High-strength crankshaft of engine and preparation method thereof

A high-strength, engine technology, used in crankshafts, mechanical equipment, shafts, etc., can solve the problems of difficult crankshaft alignment, high scrap rate, and high C content, reducing steel costs, reducing scrap rates, and improving bending and torsional strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~24

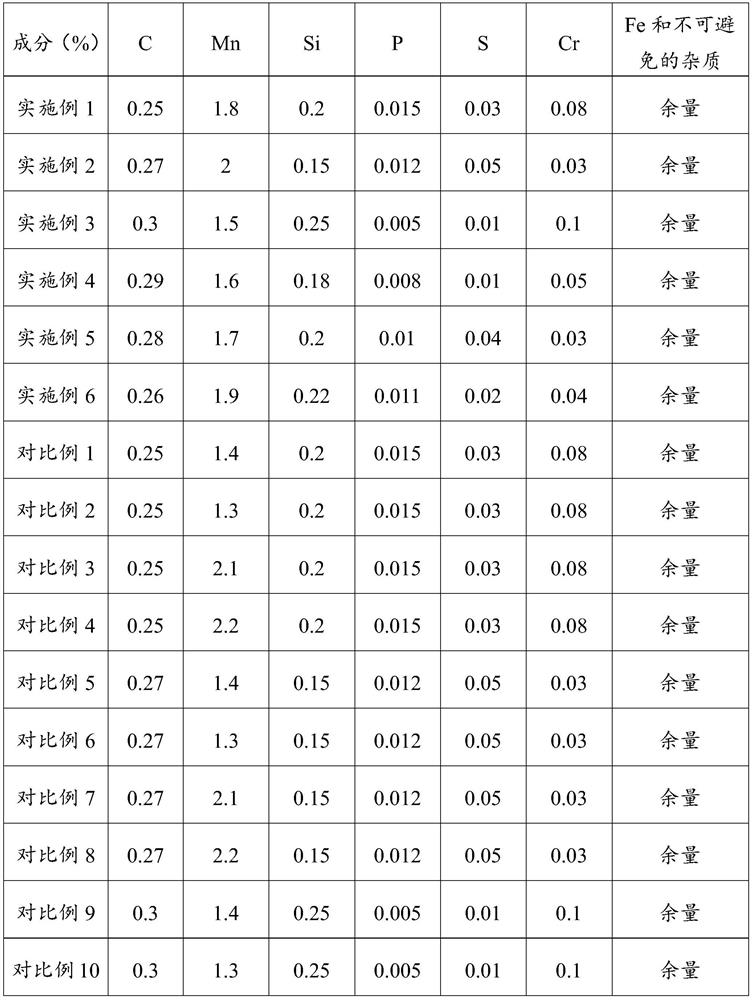

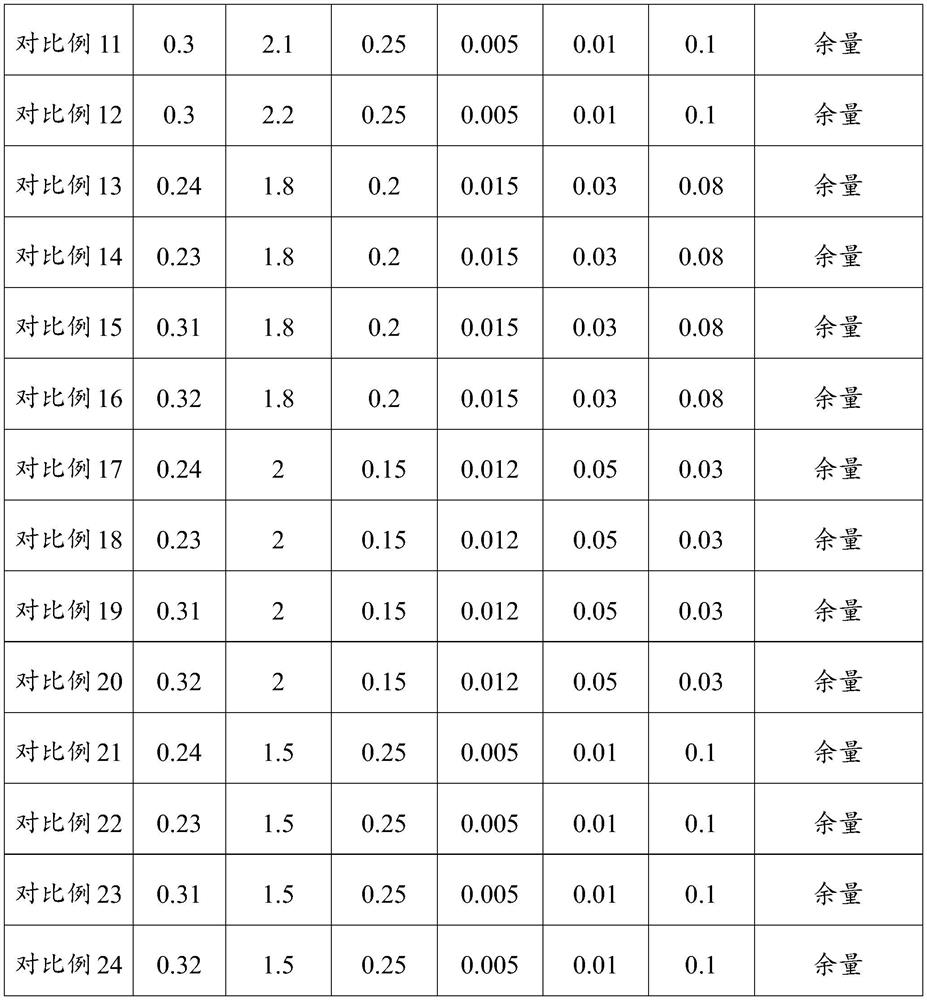

[0021] See Table 1 for the compositions of the non-quenched and tempered steels described in Examples 1-6 and Comparative Examples 1-24.

[0022] The composition of the non-quenched and tempered steel described in Table 1 Examples 1 to 6 and Comparative Examples 1 to 24

[0023]

[0024]

[0025] The preparation method of the crankshaft described in Examples 1-6 and Comparative Examples 1-25 comprises the following steps:

[0026] (1) Forging non-quenched and tempered steel;

[0027] (2) Machining into the shape of a crankshaft;

[0028] (3) Put the crankshaft at 600°C and in NH 3 Insulate in the mixed gas with RX for 2h for carbonitriding treatment;

[0029] (4) Heat the crankshaft after carbonitriding to 880°C, put it in water for quenching, take it out, and then keep it at 100°C for 1.5h.

Embodiment 1

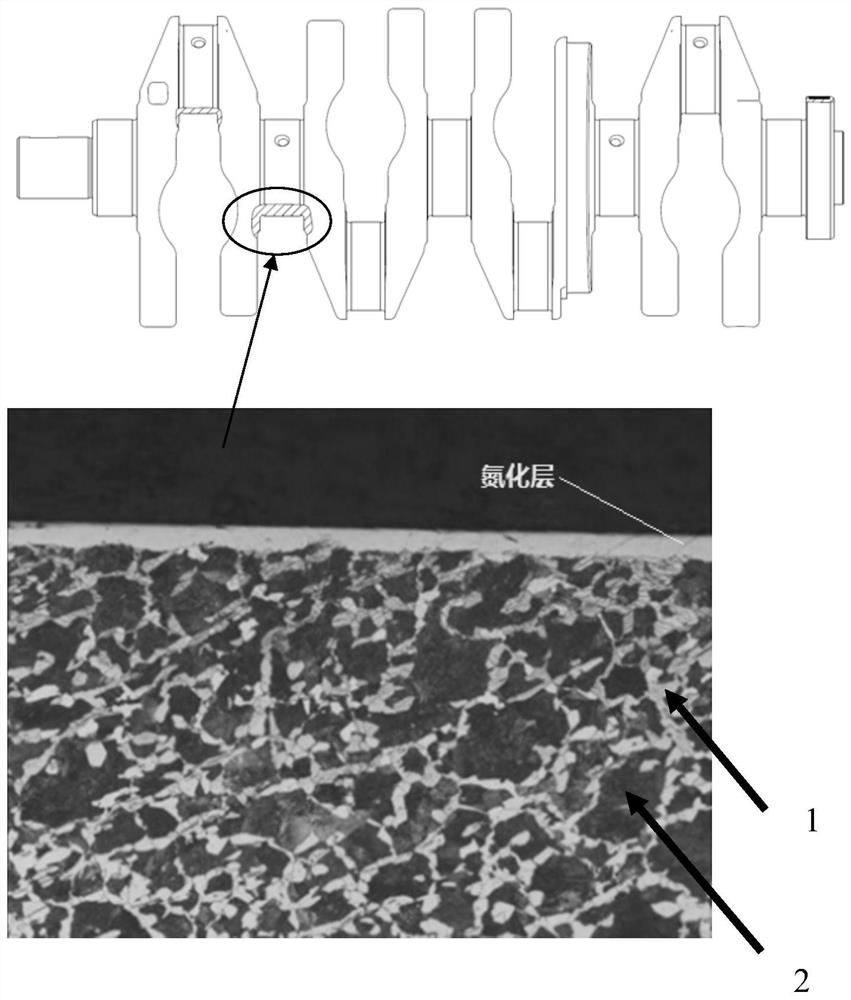

[0030] The metallographic micrograph of crankshaft described in embodiment 1, from figure 1 It can be seen that 1 is a large amount of Mn dissolved in ferrite, which is beneficial to improve the strength of ferrite, and 2 is pearlite.

Embodiment 7

[0034] The strength of the crankshaft is evaluated by the safety factor. The safety factor n=the measured bending moment of the crankshaft / the nominal working moment of the crankshaft. The evaluation of the safety factor ≥ 2.0 is defined as a high-strength crankshaft.

[0035] The engine used in this test is a 2.0L naturally aspirated engine. According to the calculation method of the nominal working bending moment of the engine crankshaft specified in the national automobile industry standard QC / T637-2000, the maximum explosion pressure of the engine cylinder (Pmax=8.5MPa) And the calculation of the relevant structural parameters of the crankshaft shows that the nominal working bending moment of the crankshaft is 352N.m. According to QC / T 637-2000 automobile engine crankshaft bending fatigue test method, the measured bending moment of the crankshaft is calculated. The test result of the measured bending moment of the crankshaft and the safety factor n when the survival rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com