Optical cable having metal corrugated pipe protective sheath

A technology of metal bellows and protective sleeves, applied in the direction of fiber mechanical structure, etc., can solve problems such as communication interruption, low resistance to pulling, and easy breakage of optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

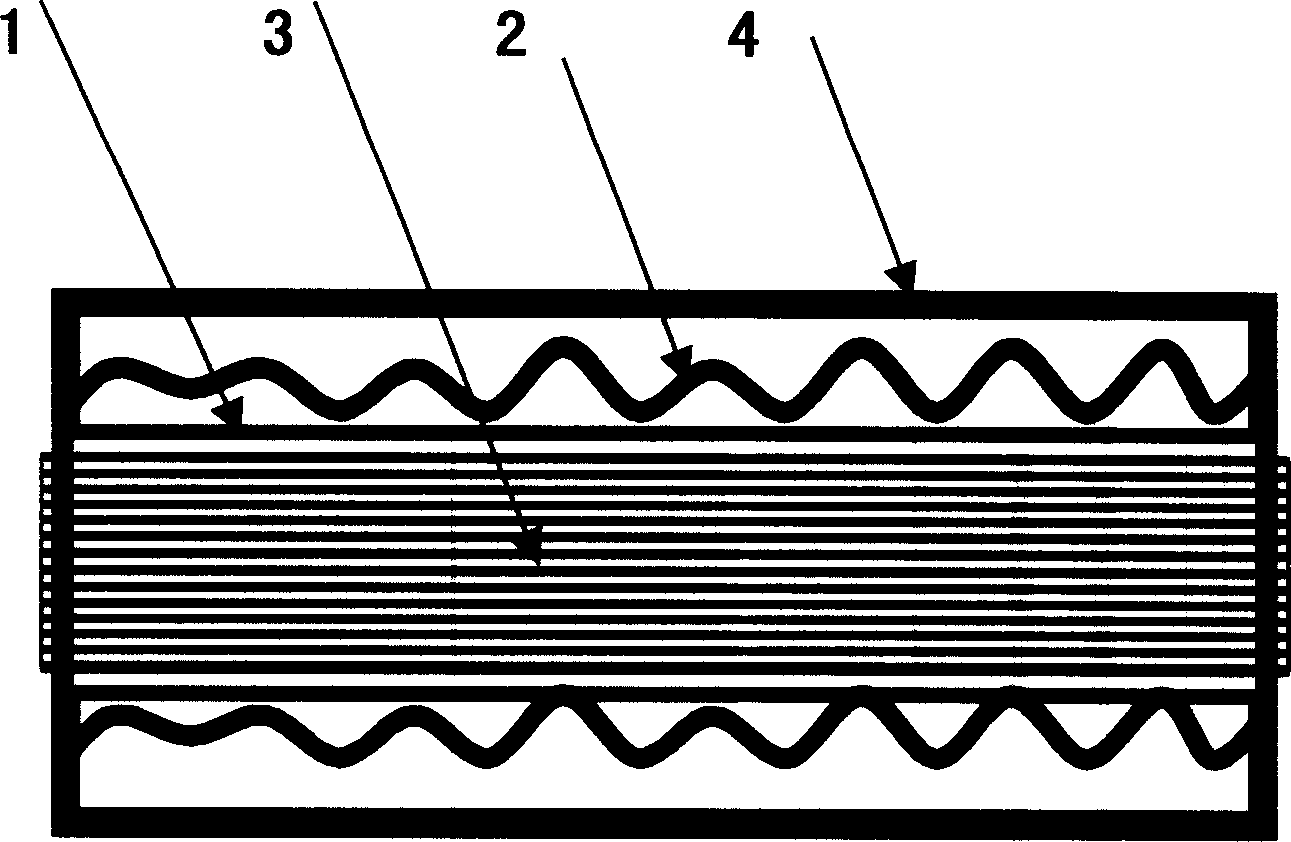

[0005] like figure 1 As shown, an optical cable with a metal bellows protective sheath of the present invention includes a flexible protective sheath 1 and a rigid protective sheath 2 in the prior art, wherein the flexible protective sheath 1 is provided with an optical fiber bundle 3, The optical fiber bundle 3 includes more than one strand of optical fiber, the rigid protective sheath 2 is arranged on the outer circumference of the flexible protective sheath 1, and the rigid protective sheath 2 is made of metal material. In the present invention In a preferred embodiment, the rigid protective sleeve 2 is made of zinc material, the rigid protective sleeve 2 is a metal bellows, and the section of the rigid protective sleeve 2 in the length direction of the optical cable is corrugated. A casing 4 is arranged on the outside of the rigid protective sheath 2, and the casing 4 is made of polyvinyl chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com