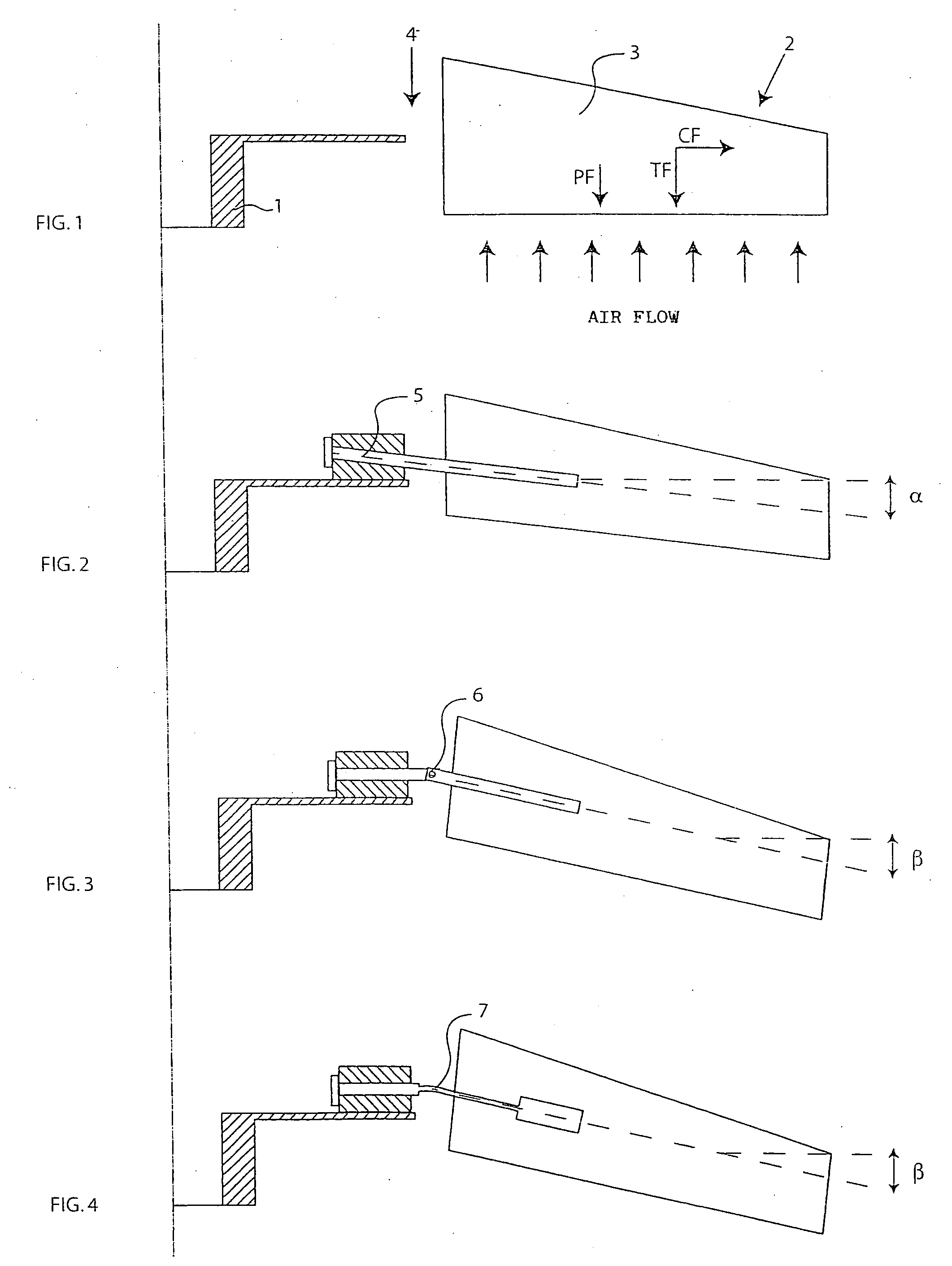

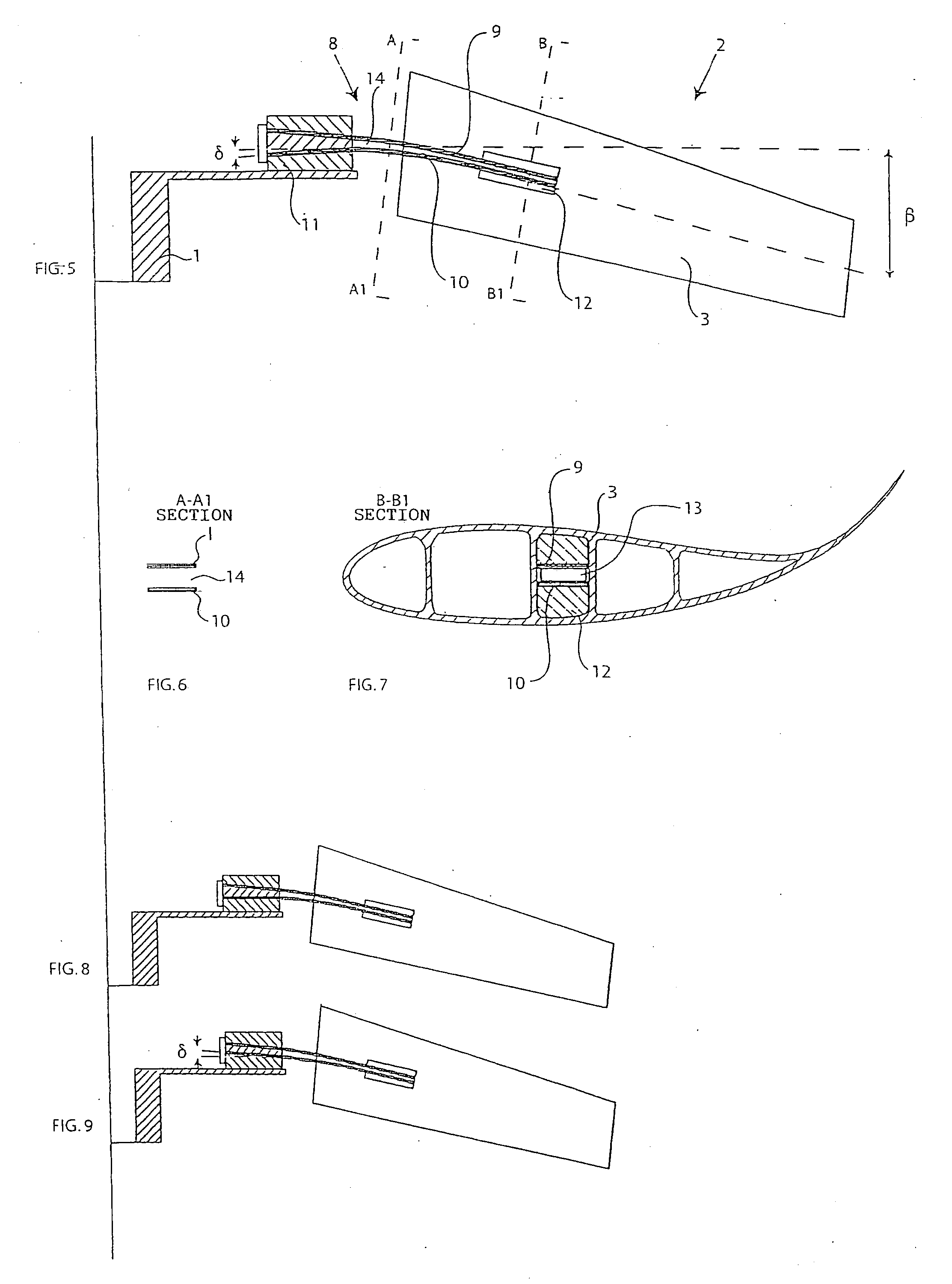

Hub-profile connection system for axial fan and axial fan provided with this connection system

InactiveUS20090035139A1Low dynamic loadLow static loadPropellersRotary propellersElectrical resistance and conductanceVertical plane

A hub-profile connection system for axial fan, consisting of a hub to which one or more blades provided with an air displacement profile are fixed, said system comprising two separate and distinct flexible elements both fixed on-hub side, to a fastening block and, on blade side, to a corresponding fastening block.Compared with the rigid constraint systems, the system of the invention offers lower static and dynamic loads, with consequent cost saving and vibration abatement. With respect to hinged constraint systems, there are the advantages of a particular construction simplicity, the possibility of graduating the freedom of movement on the vertical plane as desired and the absence of wear. Unlike flexible constraint connection systems, the invention displays a higher resistive moment (and thus the possibility of using more cost-effective materials with lower mechanical features, the section being equal), a higher torsional strength and a higher rigidity on the vertical plane (with consequent solution of the problem of excessive profile lowering in large diameter fans).

Owner:R E M HLDG

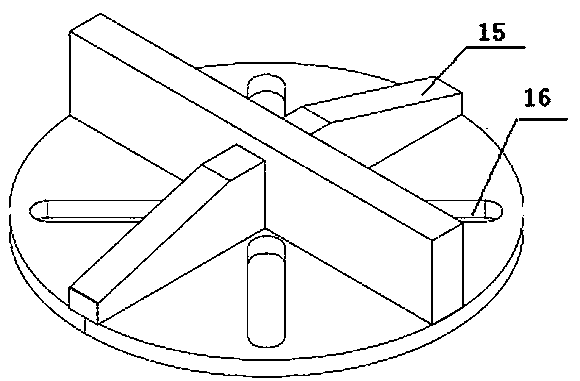

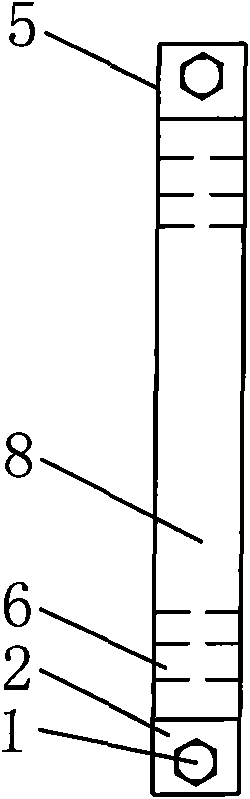

One-step forming process and die of carbon fiber driving shaft

The invention discloses one-step forming process and die of a carbon fiber driving shaft. An inner die is in a disk type structure, is partitioned and cut along a center line, is buckled in a flange type and is connected by a bolt. The inner end of an outer die is in a disk structure; the outside of the outer die is in a sleeve structure; and the outer die is portioned and cut along a center line, is buckled in a flange type and is connected by a bolt. The sleeve part of the outer die is transversely cut along a partition surface on one side to form a compressed clamping strip so as to be convenient for fastening a mandrel. Fastening lug seats are correspondingly arranged on the inner die disk and the outer die disk and are provided with bolt holes. The one-step forming process comprises the steps of 1. preparation of the carbon fiber driving shaft, 2.flange preparation, and 3, ring flange shaping. In the invention, the ring flange processing die has simple structure, is simple, convenient andfeasible for production process and is convenient and quick for processing and using; the one-step forming of the carbon fiber driving shaft and the flange can be realized and the production cost of the die and products can be reduced; the produced carbon fiber driving shaft has high concentricity; the continue track of secondary forming can be eliminated; the torsion strength of the flange of the carbon fiber driving shaft can be enhanced; and the production efficiency and the quality of products can be improved.

Owner:SHANDONG BENO COOLING EQUIP CO LTD

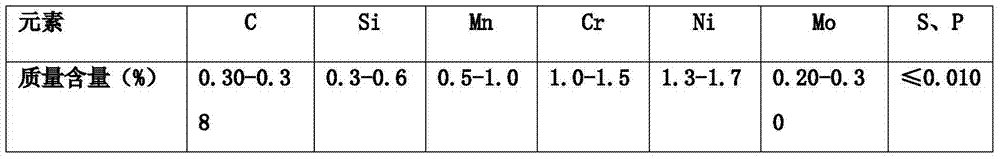

Casting process of large-scale mining excavator part driving wheel

ActiveCN103695795AImprove bending resistanceIncreased torsional strengthFoundry mouldsFoundry coresFurnace temperatureDrive wheel

The invention relates to a casting process of a large-scale mining excavator part driving wheel. The process is as below: smelting is carried out in an arc furnace with furnace temperature at 1550-1560 DEG C, aluminum, rare earth and silicon zirconium alloy are added for strong deoxidation, argon is blown into ladle for purification in order to remove impurities, and finally the oxygen content of the molten steel is no higher than 60 PPm. Pouring temperature is strictly controlled at 1550-1560 DEG C to ensure casting of high quality molten steel, molding sand employs a ferrochrome resin sand, furnace charge and normalization are carried out after shakeout, the normalization temperature is at 900-910 DEG C, riser removal and reconditioning finishing are conducted at no lower than 300-500 DEG C and, a sample plate is used for checking the position of lug of the driving wheel, and after roughing tempering is carried out at 550 DEG C and overall hardening and tempering is carried out at 920-930 DEG C. The process improves bending resistance, anti-torsion strength and surface contact strength of the driving wheel and prolongs the service life of the transmission parts.

Owner:HUZHOU ZHONGLIAN MACHINERY EQUIP

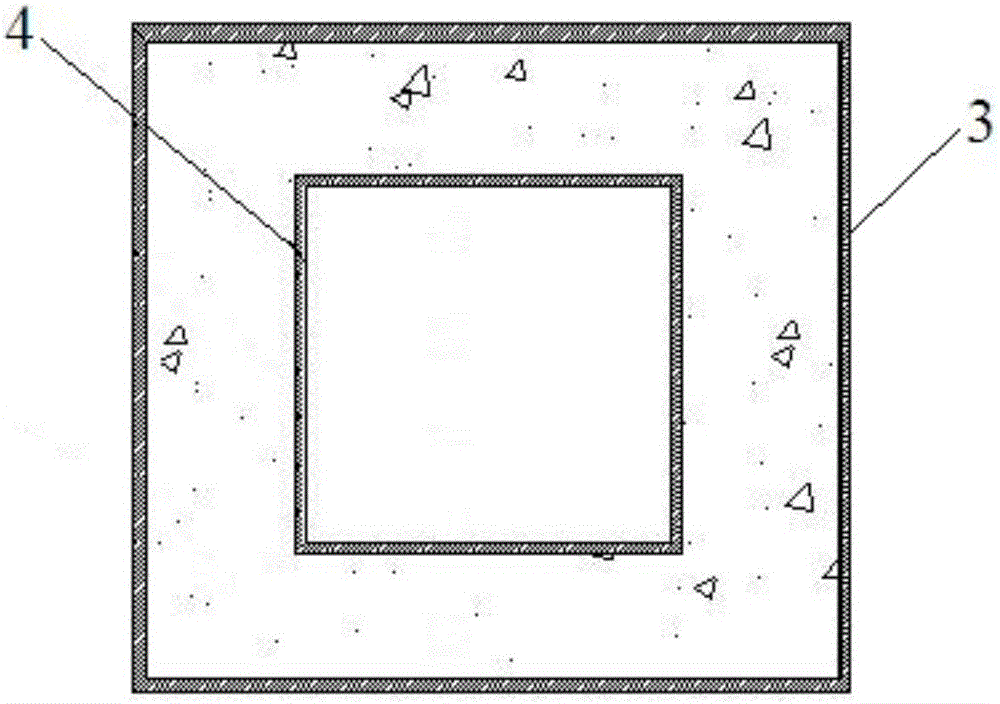

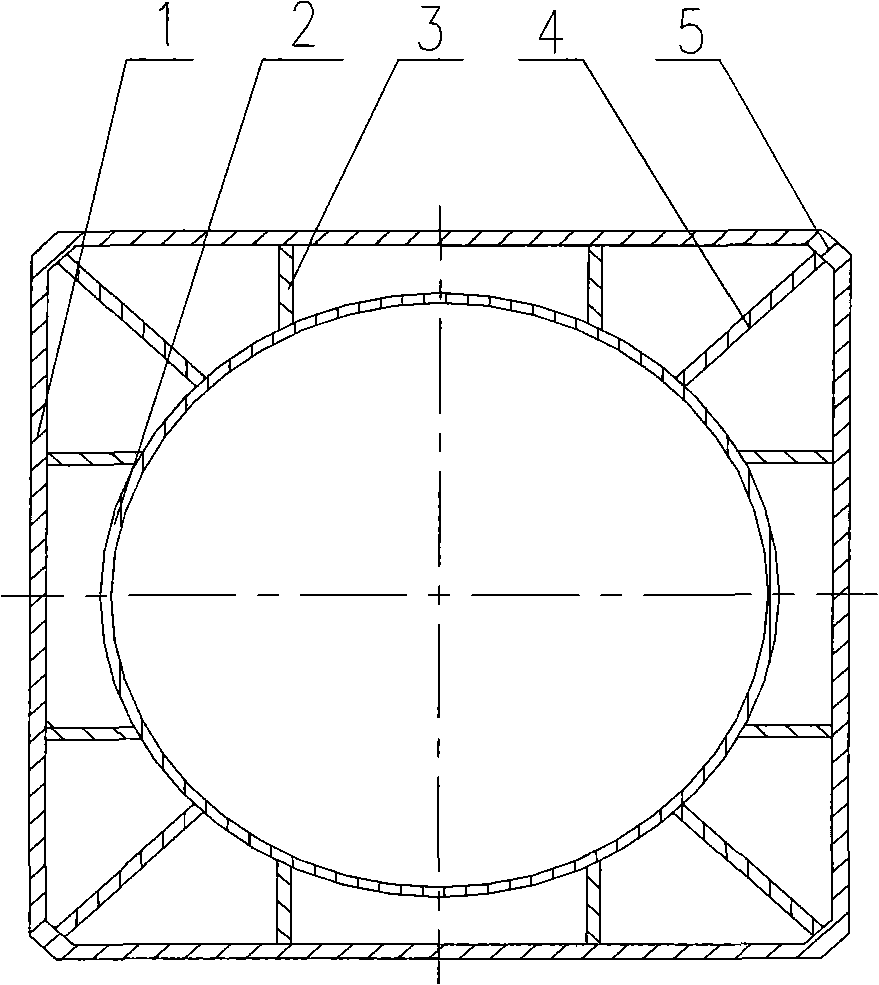

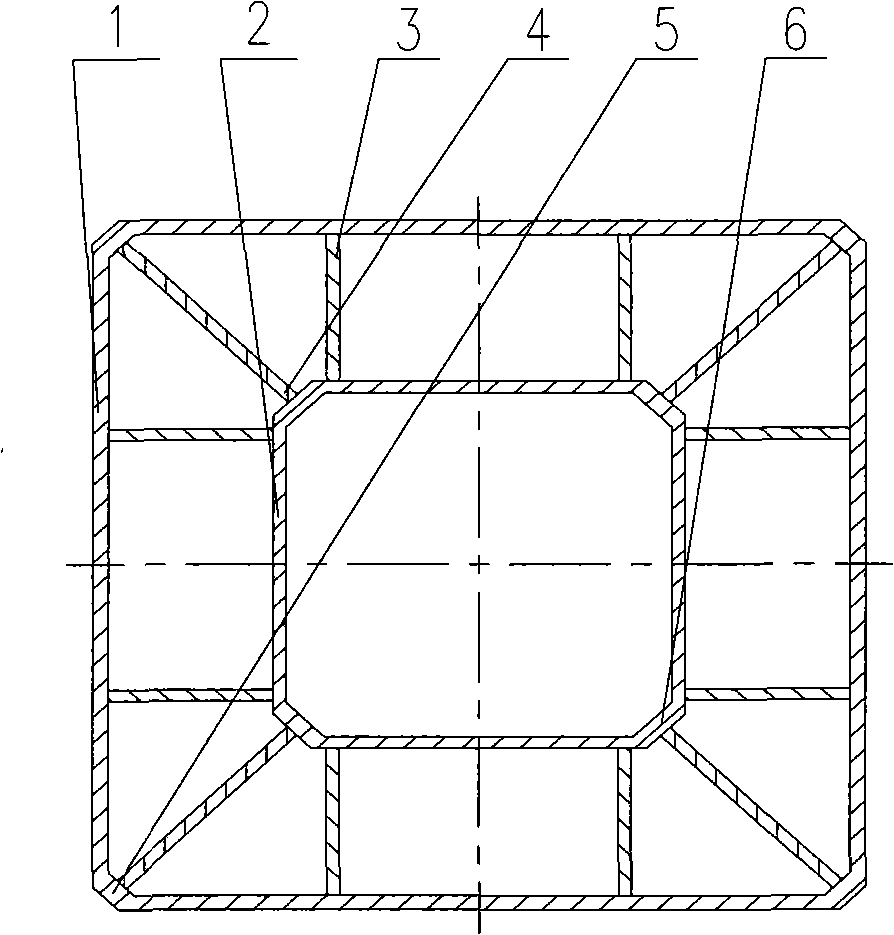

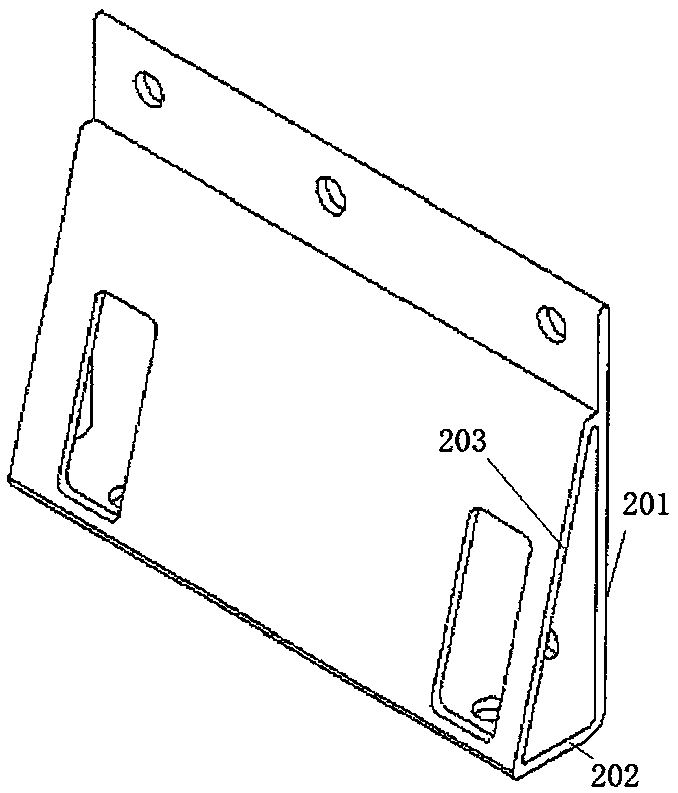

Square cartridge structure

InactiveCN101338856AImprove stress resistanceImprove bending resistanceElongated constructional elementsSteel barEngineering

The invention discloses a square cylinder structure which comprises an external cylinder, an internal cylinder, a reinforced vertical steel bar and an angle vertical steel bar. The external cylinder is connected with the internal cylinder via the angle vertical steel bar and the reinforced vertical steel bar, and the angle vertical steel bar and the reinforced vertical steel bar as well as the external cylinder form a tubular body with the approximate triangular cross section. Under the condition of the less weight addition, the invention can promote the compression strength, the bending strength, the anti-twisting intensity and stiffness, considerably save the original material, has the advantages of simple structure, light weight and low cost, can be widely applied on the field of the structure design.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

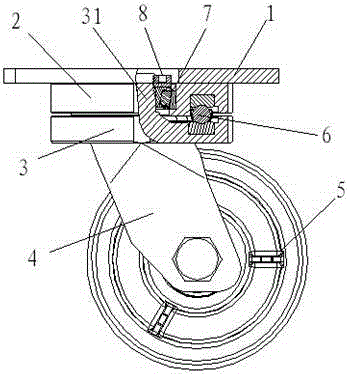

High-bearing-capacity trundle

The invention discloses a high-bearing-capacity trundle. The high-bearing-capacity trundle comprises a fixing plate, a fixed seat and a rotating seat. The fixed seat is arranged on the lower surface of the fixing plate. A first bearing is arranged between the rotating seat and the fixed seat and used for connection. A cylinder perpendicularly extending to the upper portion of the fixed seat is arranged in the middle of the rotating seat. An inner stepped hole is formed in the middle of the fixed seat, and the cylinder can penetrate the inner stepped hole. A second bearing which is arranged on the outer portion of the cylinder in a sleeving manner is arranged in the inner stepped hole. Two symmetrical vertical supporting plates are arranged on the lower portion of the rotating seat. A rolling wheel is arranged between the vertical supporting plates. In this way, the high-bearing-capacity trundle achieves steering especially by means of cooperation of the first bearing and the second bearing, so that the rotating flexibility and the torsion strength are improved, and the bearing capacity can be improved. The manufactured high-bearing-capacity trundle is higher in durability and not prone to breakage in use.

Owner:兴锋脚轮(江苏)有限公司

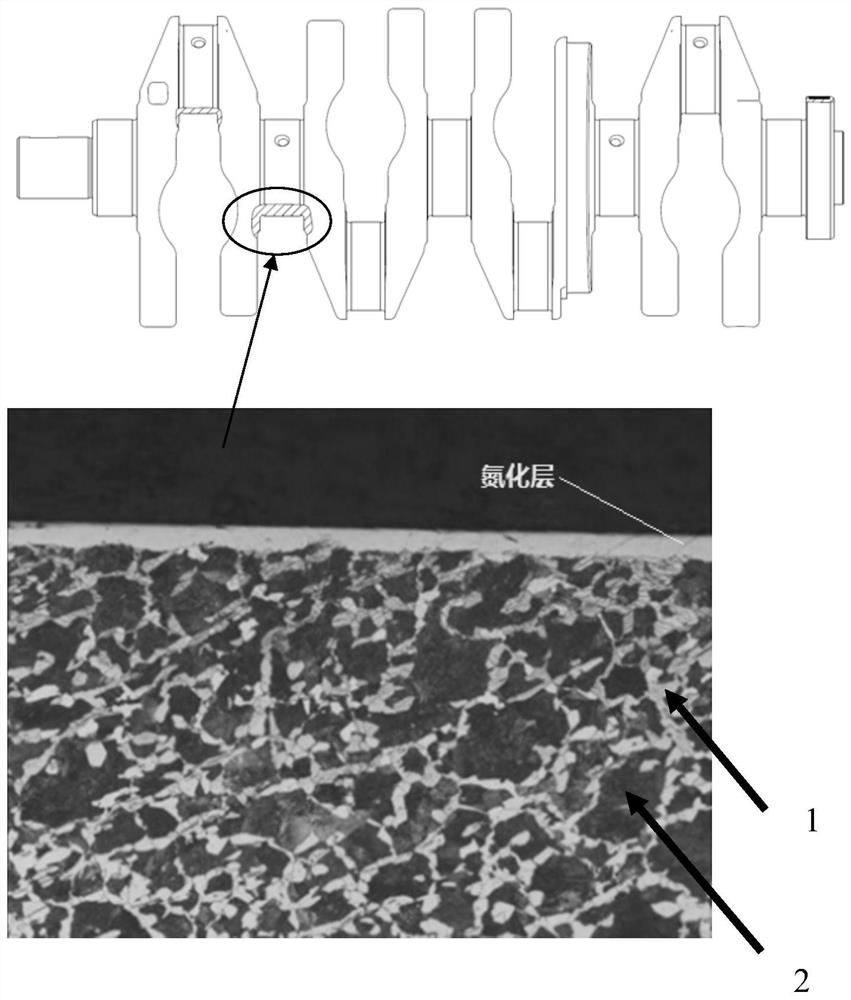

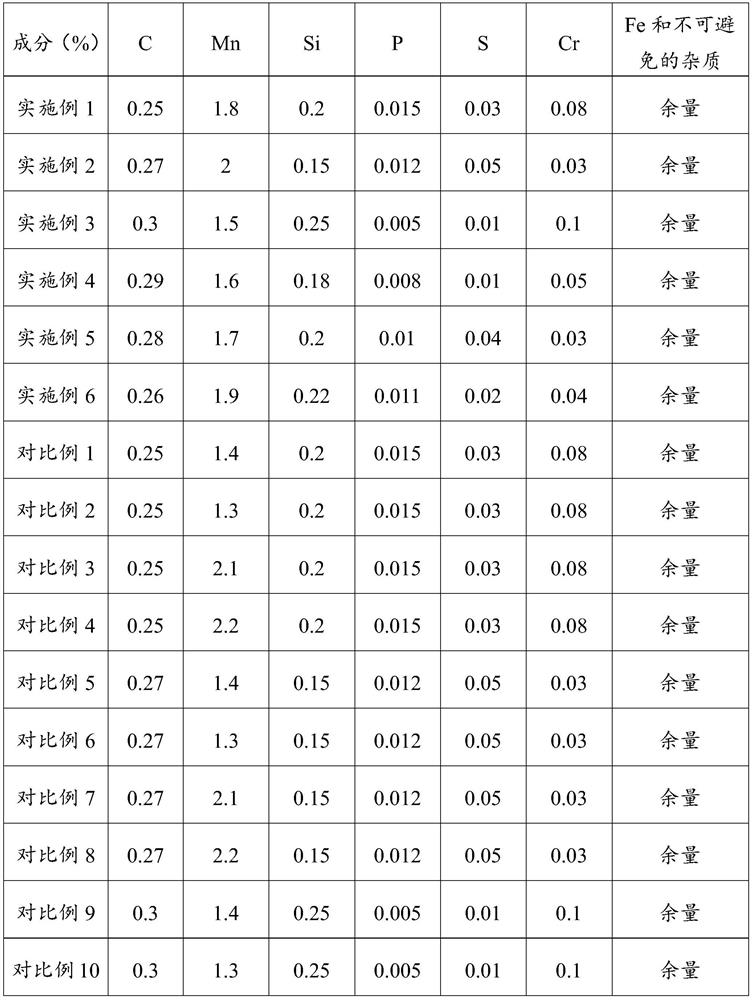

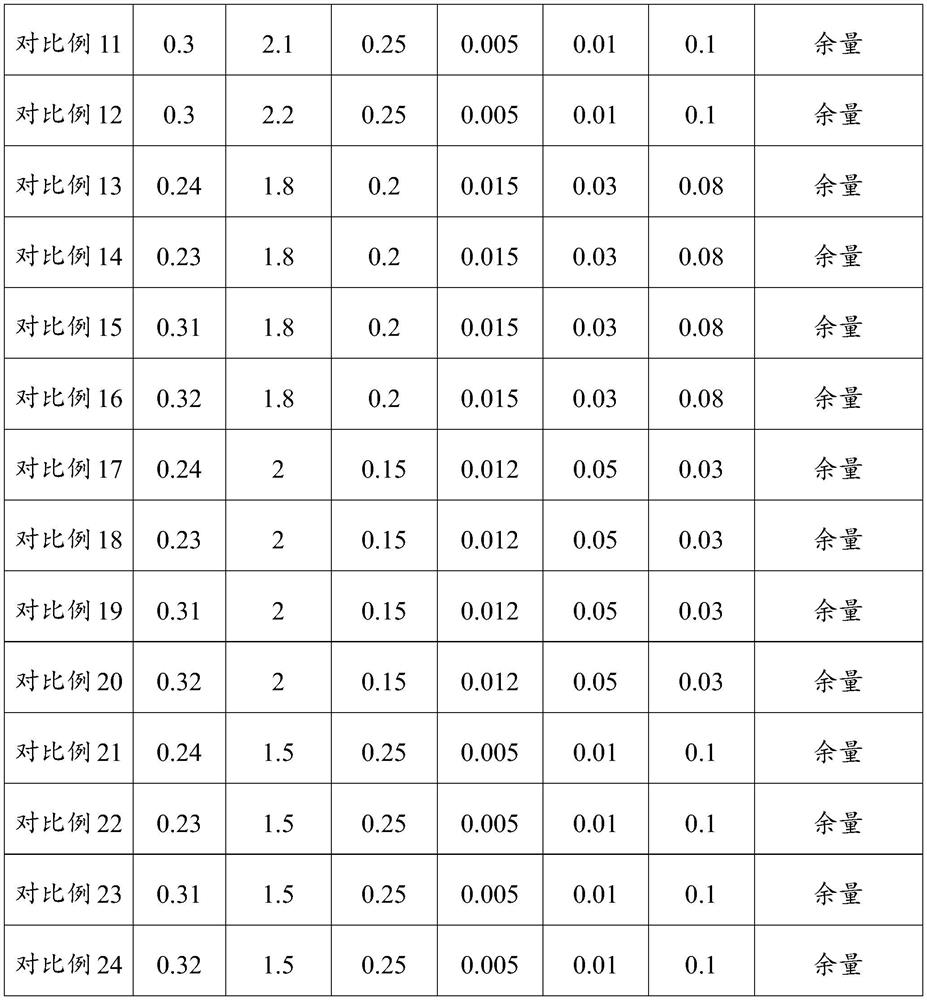

High-strength crankshaft of engine and preparation method thereof

InactiveCN112442641AEasy to bendHigh strengthCrankshaftsSolid state diffusion coatingTorsional strengthUltimate tensile strength

The invention discloses a high-strength crankshaft of an engine. The crankshaft is made of non-quenched and tempered steel. The non-quenched and tempered steel comprises, by weight, 0.25-0.3% of C, 1.5-2.0% of Mn, 0.15-0.25% of Si, less than or equal to 0.015% of P, less than or equal to 0.05% of S, 0.03-0.1% of Cr and the balance Fe and inevitable impurities. According to the crankshaft, the C content is low, so that a crankshaft blank is easy to straighten, and the rejection rate of the crankshaft blank is decreased; the Mn content is high, so that the strength of the crankshaft material isimproved; rare metals Mo and V are not added, so that the steel cost is reduced; and the bending strength and the torsional strength of the crankshaft are greatly improved through the strengthening mode of carbonitriding (soft nitriding) and water quenching.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

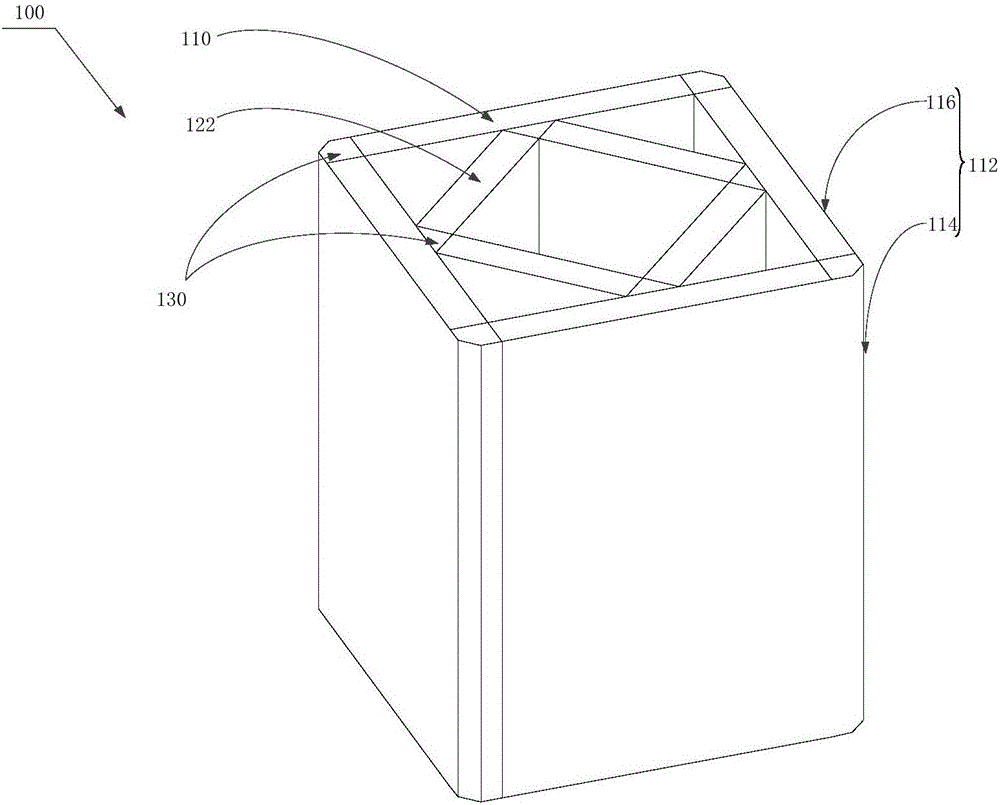

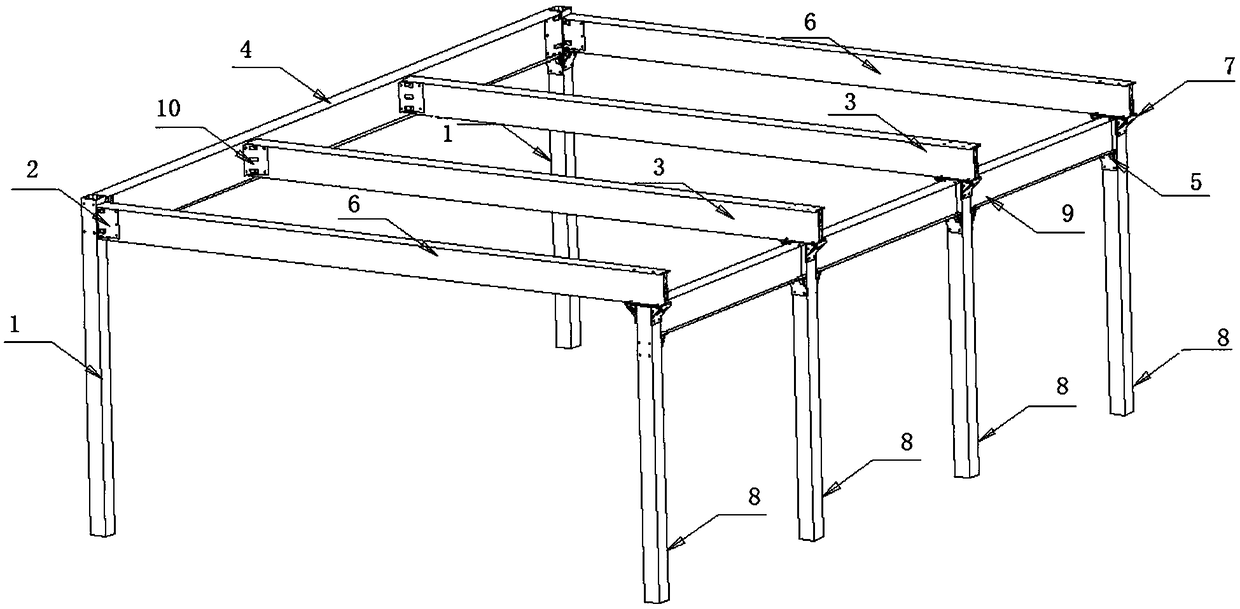

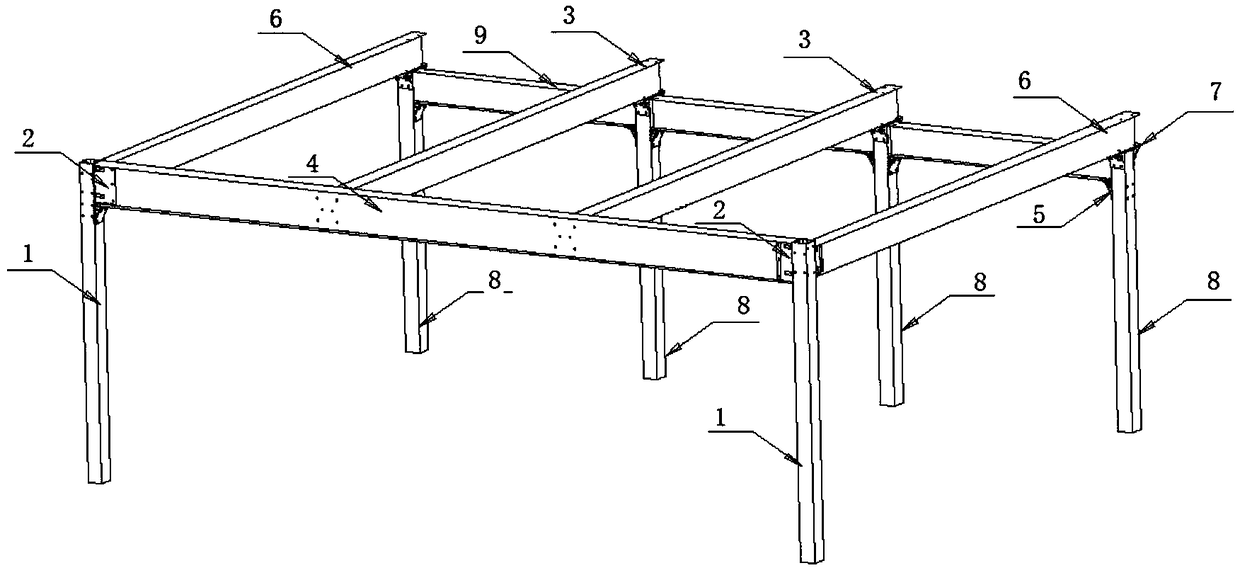

Full-aluminum stereo parking equipment frame

InactiveCN108487710ARealize pure screw fixationImprove recycling ratesBuilding constructionsParkingsStructural engineeringTorsion strength

The invention discloses a full-aluminum stereo parking equipment frame. The full-aluminum stereo parking equipment frame comprises two or more front vertical columns, two or more rear vertical columns, a front beam, a rear cross beam, two edge longitudinal beams and a middle longitudinal beam. The front beam is transverselyfixed to the top ends of the front vertical columns, the rear cross beam istransversely fixed to the top ends of the rear vertical columns, and profiles used by the front beam and the rear cross beam are II-shaped multi-cavity profiles. Stiffening ribs and reinforcing barsare designed on the inner surfaces of cavities. One ends of the edge longitudinal beams are fixedly connected with the front beam, the other ends of the edge longitudinal beams are fixedly connected with the rear cross beams, and one ends of the middle longitudinal beams are fixedly connected with the front beam. The other ends of the middle longitudinal beams are fixedly connected with the rear cross beam, and the profiles used by the edge longitudinal beams and the middle longitudinal beams are II-shaped triangular multi-cavity aluminum profiles. The II-shaped triangular multi-cavity aluminum profiles can improve the strength and stability of the middle longitudinal beams and the edge longitudinal beams, and the anti-torsion strength of the front beam and the rear cross beam can be reinforced through the II-shaped multi-cavity aluminum profiles with the stiffening ribs. Connecting components can be placed on the abdomens of the II-shaped profiles, thus the II-shaped profiles are conveniently connected with the longitudinal beams and the vertical columns through bolts, and dismounting and mounting are flexible and convenient.

Owner:ALNAN ALUMINIUM CO LTD

Longitudinally Ground File Having Increased Resistance to Torsional and Cyclic Fatigue Failure

InactiveUS20090229129A1Revolution surface grinding machinesWristbandsDental instrumentsEndodontic files

Owner:DENTSPLY SIRONA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com