Winding and packing device for manufacturing of waterproof cloth for teenagers

A technology for teenagers and fabrics, which is applied to the field of winding and packaging devices for the production of waterproof fabrics for teenagers, can solve the problems of time-consuming, inability to cut, and prevent fabrics, etc., and achieve the effects of compact fabric winding, improved work efficiency, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

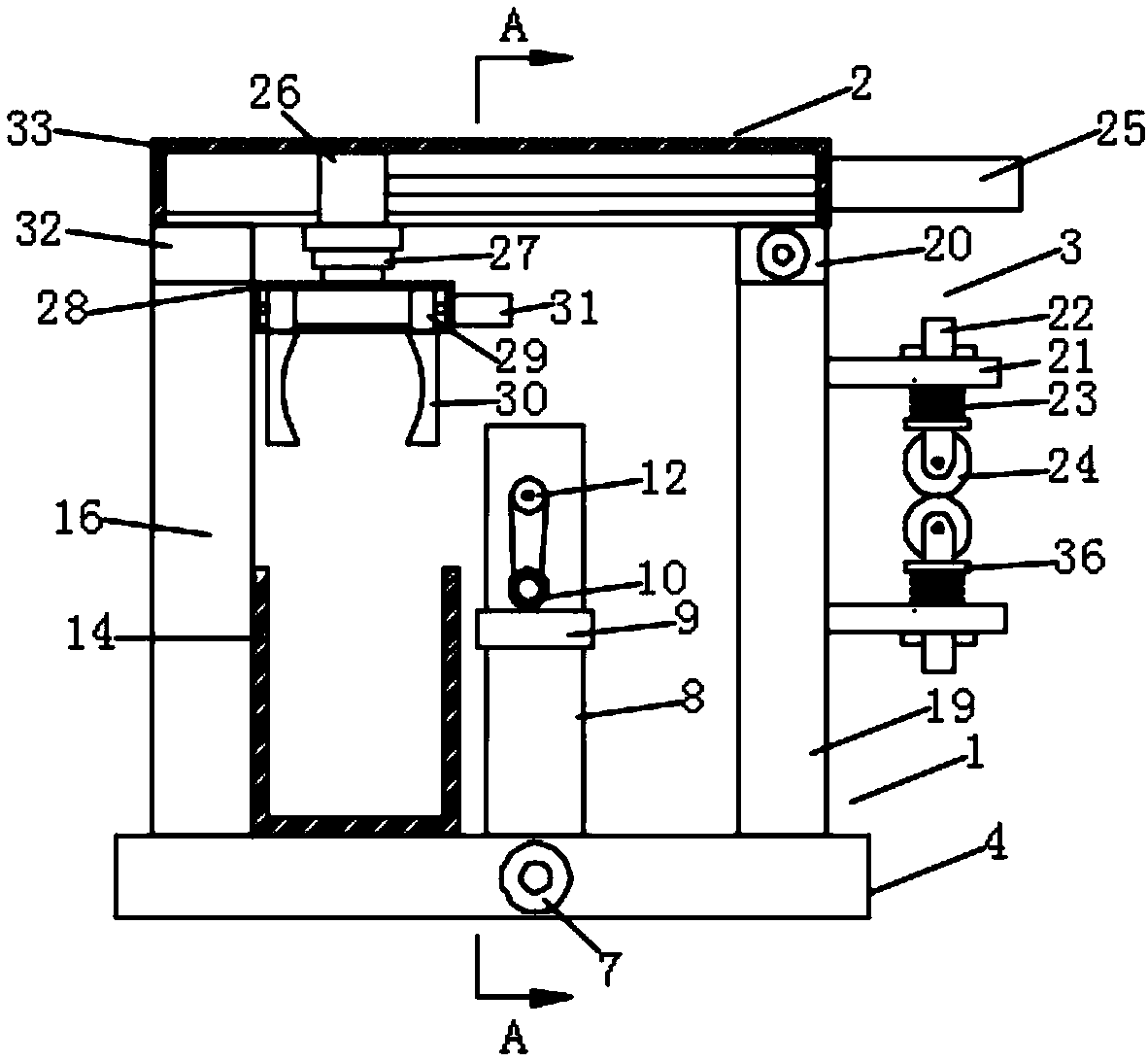

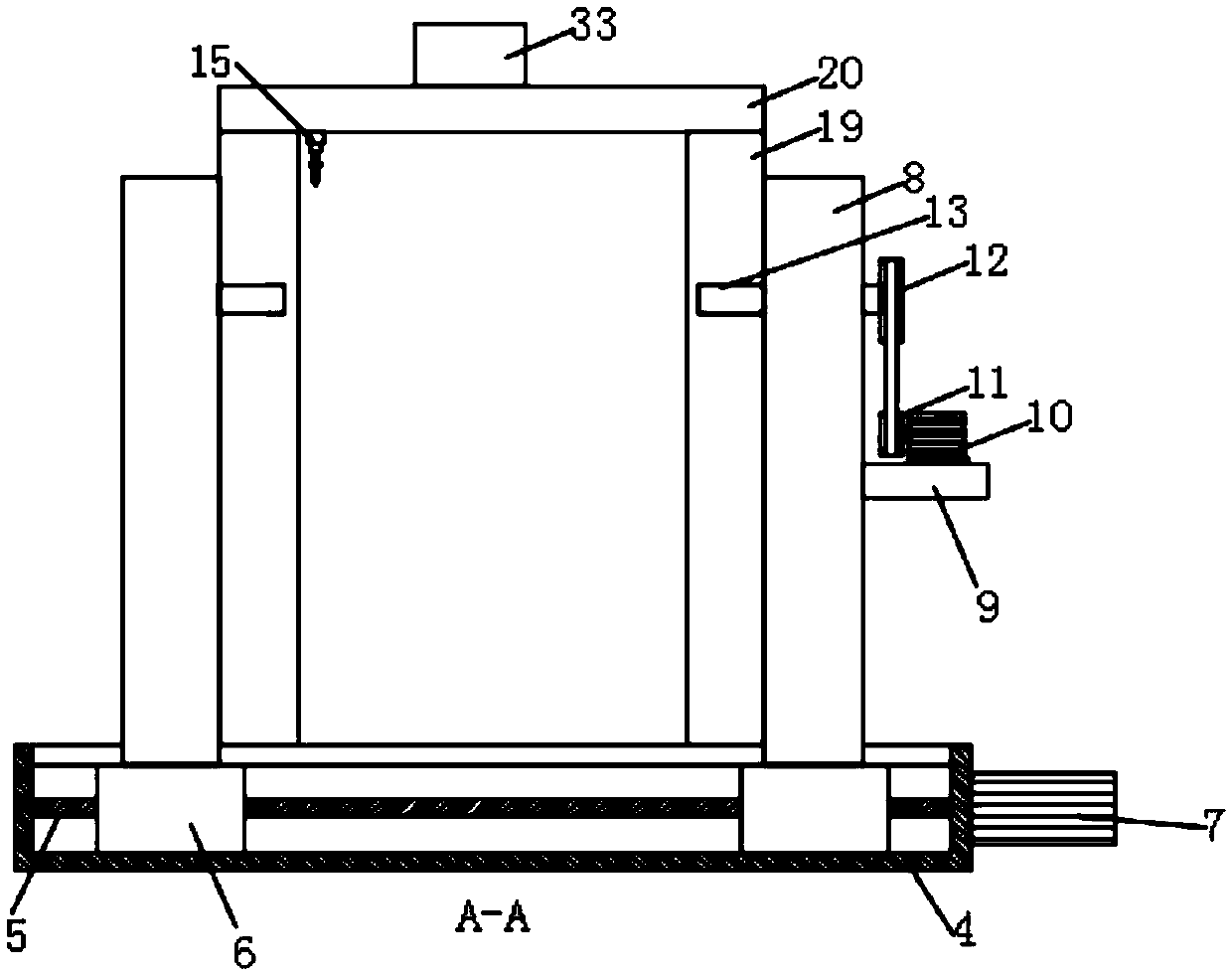

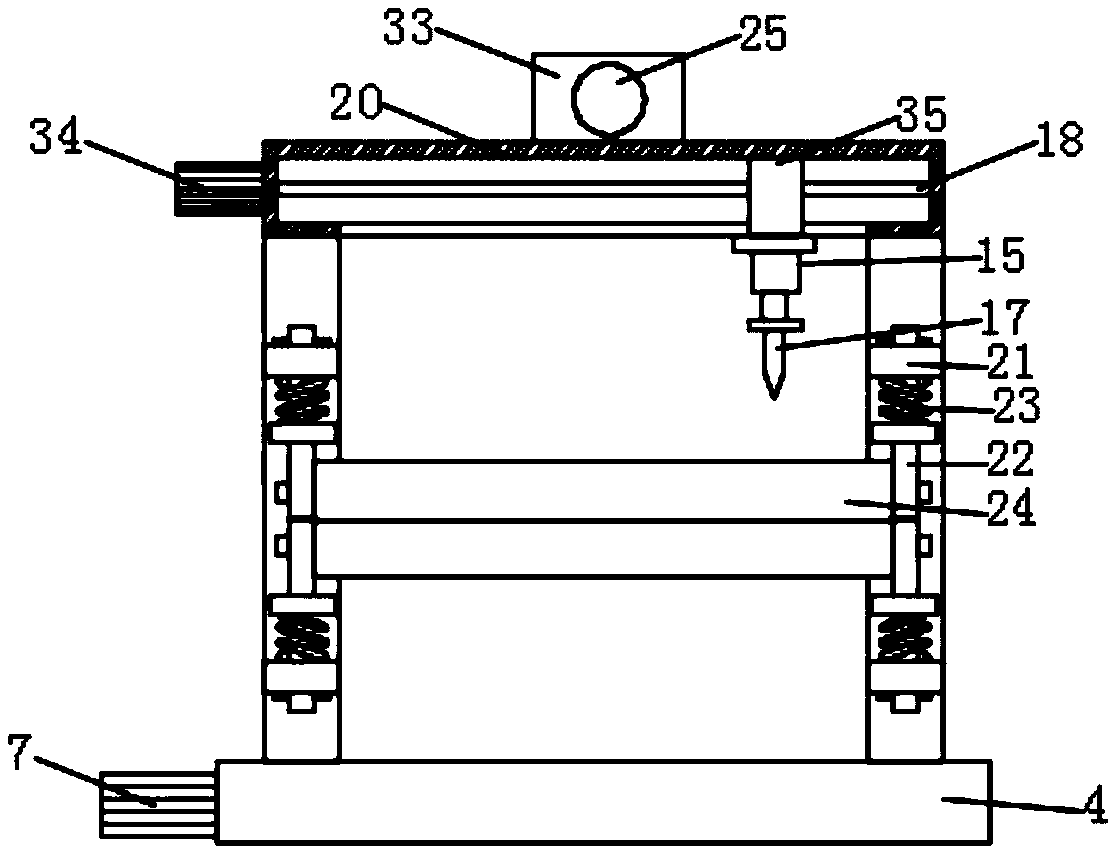

[0020] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a rolling and packaging device for the manufacture of waterproof cloth for teenagers, including a support mechanism 1, a material receiving mechanism 2 and a cutting mechanism 3, and the support mechanism 1 is composed of a fixed base 4, an adjustable It consists of screw mandrel 5, distance-adjusting slider 6, distance-adjusting motor 7, distance-adjusting pillar 8, fixed table 9, winding motor 10, driving pulley 11, driven pulley 12 and rotating shaft 13, and the fixed base 4 There are two distance-adjusting sliders 6 connected symmetrically inside, and the internal rotation of the fixed base 4 is connected with a distance-adjusting screw rod 5, and the outer side of the fixed base 4 is fixedly connected with a distance-adjusting motor 7, and the distance-adjusting motor The output end of 7 is fixedly connected with distance-adjusting screw rod 5, and the outside of descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com