Rice Seedling Seeder

A technology for raising rice seedlings and seeding machine, applied in the field of seeding machine, can solve the problems of uneven seeding, not enough uniformity, not meeting the requirements of machine planting, etc., and achieve the effect of improving seeding uniformity and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

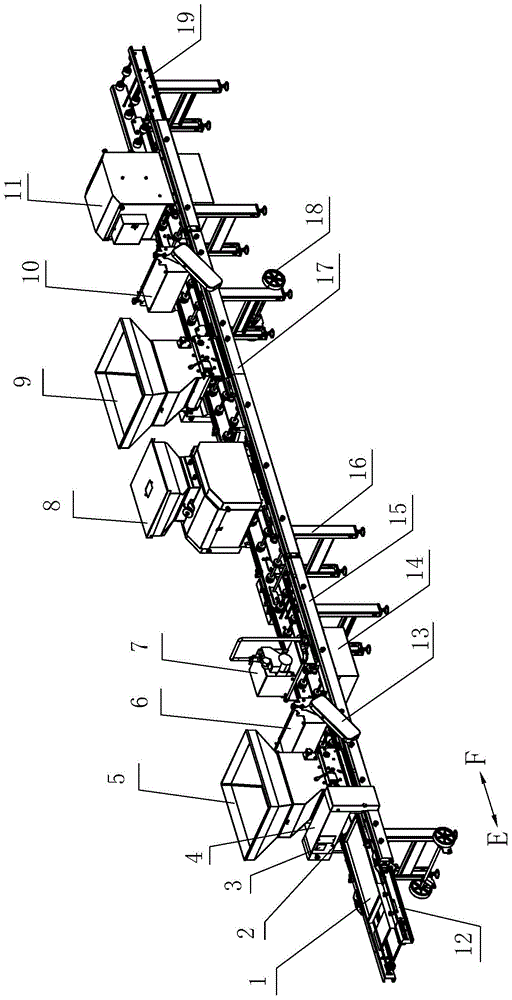

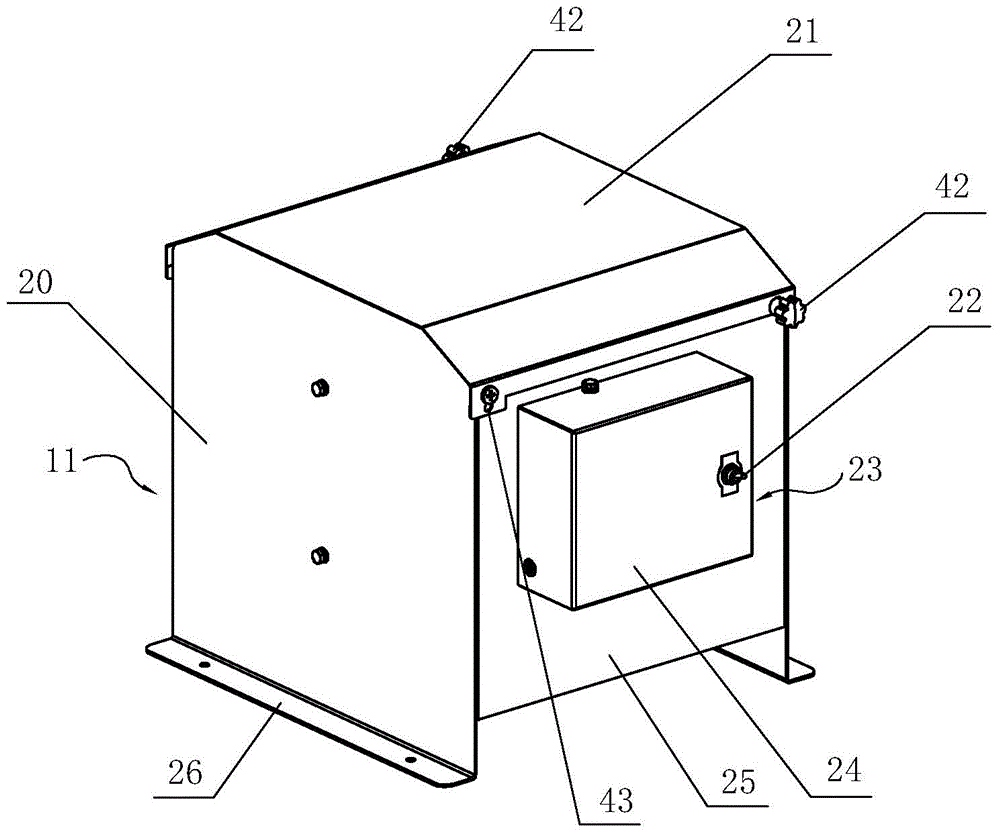

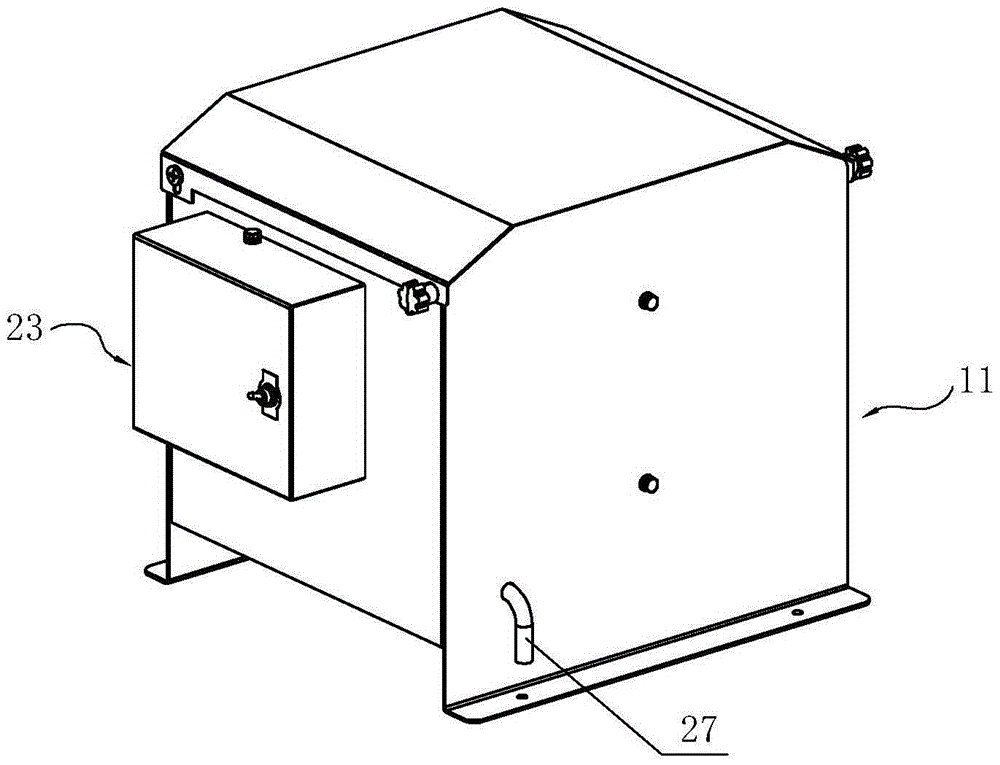

[0038] Such as Figure 1 to Figure 17 As shown, the rice seedling planter of the present invention includes a support frame 16, a conveying guide rail, a conveying motor, a soil laying device 5, a soil brushing device I6, a water spray device 7, a seeding device 8, a soil covering device 9, and a soil brushing device II10. The conveying guide rail is arranged on the support frame 16, and the conveying motor, the soil spreading device 5, the soil brushing device I6, the water spray device 7, the seeding device 8, the soil covering device 9, and the soil brushing device II10 are respectively arranged on the conveying guide rail in sequence. The bottom of the support frame 16 is connected with wheels 18, and the conveying guide rail includes an auxiliary guide rail 12 located at the front end, a soil-laying guide rail 15 connected with the auxiliary guide rail 12, a soil-covering guide rail 17 connected with the soil-laying guide rail 15, and an extension guide rail connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com