A self-tensioning tendon and its installation method

A tension tendon and self-tensioning technology, which is applied in anchoring arrangements, transportation and packaging, and ship construction, can solve problems such as low installation efficiency, increased installation risks, and long installation process time, so as to achieve tension and reduce installation Risk, installation time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

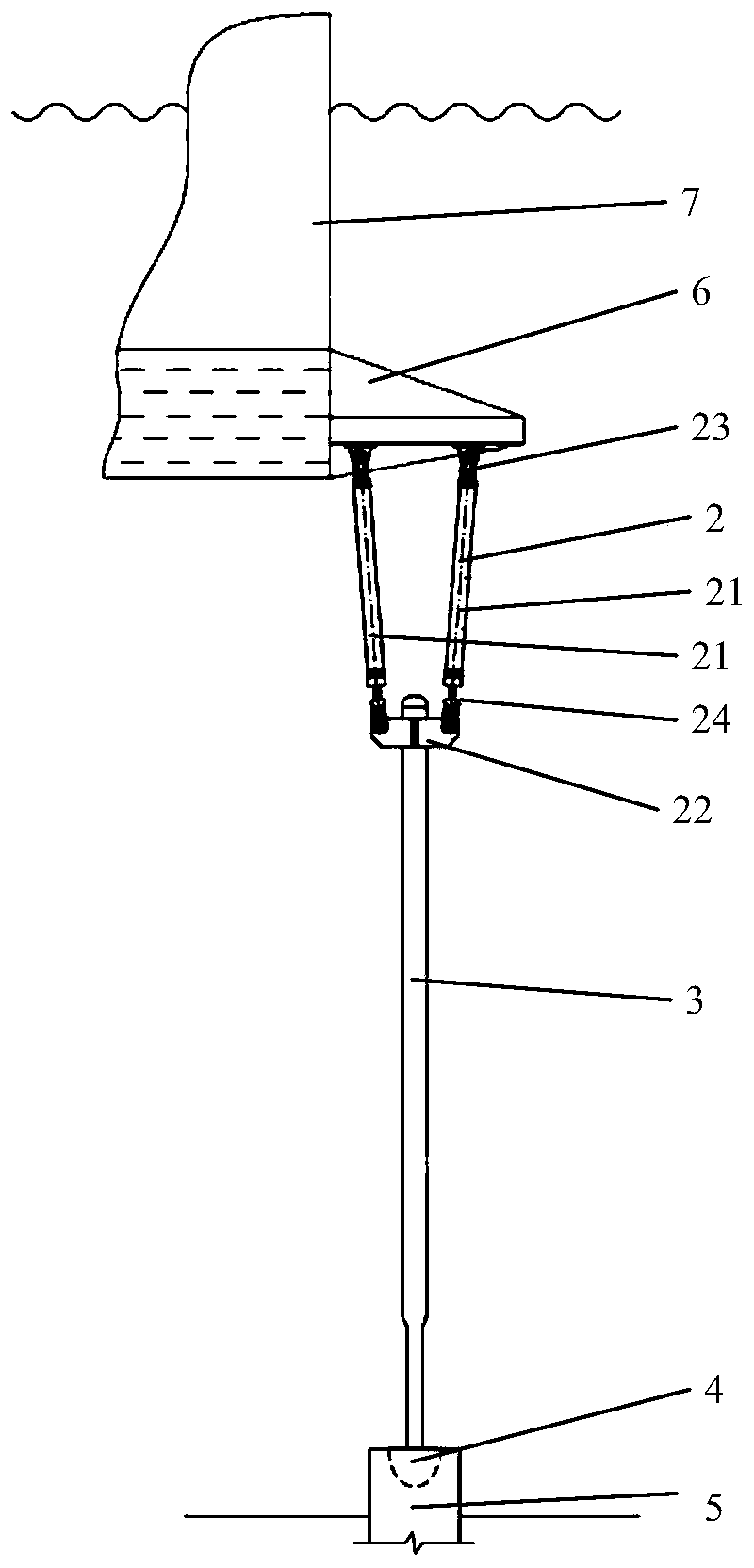

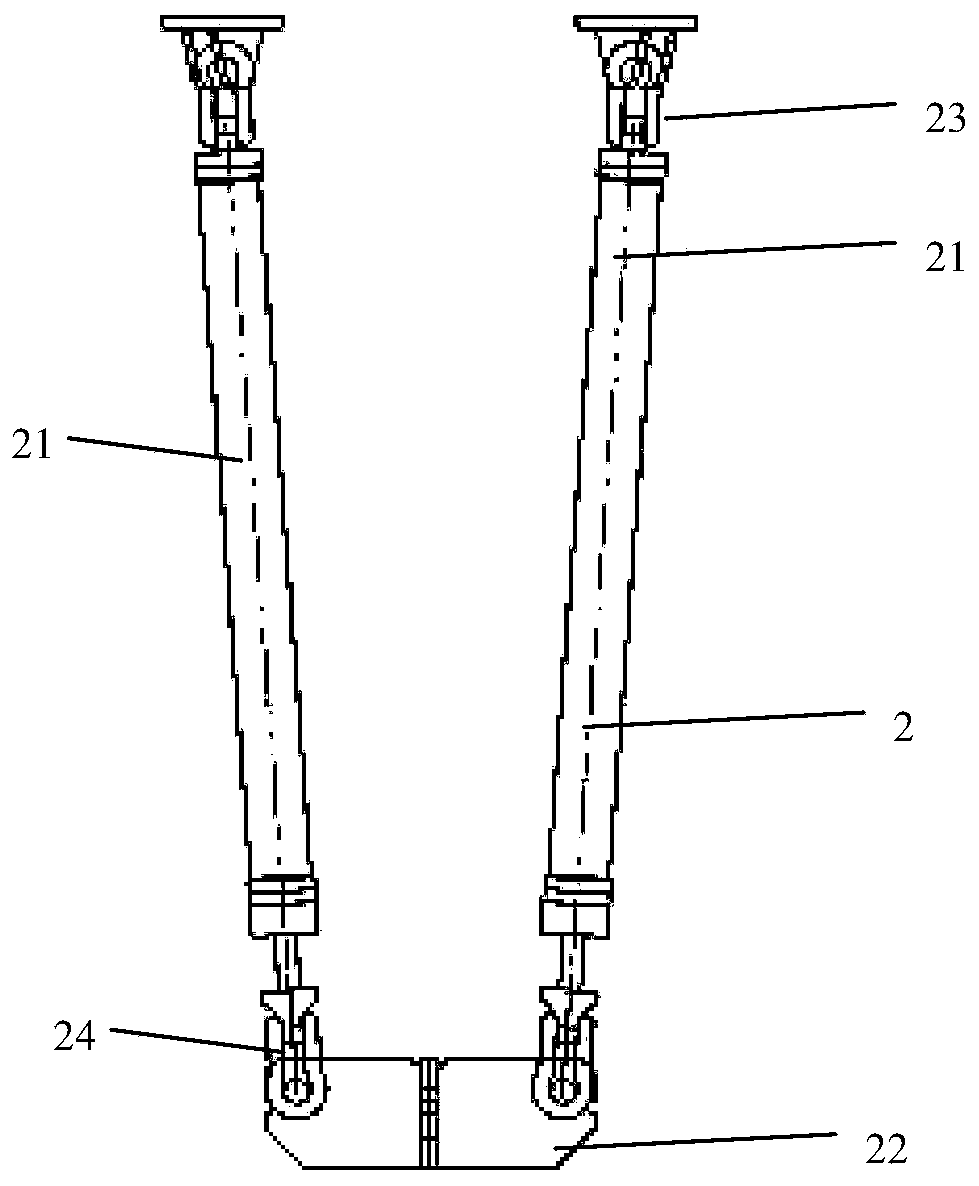

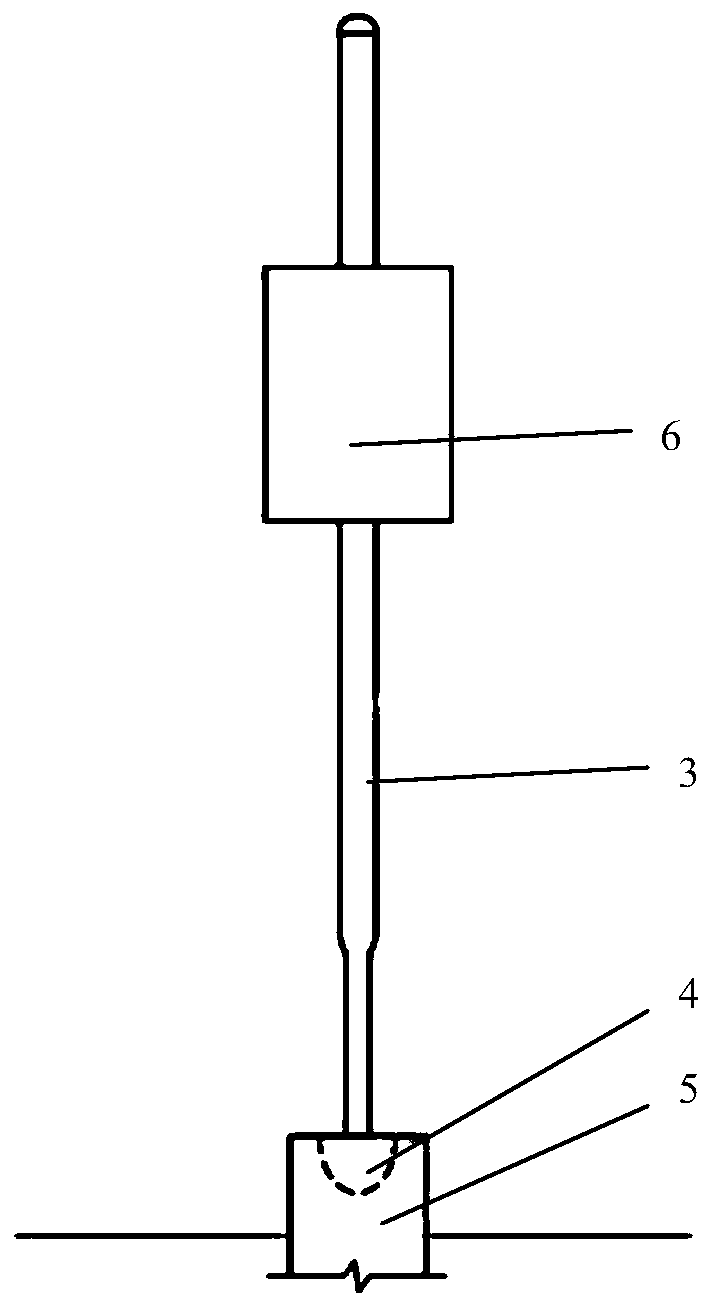

[0045] Figure 4 It is the schematic diagram of step 1 and step 2 of the self-tensioning tendon of the present invention, Figure 5 is the schematic diagram of step 3 of the self-tensioning tendon of the present invention, Image 6 It is a schematic diagram of step 4 of the self-tensioning tendon of the present invention, please refer to Figure 4 to Figure 6 shown.

[0046] In a further embodiment of the present invention, it also includes a method for installing self-tensioning tendons, including:

[0047] Step 1: Assemble the tension tendon main body 3 and the bottom connector 4 to form a single tension tendon, fix the temporary buoy 6 on the single tension tendon, lift the single tension tendon and lower it, insert the anchor foundation 5, and complete the tension tendon pre-installation;

[0048] Step 2: The floating platform 7 is towed to the installation site, positioned above the single tendon of the tension tendon, the guide rope is lowered and connected to the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com