Automatic laminating labeling machine

A labeling machine, automatic technology, applied in the direction of labeling machines, labels, winding strips, etc., can solve the problems of unsatisfactory label winding, difficult production and maintenance, poor versatility, etc., to improve the quality of label lamination, The effect of improving the winding quality and facilitating maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

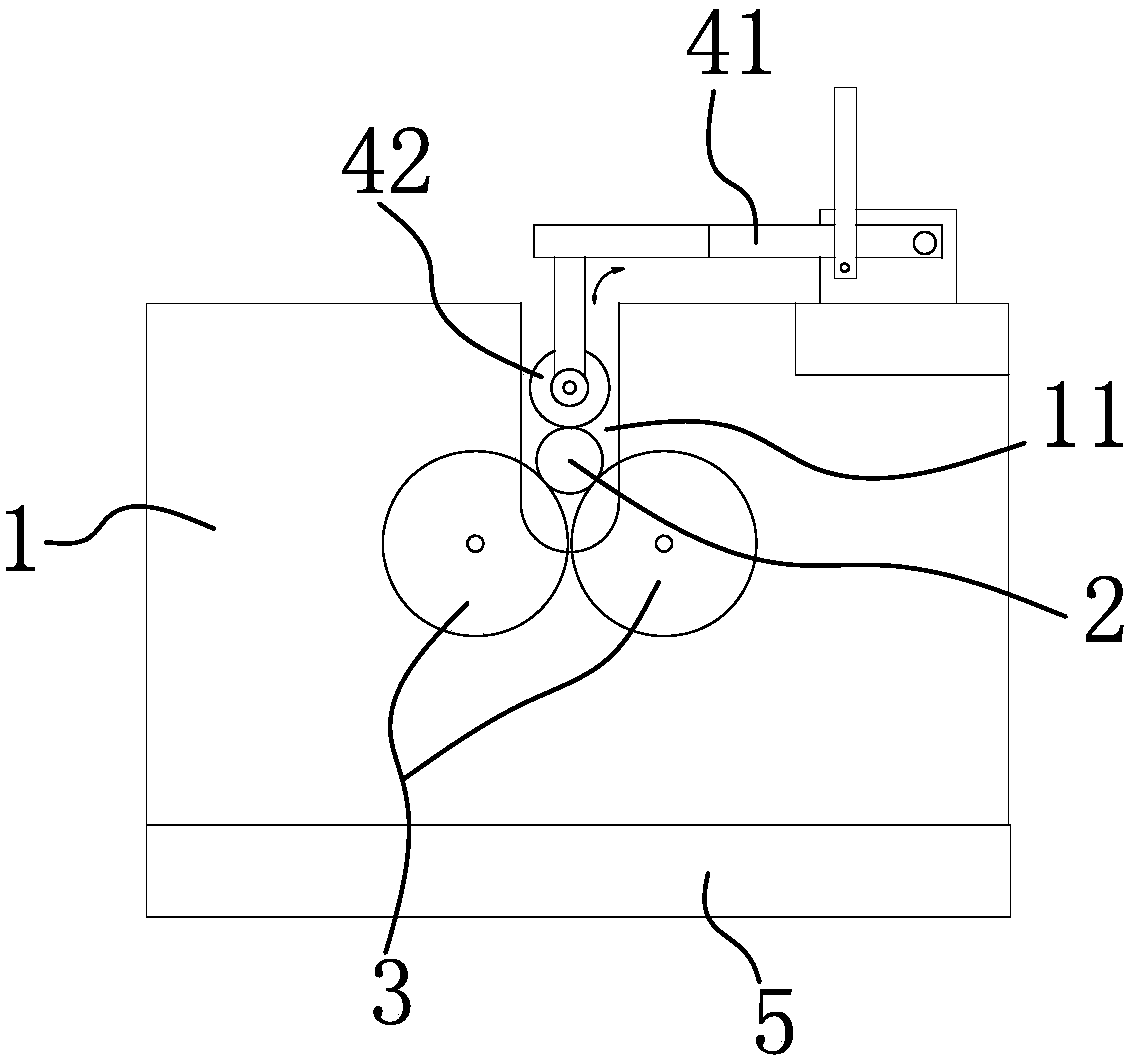

[0057] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

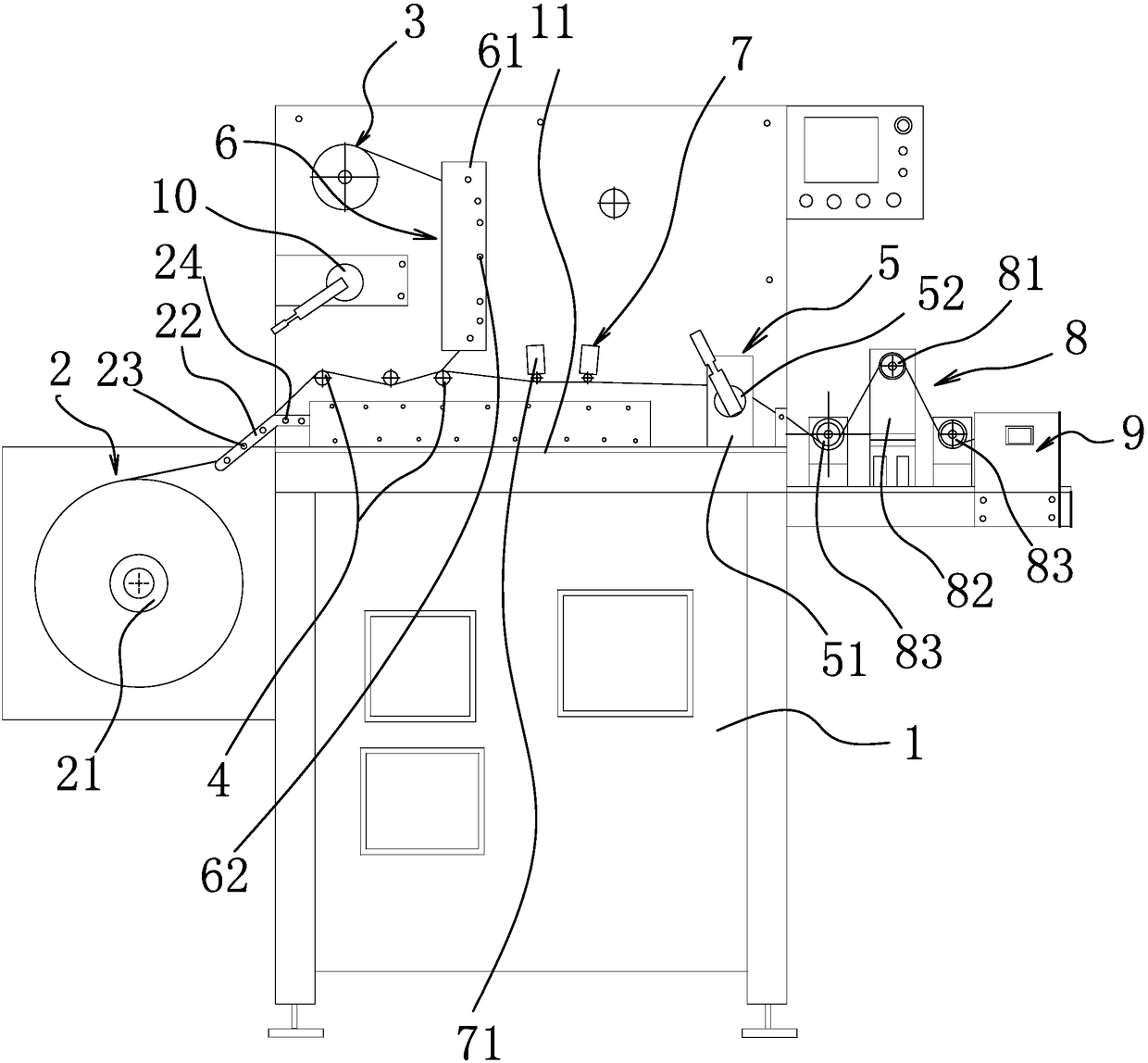

[0058] Such as figure 1 As shown, the automatic bonding and labeling machine includes a frame 1 with a conveying platform 11, and a display interface and a control interface are provided on the conveying platform 11.

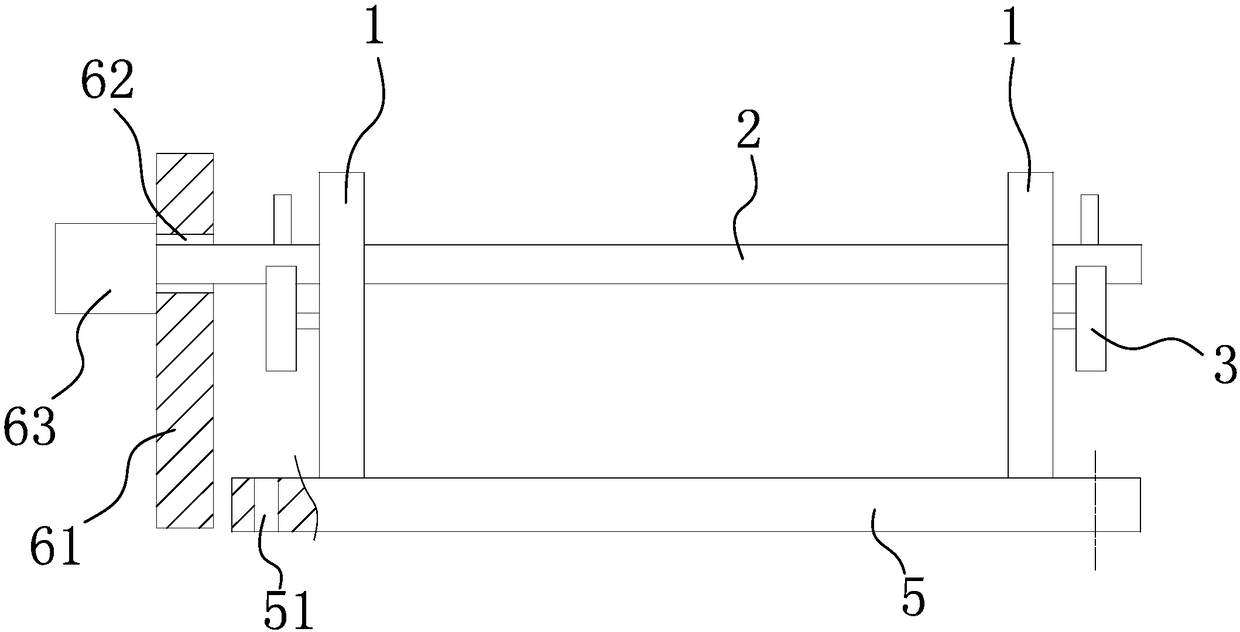

[0059] The feeding end of the conveyor table 11 is provided with a discharge mechanism 2, which unwinds the adhesive tape. The inclined positioning guide frame 22 inclined downwards is provided with some guide rollers 23 arranged successively from bottom to top on the inclined positioning guide frame 22. 22 is also provided with some guide rollers 24 that are horizontally spaced apart.

[0060] Through the above structure, it can realize the positioning after discharging, avoiding the phenomenon of floating and sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com