Metal coiled material surface embossing device based on same-side arrangement of rolling and discharging

A metal coil material, retractable material technology, applied in the direction of decorative art, embossed ornaments, etc., can solve the problems of easy tension, large footprint, and inability to become

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be described below in conjunction with specific embodiments.

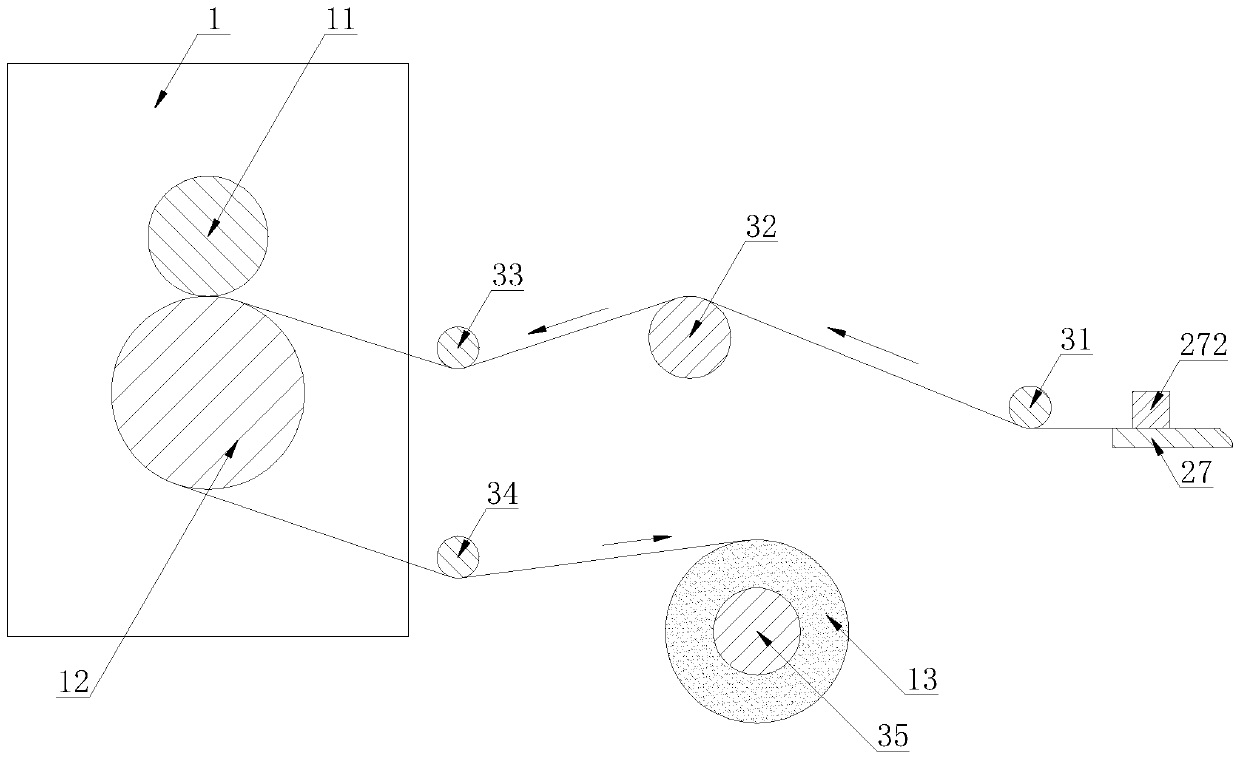

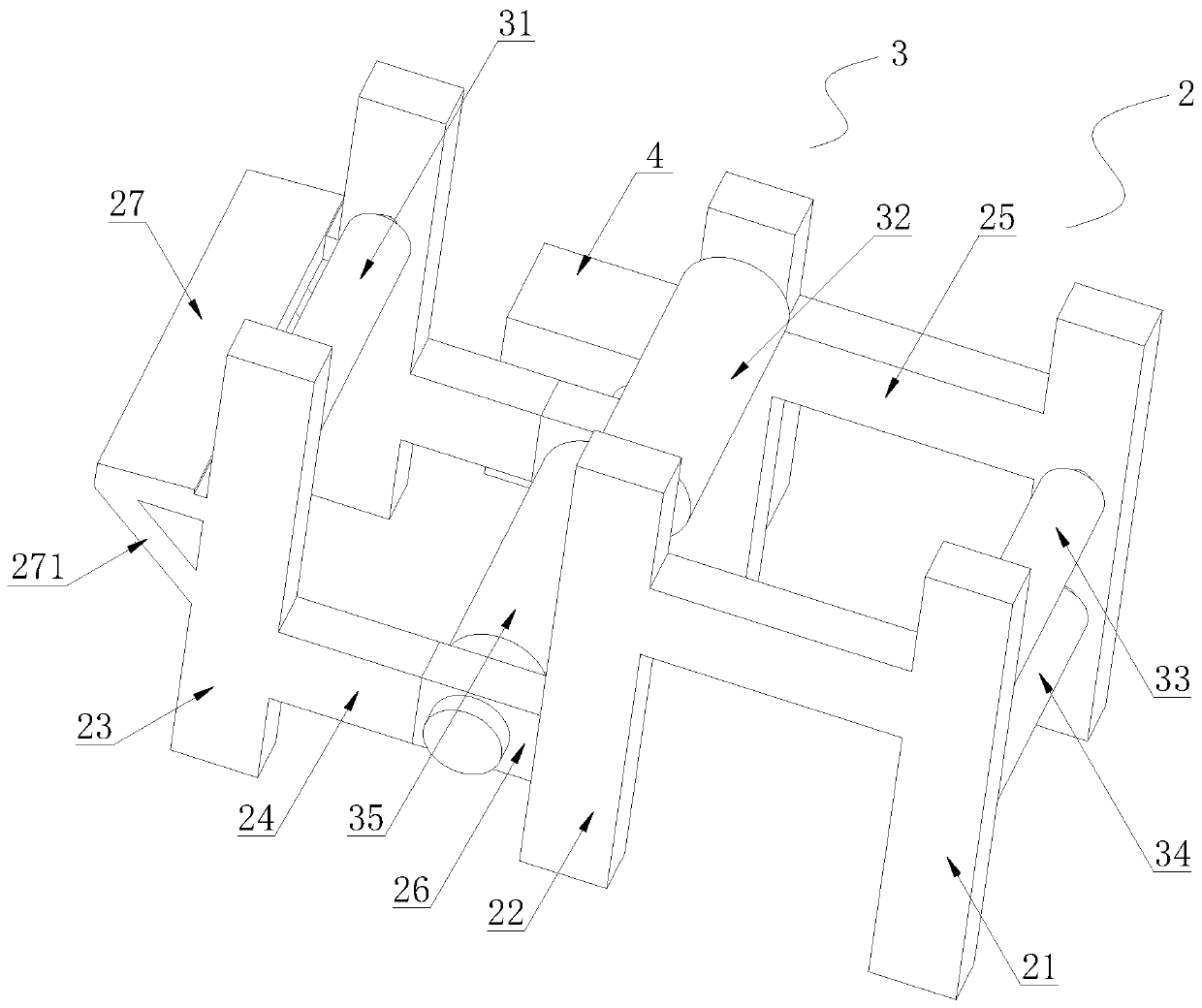

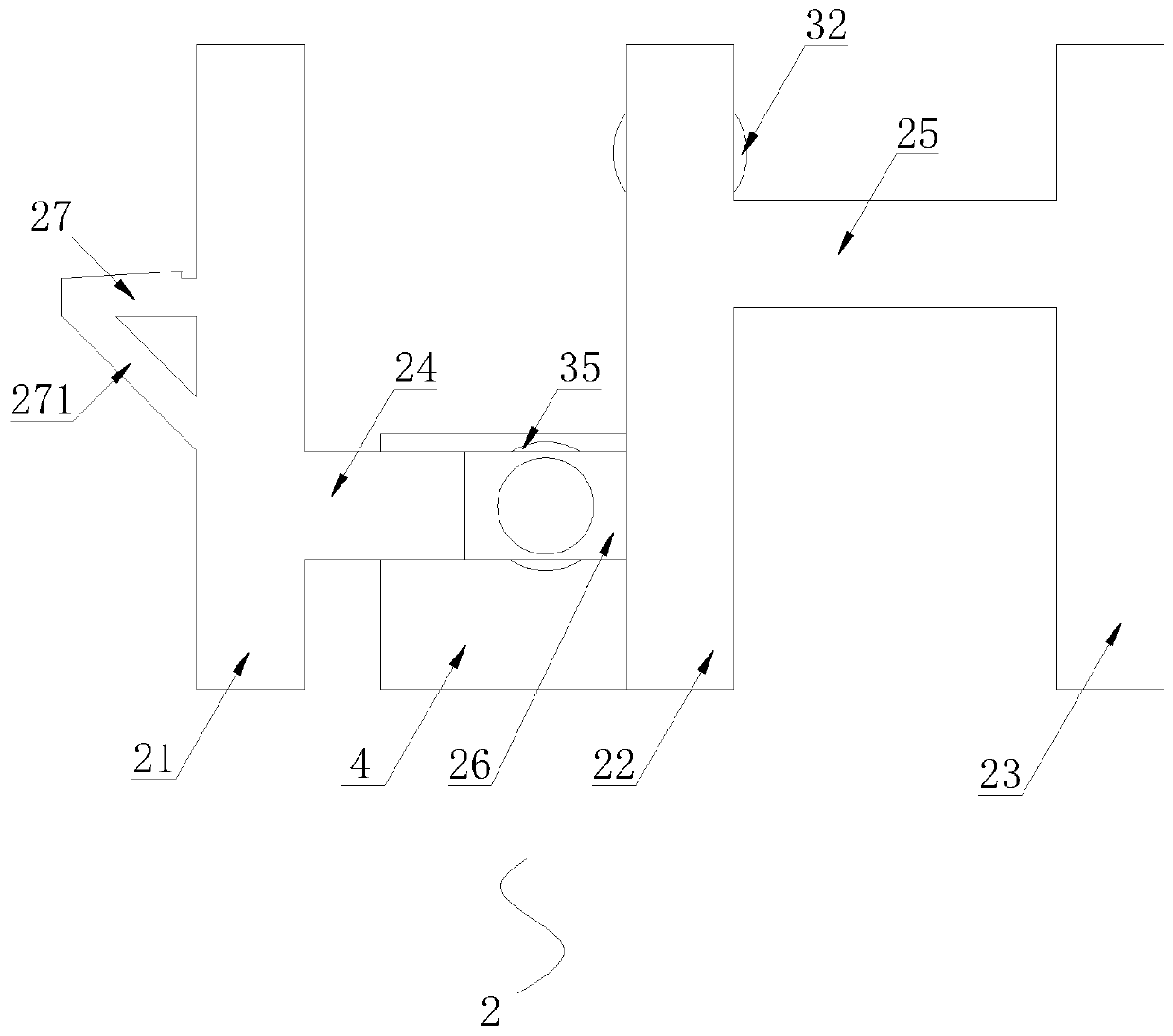

[0020] figure 1 It is a schematic diagram of the embossing tension position, figure 2 It is a schematic diagram of the overall structure of the frame and the feeding roller of the receiving roller, such as figure 1 and figure 2 As shown, the embossing device of the present invention is used for embossing a plate 13 and includes: a support 1 on which an upper embossing roller 11 and a lower embossing roller 12 are installed. Also includes: frame 2, according to the order of feeding, the first tension roller 31, the feeding roller 32, the second tension roller 33, the third tension roller 34, and the receiving roller 35 are successively installed on the frame 2 .

[0021] Both the feeding roller 32 and the receiving roller 35 are located on the same side of the support 1 , and the axes of the feeding roller 32 and the receiving roller 35 are not located on the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com