Automatic feeding, grabbing and installing integration device for screen cloth

A technology of automatic feeding and automatic feeding, applied in thin material handling, transportation and packaging, separation of objects, etc., can solve the problems of difficult to grasp accurately, impossible to achieve, poor grasping effect, etc., to improve production efficiency and increase compaction. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

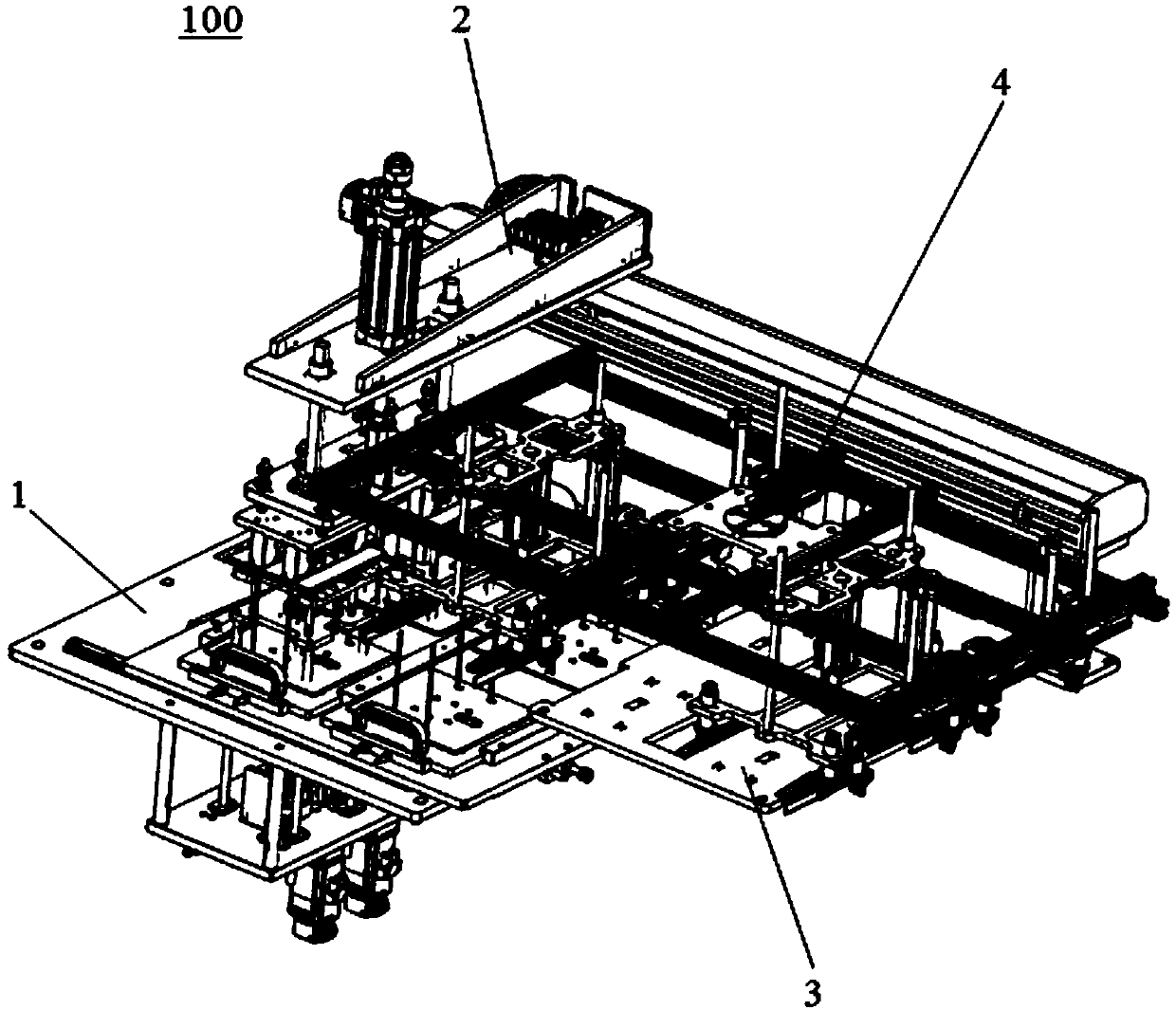

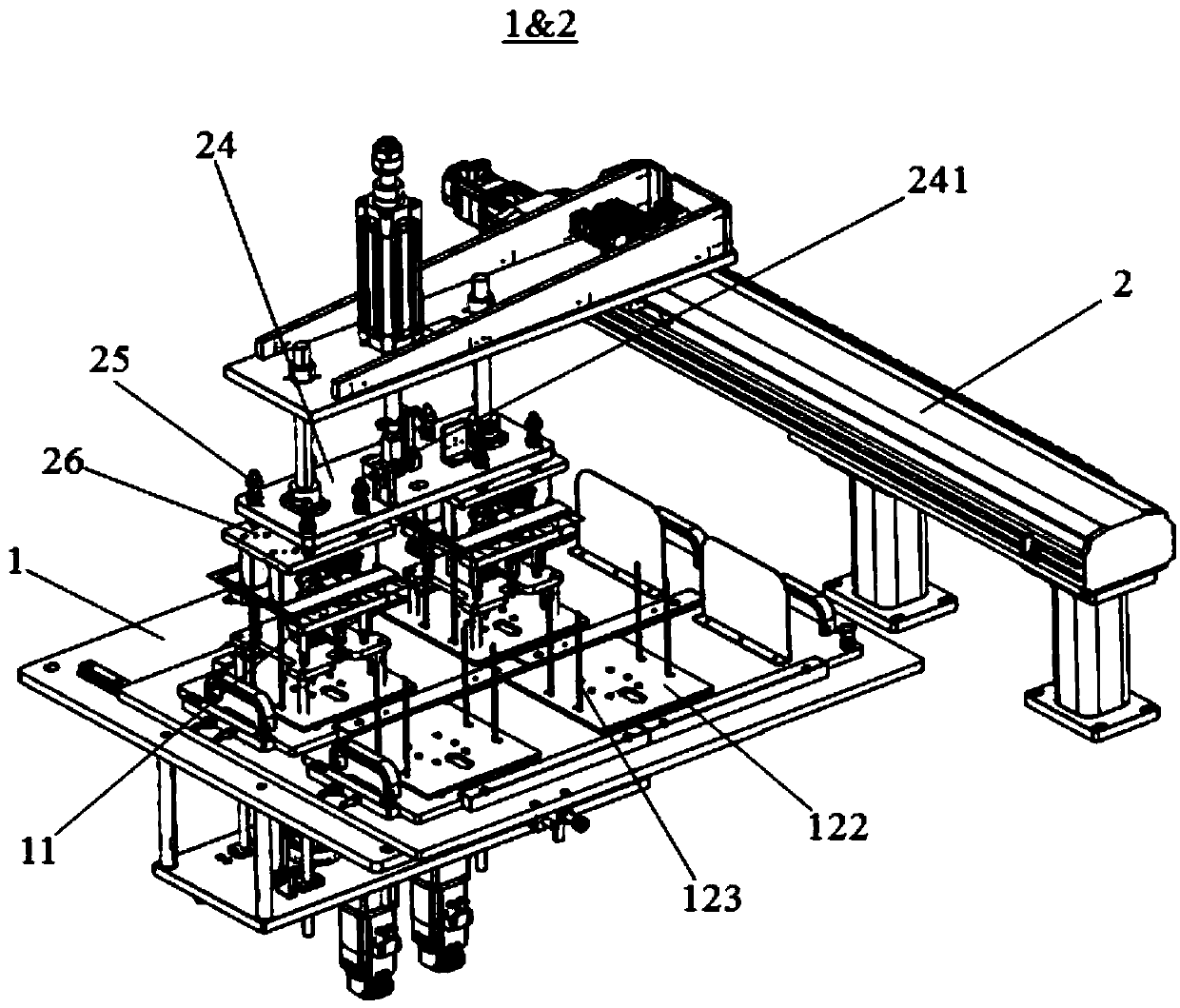

[0036] Please refer to Figure 1-Figure 8 , the present embodiment is an integrated device 100 for automatic feeding, grasping and installation of mesh cloth, which includes an automatic mesh cloth feeding unit 1, a floating mesh cloth grabbing unit 2, a mesh cloth transfer unit 3, and a mesh cloth cover installation gripper Unit 4.

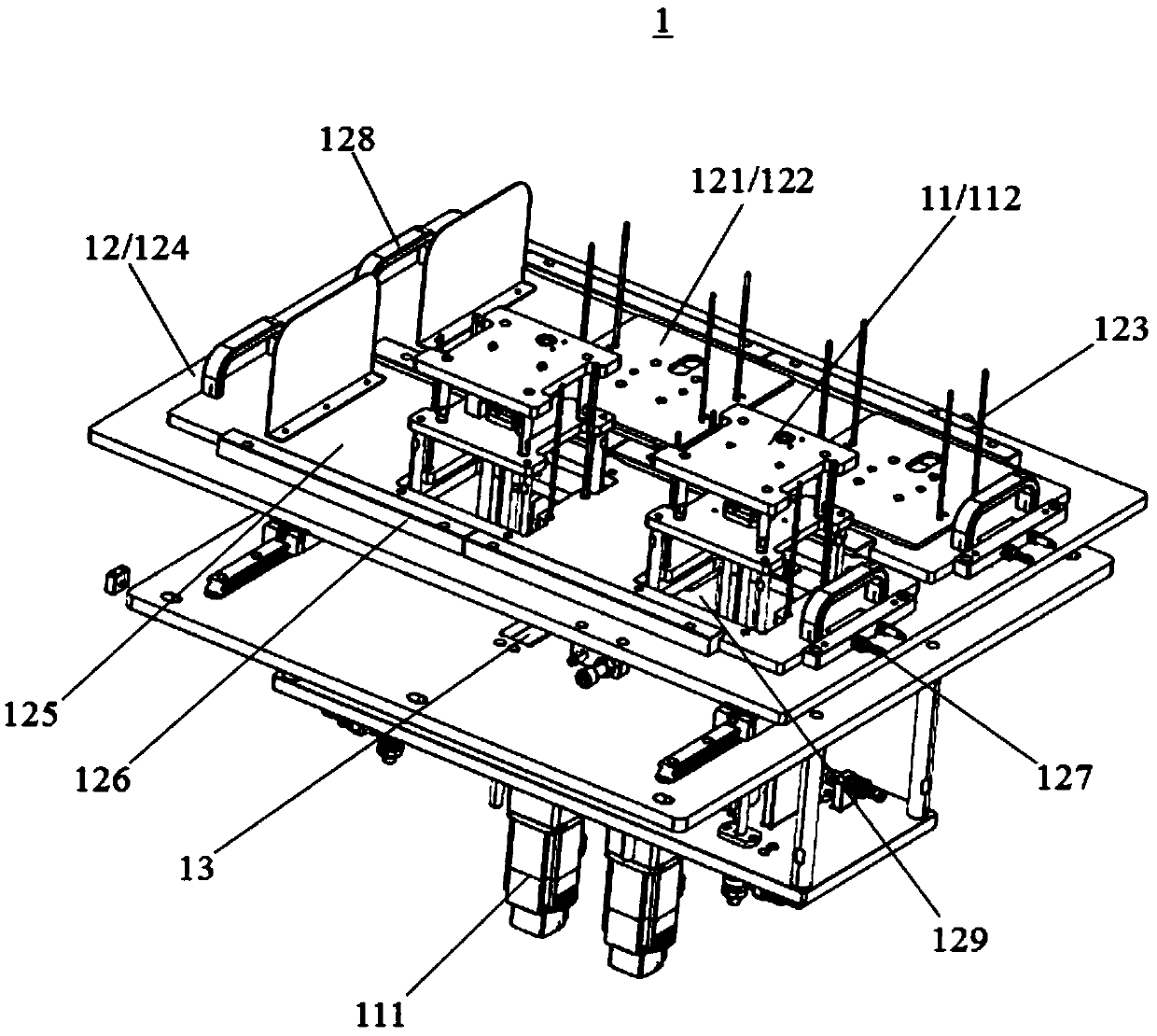

[0037] Please refer to Figure 2-Figure 3 , Mesh automatic feeding unit 1 is provided with a mesh feeding station and a mesh replenishment station. A jacking device 11 is provided on the mesh feeding station, and the mesh automatic feeding unit 1 includes a material receiving tray 12, which drives the material receiving tray 12 at the mesh feeding station and the mesh replenishment. The first driving member 13 for switching between stations.

[0038] Two independent silo units 121 are arranged on the material receiving tray 12. In order to improve the installation efficiency of the mesh cloth and match the number of products injection molded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com