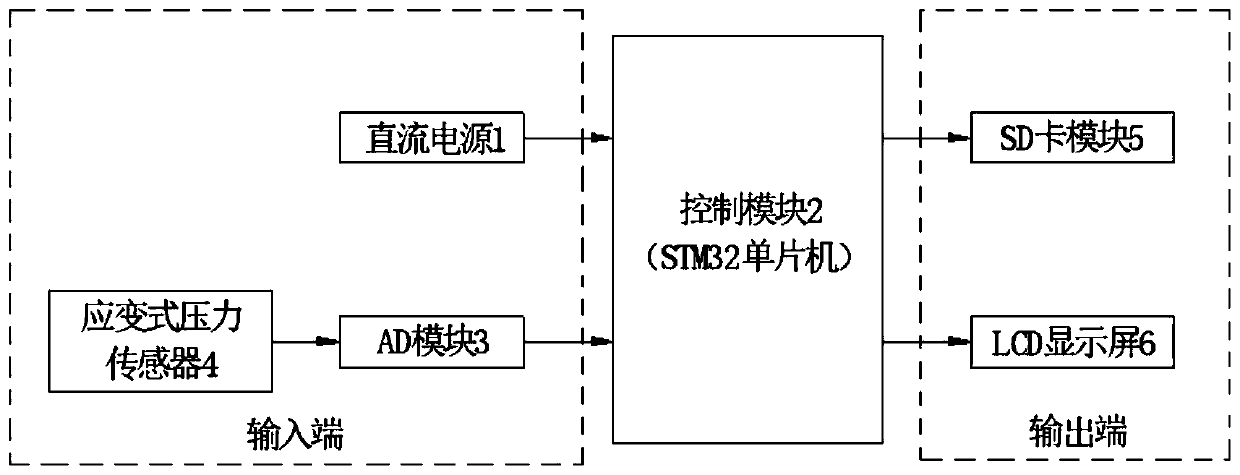

Wire electrical discharge machining electrode wire tension detection and LCD image display device

An image display device and a technology for cutting electrodes, which are applied in the direction of electrode manufacturing, accessory devices, electric processing equipment, etc., can solve problems such as the inability to detect the tension of electrode wires, etc., and achieve the effects of stable output graphics, sensitive response, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

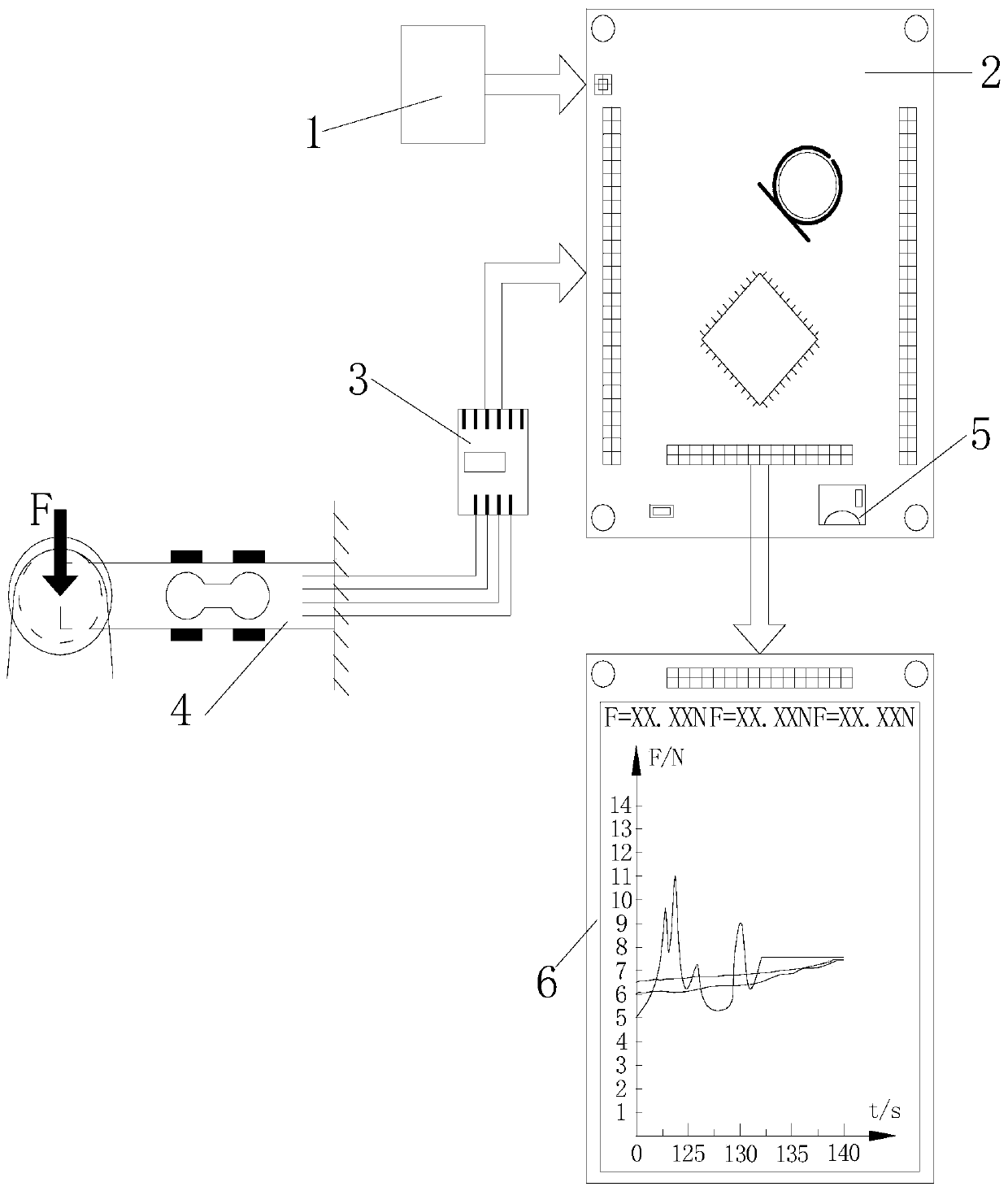

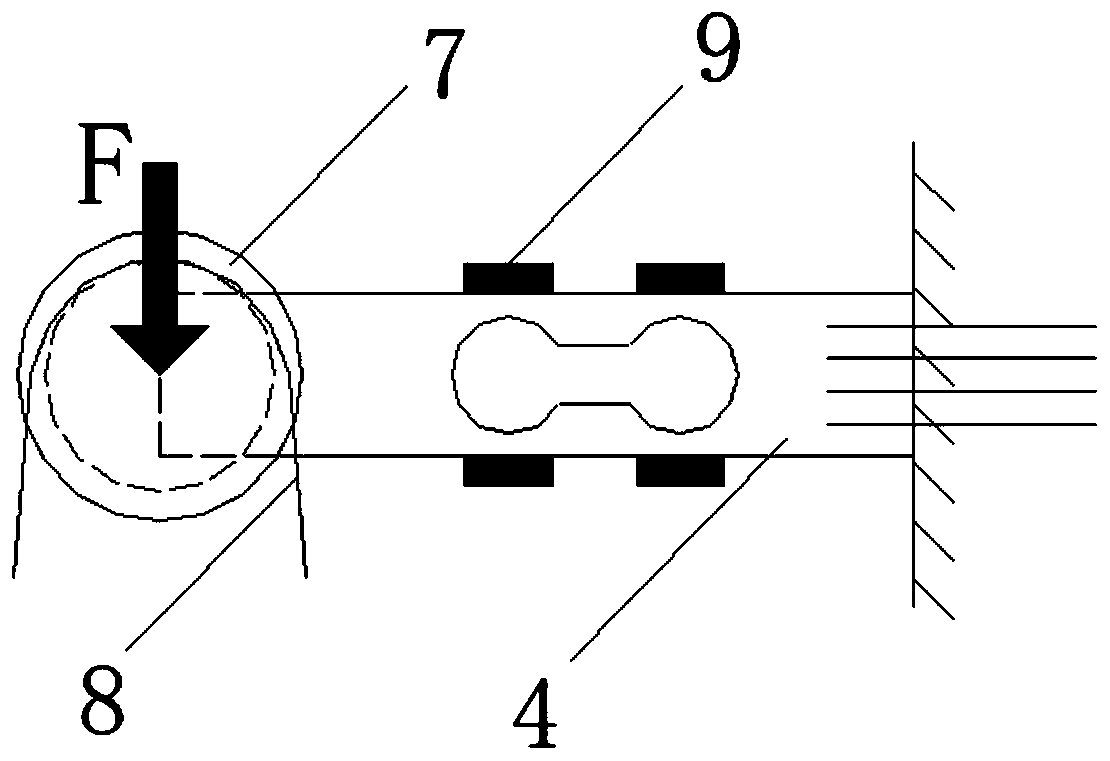

[0044] Using the traditional WEDM machine tool, there is no wire tension detection function in the processing process, so it has a great impact on the processing quality and efficiency, and wire breakage cannot be avoided. Adopting the present invention can detect the tension of the electrode wire in real time, and dynamically display three curves and three tension values in real time on the LCD display screen 6, corresponding to the real-time tension value, the average tension value of the first 10s, and the average tension value of the first 100s respectively, and the X axis is time. The measuring range is 140s, the Y axis is tension, the measuring range is 14N, and the minimum precision is 0.05N.

[0045] Therefore, the tension of the electrode wire can be monitored in real time, and the tension change can be intuitively understood through the image displayed on the LCD. The detected tension can be further controlled to improve the processing quality, efficiency and avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com