Vertical single-/double-surface napping machine

A technology of single-sided and double-sided sanding machine, which is applied in the direction of fabric surface trimming, textile and paper making, and roughening. It can solve the problems of large space occupation, high labor cost, and long time consumption, and achieve high degree of automation and sanding effect. Good and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

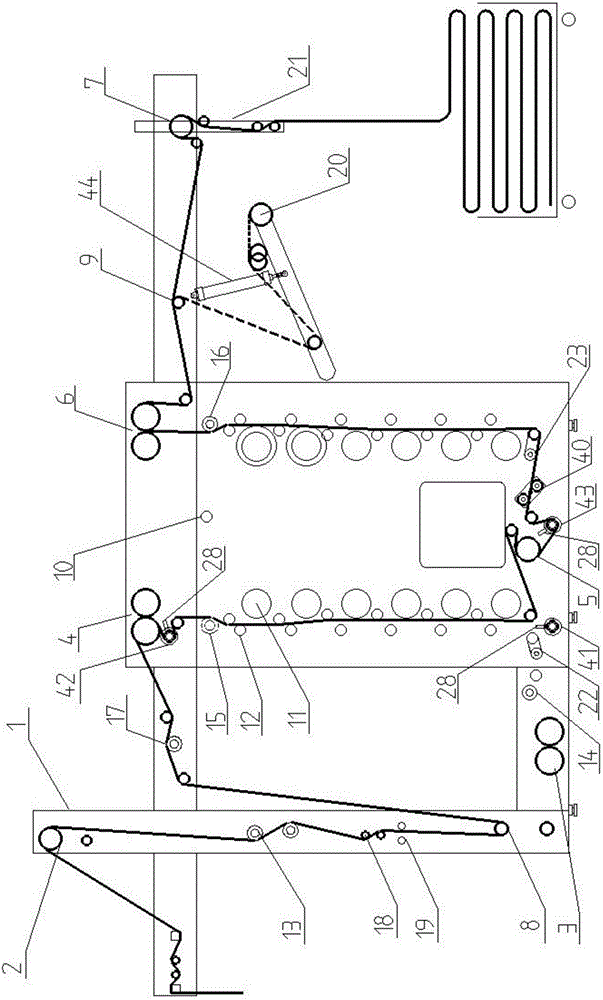

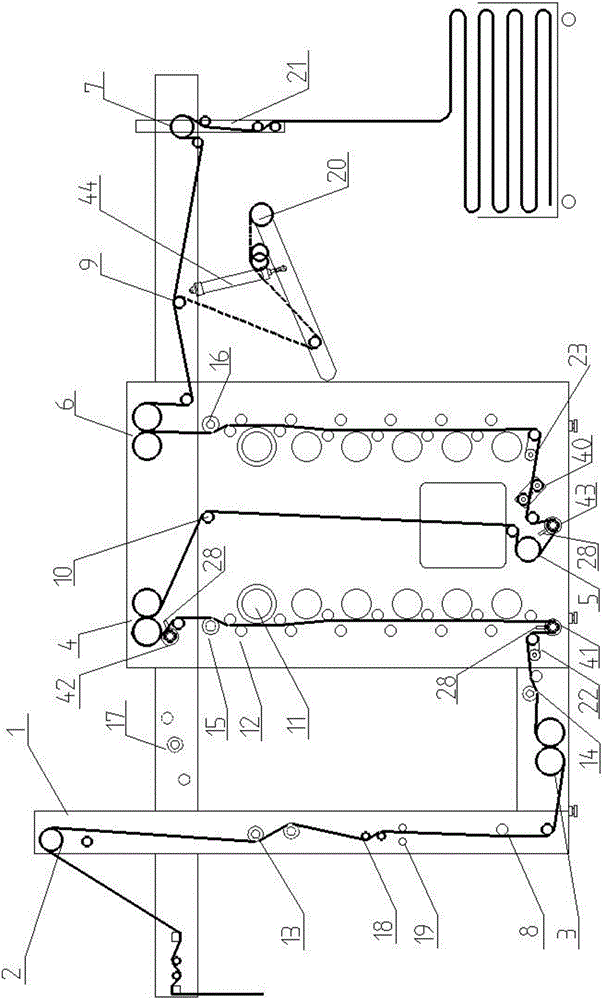

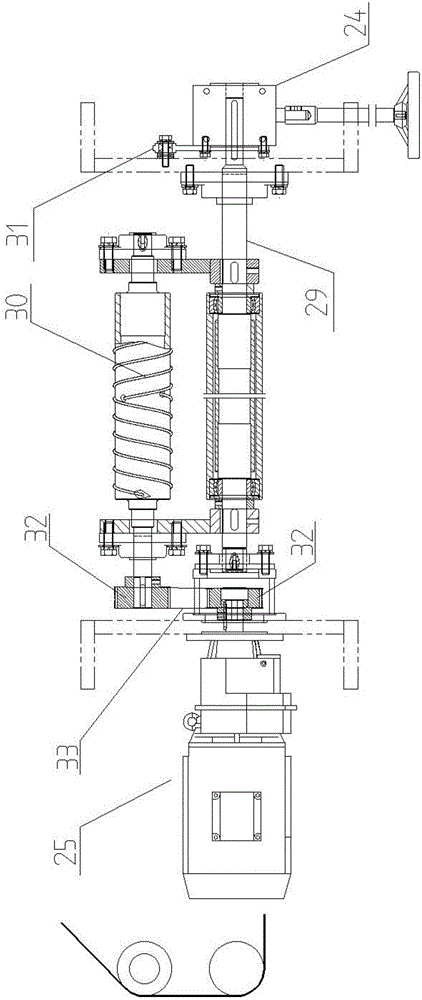

[0025] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

[0026] refer to Figure 1-4 , a vertical single and double-sided sanding machine, including a frame 1, a cloth feeding mechanism and a cloth discharging mechanism are arranged on the frame 1, and front and rear two stages of sanding are arranged between the cloth feeding mechanism and the cloth discharging mechanism Mechanism, each section of sanding mechanism is made up of 6 sanding roller assemblies, and described sanding roller assembly comprises sanding roller 11 and the pressing roller assembly 12 that fabric is pressed and attached to the side of sanding roller 11; The traction roller assembly Ⅲ4 and the traction roller assembly Ⅴ6 are respectively arranged above the last two stages of sanding mechanism; the tension roller assembly Ⅱ42 and the spreading roller assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com