Optical cable with flame-retarding baffer layer

A buffer layer, optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of communication interruption, low fire resistance and flame retardant ability of protective sleeve, and easy breakage of optical fiber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

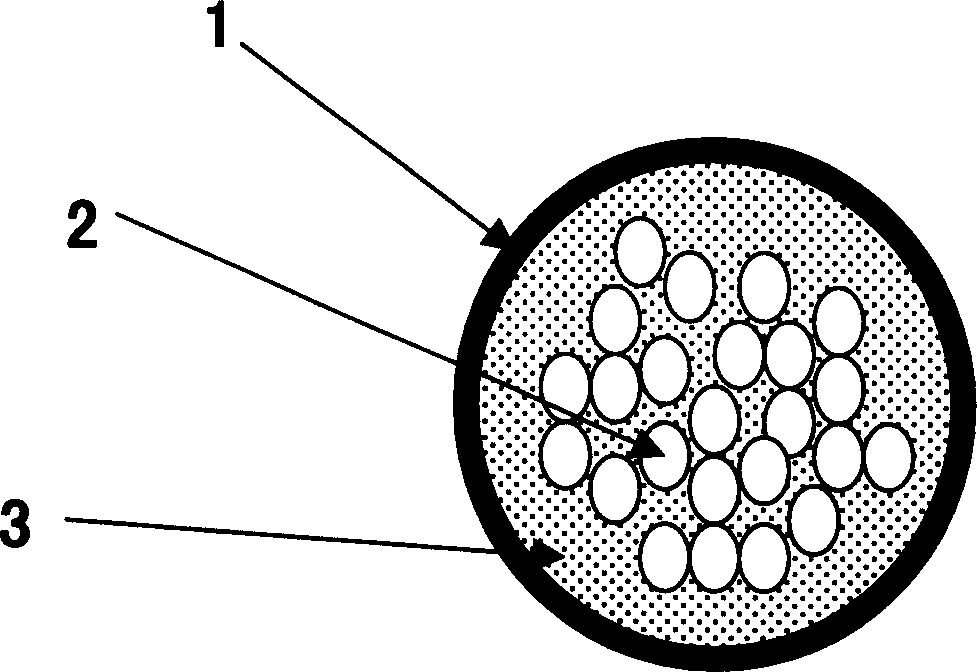

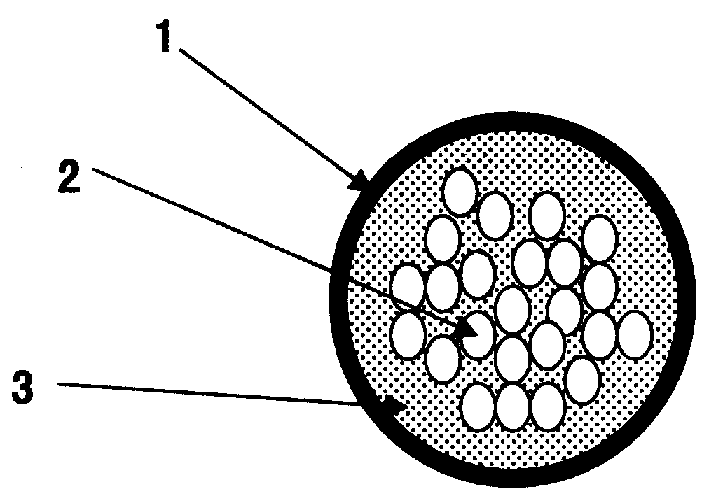

[0005] Such as figure 1 As shown, the present invention is equipped with a flame-retardant buffer layer of optical cable, including a protective cover 1 in the prior art, wherein, the protective cover 1 is provided with an optical fiber 2, between the protective cover 1 and the Between the optical fibers 2 described above, polyvinyl alcohol fibers 3 in the prior art are filled, and the diameter of the polyvinyl alcohol fibers 3 is between 0.000001 mm and 0.0001 mm, and the polyvinyl alcohol fibers 3 Extend along the length direction of the optical fiber 2 . The present invention compares with the prior art, because the polyvinyl alcohol fiber in the prior art is filled between the protective cover in the prior art and the described optical fiber, so friction and displacement between the optical fibers can be prevented, At the same time, the anti-pull ability of the optical cable is increased, and the polyvinyl alcohol fiber has the characteristics of flame retardancy, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com