Vamp cloth rolling device of anti-deviation structure for production of cotton shoes

A winding device and anti-offset technology, applied in thin material processing, strip winding, transportation and packaging, etc., can solve the problems of uncompact winding and no anti-offset function of the fabric, and avoid wrinkles and folds. Uneven, easy to disassemble, to avoid the effect of offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

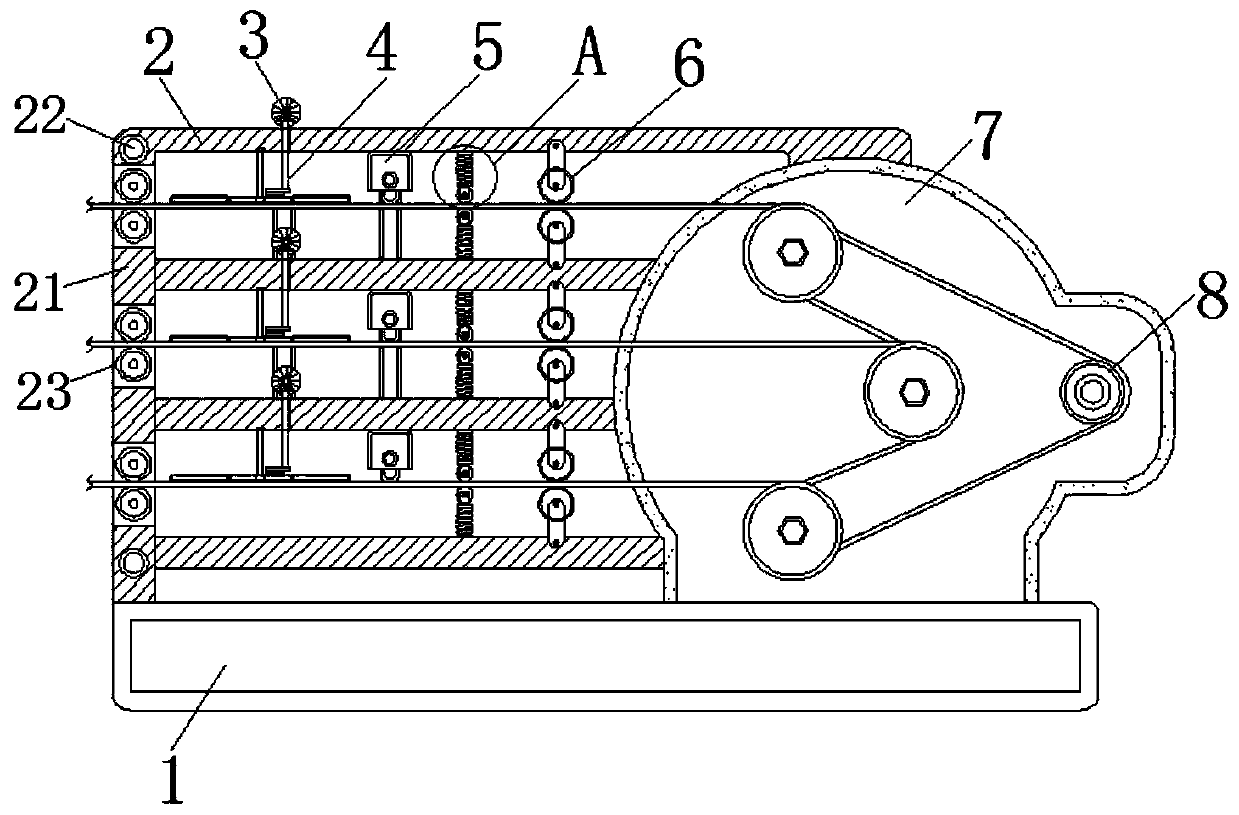

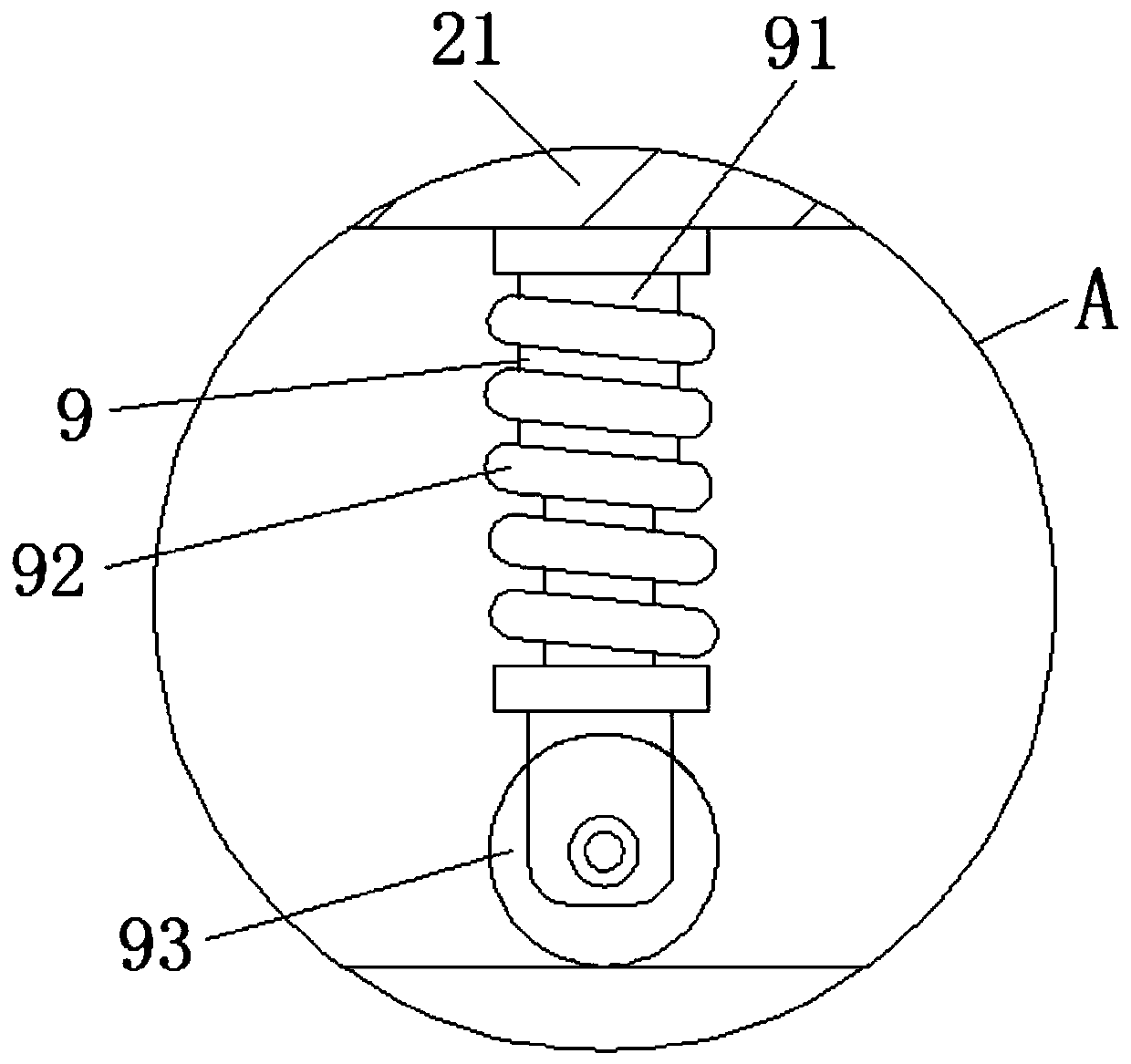

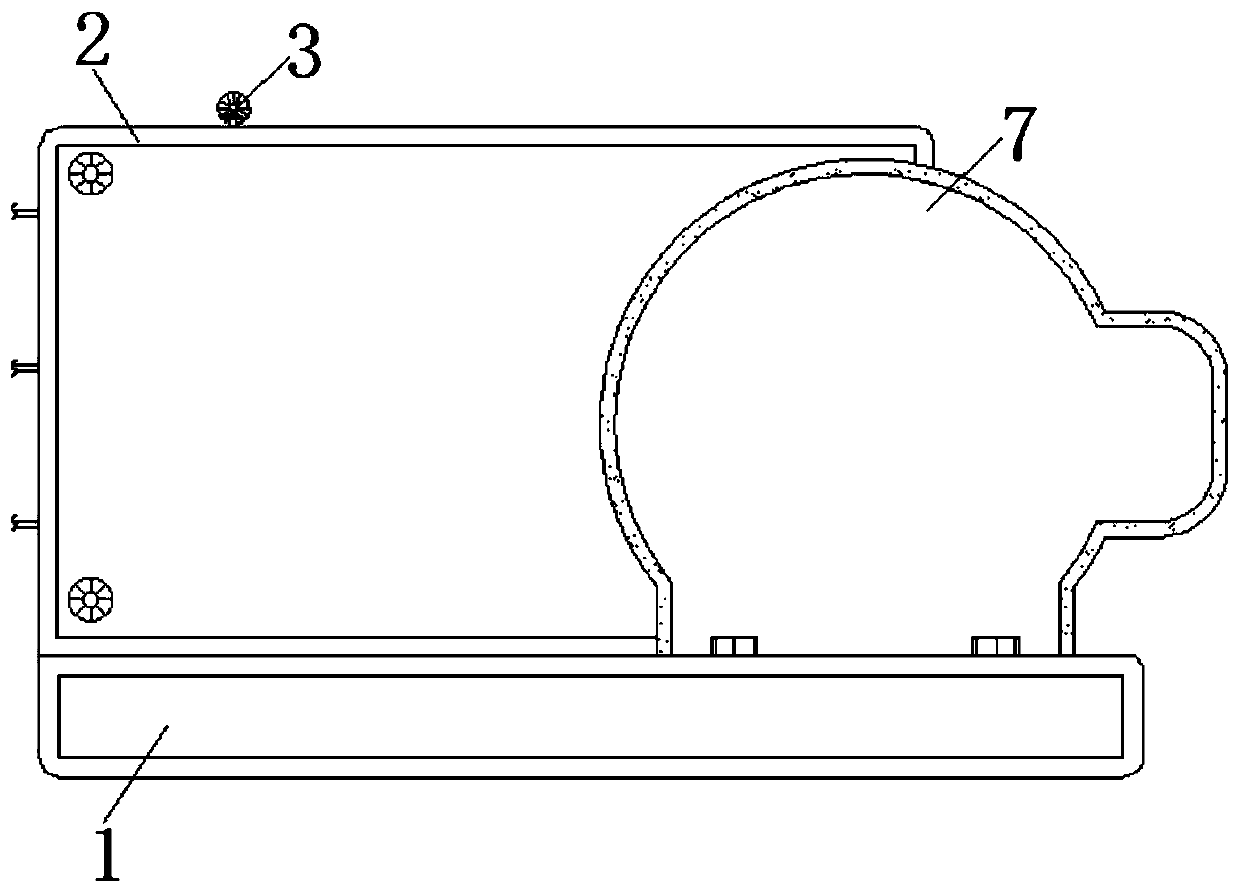

[0031] A shoe upper cloth winding device with an anti-deviation structure for cotton shoe production, including a fixed base 1, a first connecting mechanism 2 is fixedly installed on the left top of the fixed base 1, and the first connecting mechanism 2 includes a first fixing frame 21. The first limiting rod 22, the first limiting roller 23, the first fixing bolt 24 and the second fixing frame 25, the upper and lower sides of the first fixing frame 21 are fixedly connected with the first limiting rod 22, the first The inner side of the fixed frame 21 is evenly equipped with the first limit roller 23, the surface of the first limit rod 22 is inserted with the second fixed frame 25, and the surface of the second fixed frame 25 is fixedly installed with the first fixing bolt 24, the second A connecting mechanism 2 plays a role of supporting and connecting the parts of the device to ensure the stable operation of the parts. The inner side of the first connecting mechanism 2 is uni...

Embodiment 2

[0036] Embodiment 2: A shoe upper fabric winding device with an anti-deviation structure for the production of cotton shoes, including a fixed base 1, a first connecting mechanism 2 is fixedly installed on the top left side of the fixed base 1, and the first connecting mechanism 2 includes The first fixed frame 21, the first limiting rod 22, the first limiting roller 23, the first fixing bolt 24 and the second fixed frame 25, the upper and lower sides of the first fixed frame 21 are fixedly connected with the first limiting rod 22. The first limiting rod 22 can be inserted inside the second fixing frame 25 to facilitate the installation of the first fixing frame 21 and the second fixing frame 25. The inside of the first fixing frame 21 is evenly installed with the first limiting Roller 23, the first limit roller 23 is provided with three groups, can carry out position limit to three groups of cloth simultaneously, the surface of the first limit rod 22 is inserted with the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com