Moon cake processing molding equipment

A technology for processing and forming moon cakes, which is applied in the field of moon cake processing and forming equipment, can solve the problems of inability to be completed in a centralized manner, labor-intensive labor, cumbersome preparations, etc., and achieve the effects of improving service life, facilitating subsequent processing, and enriching flavors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

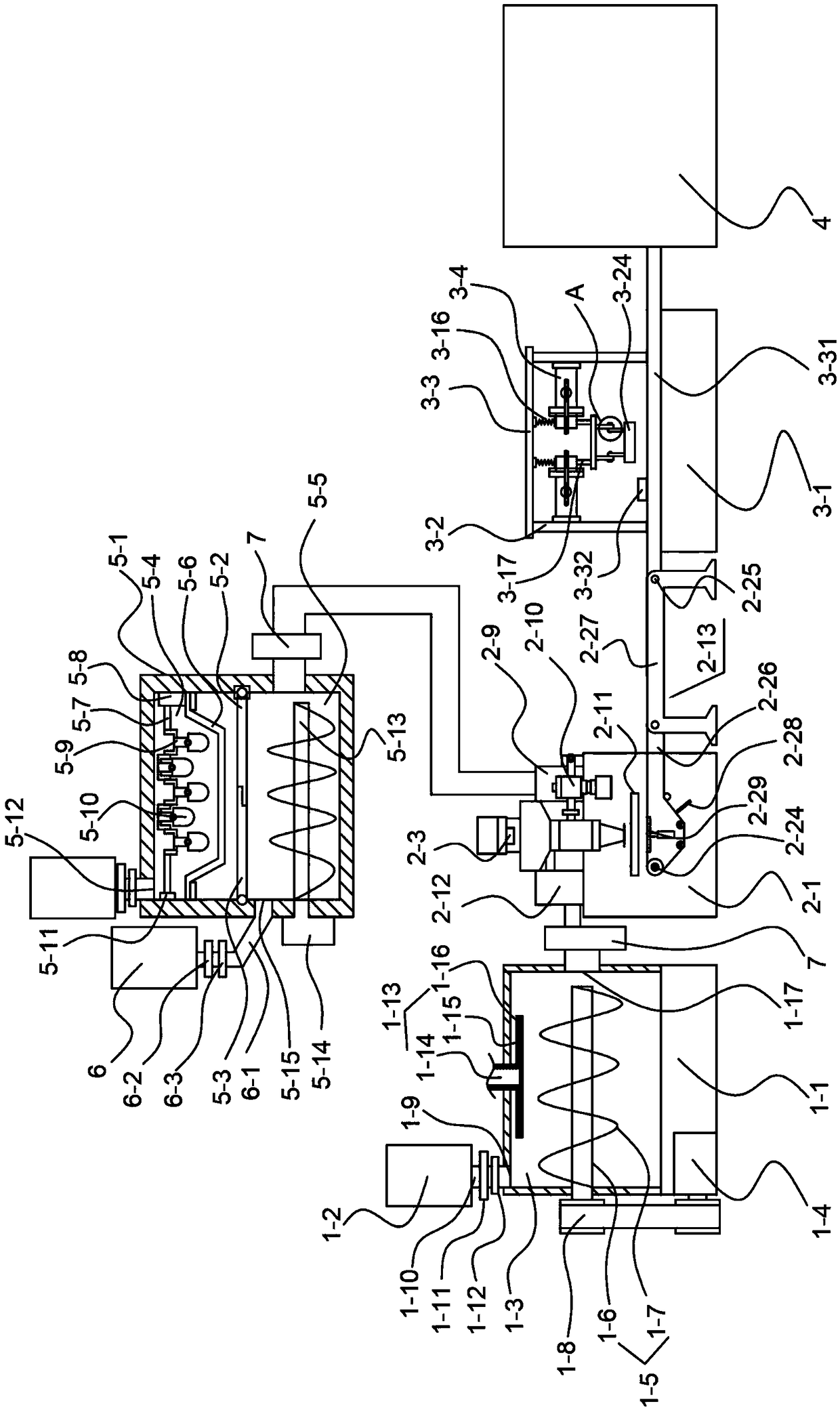

[0043] Such as Figure 1-11 As shown, a mooncake processing and forming equipment includes a dough mixer 1, an encapsulation machine 2, a forming machine 3 and an automatic plate-setting machine 4 connected in sequence; one side of the encapsulation machine 2 is provided with encapsulation mixing and crushing Machine 5;

[0044] The dough mixer 1 includes a base 1-1, a flour storage box 1-2 and a kneading cylinder 1-3 fixedly arranged above the base 1-1, and one end of the base 1-1 is provided with a motor 1-4 , the mixer 1-3 is provided with an agitator 1-5, the agitator 1-5 includes a rotating shaft 1-6 and a helical stirring blade 1-7, and the output shaft of the motor 1-4 passes through a pulley 1-8 is connected with the rotating shaft 1-6; the top of the kneading cylinder 1-3 is provided with a powder inlet 1-9 near the side of the motor 1-4, and the flour storage box 1-2 It is connected to the powder inlet 1-9 through the screw conveying pipeline 1-10, and the first me...

Embodiment 2

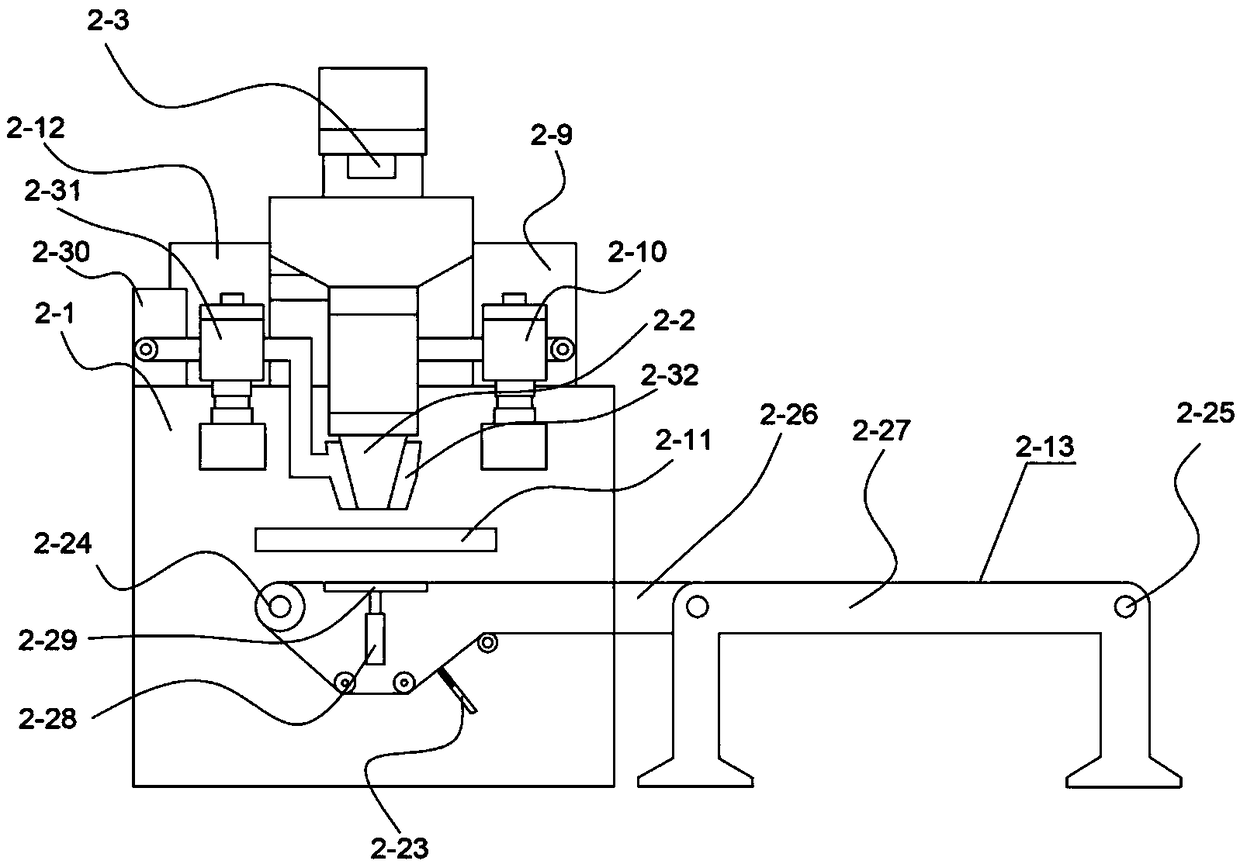

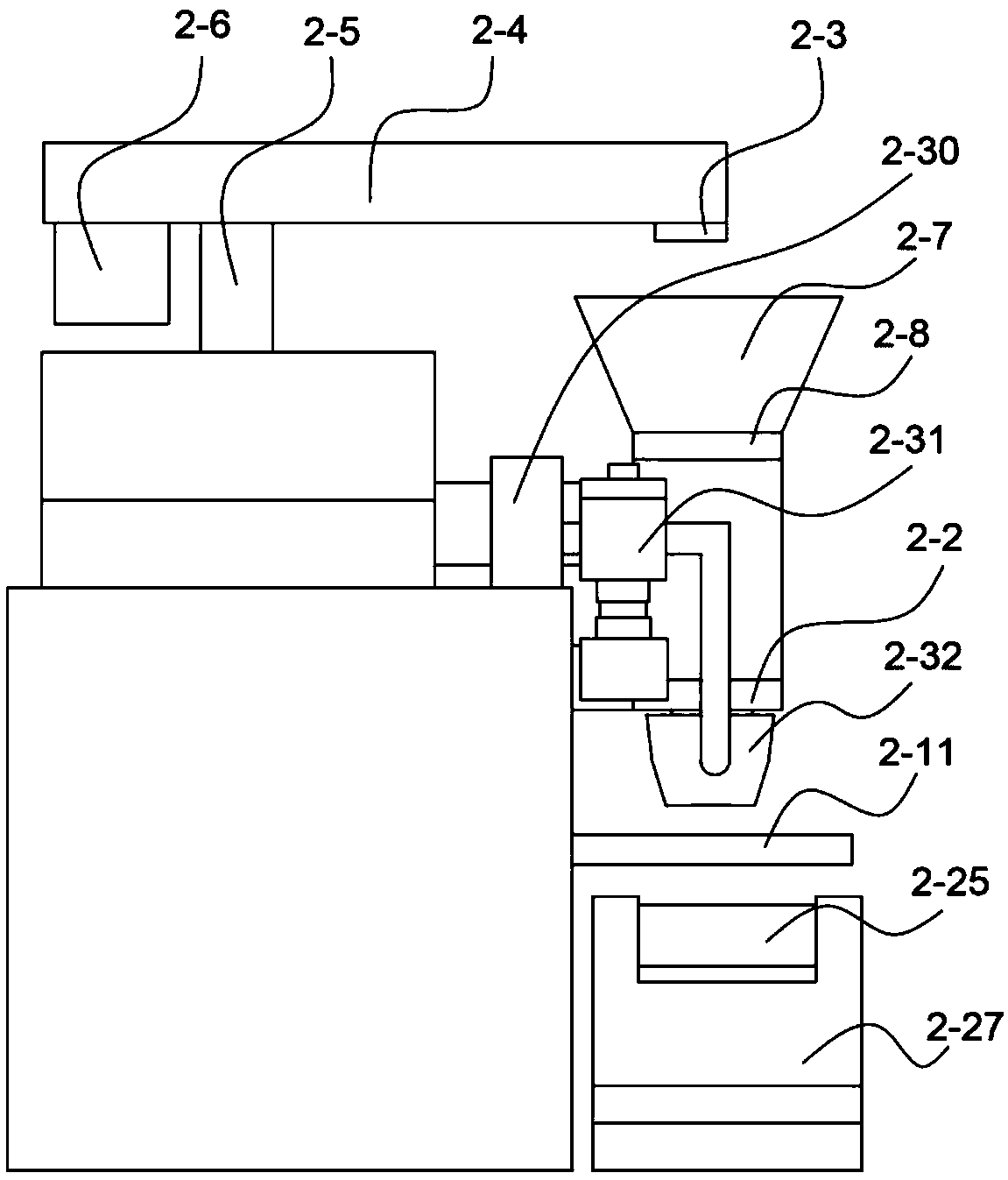

[0048] Such as Figure 1-3 As shown, on the basis of Embodiment 1, this embodiment includes a stuffing machine body 2-1, a cutting device 2-11 and a conveying device 2-13 arranged on the stuffing machine body 2-1. The stuffing machine body 2-1 is provided with the first stuffing box 2-9, the second stuffing box 2-12, the pie crust box 2-30, the horizontal conveying shaft 2-4 and the vertical conveying shaft 2-5, so The first stuffing box 2-9 is connected with the first discharge port 2-2 through the first extrusion device 2-10; the second stuffing box 2-12 is connected with the vertical conveying shaft 2-5, and the horizontal The conveying shaft 2-4 is arranged on the stuffing machine body 2-1 through the vertical conveying shaft 2-5, and one end of the transverse conveying shaft 2-4 is provided with a second discharge port 2-3, and the other end is provided with a driving conveying shaft motor 2-6, the pie crust box 2-30 is connected with a third discharge port 2-32 through ...

Embodiment 3

[0053] Such as Figure 4-10 As shown, in this embodiment, on the basis of Embodiment 1, the molding machine 3 includes a workbench 3-1, and both sides of the upper surface of the workbench 3-1 are fixedly connected with support rods 3-2. The top of the support rod 3-2 is fixedly connected with a top plate 3-3, and the opposite sides of the two support rods 3-2 are symmetrically provided with two drive devices 3-4, and the drive device 3-4 includes a drive box 3-4. 5, and one side of the drive box 3-5 is fixedly connected with the support rod 3-2, the inside of the drive box 3-5 is fixed with a drive motor 3-6, and the output shaft of the drive motor 3-6 runs through the drive box 3-5 and extends to the outside of the drive box 3-5, the protruding end of the output shaft of the drive motor 3-6 is fixedly connected with a disc 3-7, and the first drive rod 3 is eccentrically arranged on the disc 3-7 -8, the side of the driving box 3-5 away from the support bar 3-2 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com