Active wire paying-off rewinder of aluminum clad steel wires

A kind of aluminum-clad steel wire, active technology, applied in the direction of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of breaking, single wire strain, etc., to reduce traction, reduce labor intensity, and uniform tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with accompanying drawing, the present invention is described in detail:

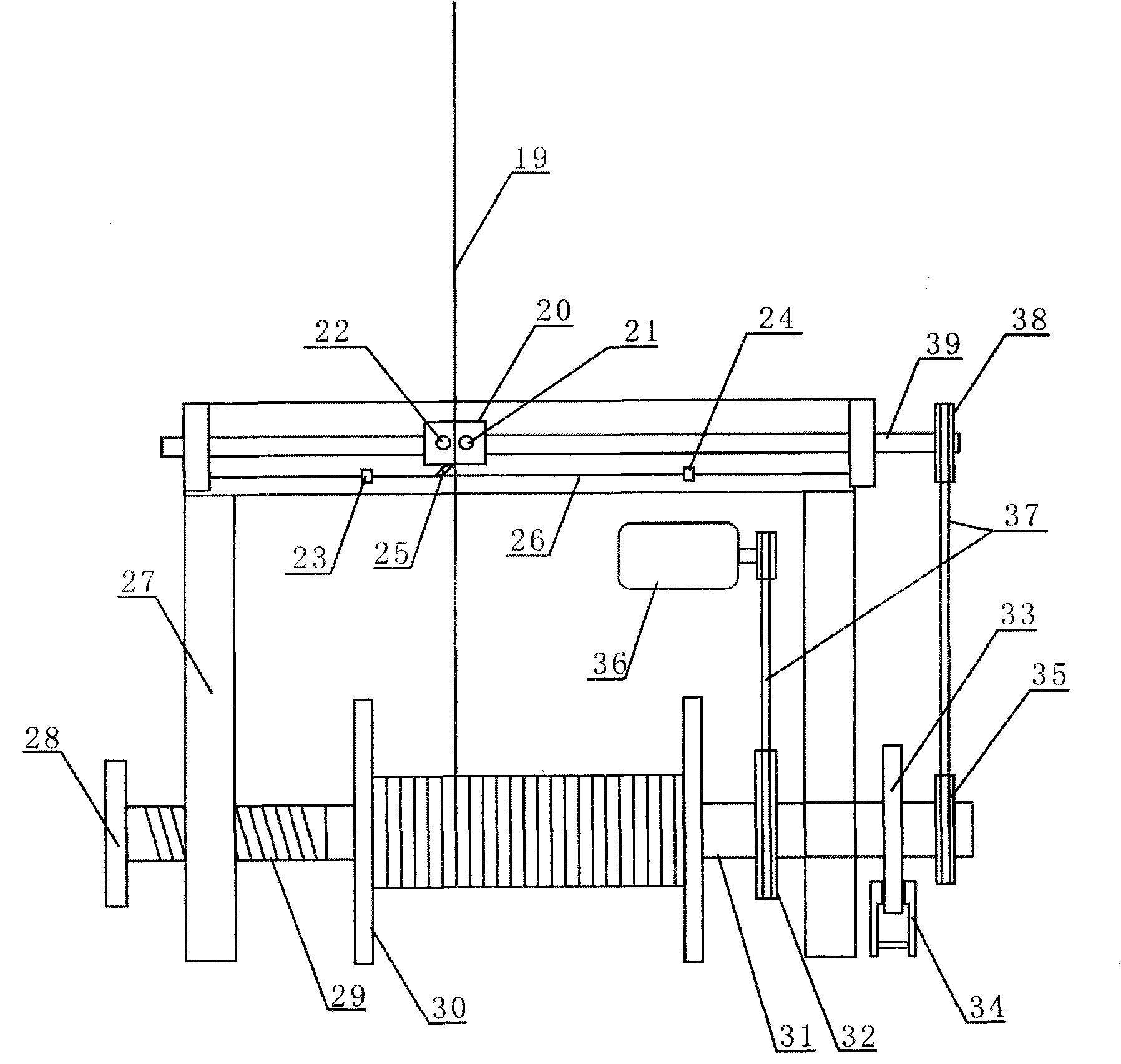

[0014] The active pay-off and rewind equipment for aluminum-clad steel wire according to the present invention is composed of an active pay-off mechanism, a tension mechanism and an automatic wire arranging and take-up mechanism.

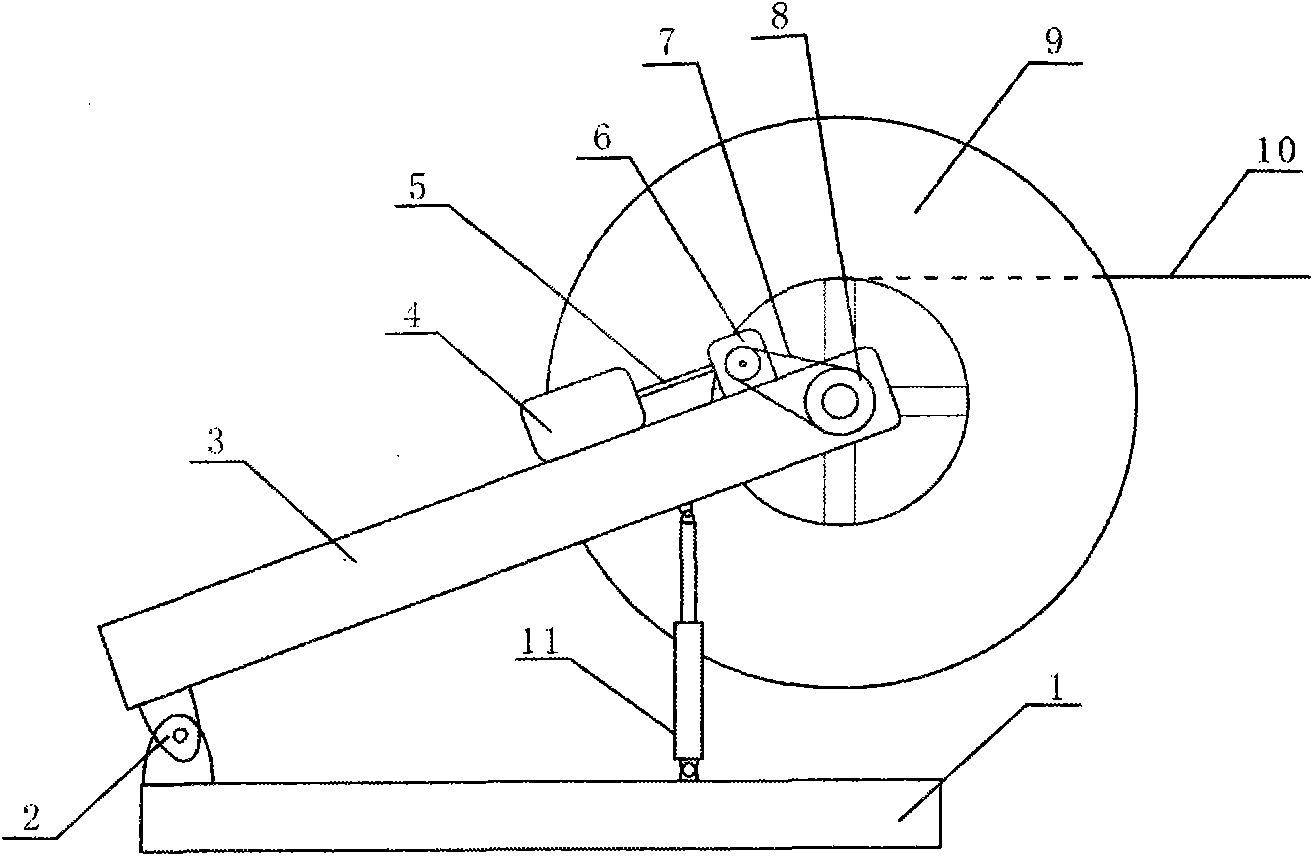

[0015] figure 1 Shown is an active pay-off mechanism, which is to install an aluminum-clad steel wire large plate tool 9 on the pay-off machine support 3. In order to facilitate loading and unloading of the aluminum-clad steel wire large plate tool 9, the pay-off machine support 3 can be designed as a lifting structure. The pay-off machine support 3 is connected on the pay-off machine base 1 by the pay-off machine rotating shaft 2, and the pay-off machine hydraulic cylinder 11 is set between the pay-off machine support 3 and the pay-off machine base 1 to realize the lifting of the pay-off machine support 3. A motor 4 is also installed on the pay-off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com