Heating system of continuous annealing wire drawing machine

A technology of heating system and wire drawing machine, applied in the field of continuous annealing wire drawing machine, which can solve the problems that the temperature is difficult to be fully utilized, the drawing tension is inconvenient to adjust, and the position of the steel wire is easy to change during transmission, so as to achieve the change of tension degree and simple operation , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

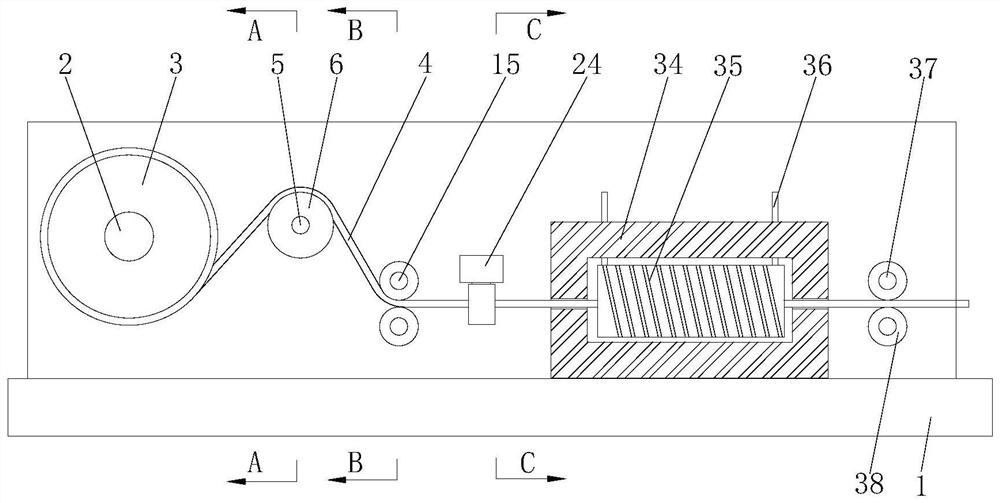

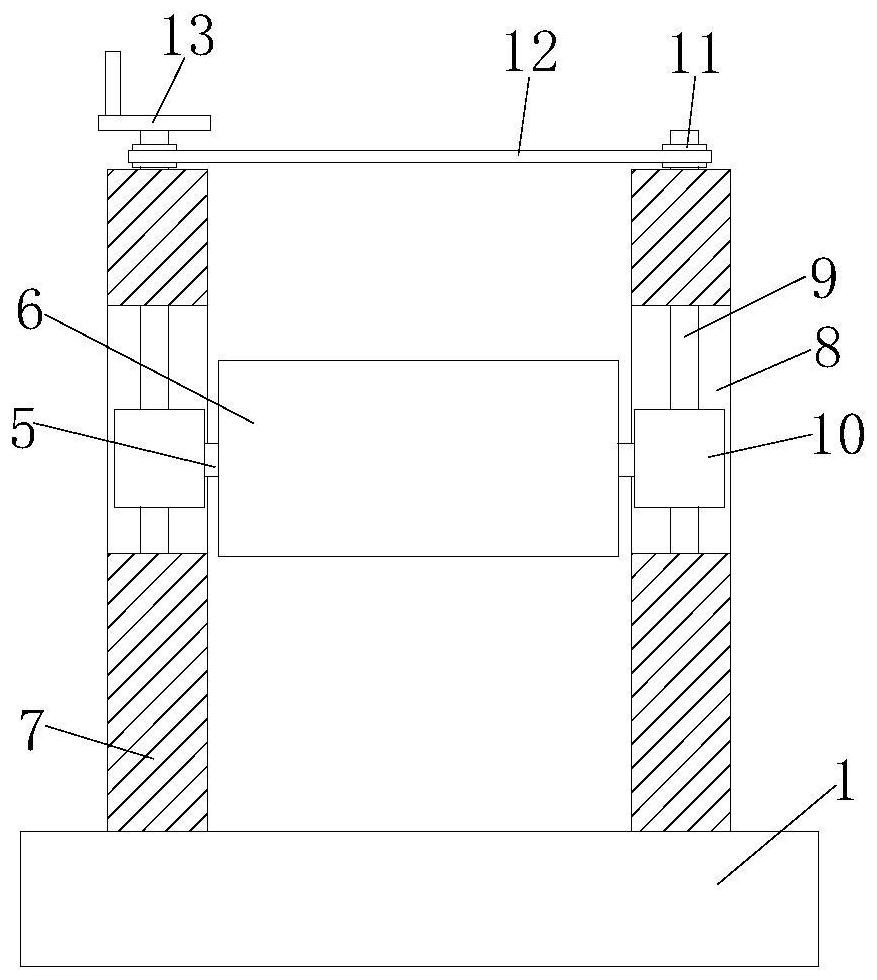

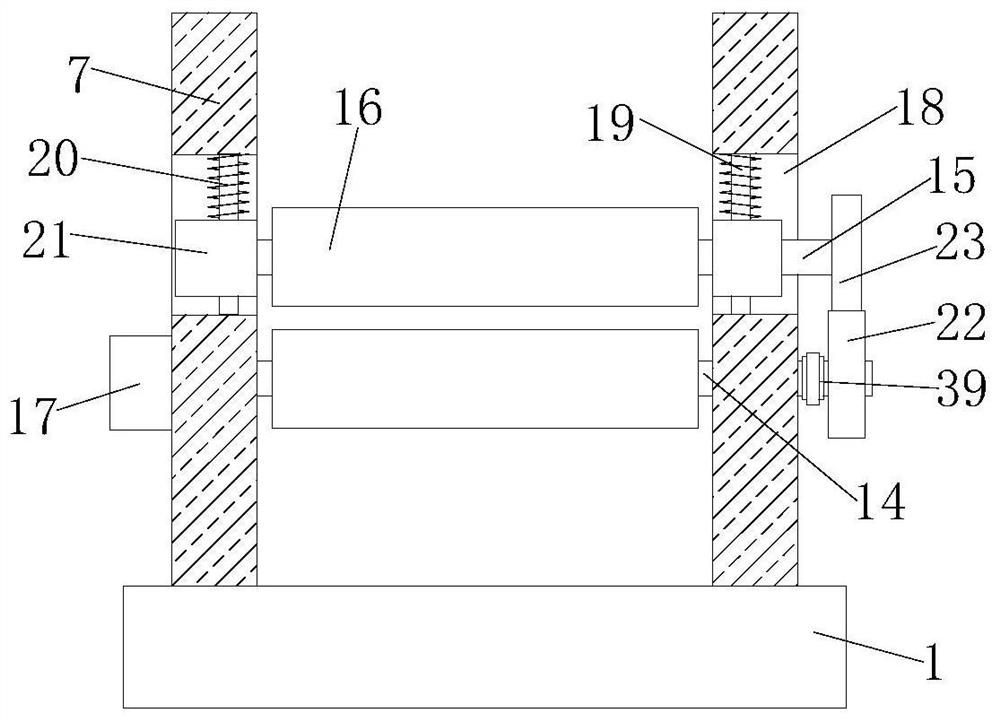

[0029] refer to Figure 1-5 , a heating system for a continuous annealing wire drawing machine, comprising a base 1, two symmetrically arranged support plates 7 are fixedly installed on the top of the base 1, and a first rotating shaft 2 is rotationally connected to the two supporting plates 7, and the first rotating shaft 2 The outer fixed sleeve is provided with a pay-off roller 3, and the outer side of the pay-off roller 3 is wound with a copper wire 4, and the second rotating shaft 5 is rotatably connected to the two support plates 7, and the outer fixed sleeve of the second rotating shaft 5 is provided with a tension roller 6 A third rotating shaft 14 and a third rotating shaft 14 are rotatably connected to the two support plates 7, and the outer sides of the third rotating shaft 14 and the fourth rotating shaft 15 are fixedly sleeved with guide rollers 16, and are fixedly installed between the two support plates 7. On the same fixed plate 24, two symmetrical clamping blo...

Embodiment 2

[0040] refer to Figure 1-5 , a heating system for a continuous annealing wire drawing machine, including a base 1, two symmetrically arranged support plates 7 are welded on the top of the base 1, and a first rotating shaft 2 is rotatably connected to the two supporting plates 7, and the outer side of the first rotating shaft 2 The fixed sleeve is provided with a pay-off roller 3, the outer side of the pay-off roller 3 is provided with a copper wire 4, the second rotating shaft 5 is rotatably connected to the two support plates 7, and the outer fixed sleeve of the second rotating shaft 5 is provided with a tension roller 6, The third rotating shaft 14 and the third rotating shaft 14 are rotatably connected to the two supporting plates 7, and the outer sides of the third rotating shaft 14 and the fourth rotating shaft 15 are fixedly sleeved with guide rollers 16, and the two supporting plates 7 are welded with the same The fixed plate 24 is slidably connected with two symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com