Round steel pipe fully-bearing type vehicular framework

A round steel tube, full load-bearing technology, applied in the direction of load-bearing body structure, vehicle parts, superstructure, etc., can solve the problems of poor bending performance of rectangular or square tubes, waste of materials and processing time, and excessive welding seam and welding deformation. , to achieve the effect of improving safety factor, improving work efficiency, reducing welding seam and welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

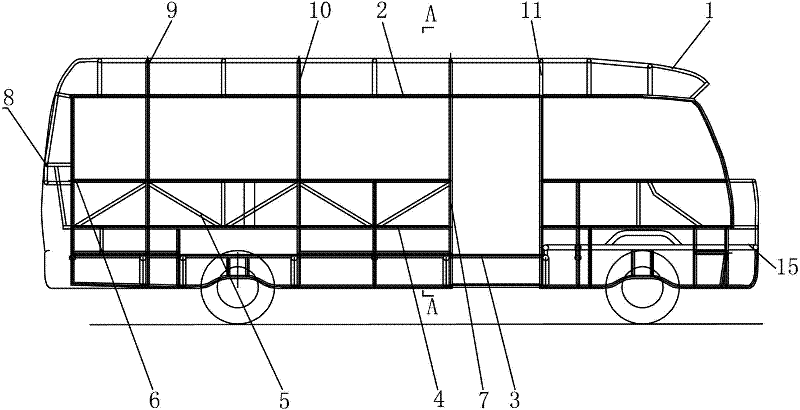

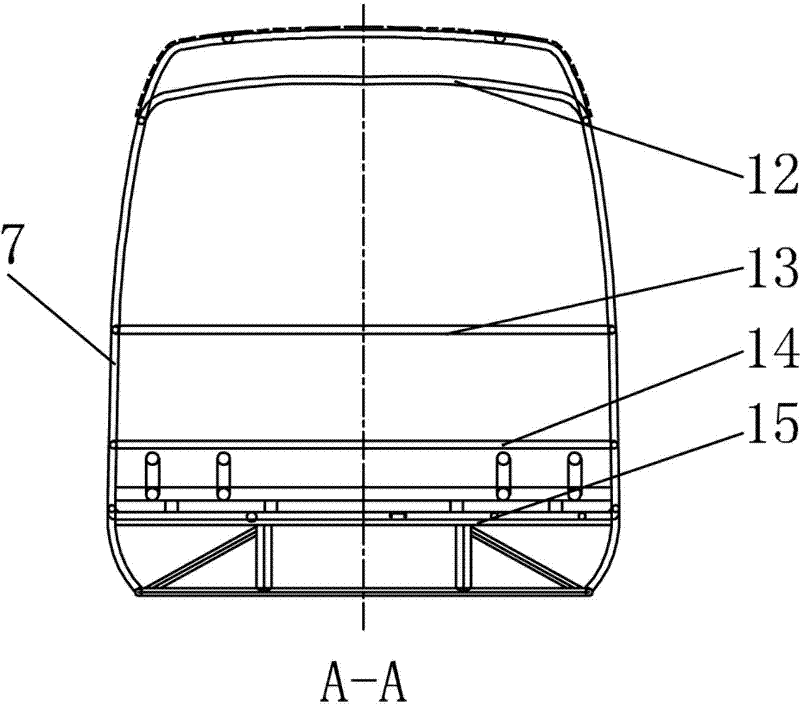

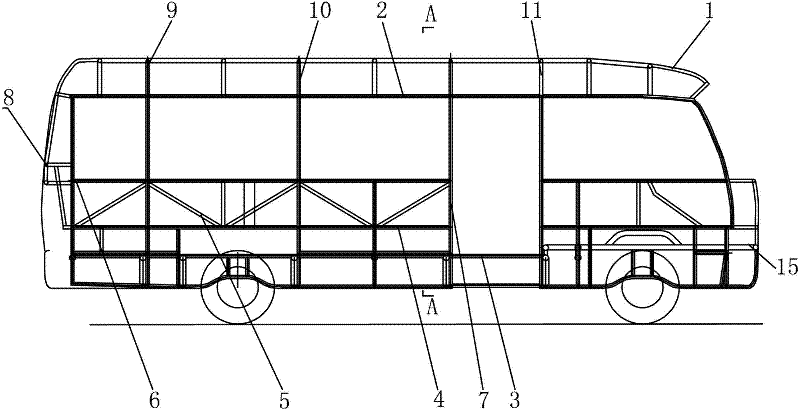

[0010] As shown in the figure: the body is all welded with seamless steel pipes by advanced CNC three-dimensional pipe bending machine. The bottom frame and the front and rear walls, side walls, and roof are connected by integral circular pipes without disconnected welds; the passenger door front closed ring 11 and the passenger door rear closed ring 7 are arranged on the upper, lower and both sides of the body frame , front closed ring 10 of rear wheel, rear closed ring 9 of rear wheel; above-mentioned closed ring all adopts a complete steel bar to be bent to form a closed annular structure, and is welded together with vehicle body longitudinal skeleton and reinforcing brace 5, forms round steel pipe complete Carry the body. The top frame 1 of the front roof curved beam of the present invention, the upper beam 2 of the window, the bottom frame 3, the waist beam 4, the reinforcement brace 5, the lower beam 6 of the window, the rear frame 8, the upper beam 12 of the front winds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com