Embedded rolling device

An embedded, cloth-rolling technology, applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve the problems of uneven cloth, uneven sides, not tight enough, etc. Tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

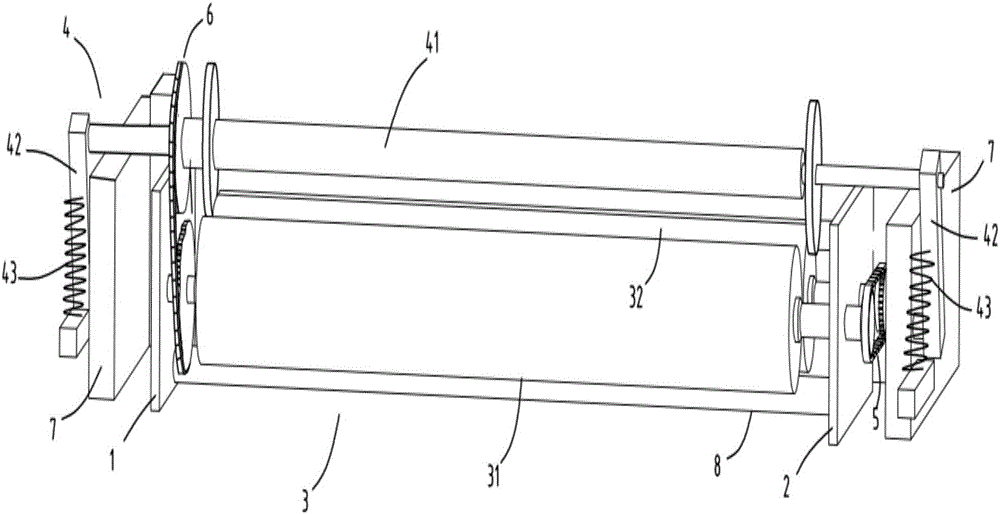

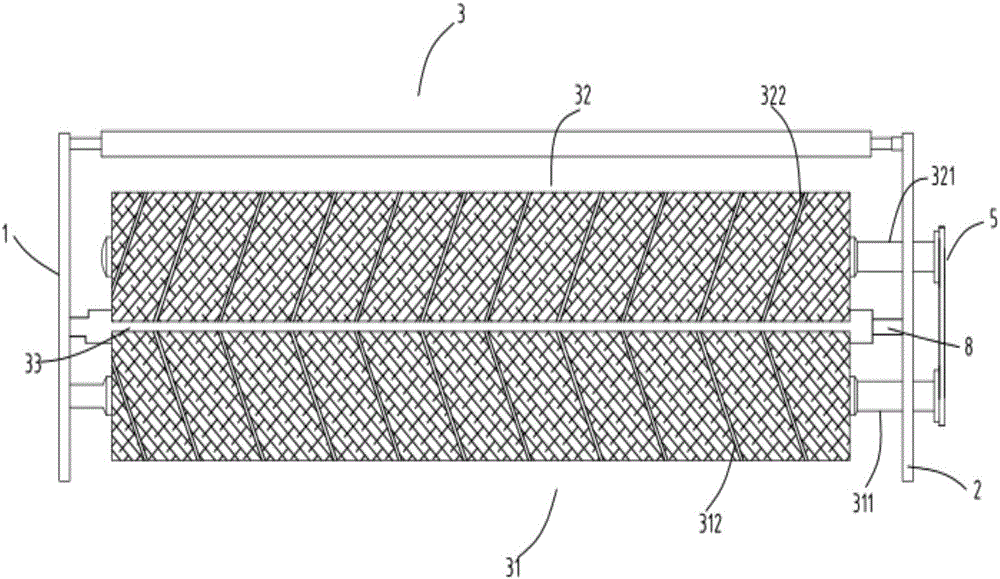

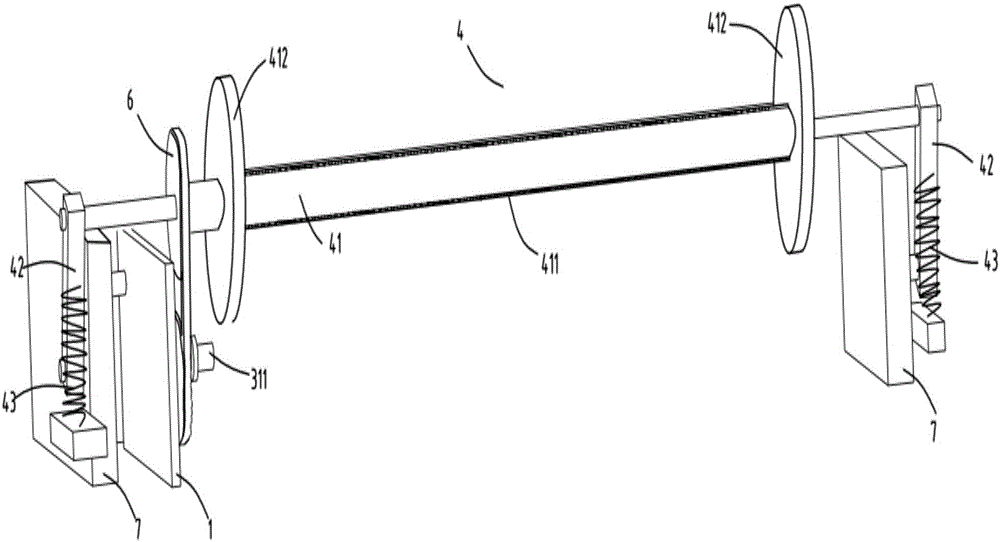

[0026] figure 1 is a schematic diagram of the embedded coiling device, figure 2 It is a schematic diagram of the structure of the cloth rolling device, image 3 It is a schematic diagram of the structure of the auxiliary winding device, Figure 4 It is a simplified schematic diagram of the rotation direction of each rotating part of the rolling device viewed from the right. Such as figure 1 , figure 2 , image 3 as well as Figure 4 As shown, what is provided in this embodiment is an embedded rolling device, including a left frame 1, a right frame 2, and a cloth rolling device 3; the cloth rolling device 3 includes a cloth rolling shaft a31 and a Cloth roll shaft b32, the speed of cloth roll shaft a31 is greater than that of cloth roll shaft b32; the cloth roll shaft a31 and cloth roll shaft b32 are arranged in parallel with a gap 33 between them; an auxiliary winding device 4 is also included; The auxiliary winding device 4 includes a roller 41, a fixed rod 42 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com