Square cartridge structure

A technology of outer cylinder and inner cylinder, applied in the direction of slender elements, building elements, etc., can solve the problems of weight increase, raw material waste cost, etc., and achieve the effect of light weight, uniform force on the side wall, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

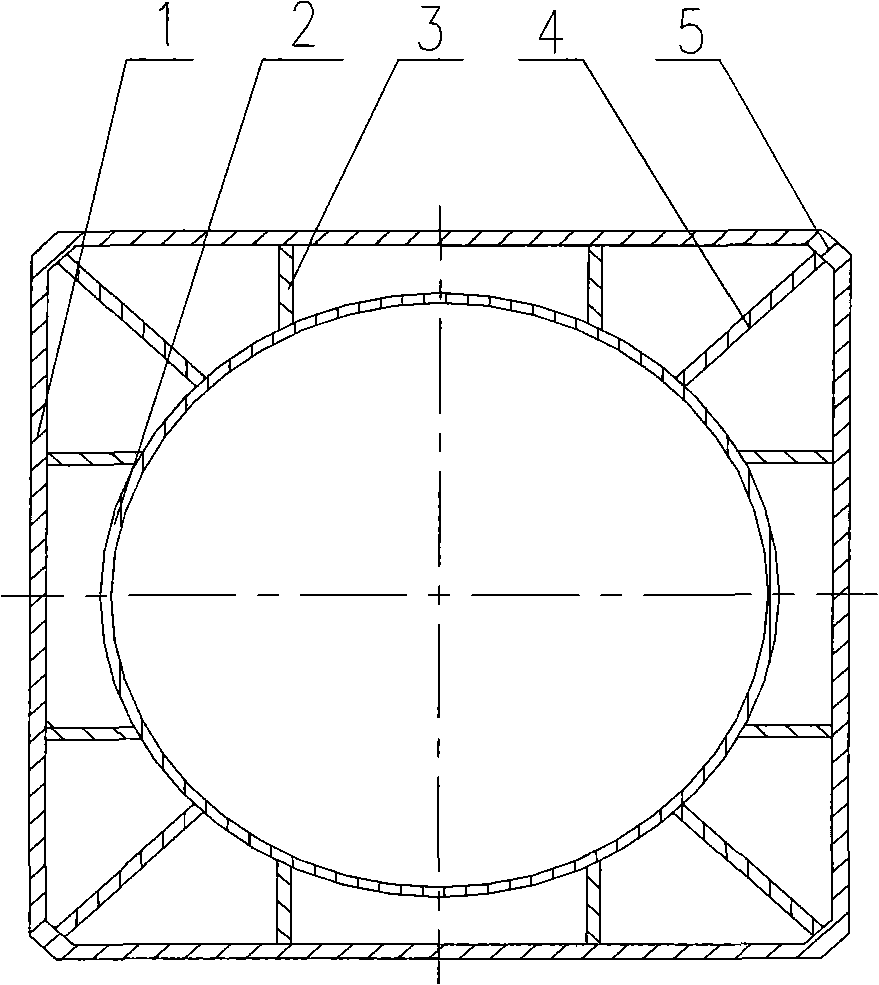

[0014] Such as figure 1 As shown, the square cylinder structure of the present invention includes an outer cylinder 1, an inner cylinder 2, a reinforced vertical rib 3, and an angle vertical rib 4; the inner cylinder 2 is a cylinder with a circular cross section; the outer cylinder 1 passes four Corner vertical ribs 4 and eight reinforced vertical ribs 3 are connected with inner tube 2 , one end of four corner vertical ribs 4 is respectively connected with four corners 5 of outer tube 1 , and the other end is connected with inner tube 2 respectively. Eight reinforcing vertical ribs 3 are respectively perpendicular to the four side walls of the outer cylinder 1, and each corner vertical rib 4 forms two tubular bodies with approximately triangular cross-sections with the outer cylinder 1 and two adjacent reinforcing vertical ribs 3 respectively. Since the reinforcing vertical rib 3 is perpendicular to the side wall, the compressive and bending strength of the square tube structu...

Embodiment 2

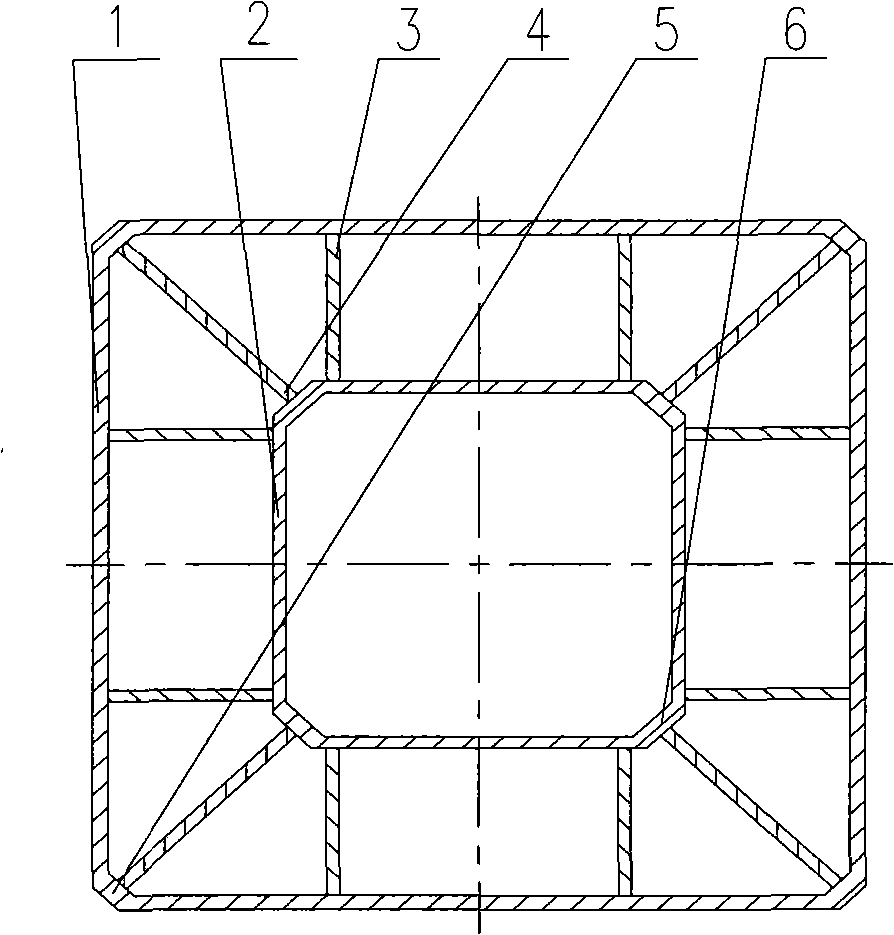

[0016] Such as figure 2 As shown, the square cylinder structure of the present invention includes an outer cylinder 1, an inner cylinder 2, a reinforced vertical rib 3, and a corner vertical rib 4; the inner cylinder 2 is a square tube in section; the outer cylinder 1 passes through four corners The vertical ribs 4 and eight reinforced vertical ribs 3 are connected with the inner cylinder 2, one end of the four corner vertical ribs 4 is respectively connected with the four corners 5 of the outer cylinder 1, and the other end is connected with the four corners 6 of the inner cylinder 2 respectively. Eight reinforcing vertical ribs 3 are respectively perpendicular to the four side walls of the outer cylinder 1, and each corner vertical rib 4 forms two tubular bodies with approximately triangular cross-sections with the outer cylinder 1 and two adjacent reinforcing vertical ribs 3 respectively. Since the reinforcing vertical rib 3 is perpendicular to the side wall, the compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com