Automatic clamping and mounting equipment for synchronous chain wheel assembly

A technology for installing equipment and synchronous chains, which is applied to transmission devices, mechanical equipment, metal processing equipment, etc., can solve problems such as troublesome installation of chains and sprockets, and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-7 The application is described in further detail.

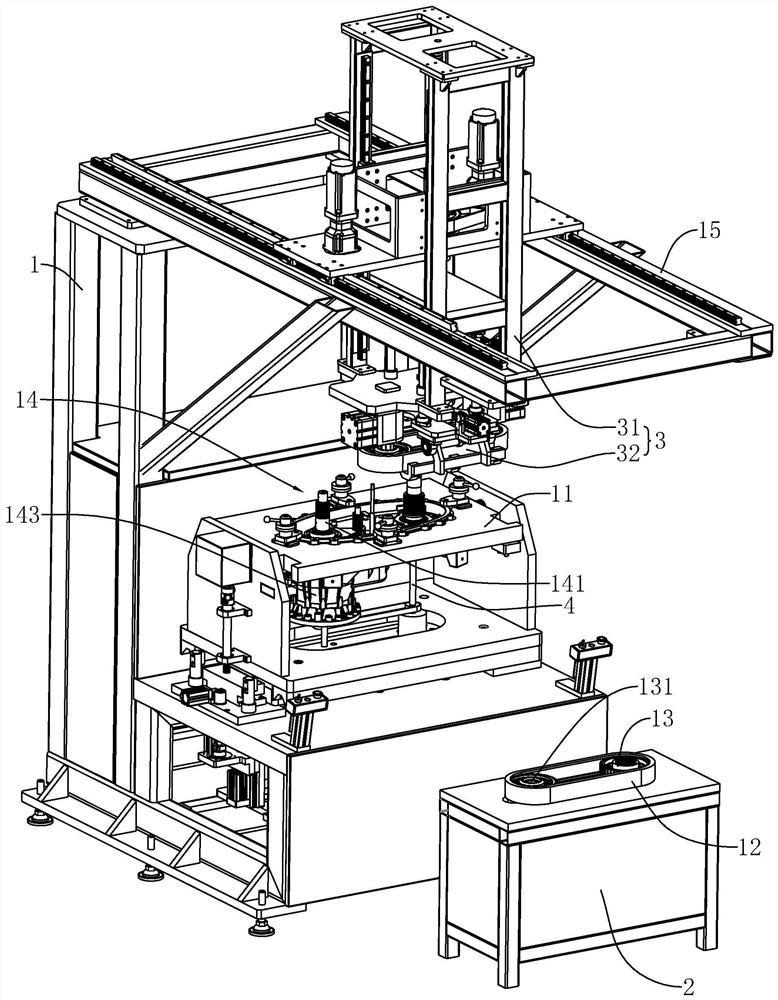

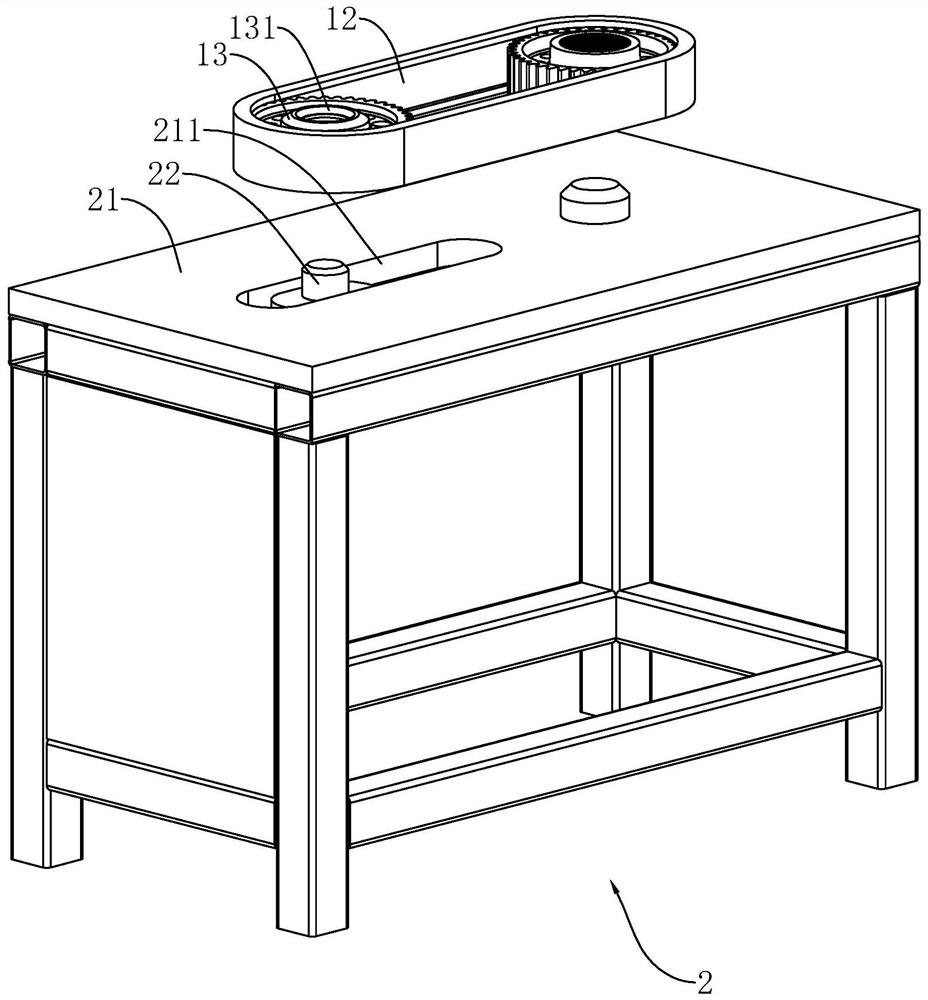

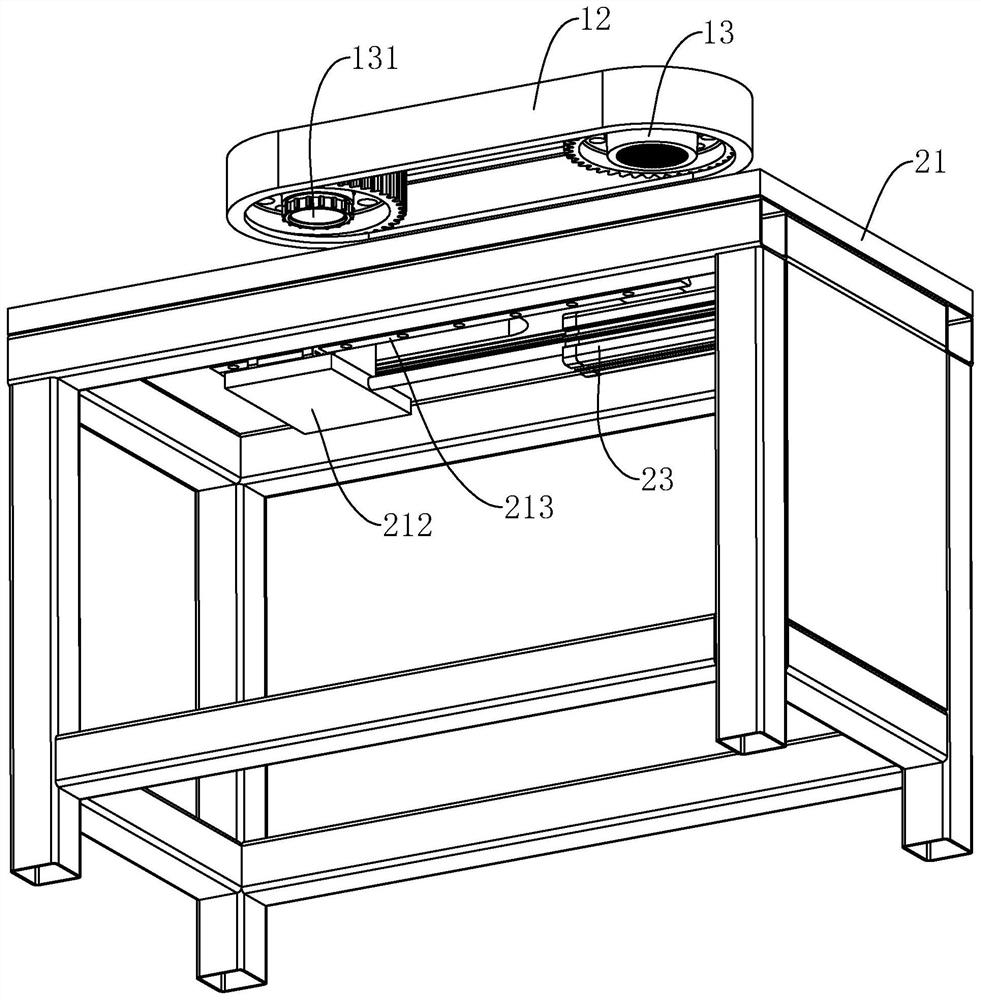

[0042] refer to figure 1 , there is such a workpiece 14, the workpiece 14 includes an A module and a B module, and the A module includes two sprockets 13 and a chain 12 tensioned on the two sprockets 13, and each sprocket 13 is coaxially provided with a shaft hole 131 , the B module includes a base 143 and two rotating shafts 141 rotatably connected to the base 143 , the two rotating shafts 141 correspond to each other and are installed in the shaft holes 131 of the sprocket 13 .

[0043] The embodiment of the present application discloses an automatic clamping and installing device for a synchronous sprocket assembly, which is used for assembling workpieces.

[0044] refer to figure 1 An automatic clamping and installing device for a synchronous sprocket assembly includes a frame 1 , a stage 11 mounted on the frame 1 , and a tensioning device 2 placed on one side of the stage 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com