Multifunctional test bench for plucking chain type sunflower header test

A test bench and sunflower technology, applied in the field of agricultural machinery, can solve the problems of late start, poor adaptability and high price of sunflower harvesting machinery research and development, so as to reduce plant drop loss, reduce forward resistance, and reduce shatter loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

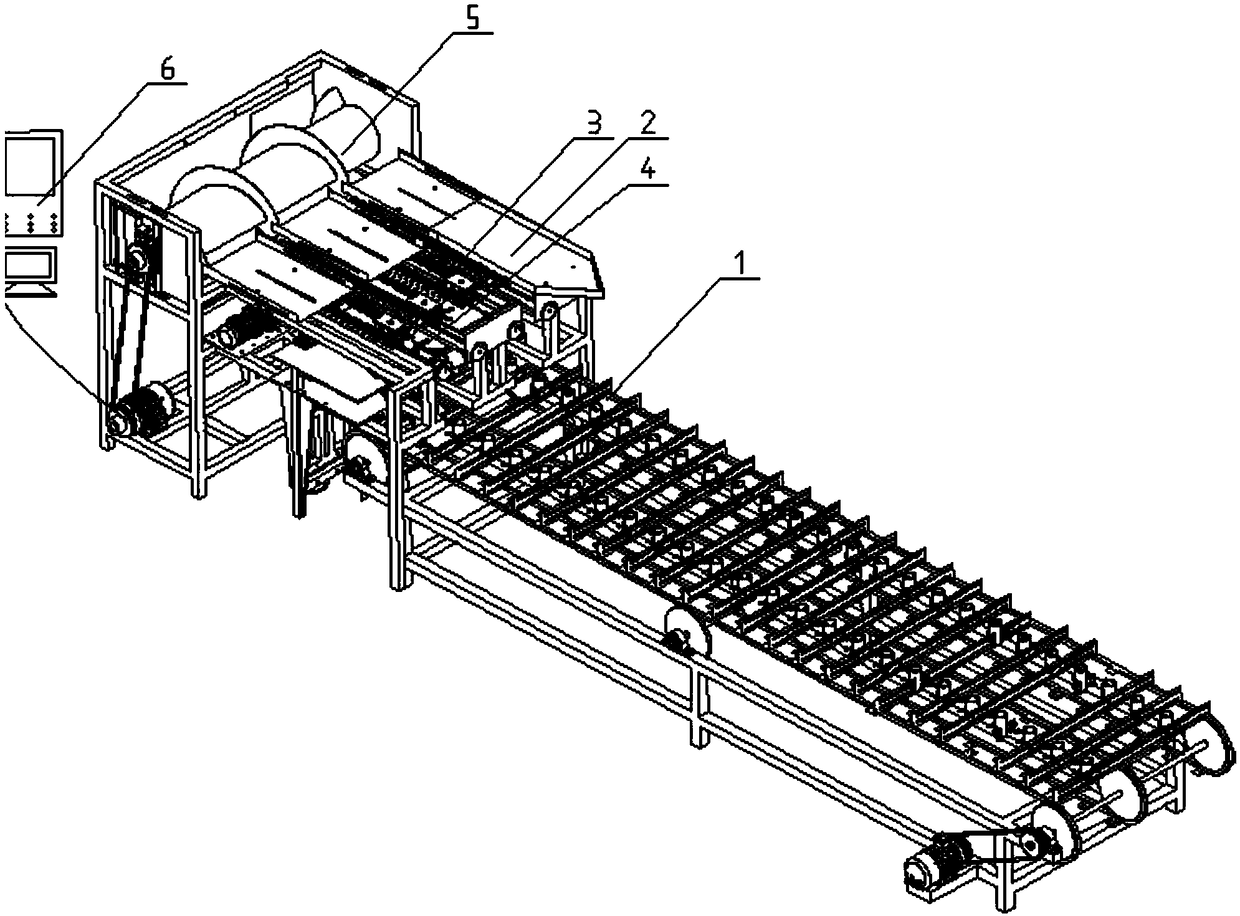

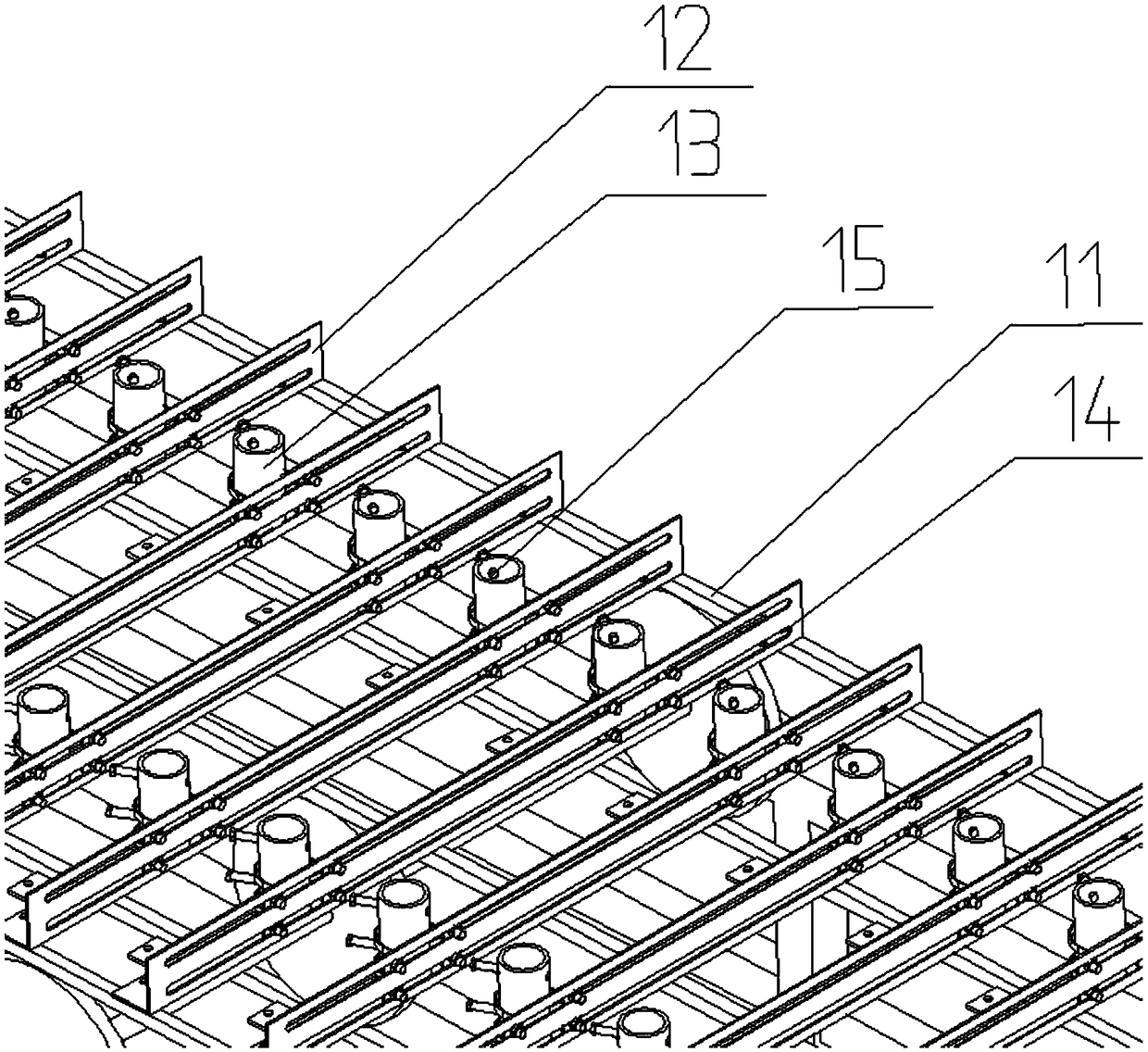

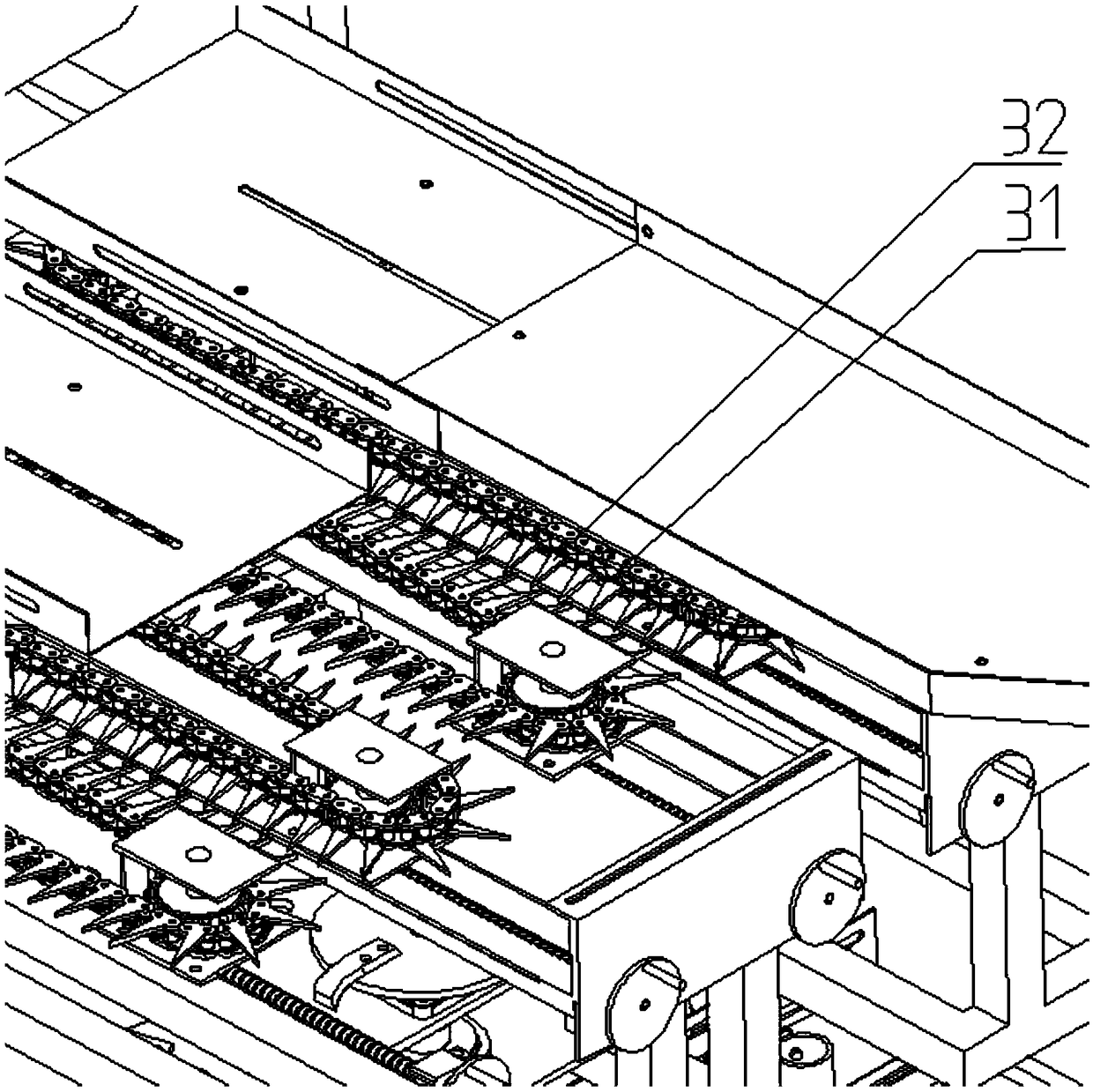

[0027] Such as figure 1 Shown, a kind of multifunctional test stand for the test of the reel-chain type sunflower header includes a feeding mechanism 1, a grain dividing mechanism 2, a reeling mechanism 3, a cutting mechanism 4, a conveying mechanism 5 and a controller 6. The feeding mechanism 1 is used to move the plant to the cutting mechanism 4 by driving the plant fixing device. The plant fixing device is used to place the plants and the distance between the adjacent plant fixing devices can be adjusted. Set in parallel, the distance between adjacent grain-distributing mechanisms 2 can be adjusted, the length of the grain-dividing mechanism 2 can be stretched, and the gap between adjacent grain-dividing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com