A hoist wire rope tension monitoring sensor for eliminating vibration peaks

A technology for monitoring sensors and eliminating vibration, which is applied in elevators, transportation and packaging, etc., can solve problems such as difficulty in ensuring safe production in coal mine enterprises, restrictions on safe operation of steel wire ropes, and inability to eliminate the friction of oil cylinders, so as to avoid complexity and distortion problems, Reasonable structural design, stable and accurate real-time monitoring of the effect of wire rope tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

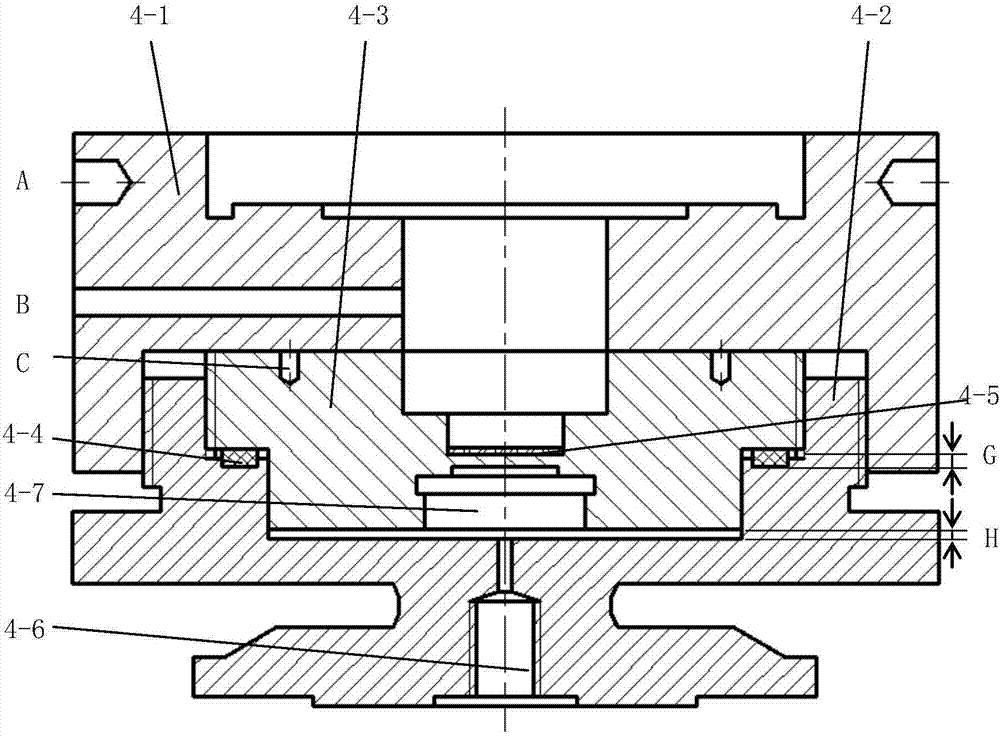

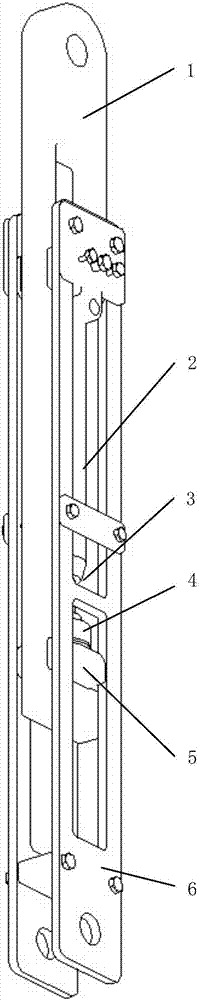

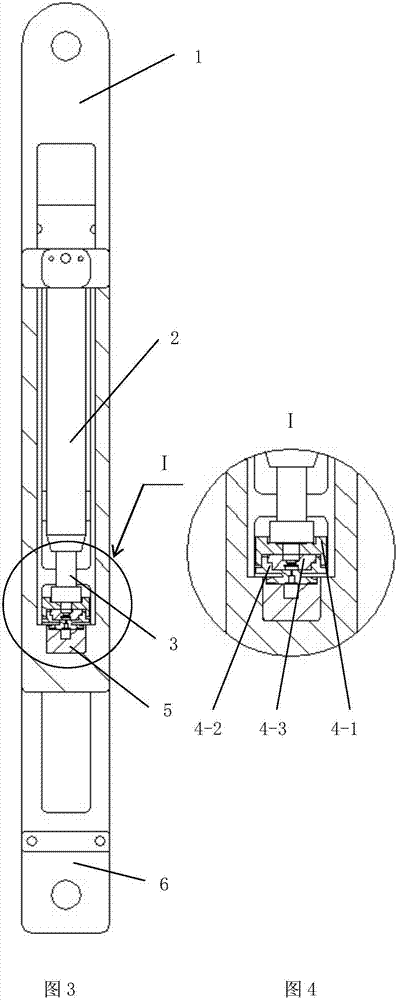

[0020] Such as figure 1 As shown, the hoist wire rope tension monitoring sensor for eliminating the vibration peak value of the present invention is mainly composed of an upper cover 4-1 that is dynamically matched with the telescopic rod 3 of the hydraulic cylinder, a disc body 4-2 that is dynamically matched with the slider 5, and a The upper cover is composed of the oil cavity cylinder 4-3 wrapped by the disc body; the upper end surface of the upper cover 4-1 is provided with a groove for supporting the telescopic rod 3 of the oil cylinder, and the diameter of the groove of the upper cover 4-1 is larger than that of the telescopic rod of the oil cylinder 3 The diameter is 1 mm; there is an inner hole in the middle of the groove, and a wire lead-out hole B communicating with the inner hole of the groove is opened on the outer edge of the upper cover 4-1 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com