Adjustable rolling device of printer

A winding device, adjustable technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of loose printing paper, inconvenient loading and unloading cutting, printing paper position offset, etc., to achieve tight winding , Stable winding and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, technical features, invention objectives and technical effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

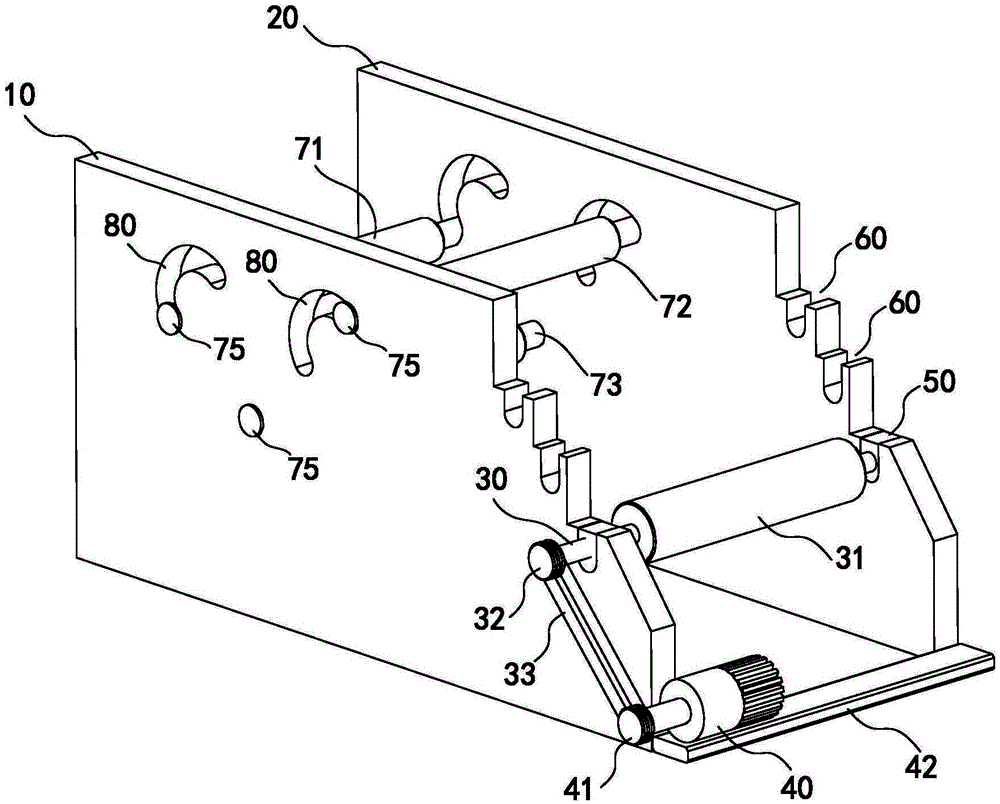

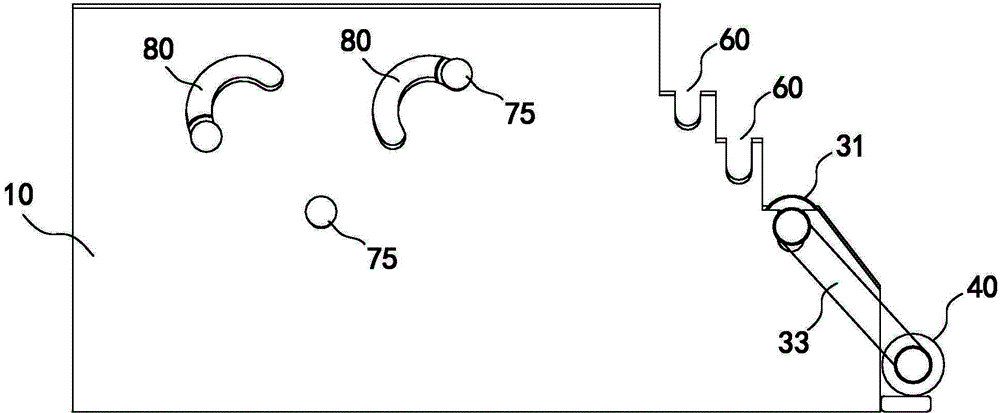

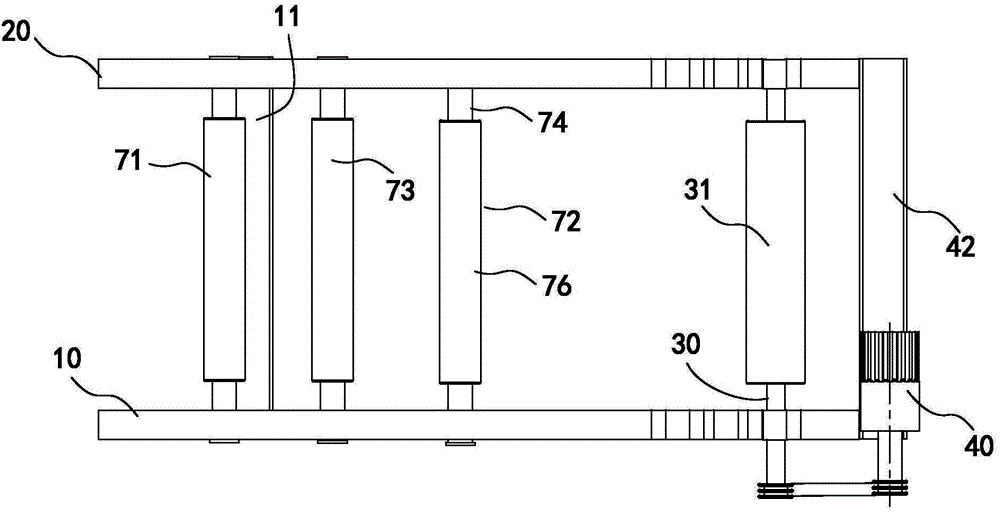

[0022] Such as figure 1 , figure 2 and image 3 Shown is an adjustable winding device for a printing press in the present invention, including a left vertical board 10 and a right vertical board 20 opposite to the left vertical board 10; the left vertical board 10 and the right vertical board 20 pass through their bottoms The connection plates 11 are connected together. Between the left vertical board 10 and the right vertical board 20, a paper guide roller and a paper delivery reel 30 are arranged, and a paper delivery roller 31 is arranged on the paper collection reel 30, and this paper delivery roller 31 is an expansion roller of the prior art , expand during rewinding, and release when rewinding is completed, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com