Apparatus for tightening threaded fasteners

A technology of threaded fasteners and fasteners, which is applied in the direction of threaded fasteners, locking fasteners, screws, etc., can solve the problem of not being able to carry high torque values, and achieve effective and uniform distribution, small mass, The effect of high torsional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

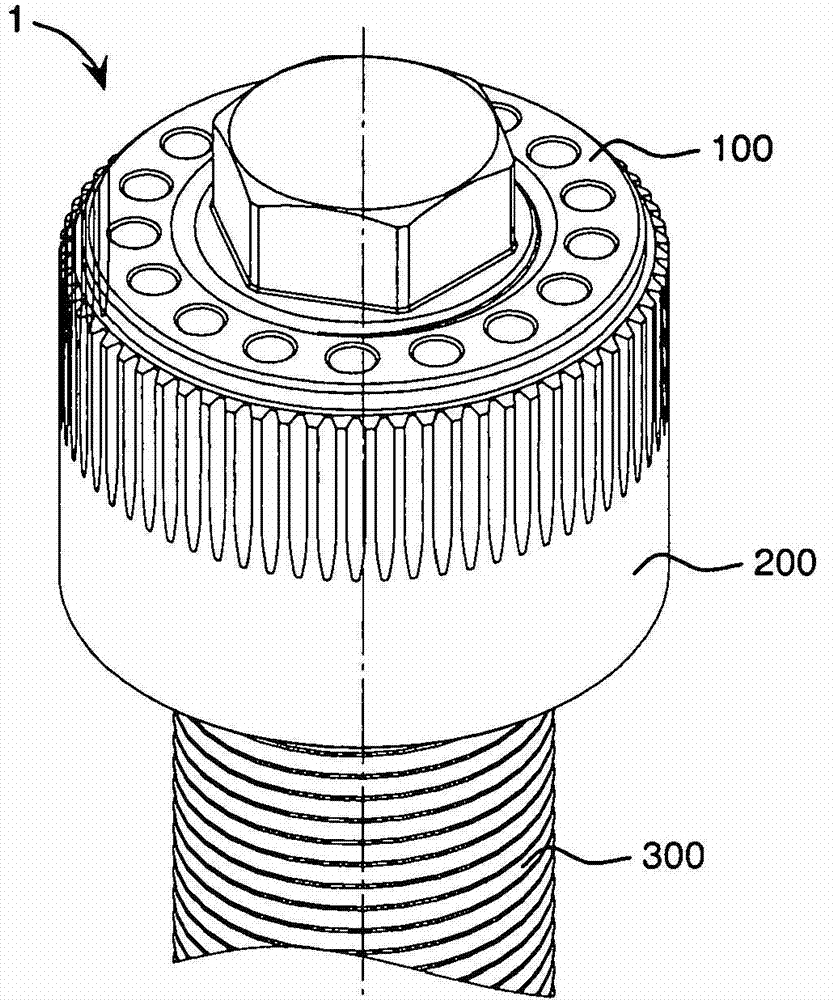

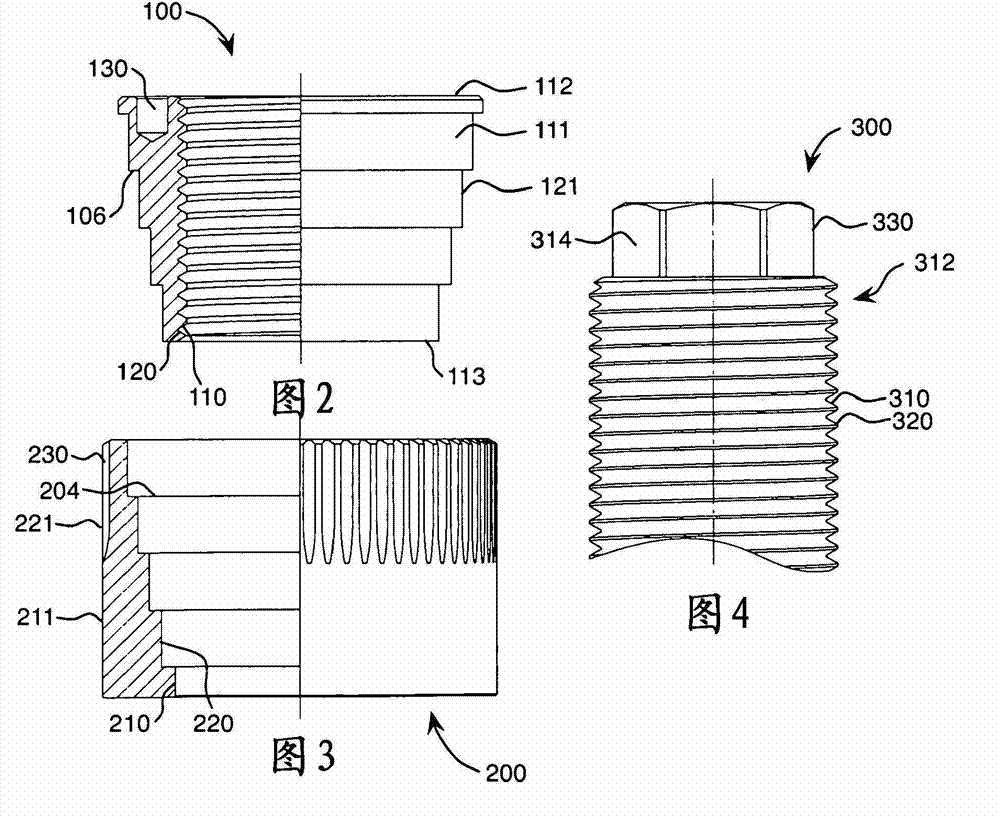

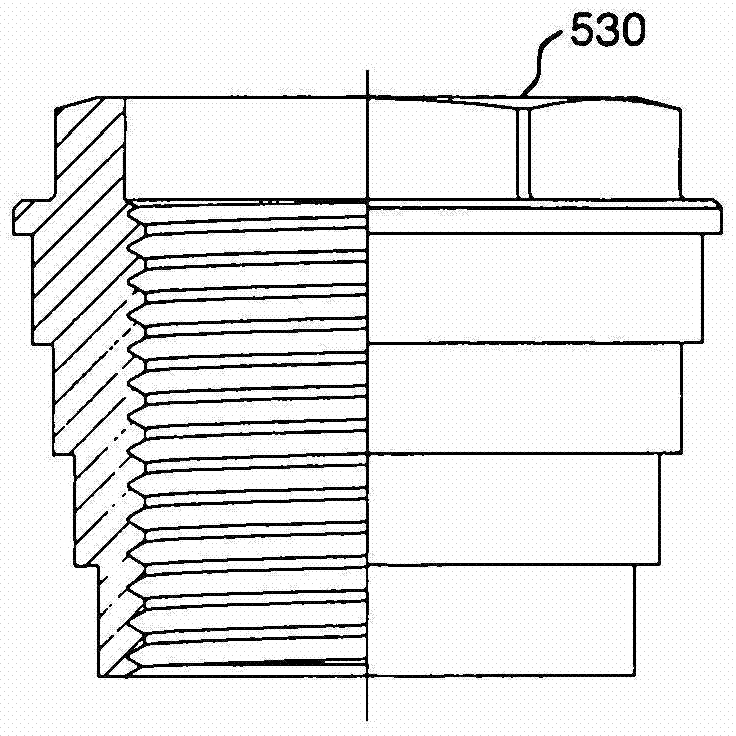

[0034] For example reference Figure 1-4 , shows a device 1 - a stepped conical fastener assembly according to an embodiment of the present invention. The device 1 has an inner sleeve part 100 and an outer sleeve part 200 and is for example for a stud 300 . The inner sleeve member 100 may be rotatably threadedly engaged with the stud 300; rotatably tapered with the outer sleeve member 200; and non-rotatably engaged with the active portion of the torque input device. The outer sleeve member 200 may be in non-rotatable engagement with the reaction portion of the torque input device; and in rotatable conical engagement with the inner sleeve member 100 . When rotated by the active part of the torque input, the inner sleeve part 100 applies a load to the stud 300 in order to close the connection (not shown).

[0035] The inner sleeve part 100 is an annular body, such as figure 1 and 2 shown in and formed as a sleeve. It has an inner surface 110 with an inner helical threading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com