Patents

Literature

36results about How to "Improve seeding uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

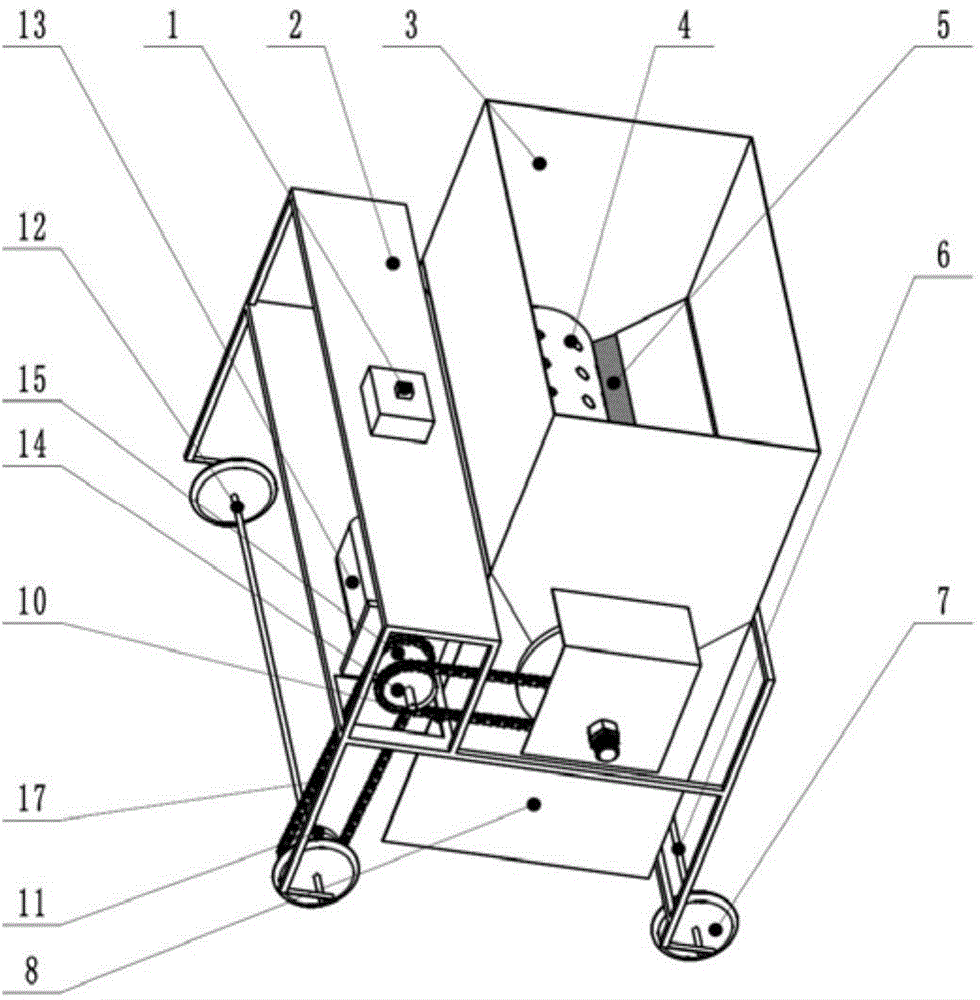

Air-sucking vibration plate type precision seeder for field seedling raising

InactiveCN102550180AImprove seeding uniformity and work efficiencyReduce seedling costSeed depositing seeder partsRegular seed deposition machinesManipulatorBiology

The invention discloses an air-sucking vibration plate type precision seeder for field seedling raising, which relates to the field of agricultural precision seeding and is mainly used for the field precision seedling raising and seeding with the planting density of 1-2 seeds / hole. The precision seeder comprises a machine frame of the seeder, a power source, an air pressure source, a vibration seed plate mechanism, a 2-degree-of-freedom manipulator, a leveling device, a quantitative seed feeding bin, a chuck, a seed guide pipe, a power generation device, a control unit and the like. The vibration seed plate mechanism and the air pressure source are mounted on the machine frame of the seeder, and a small-sized gasoline engine is adopted to supply power. According to the air-sucking vibration plate type precision seeder, the field precision seedling raising and seeding with the planting density of 1-2 seeds / hole is realized, the seeding efficiency and uniformity are effectively improved, the seedling raising cost is reduced, and further, the requirement on the size of seeds is not high, and seeds are not damaged.

Owner:JIANGSU UNIV

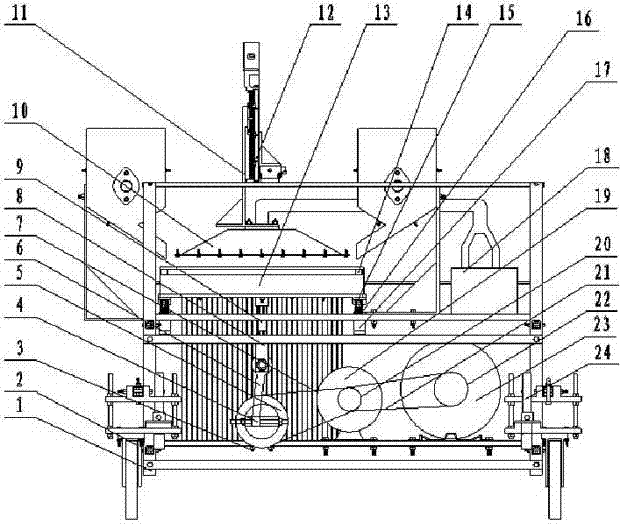

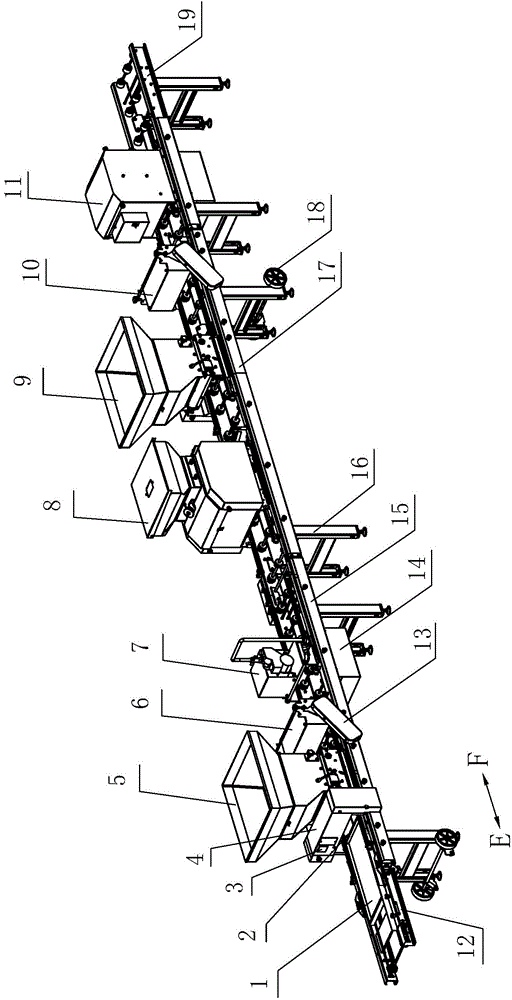

Automatic sowing machine for culturing seddlings in plastic tray

InactiveCN1596577AImprove seedling qualityImprove seeding efficiencyCultivating equipmentsRegular seed deposition machinesEngineeringUltimate tensile strength

An automatic sower for culturing seedlings in plastic trays features that the plastic trays are put on the streamline mechanism composed of conveying belts, and the basic soil applicator, seed sowing unit, covering soil applicator and soil pressing roller are sequentially arranged on the machine frame above said plastic trays.

Owner:桂先富

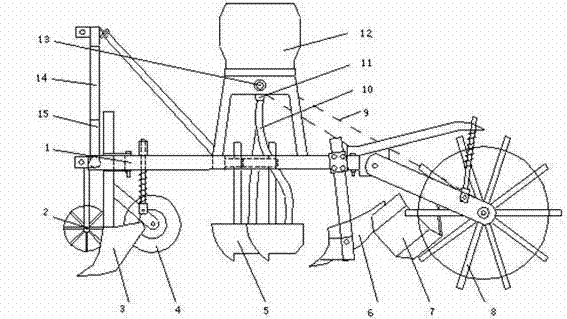

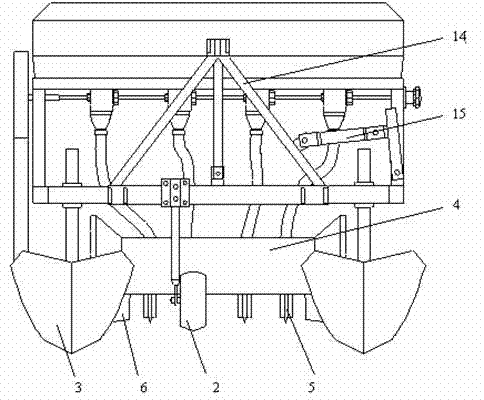

Wheat crop ridge seeding machine

The invention provides a wheat crop ridge seeding machine, relating to the technical field of agricultural machinery, in particular to a wheat crop seeding machine. A frame of the wheat crop ridge seeding machine is connected with a traction locomotive by virtue of a suspension traction frame at the front end, a driving wheel is arranged at the rear end of the frame, a seed storage tank is arranged at the upper part of the frame, a seed sowing device is arranged on the seed storage tank, and the driving wheel is connected with the seed sowing device and drives the seed sowing device by virtue of a transmission chain; the lower part of the frame is sequentially provided with a depth limiting wheel, a single-winged ridging plough, a ridging compacting machine, a seed opener, a ditch cleaning shovel and a ridge reshaping device; and the seed opener is connected with the seed sowing device by virtue of a seed drop tube. A suspension traction system, a ridge body moulding system and a precision drilling system of the seeding machine ensure earthing of a seeding trench to be uniform and ridge trench and ridge surface to be uniform, thus multiple processes such as ridging, sowing and the like can be completed at the same time, and agricultural requirements of high ridging quality, uniform seed discharging and consistent sowing depth can be met.

Owner:INST OF SOIL FERTILIZER & WATER SAVING AGRI GANSU ACAD OF AGRI SCI

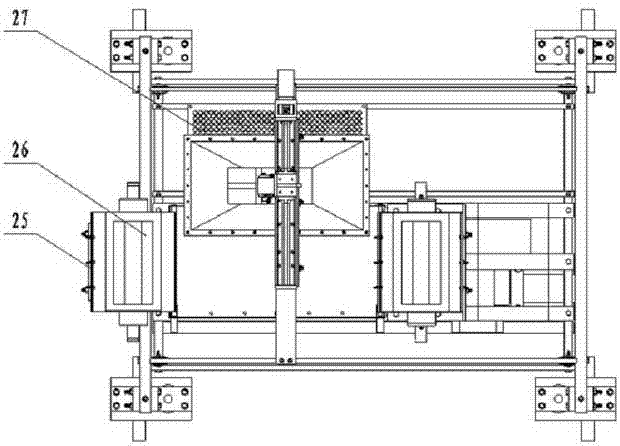

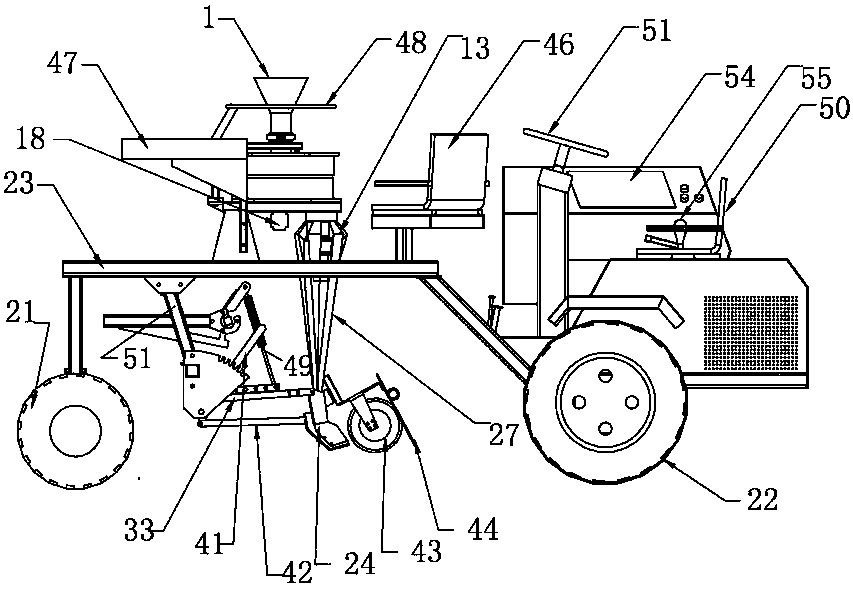

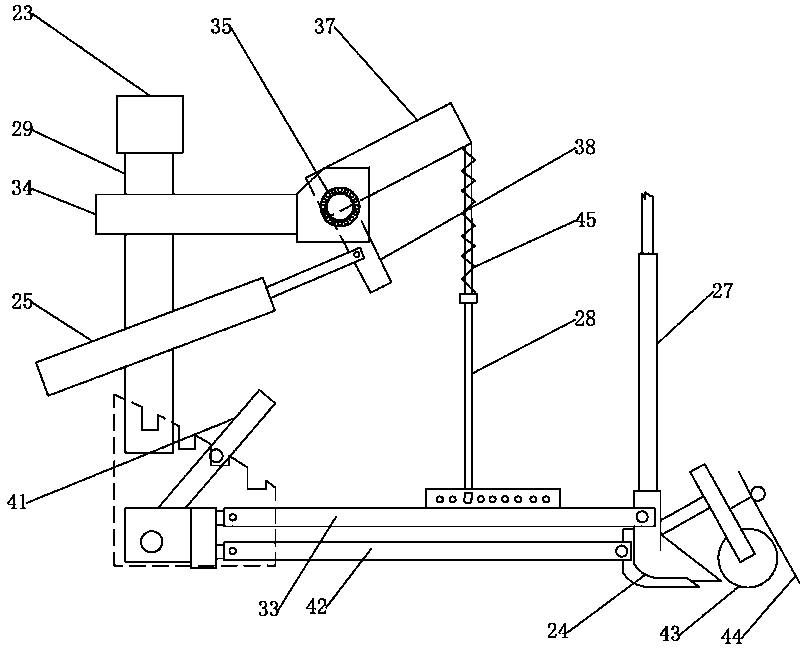

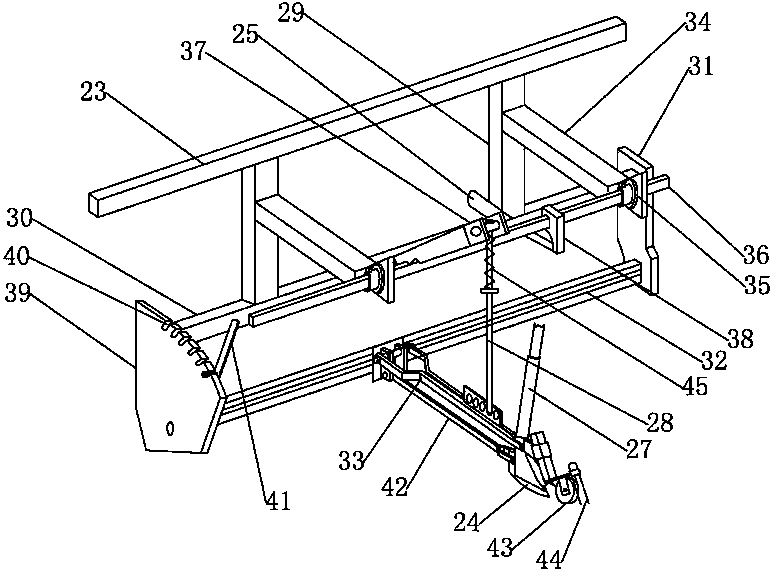

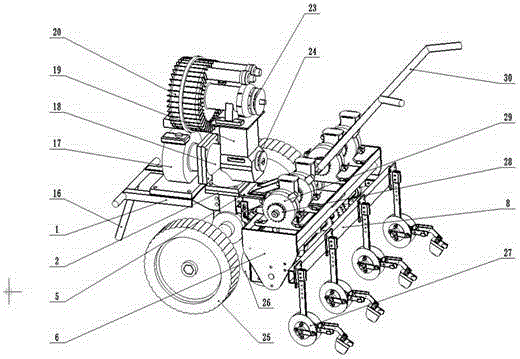

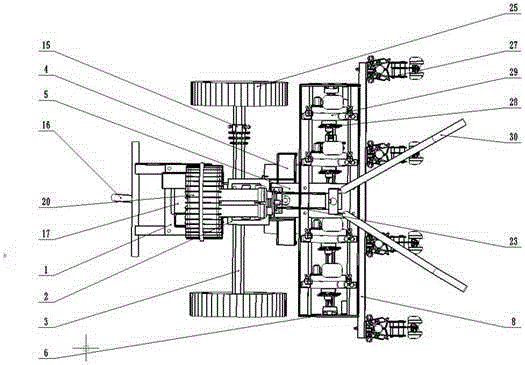

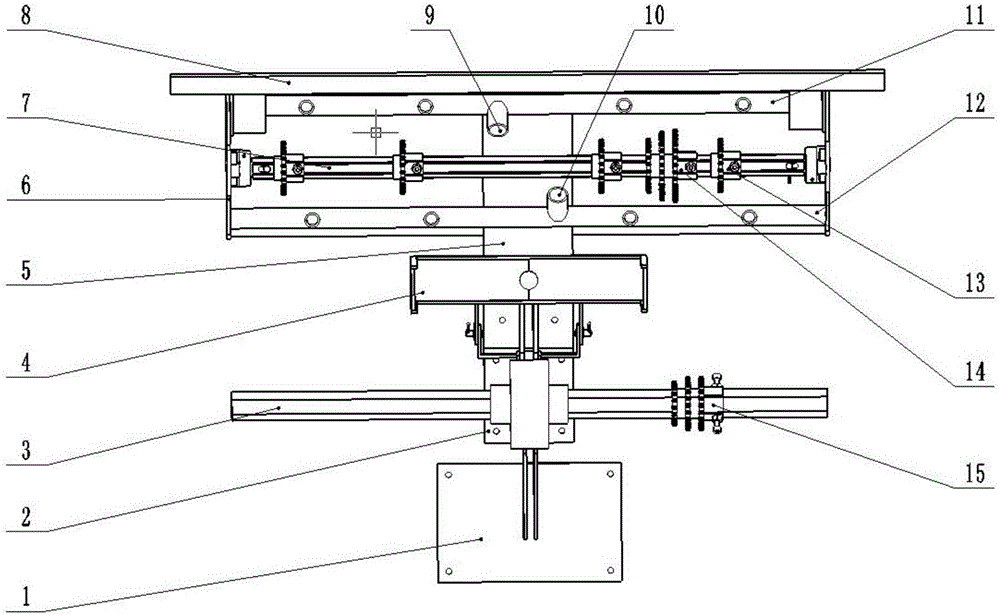

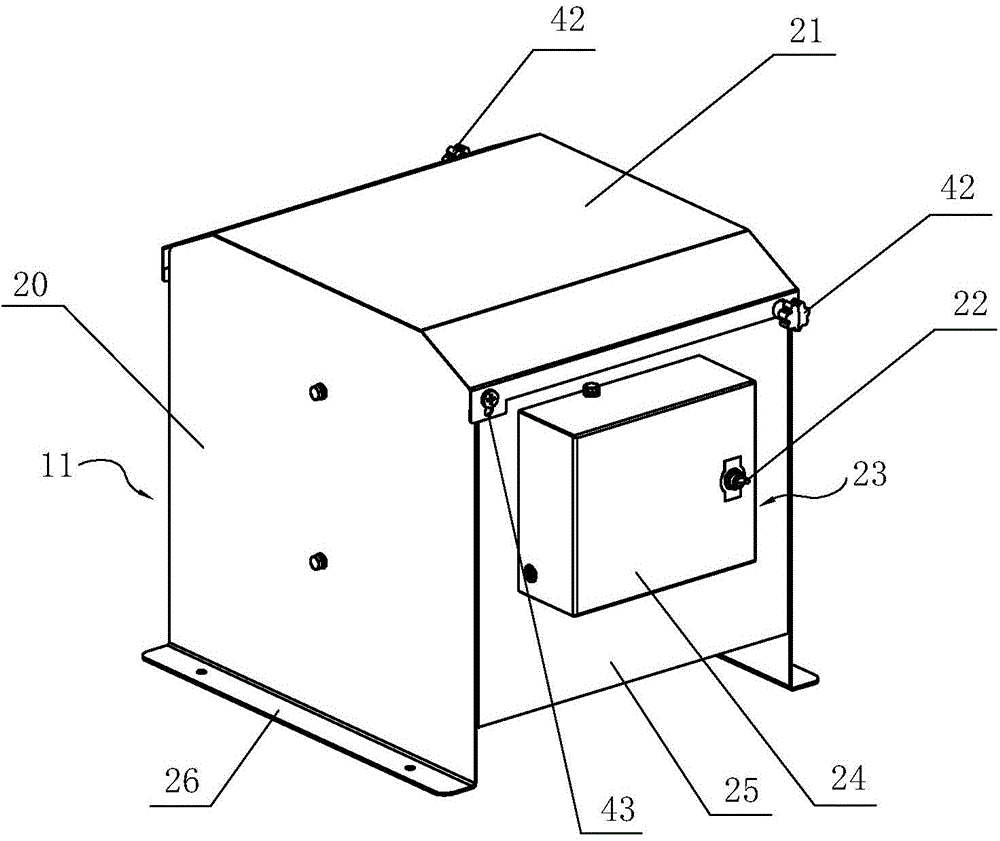

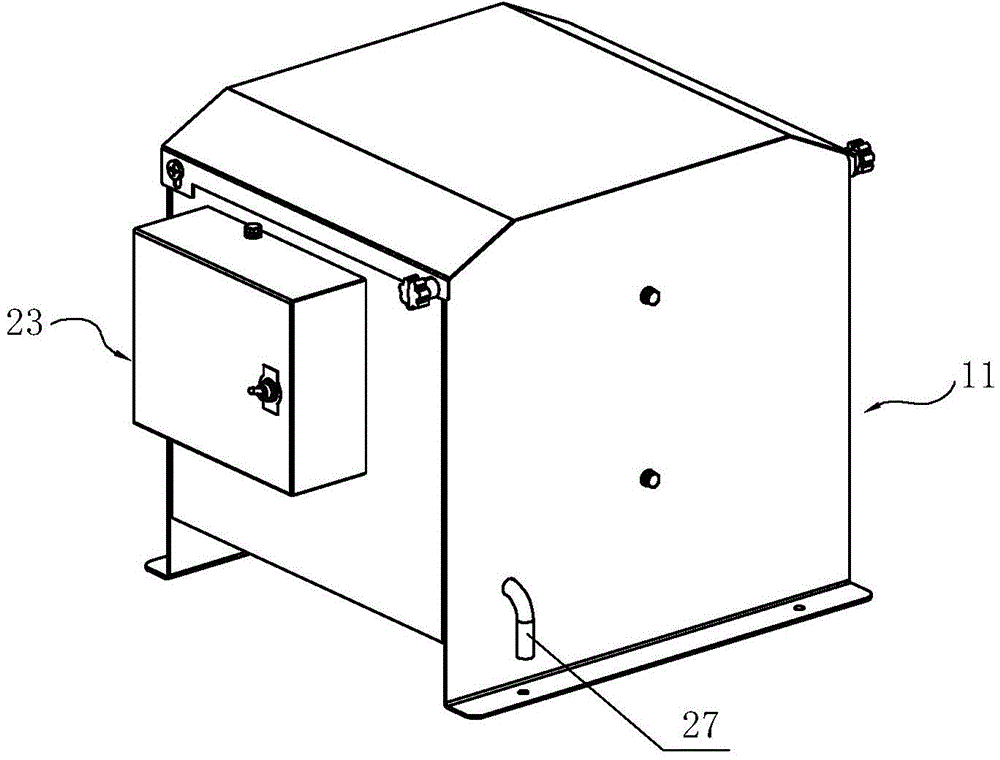

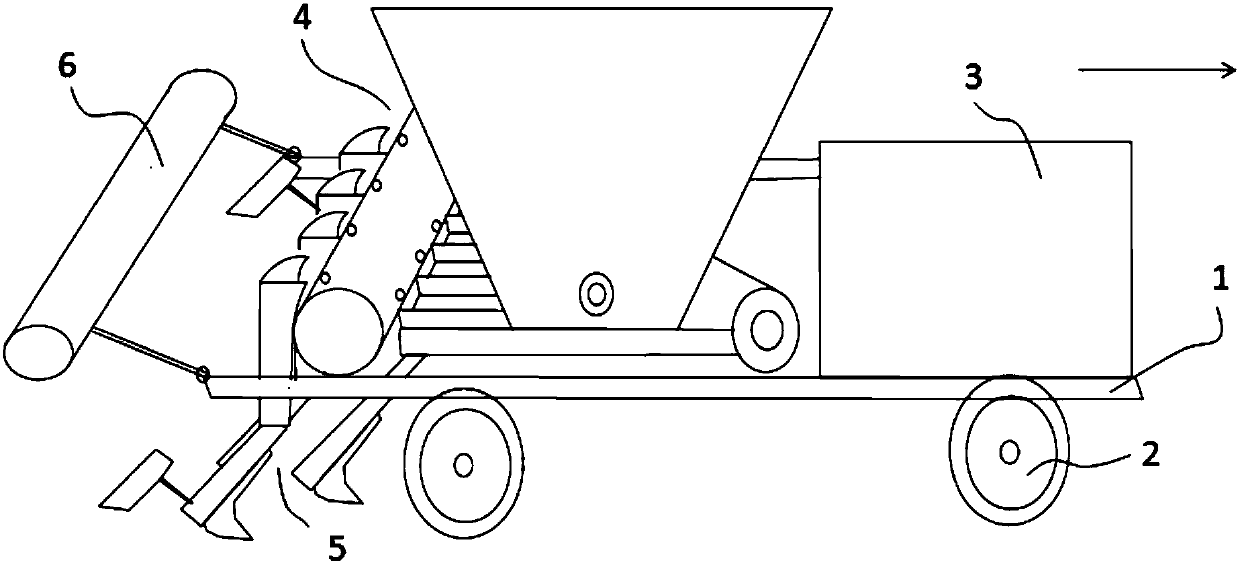

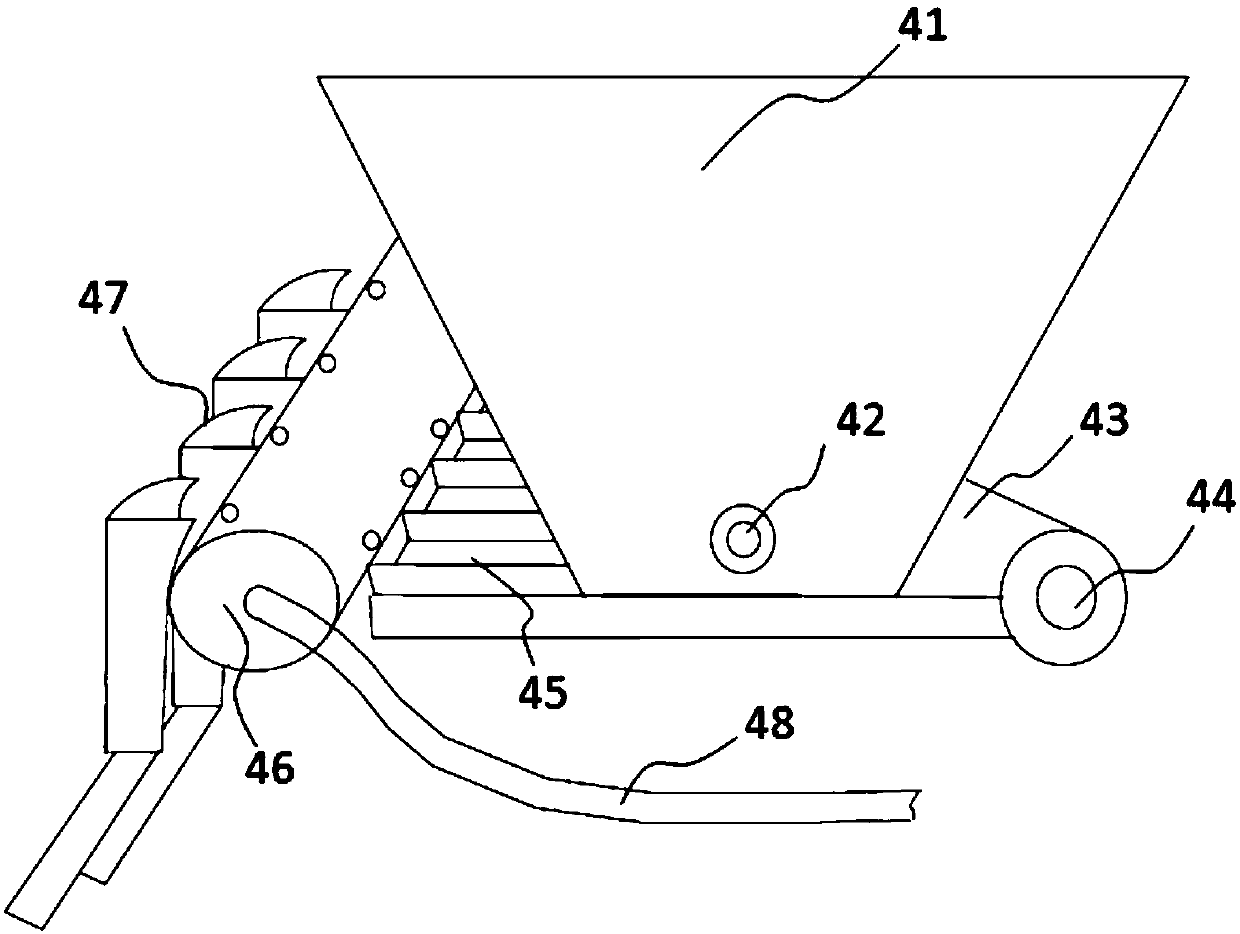

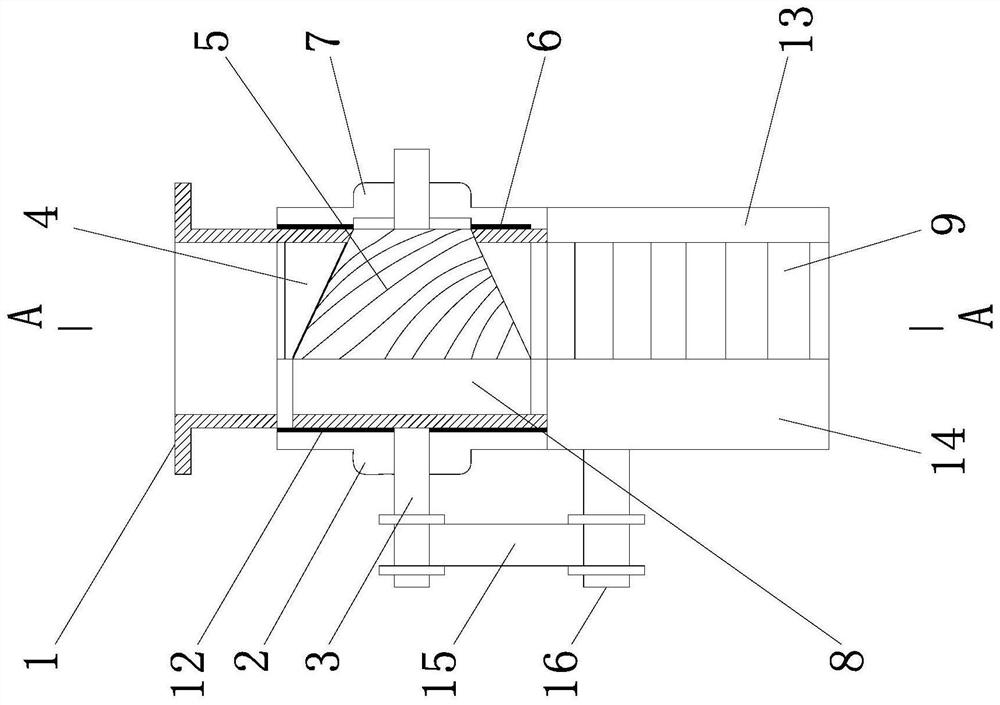

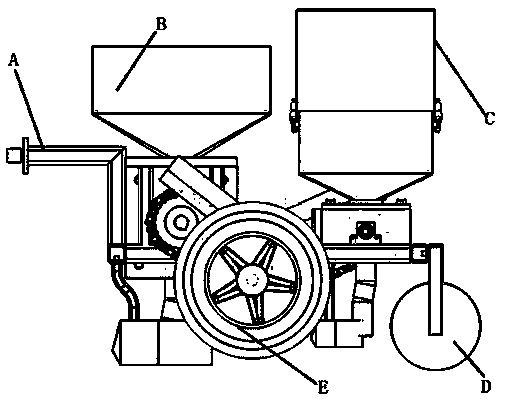

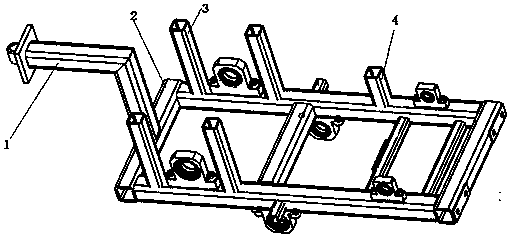

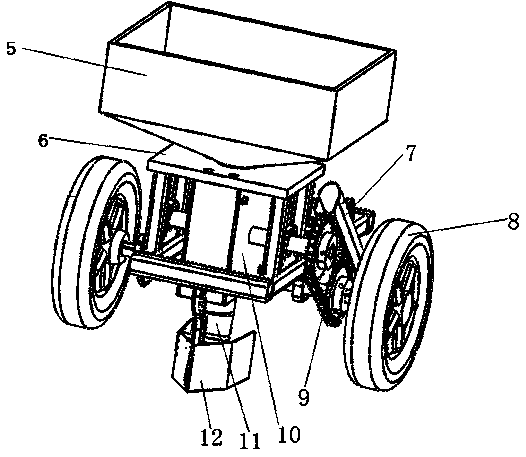

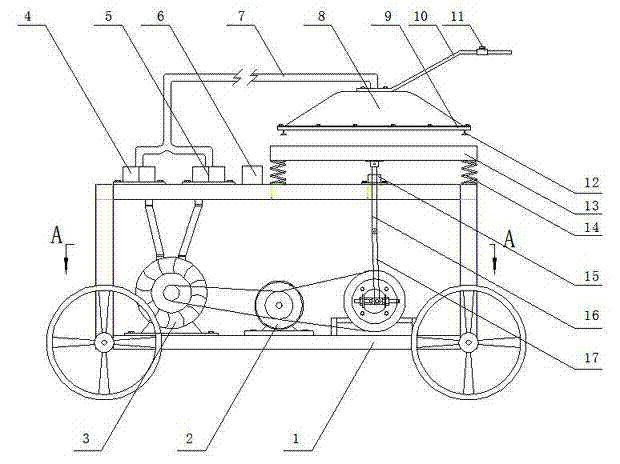

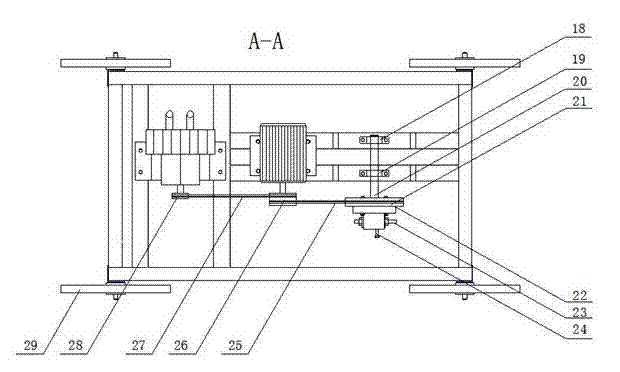

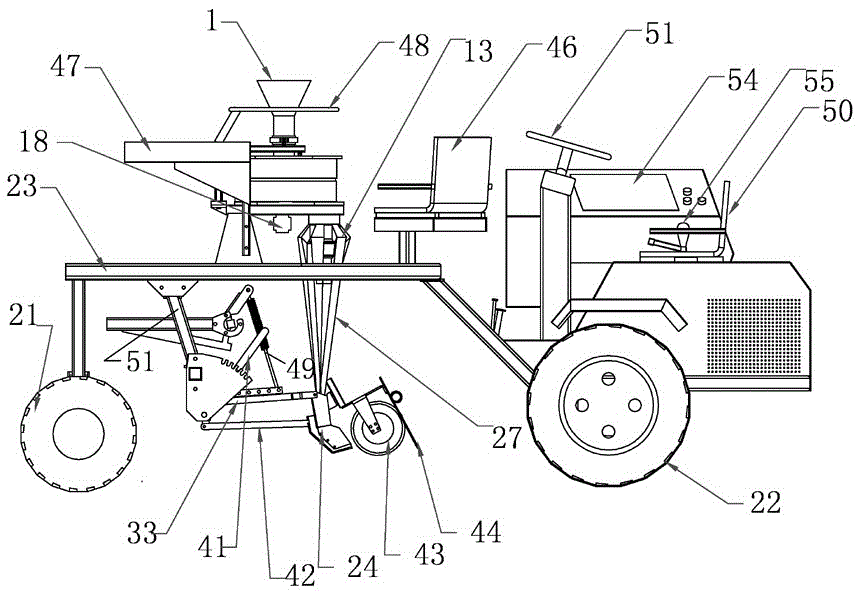

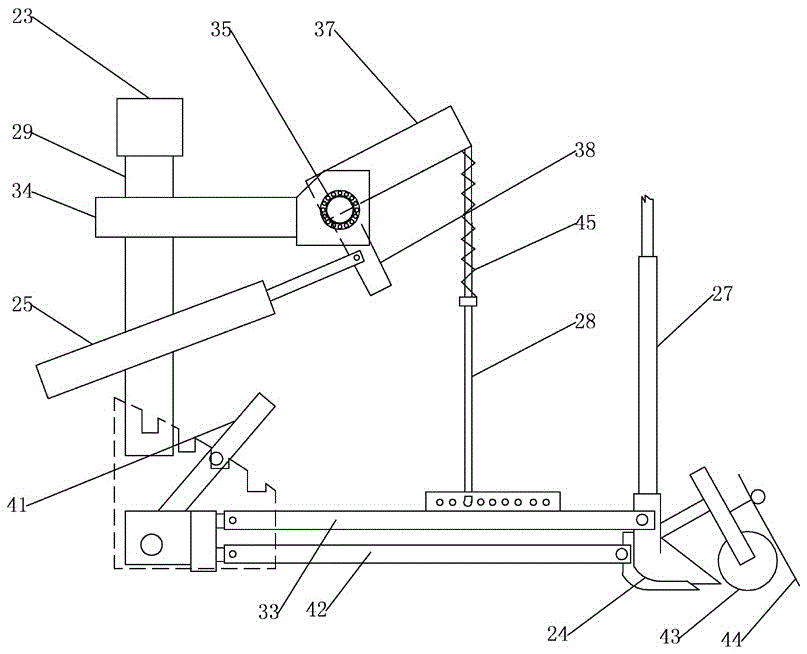

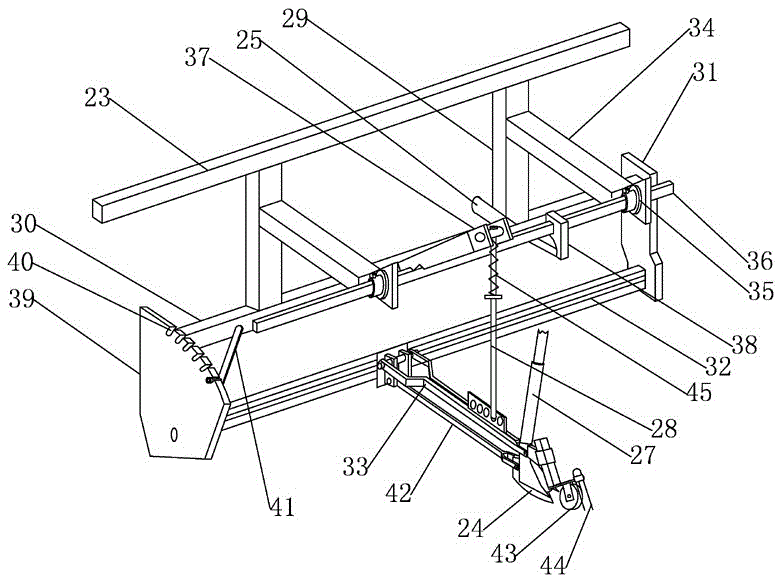

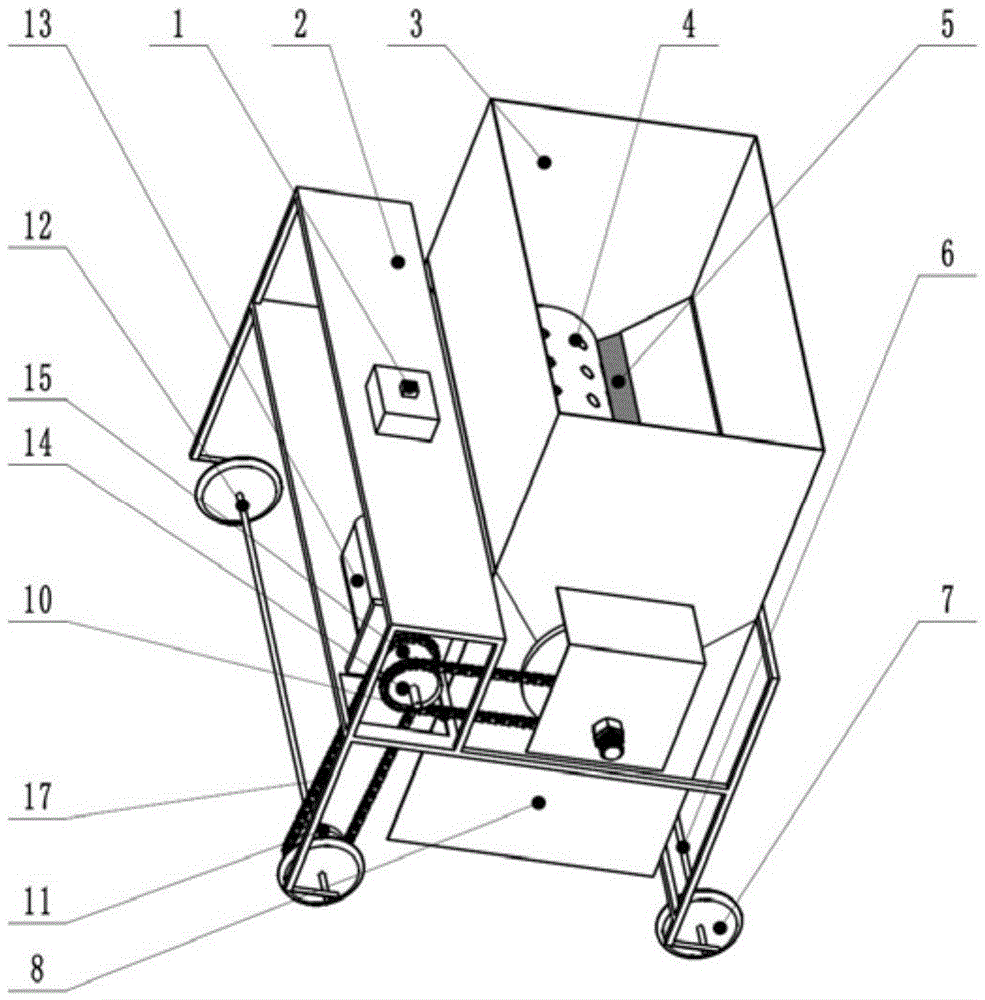

Electric self-propelled numerical-control plot drill seeder

ActiveCN104012222APrecise Control of UniformityEasy to operateSeed depositing seeder partsBroadcast seedersNumerical controlSeeder

The invention relates to an electric self-propelled numerical-control plot drill seeder aiming to solve the technical problems that plot seeders in the prior art are nonuniform in seeding and not precise enough in row length control. The electric self-propelled numerical-control plot drill seeder comprises a walking mechanism, an automatic control device, a seed separation mechanism, a furrowing and seeding mechanism and a lifting mechanism, and the seed separation mechanism, the furrowing and seeding mechanism and the lifting mechanism are correspondingly arranged on the walking mechanism; the seed separation mechanism comprises a seed separation unit and a seed storage unit, the seed separation unit is arranged above the furrowing and seeding mechanism, and the seed storage unit is arranged above the seed separation unit; the walking mechanism is an electric walking mechanism; the seed separation unit comprises a seed separation disc, a seed separation servo motor or a seed separation stepping motor, and the seed separation servo motor or the seed separation stepping motor is arranged below the seed separation disc, and drives the seed separation disc to rotate; the electric self-propelled numerical-control plot drill seeder has the advantages of uniform between-row and in-row seeding, high degree of automation, stepless row length setting (arbitrary row length setting), high row length control accuracy, simple operation, high sowing efficiency and the like.

Owner:李延民

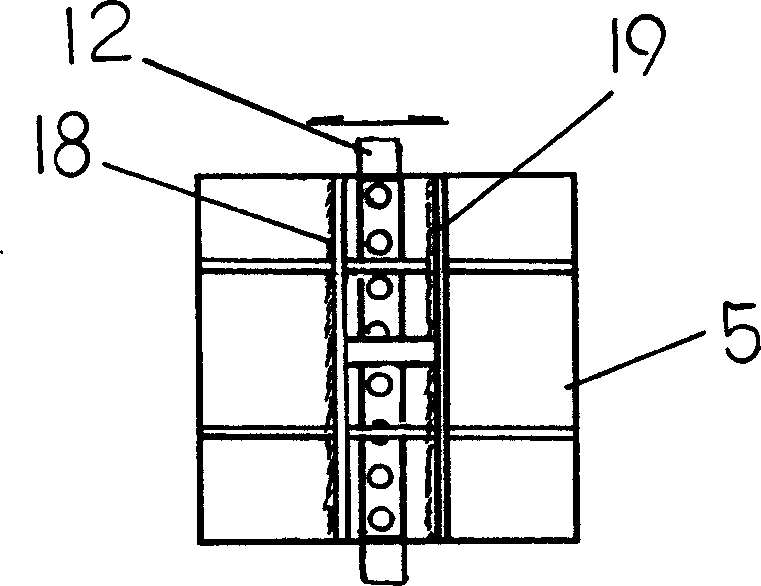

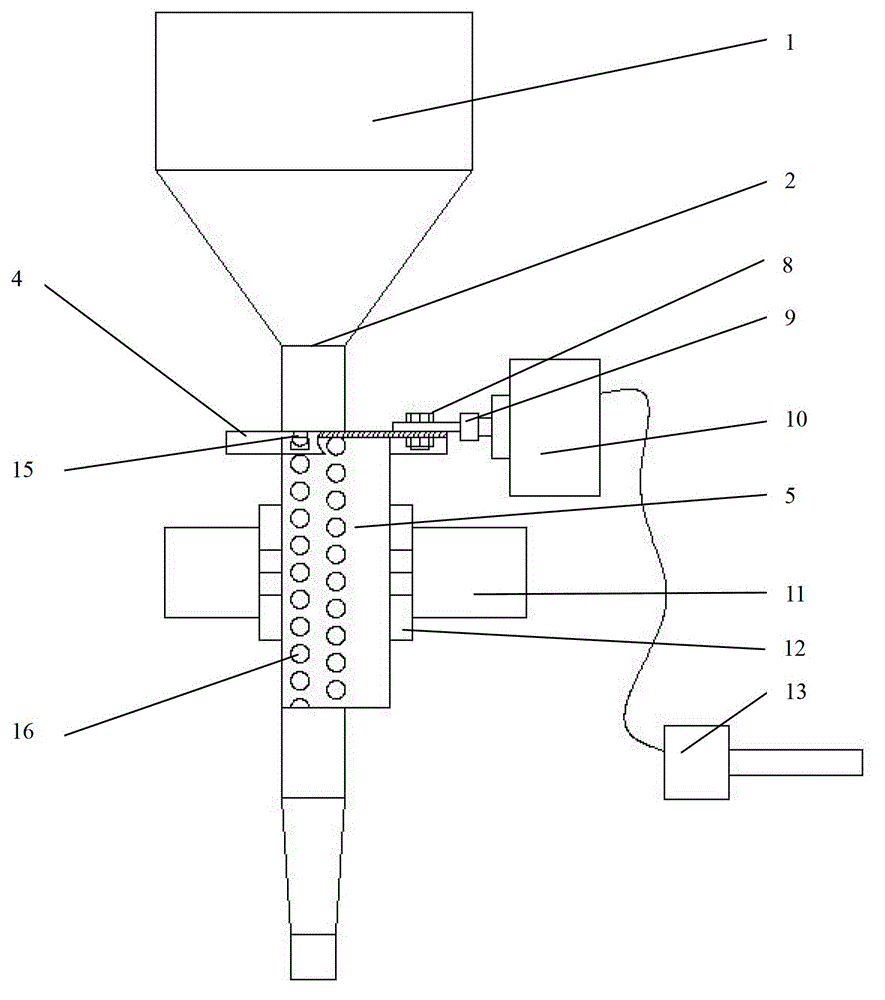

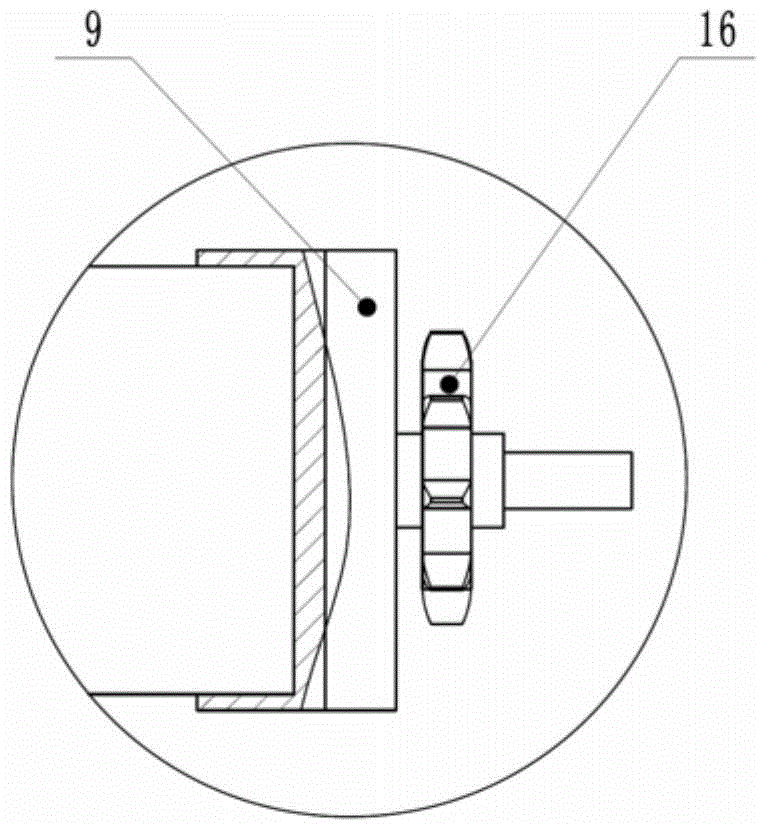

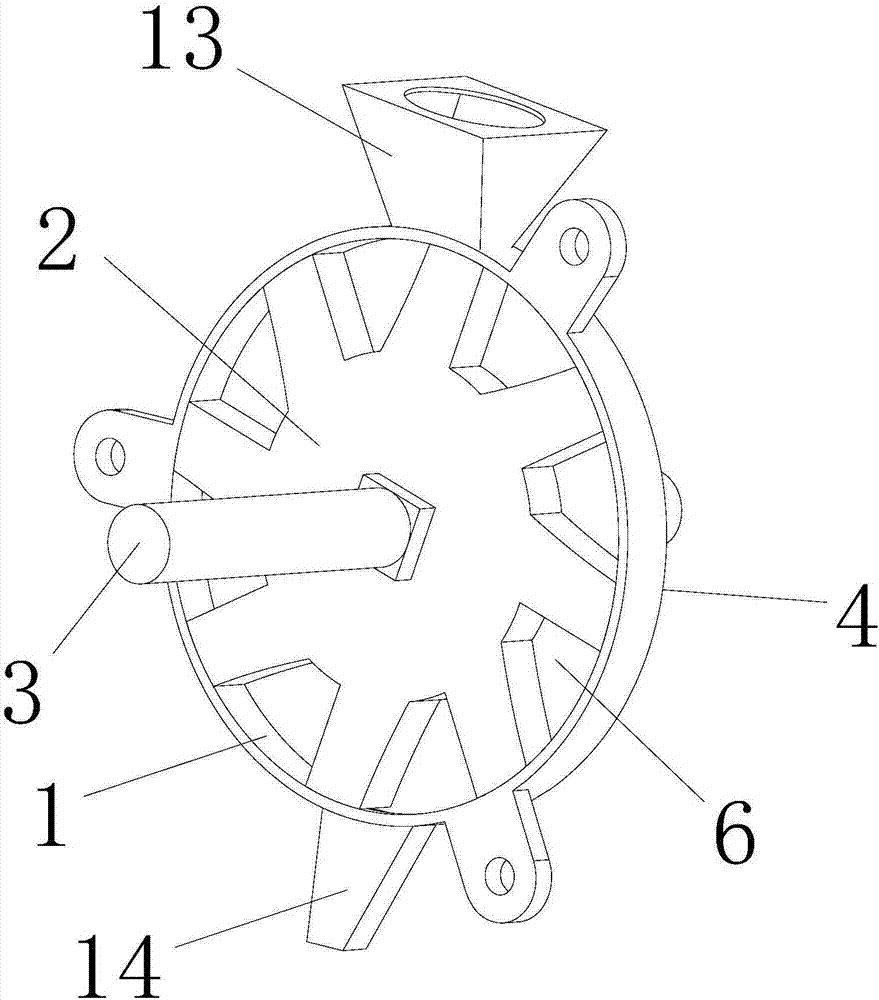

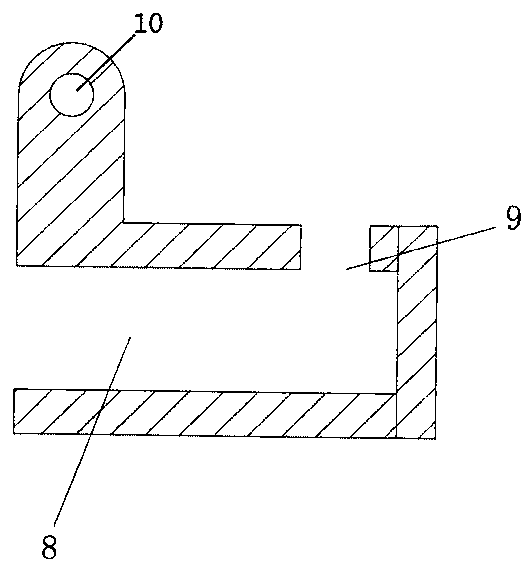

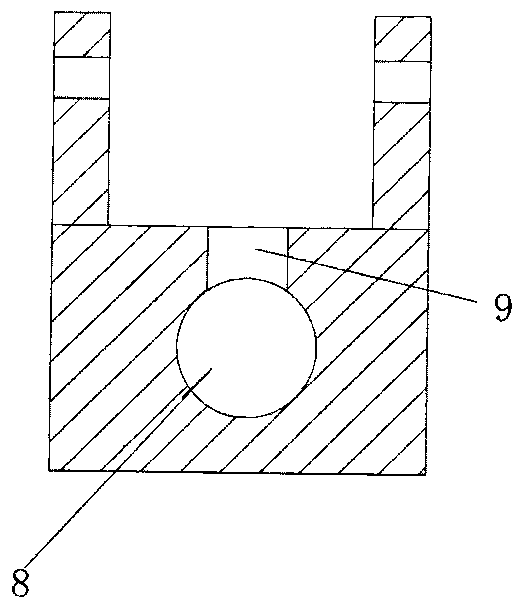

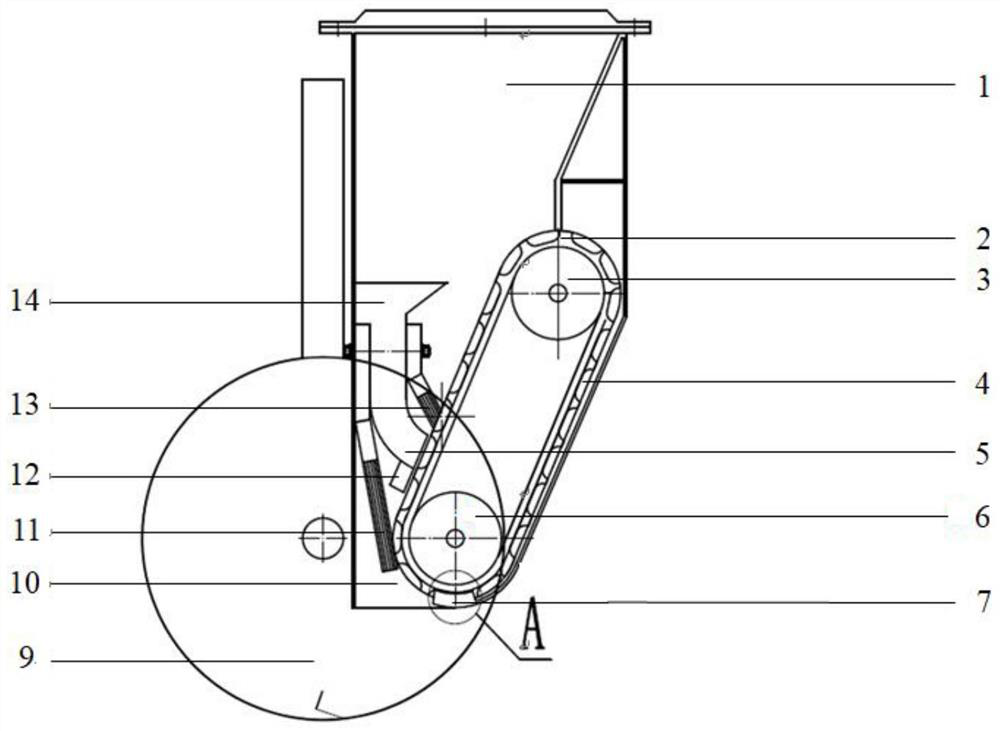

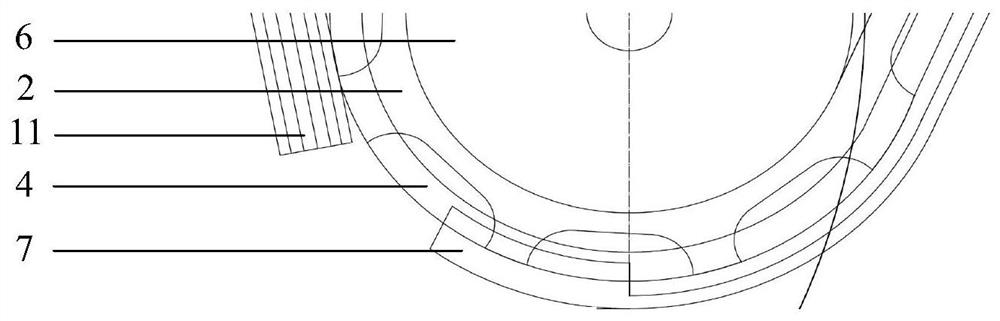

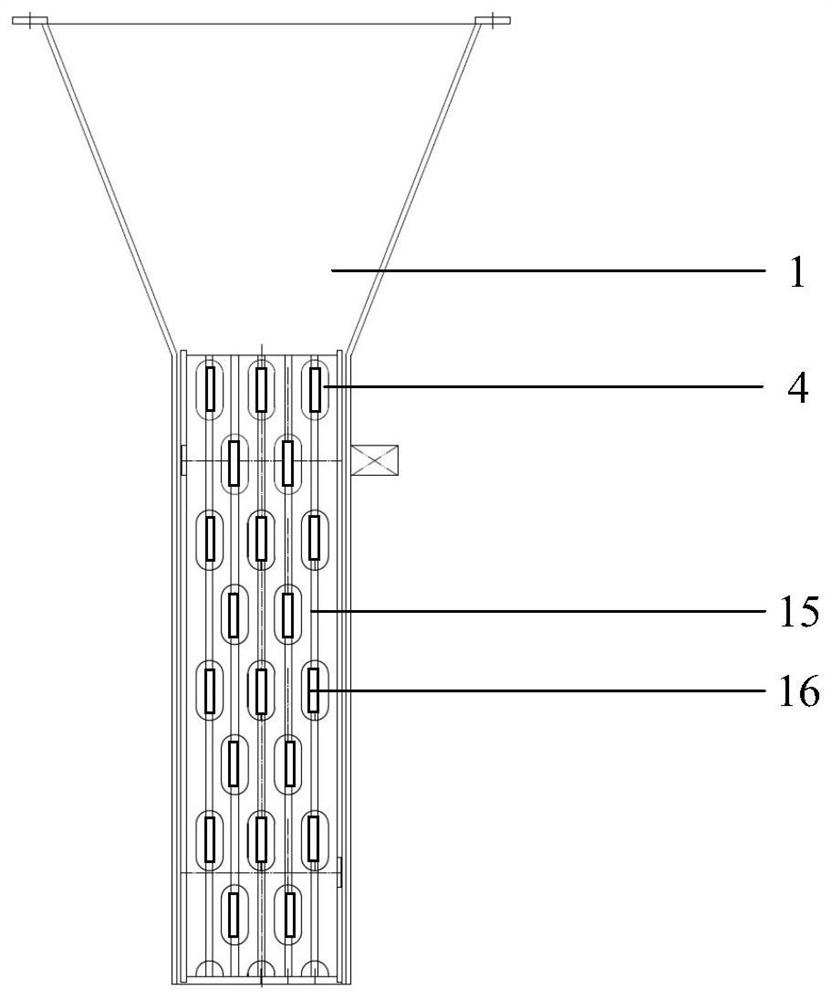

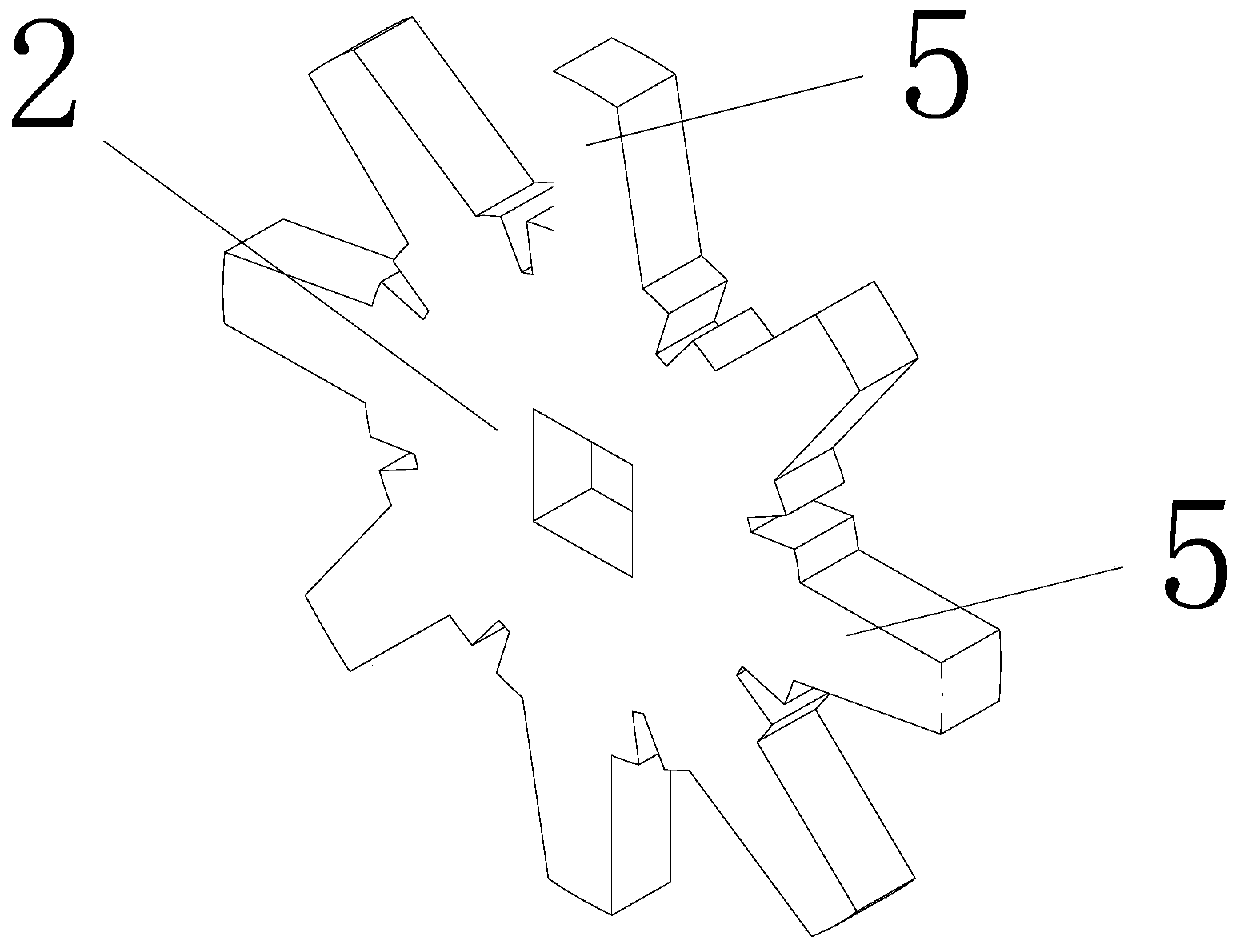

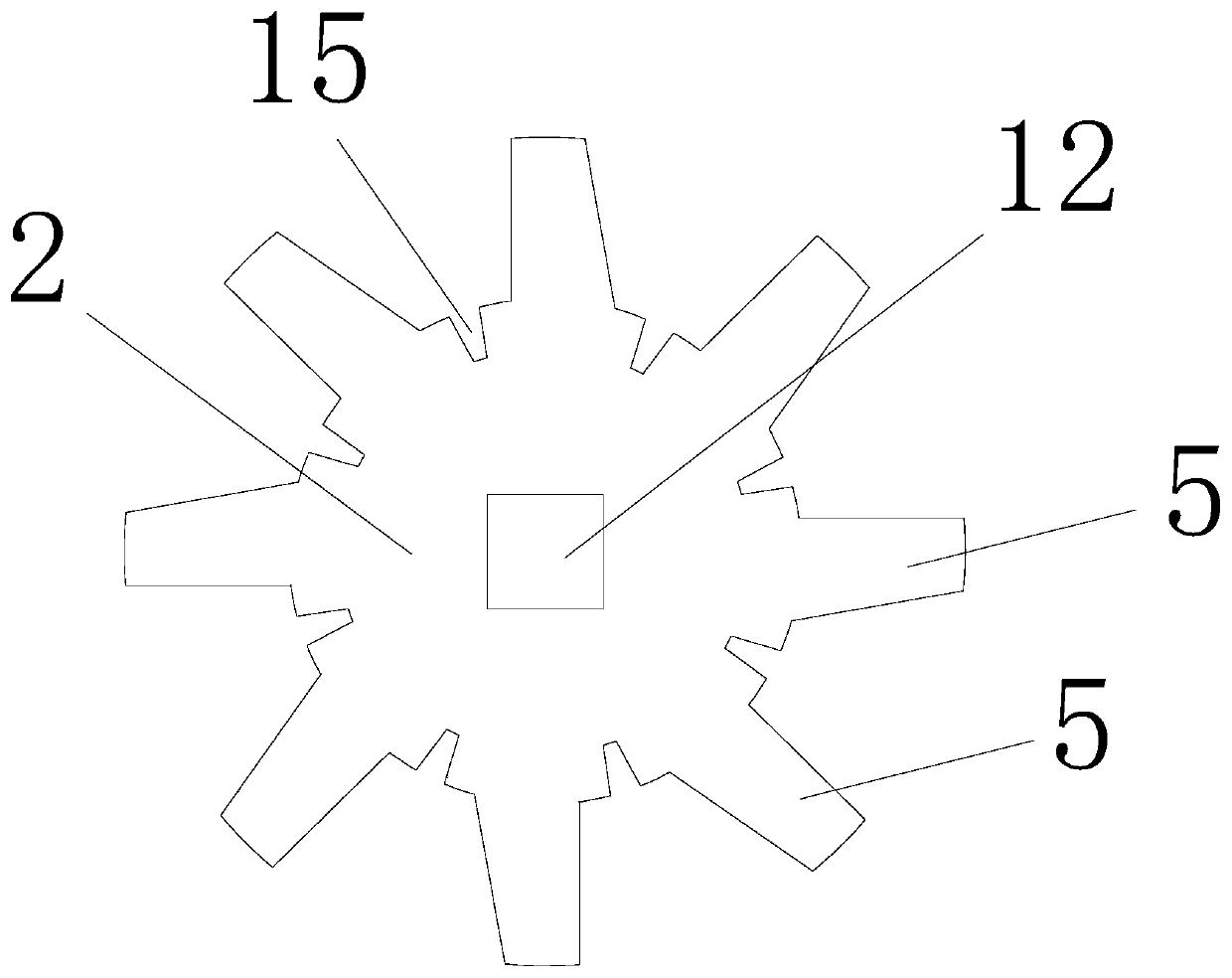

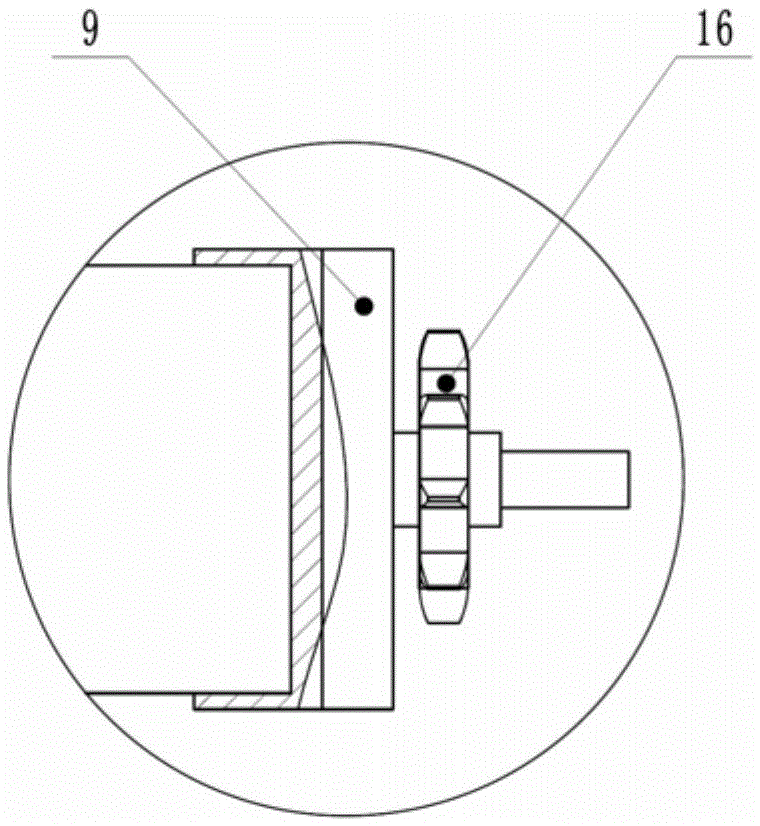

Type hole plate-type seed sowing and replanting device for alfalfa

InactiveCN102742406AImprove seeding uniformityRealize rebroadcastingSeed depositing seeder partsSowingAgriculture

The invention relates to the field of agriculture and animal husbandry machinery, especially relates to a seed sowing device for alfalfa routine seed sowing and replanting in the case of seedling missing of alfalfa. The seed sowing device comprises a seed case (1); a seed inlet (2) is disposed at the lower part of the seed case (1); the end part of the seed inlet (2) is directly faced a type-hole plate (4); type holes (15) are arranged on the type-hole plate (4); the type holes (15) are corresponding to the indents (16) of an indent wheel (5); the indent wheel (5) rotates along with a rotating shaft (11); the type-hole plate (4) is connected with a connection plate (9); the connection plate (9) is connected with an electromagnetic switch (10) which has a build-in return spring; and the electromagnetic switch (10) is connected with a detection device (13) through wires. The seed sowing and replanting device uses the electromagnetic switch to control the axial motion of the type-hole plate according to the electrical signals of the detection device, realizing the functions of sowing and replanting for alfalfa seeds; and has the advantages of uniform in sowing and adjustable in sowing amount, satisfying the agronomic requirements of sowing in line.

Owner:CHINA AGRI UNIV

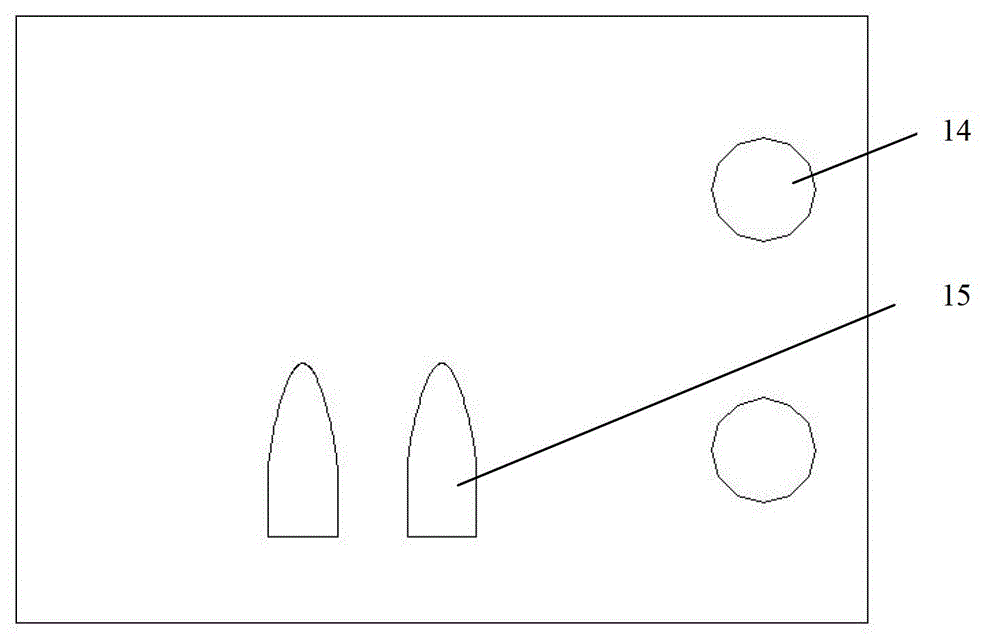

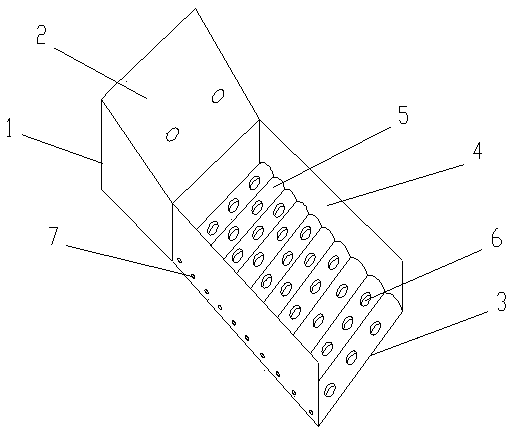

Discharge device for seeding unmanned aerial vehicle

InactiveCN105366054AImprove seeding uniformityImprove sowing qualityAircraft componentsLaunching weaponsEngineeringSowing

The invention discloses a discharge device for a seeding unmanned aerial vehicle. The discharge device comprises a discharge device body which is connected to and mounted at the bottom of the unmanned aerial vehicle. One end of the discharge device body is equipped with a mounting frame, and the other end of the discharge device body is equipped with a discharge slope plate. The two sides of the discharge slope plate are each equipped with a baffle. Both the upper and lower ends of the discharge slope plate are open. Multiple discharge rollers are arranged on the bottom of the discharge slope plate. The discharge rollers are each equipped with a plurality of discharge holes. Through the scheme, the seeding uniformity and seeding quality of the sowing unmanned aerial vehicle are improved by mounting the discharge slope plate equipped with the discharge rollers, the discharge rollers discharge seeds in a rolling manner, and seeds are continuously discharged out of the discharge device through the discharge holes of the discharge rollers while rolling.

Owner:WUXI MIRACLE SCI & TECH CO LTD

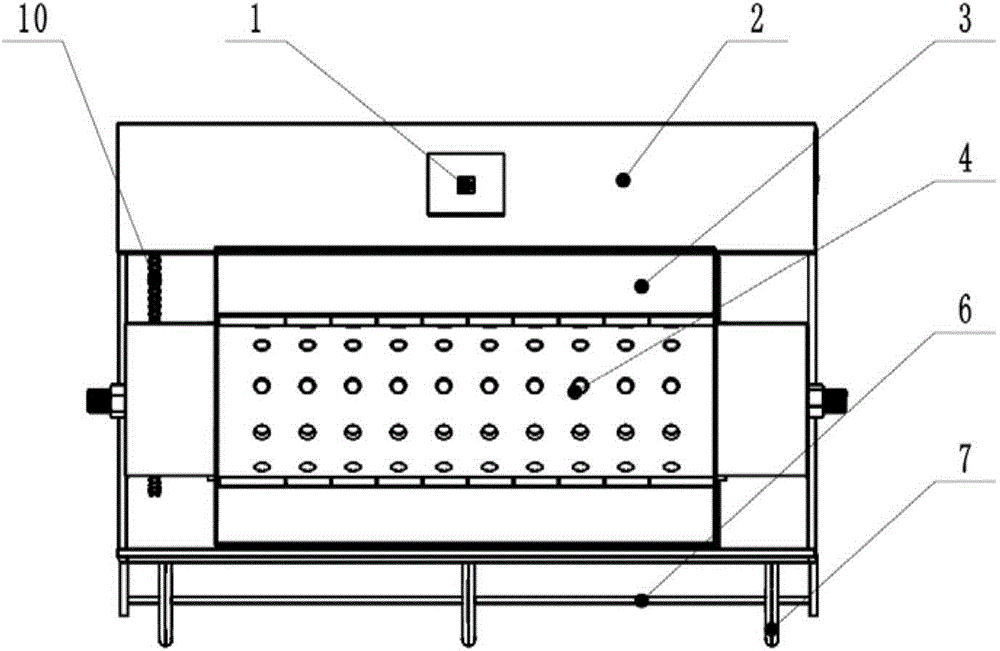

Rice Seedling Seeder

ActiveCN103947341BAvoid water sprayingImprove work efficiencySeed depositing seeder partsRegular seed deposition machinesEngineeringElectric control

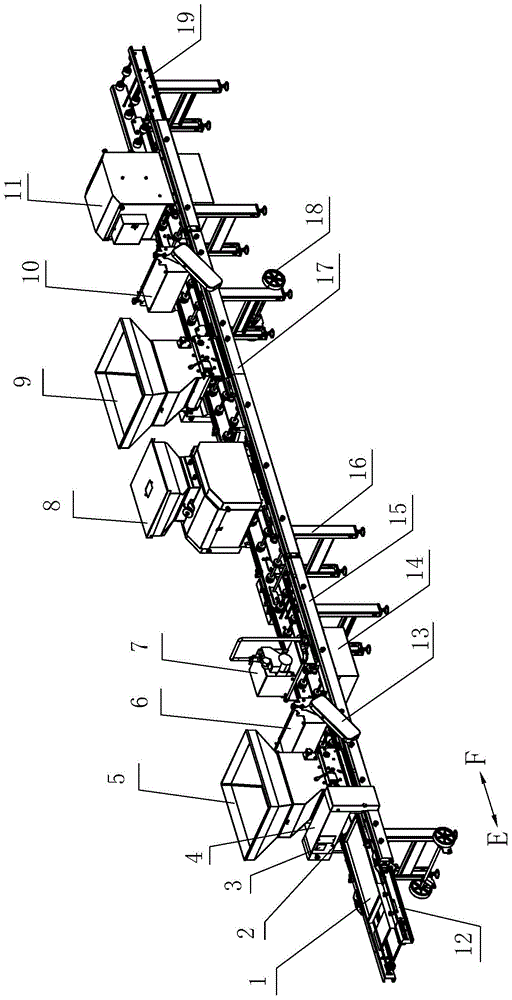

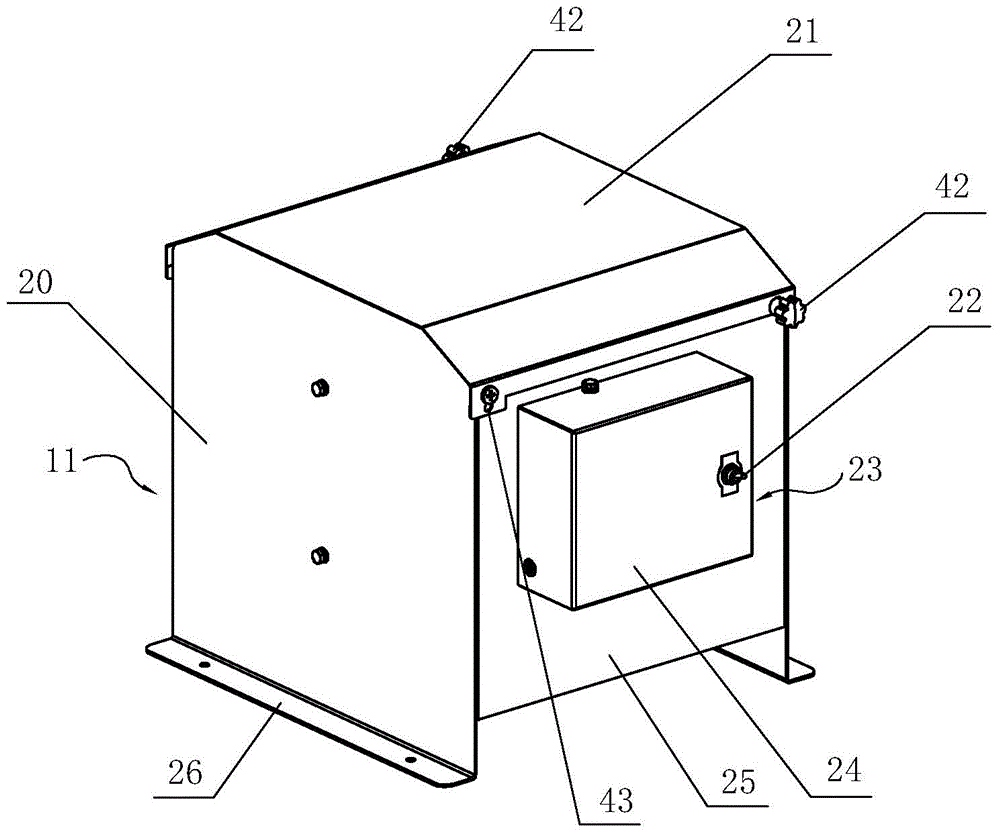

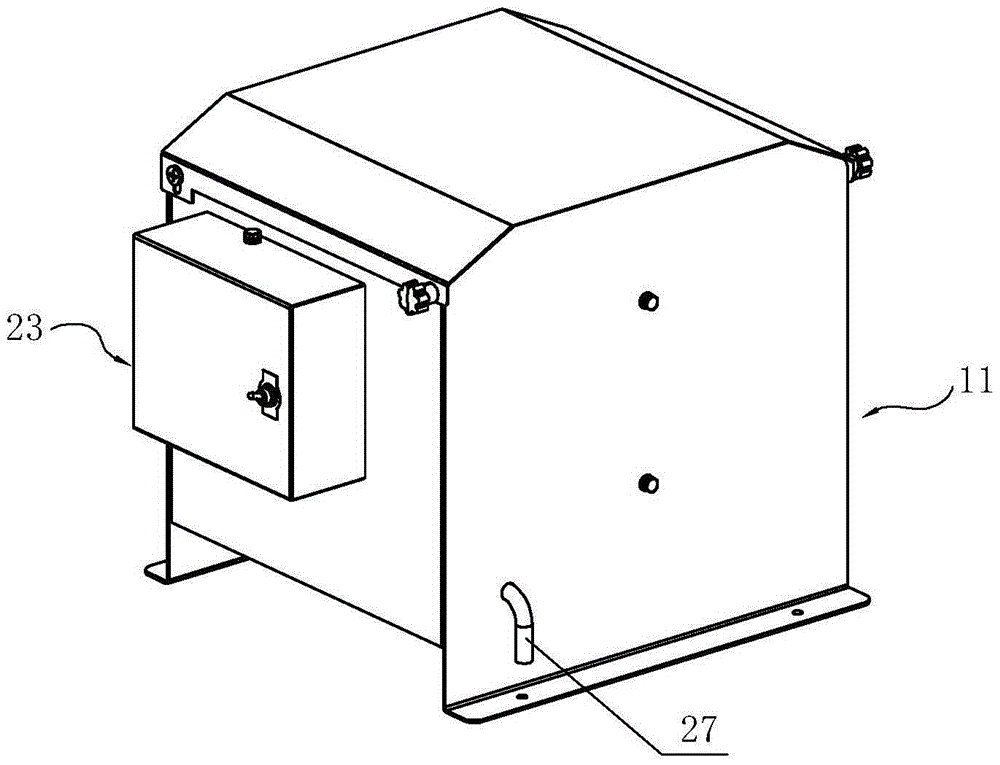

The invention relates to a paddy rice seedling-cultivation sowing machine belonging to a sowing machine. The paddy rice seedling-cultivation sowing machine comprises a bracing frame and a conveying guide rail arranged on the bracing frame; the paddy rice seedling-cultivation sowing machine also comprises a conveying motor, a soil paving apparatus, a soil brushing apparatus I, a water spraying apparatus, a sowing apparatus, a soil covering apparatus and a soil brushing apparatus II which are successively arranged on the conveying guide rail; and the paddy rice seedling-cultivation sowing machine also comprises an atomization apparatus arranged behind the soil brushing apparatus II and on the conveying guide rail. The atomization apparatus comprises an atomization box, a spray device and an electric control device; the atomization box is fixedly connected with two conveying guide rails; the spraying device comprises a water pump, a water suction pipe, a water outlet pipe, an atomization water pipe, an atomization nozzle and atomization water pipe positioning devices; the atomization water pipe positioning devices are arranged on two opposite sidewalls in the atomization box; the atomization nozzle is connected with the atomization water pipe; the atomization water pipe is positioned on the atomization water pipe positioning device; and the power supply of the electric control device is electrically connected with the water pump.

Owner:LIUZHOU WULING LIUJI POWER

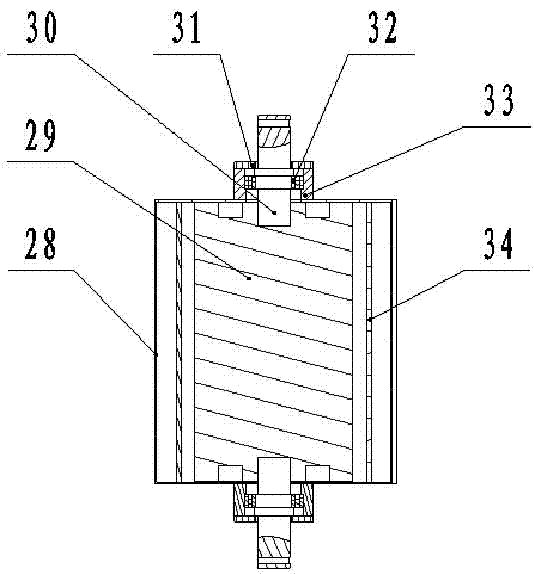

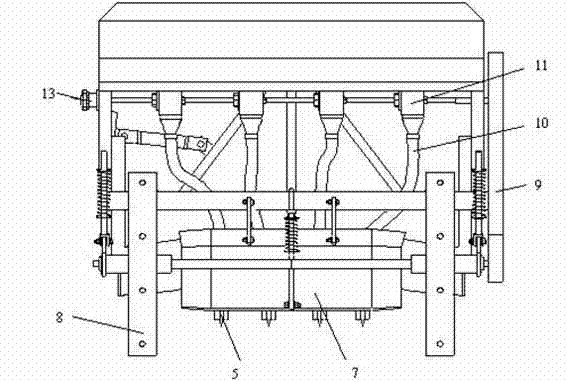

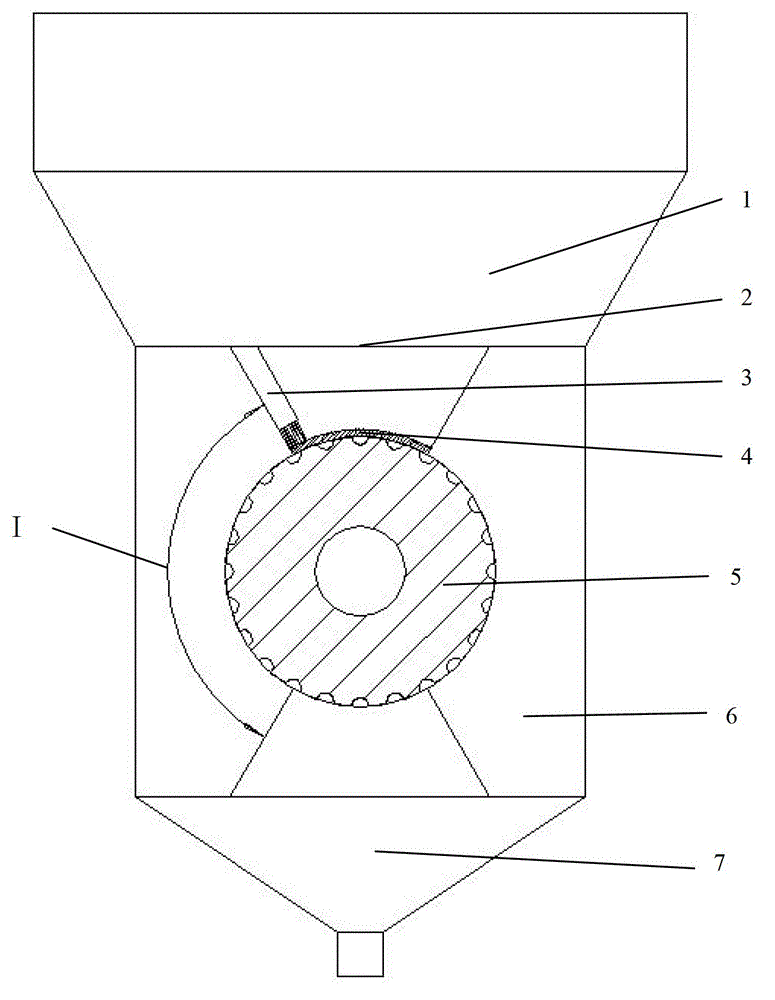

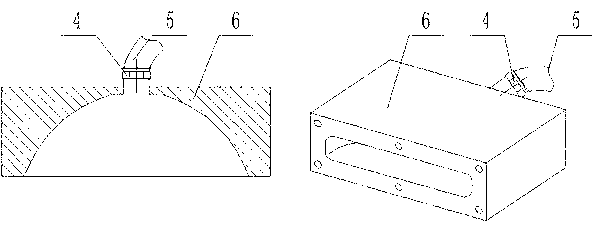

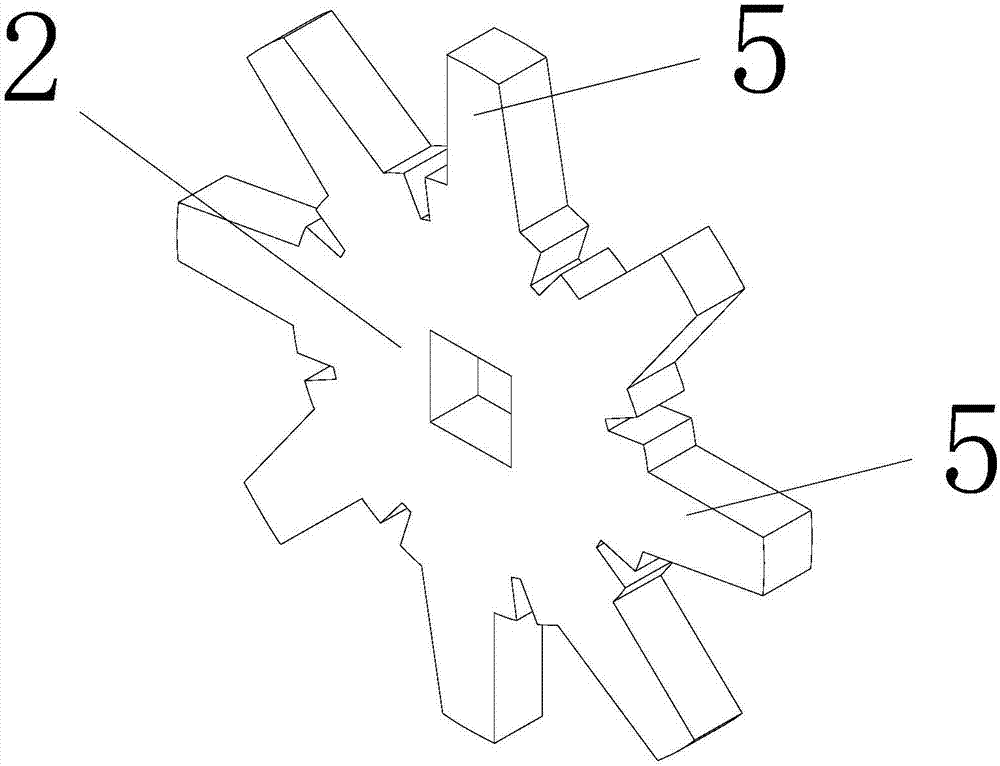

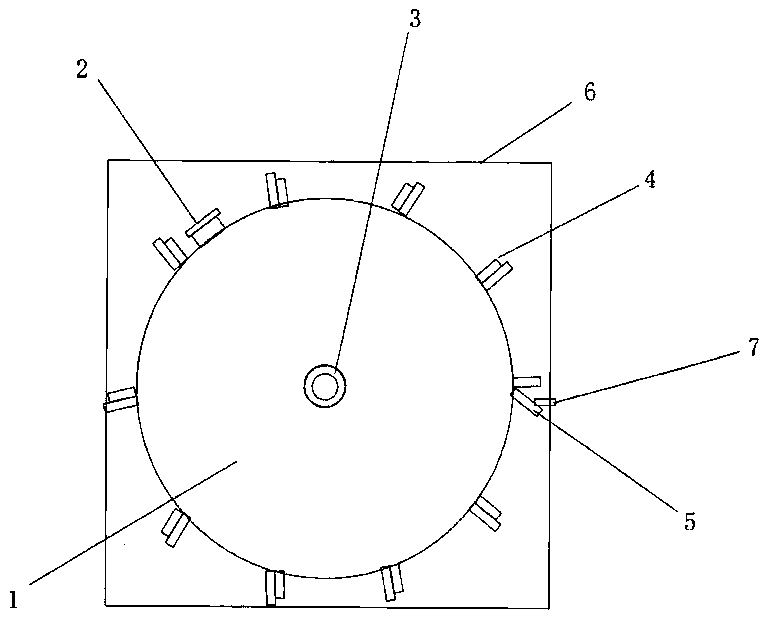

Hybrid rice aspirated-air type seed sucking plate

ActiveCN103125180AInhibit sheddingStable airflowSeed depositing seeder partsSingle grain seedersSeedlingEnvironmental geology

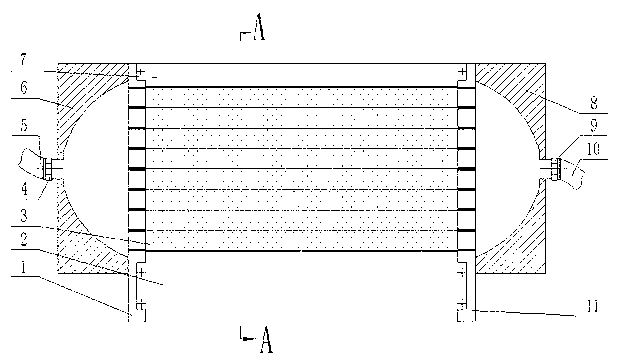

The invention discloses an aspirated-air type seed sucking plate used for hybrid rice seedling raising and seeding. The aspirated-air type seed sucking plate mainly comprises a frame I, a frame II, parallel air passages, an air cavity, an air pressure valve, a flexible pipe and the like. The seed sucking plate is formed by combining multiple groups of parallel air passages, seed sucking holes are distributed in the parallel air passages in a staggered manner, each parallel air passage is an independent air cavity, and air flow in the air cavity is uniform and stable. The aspirated-air type seed sucking plate disclosed by the invention can be applied to rice seedling raising and precise seeding of hybrid rice, seeding uniformity is effectively improved, and further seeding quality is improved.

Owner:JIANGSU UNIV

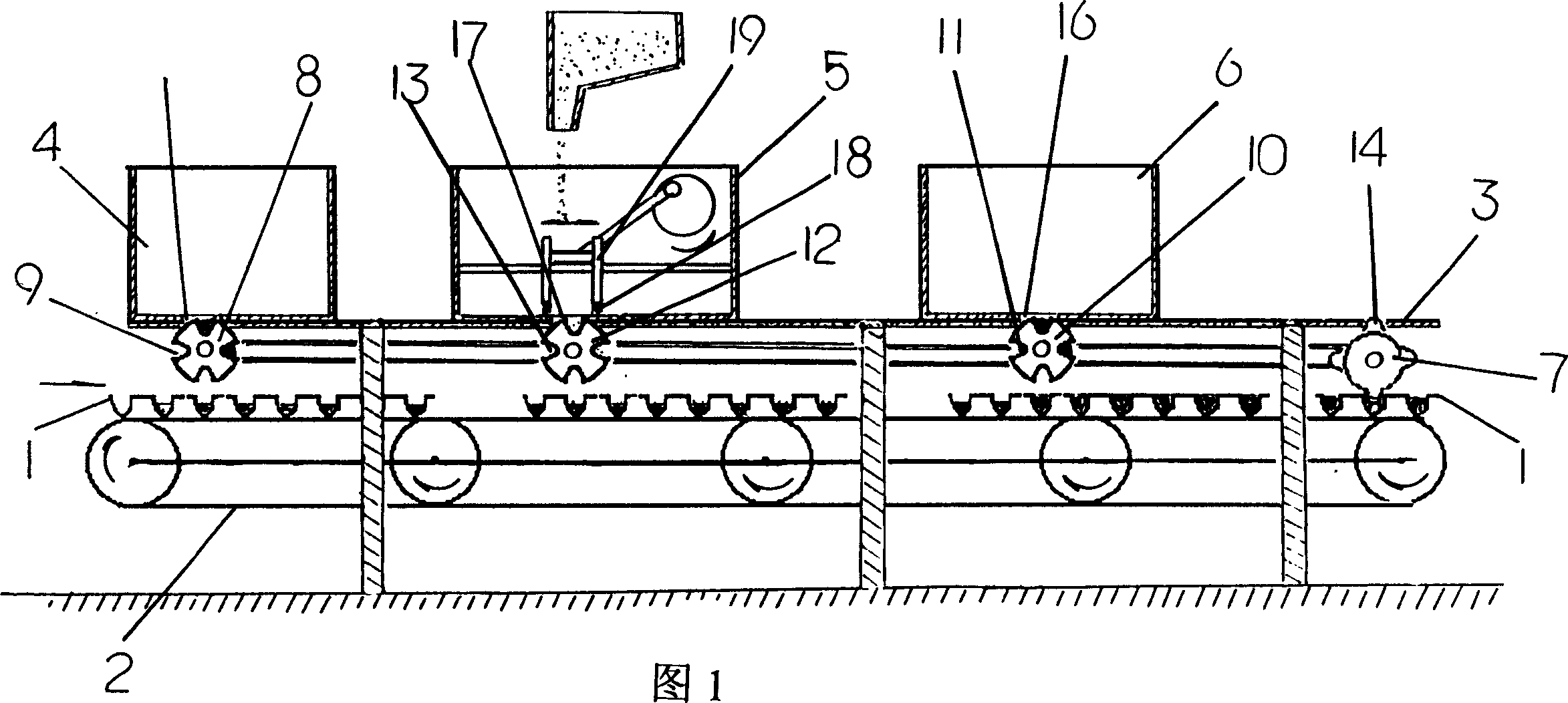

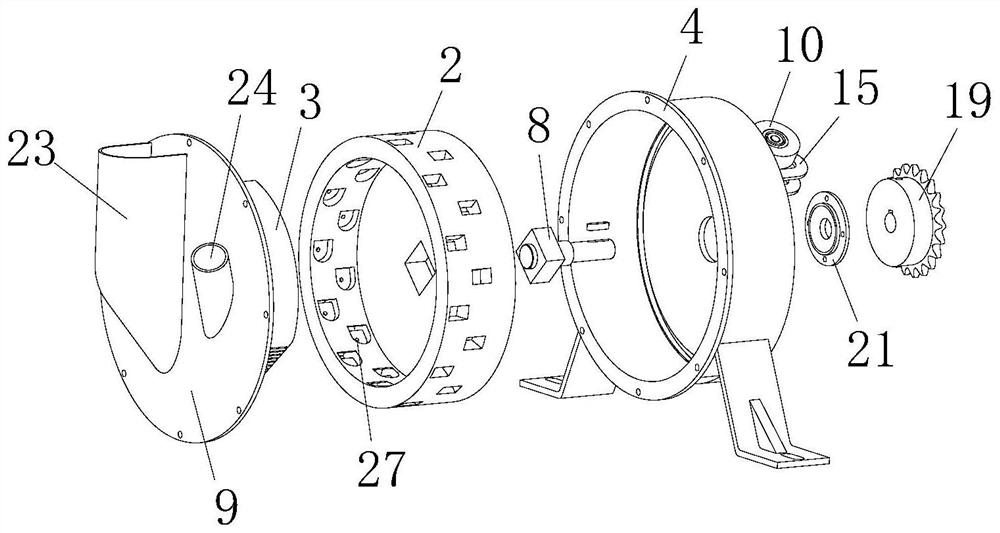

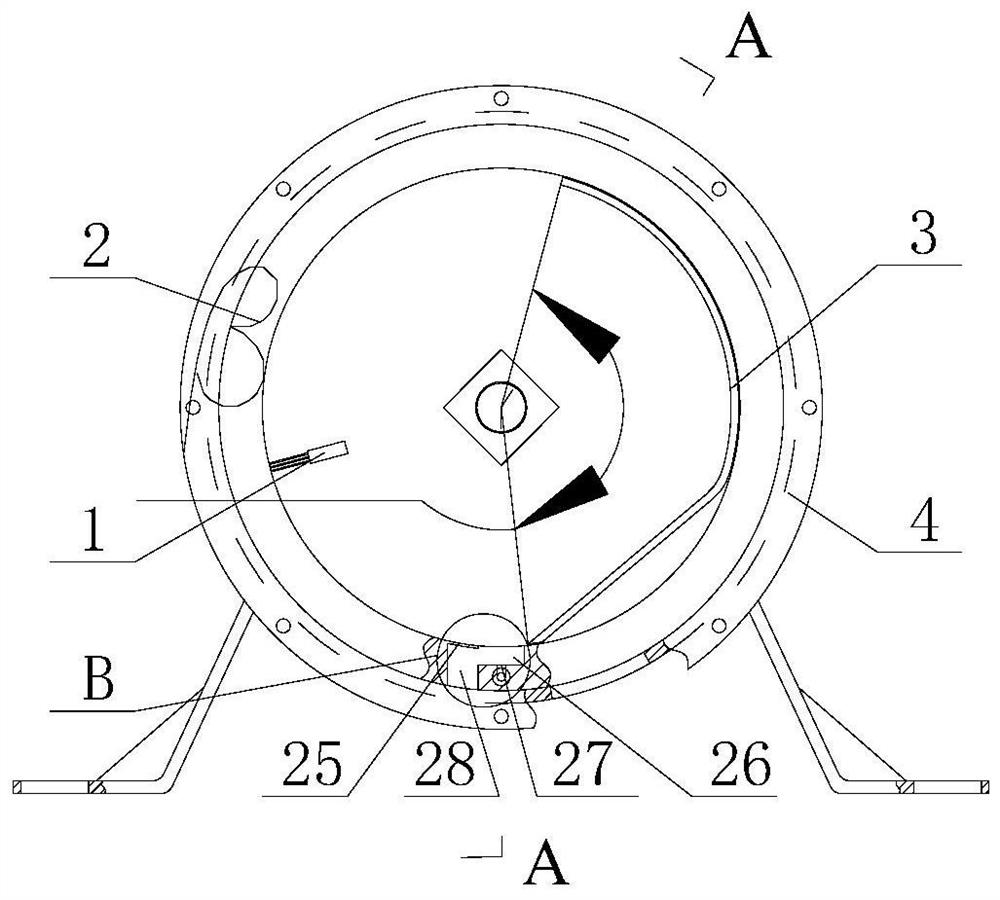

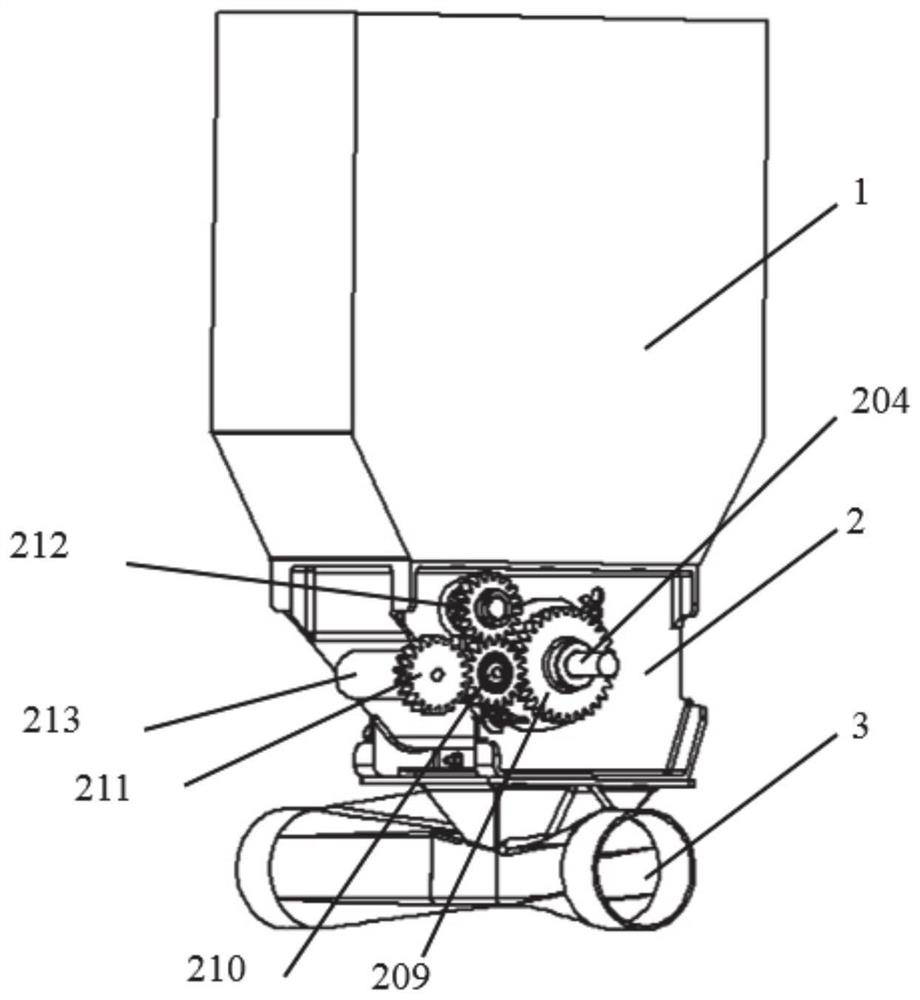

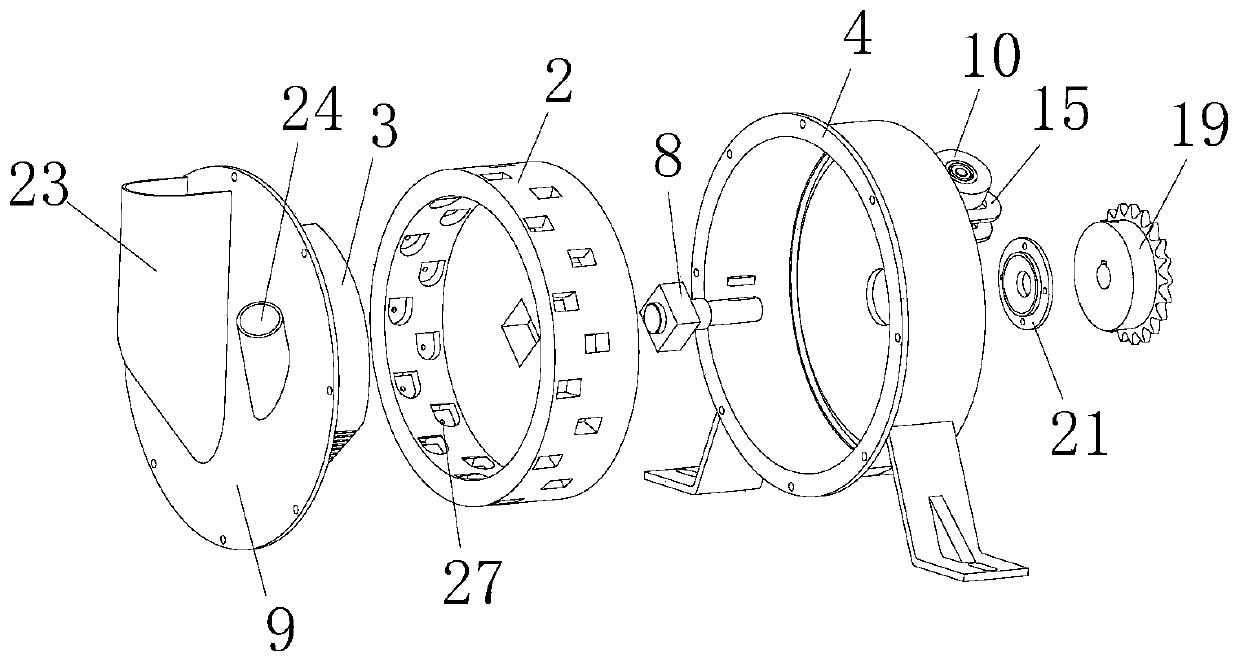

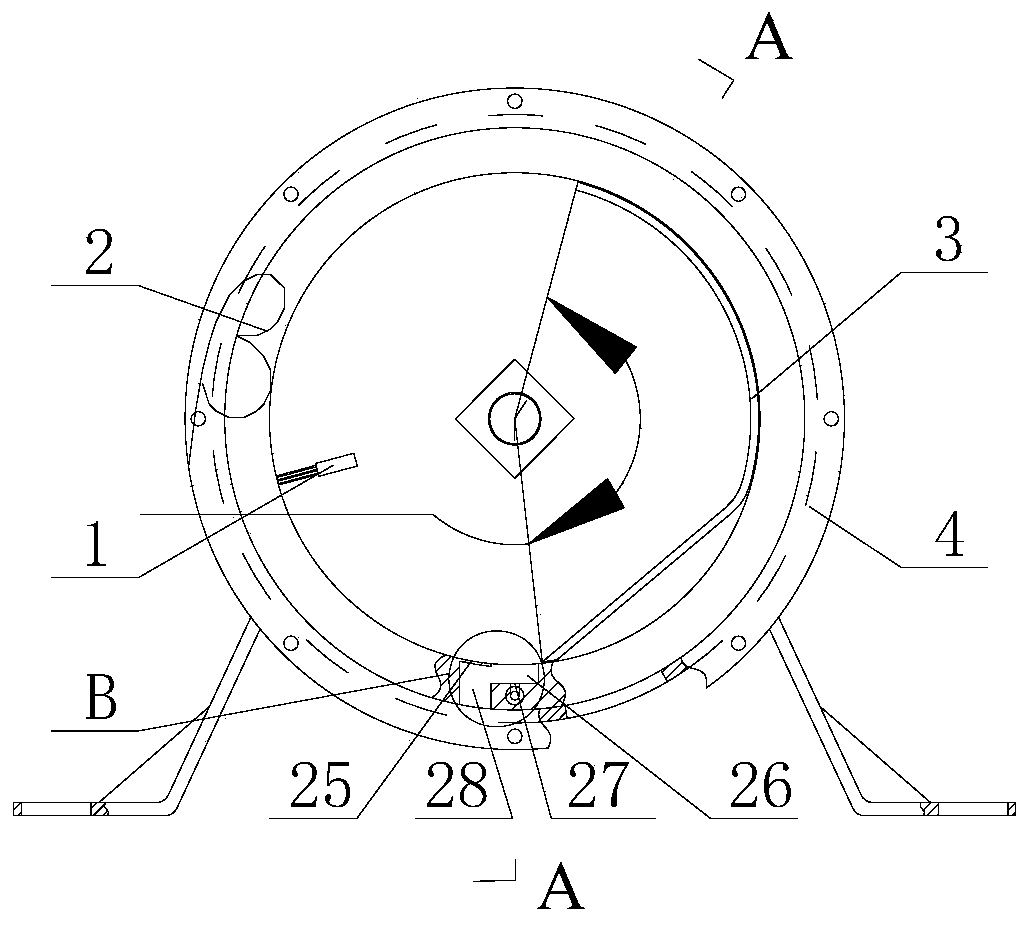

Drum-type precise sowing device for hole sowing of vegetable seeds

ActiveCN104620735AAvoid damageSame distanceSeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringSprocket

The invention discloses a drum-type precise sowing device for hole sowing of vegetable seeds. The device comprises a switch, a stander, a feed hopper, a seed metering device, a brush, a rear walking wheel axle, wheels, a blanking hopper, an overrun clutch, a plurality of chains, a plurality of chain wheels, a front walking wheel axle and a motor, wherein the motor, the front walking wheel axle and the wheels are arranged at the front end of the stander; the rear walking wheel axle and the wheels are arranged at the rear end of the stander; the feed hopper, the seed metering device, the brush and the blanking hopper are arranged in the middle of the stander; the motor can be used for controlling the front walking wheel axle, the rear walking wheel axle and the seed-metering device by chain transmission. The drum-type precise sowing device has the characteristics of being simple in structure, convenient to operate and the like, and can be used for precisely and evenly sowing seeds at equal intervals.

Owner:ZHEJIANG UNIV

Mini-type pneumatic vegetable precision seeder

InactiveCN105850304AControl consistencyEffective looseningPlantingFurrow making/coveringSeederDrive wheel

The invention discloses a miniature pneumatic precision seeder for vegetables, which comprises a power unit, a supporting main board 5 and a depth-gauge wheel 26, one end of the supporting main board 5 is installed with a seeding unit, and the other end of the supporting main board 5 is installed with a A power unit, a fan transmission unit is arranged above the power unit, a front shaft 3 is installed below the power unit, a first sprocket set 15 is installed on the front shaft 3, and two ends of the front shaft 3 are respectively installed Traveling wheel 25, limited depth wheel support 4 is installed on the described support main board 5, and described depth limit wheel 26 is installed on the depth limit wheel support 4. The invention integrates the frame structure of the tiller and the pneumatic seed metering device, can efficiently complete the sowing operation, has strong adaptability, and is suitable for field and facility agriculture.

Owner:HUAZHONG AGRI UNIV

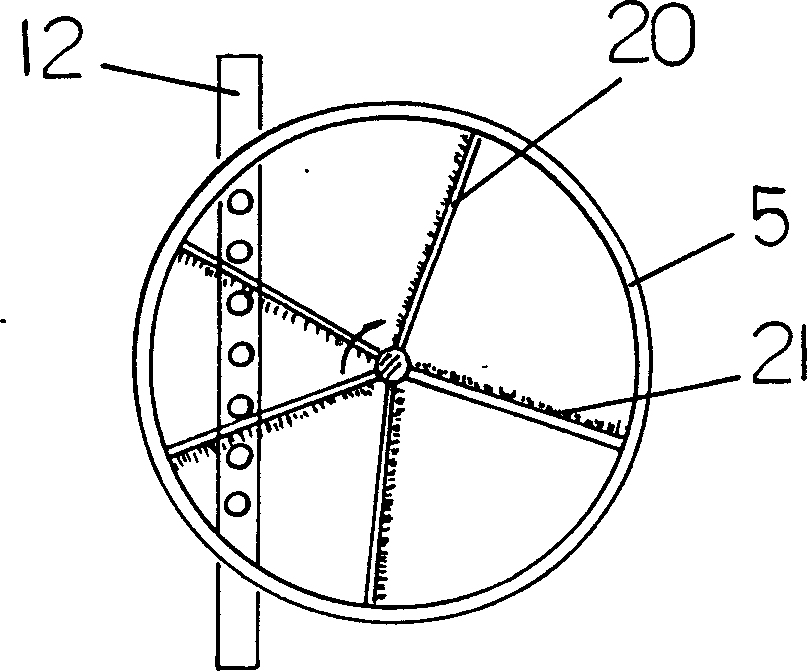

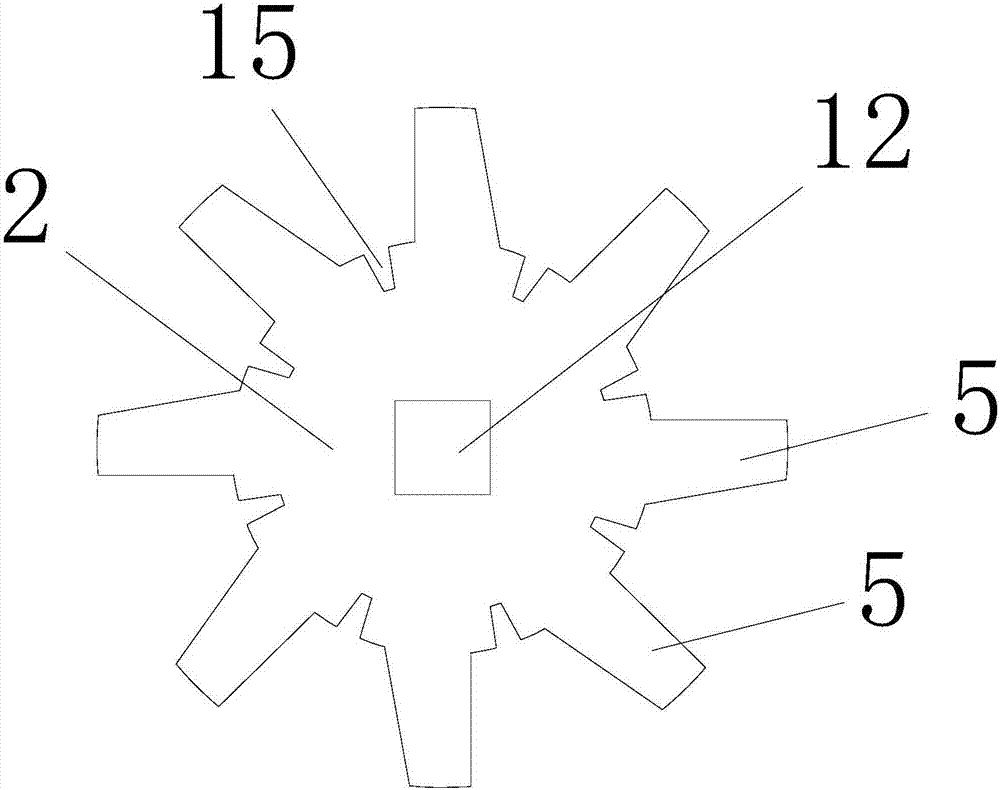

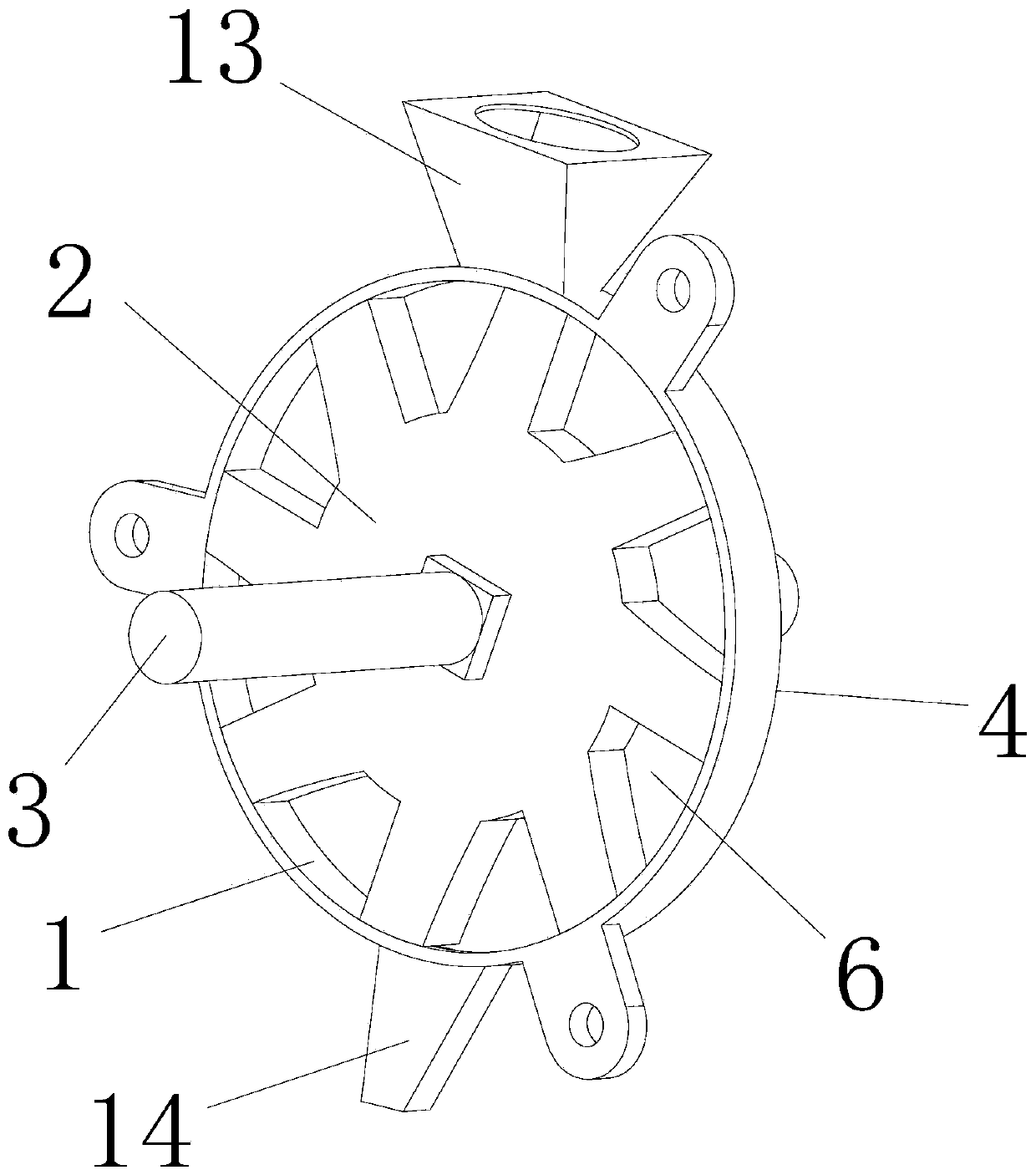

Rice precise direct-seeding and cavitating device

ActiveCN107124942AChange speedEnhanced cavitationDibble seedersAgriculture gas emission reductionCircular discCavitation

The invention discloses a rice precise direct-seeding and cavitating device, which comprises a shell, a cavitating disk and a transmission shaft, wherein a disk cavity is formed in the shell, and the cavitating disk is arranged in the disk cavity; the cavitating disk comprises a connecting portion connected with the transmission shaft and a plurality of cavity partition plates radially extending out of the outer side of the connecting portion, a seed cavity is formed among every two adjacent partition cavity plates and a cavity wall of the disk cavity, a seed inlet for seeds to enter the seed cavities is formed in the upper portion of the disk cavity, and a seed output opening for the seeds in the seed cavities to be output is formed in the lower portion of the disk cavity; when the seed inlet is communicated with the seed cavities, the seeds can enter the seed cavities through the seed inlet; when the seed cavities are communicated with the seed output opening, the seeds in the seed cavities are output from the seed output opening. The rice precise direct-seeding and cavitating device disclosed by the invention is simple and reliable, convenient and quick to install, capable of effectively improving cavitation of sowing in line and capable of meeting different requirements of rice precise hole sowing.

Owner:SOUTH CHINA AGRI UNIV

Paddy rice seedling-cultivation sowing machine

ActiveCN103947341AAvoid water sprayingImprove work efficiencySeed depositing seeder partsRegular seed deposition machinesEngineeringElectric control

The invention relates to a paddy rice seedling-cultivation sowing machine belonging to a sowing machine. The paddy rice seedling-cultivation sowing machine comprises a bracing frame and a conveying guide rail arranged on the bracing frame; the paddy rice seedling-cultivation sowing machine also comprises a conveying motor, a soil paving apparatus, a soil brushing apparatus I, a water spraying apparatus, a sowing apparatus, a soil covering apparatus and a soil brushing apparatus II which are successively arranged on the conveying guide rail; and the paddy rice seedling-cultivation sowing machine also comprises an atomization apparatus arranged behind the soil brushing apparatus II and on the conveying guide rail. The atomization apparatus comprises an atomization box, a spray device and an electric control device; the atomization box is fixedly connected with two conveying guide rails; the spraying device comprises a water pump, a water suction pipe, a water outlet pipe, an atomization water pipe, an atomization nozzle and atomization water pipe positioning devices; the atomization water pipe positioning devices are arranged on two opposite sidewalls in the atomization box; the atomization nozzle is connected with the atomization water pipe; the atomization water pipe is positioned on the atomization water pipe positioning device; and the power supply of the electric control device is electrically connected with the water pump.

Owner:LIUZHOU WULING LIUJI POWER

Garlic seeder

PendingCN107593009AImprove seeding uniformityGuaranteed outputSpadesPlantingSeederAgricultural engineering

The invention provides a garlic seeder. The garlic seeder comprises a rack, traveling wheels and a head, wherein the traveling wheels are mounted at the bottom of the rack; and the head is mounted atthe front end of the rack. The garlic seeder is characterized by further comprising a sowing mechanism, a duplex plough and a soil pressing roll, wherein the sowing mechanism is arranged in the middleof the rack and comprises a plurality of sowing openings; the sowing mechanism uniformly sows garlic seeds via the sowing openings; the duplex plough is arranged at the bottom of the rack and comprises a plurality of rows of plough heads; the duplex plough is positioned on the front sides of the sowing openings of the sowing mechanism and is used for implementing uniform ploughing; and the soil pressing roll is arranged at the rear end of the rack, can rotate in the up-down direction, and is positioned on the rear side of the duplex plough.

Owner:黄新

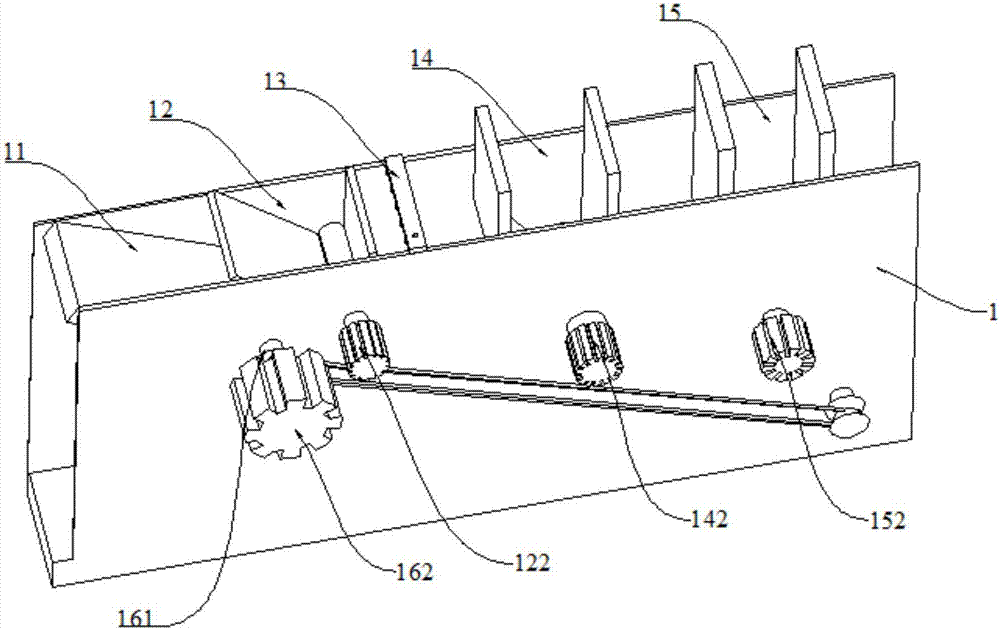

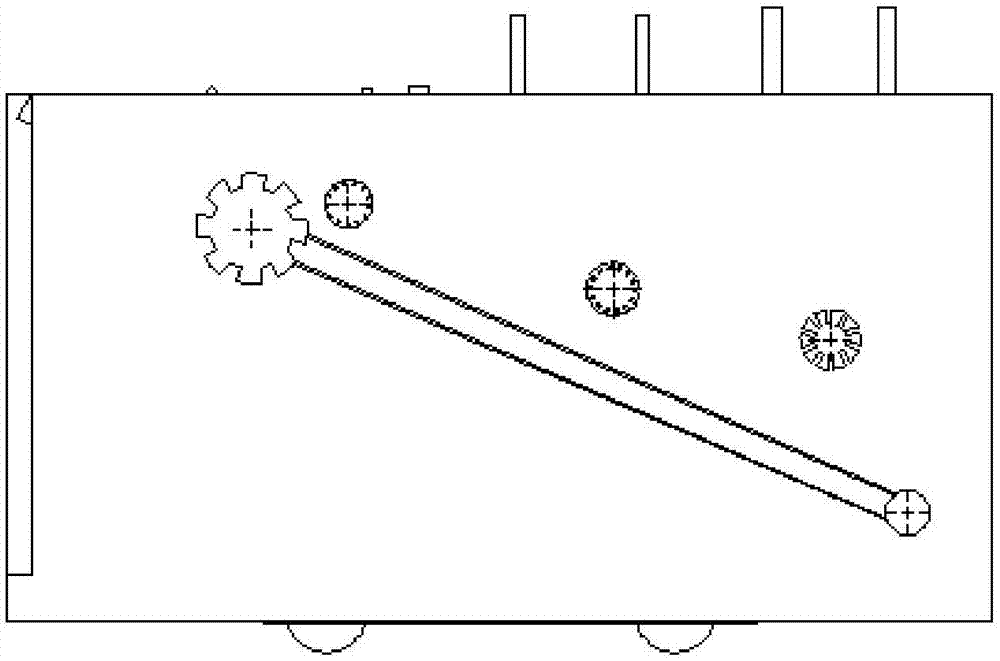

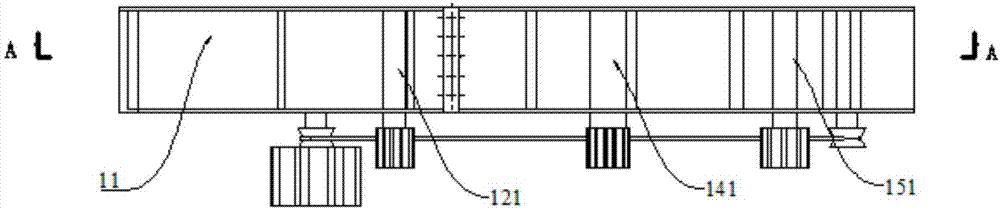

Sowing mechanism for garlic

PendingCN107646261AImprove seeding uniformityGuaranteed outputPotato plantersAgricultural engineeringStructural engineering

The invention provides a sowing mechanism for garlic. The sowing mechanism comprises a feeding bin, a feeding hopper, a rotary material sucking cylinder and sowing pipes corresponding to material sucking holes, wherein a stirring shaft is arranged in the feeding bin; a plurality of discharging openings are formed in the lower part of the feeding bin; the feeding hopper is arranged below the feeding bin; a plurality of guiding chutes which are in one-to-one correspondence to the discharging openings are formed in the rear end of the feeding hopper; an eccentric wheel is arranged at the front end of the feeding hopper and drives the guiding chutes to vertically jitter; the rotary material sucking cylinder is arranged on the rear side of the feeding hopper; at least one row of material sucking holes are formed in the outer wall of the rotary material sucking cylinder along the axial direction; each row of material sucking holes comprise the material sucking holes which are in one-to-one correspondence to the guiding chutes; an air suction channel communicating with the material sucking holes is arranged inside the rotary material sucking cylinder; the sowing tubes are arranged on therear side of the rotary material sucking cylinder; feeding openings are formed in the upper ends of the sowing pipes; a sowing opening is formed in the lower end of the rotary material sucking cylinder.

Owner:黄新

Sowing machine high in emergence rate

InactiveCN107926229AImprove germination rateQuality improvementPlantingWatering devicesSeederWater storage tank

The invention provides a planter with a high seedling emergence rate. In the planter, a water storage tank is arranged between the soil spreading box and the seeding box, and a plurality of nozzles are arranged at the lower end of the water storage tank. The cutting of the seedling soil can ensure that the bottom soil is laid smoothly. On the other hand, it is convenient to spray water on the seedling trays covered with the bottom soil, thereby ensuring the water needed for seedling cultivation and improving the emergence rate; The surface soil is easy to cause the surface soil layer to be uneven, and it is easy to cause the local backlog of the surface soil. The setting of the soil pressure roller can flatten the surface soil to ensure the uniformity of the surface soil, and the burrs on the soil pressure roller can improve the seedling tray. Permeability, promote the growth of seedlings.

Owner:新昌县汉良苗木专业合作社

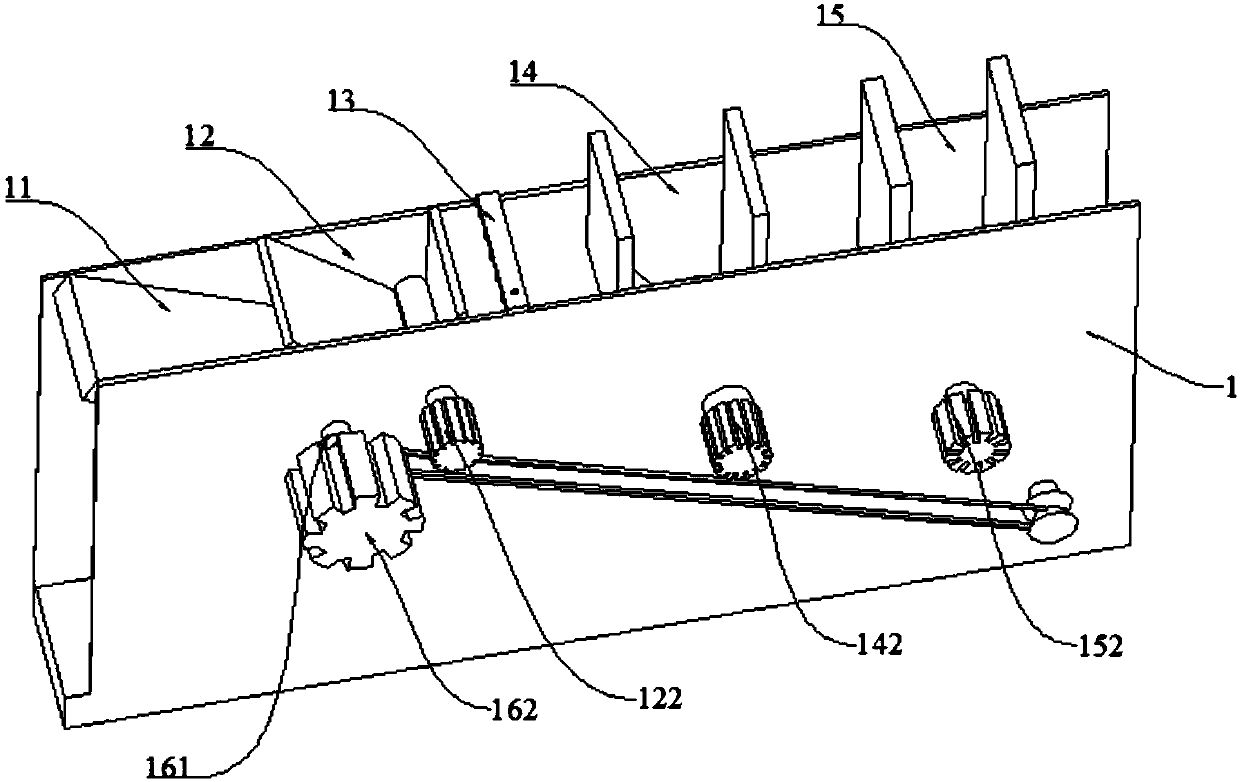

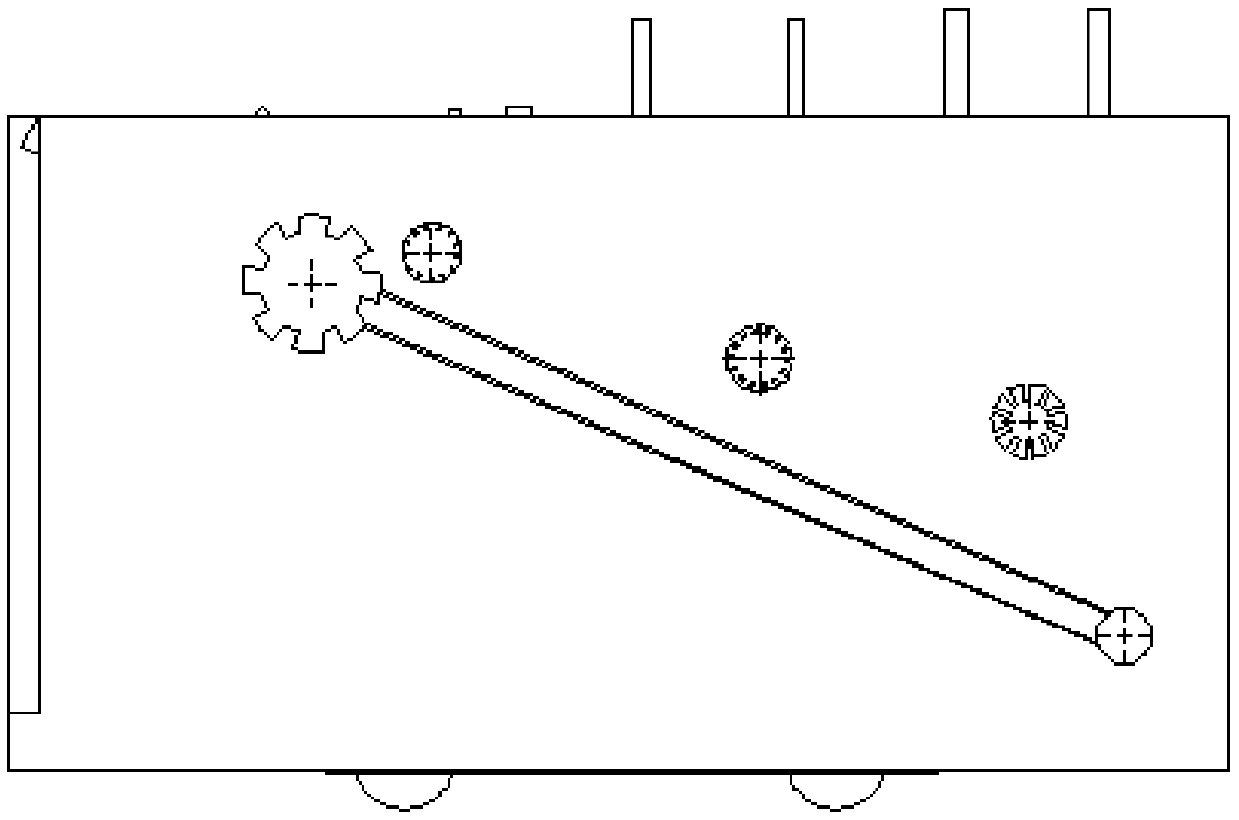

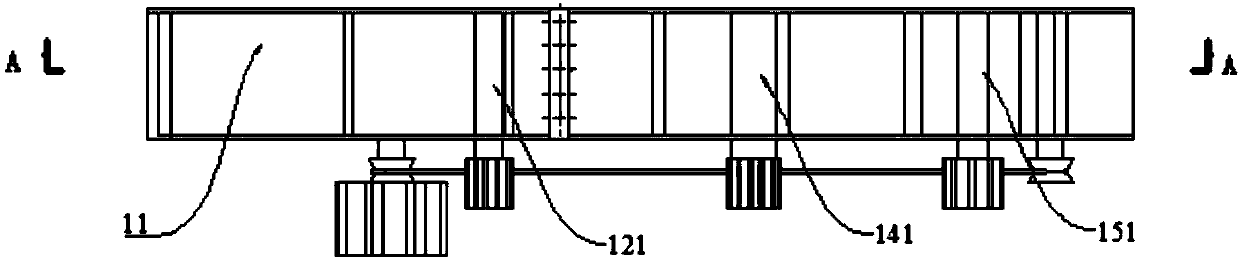

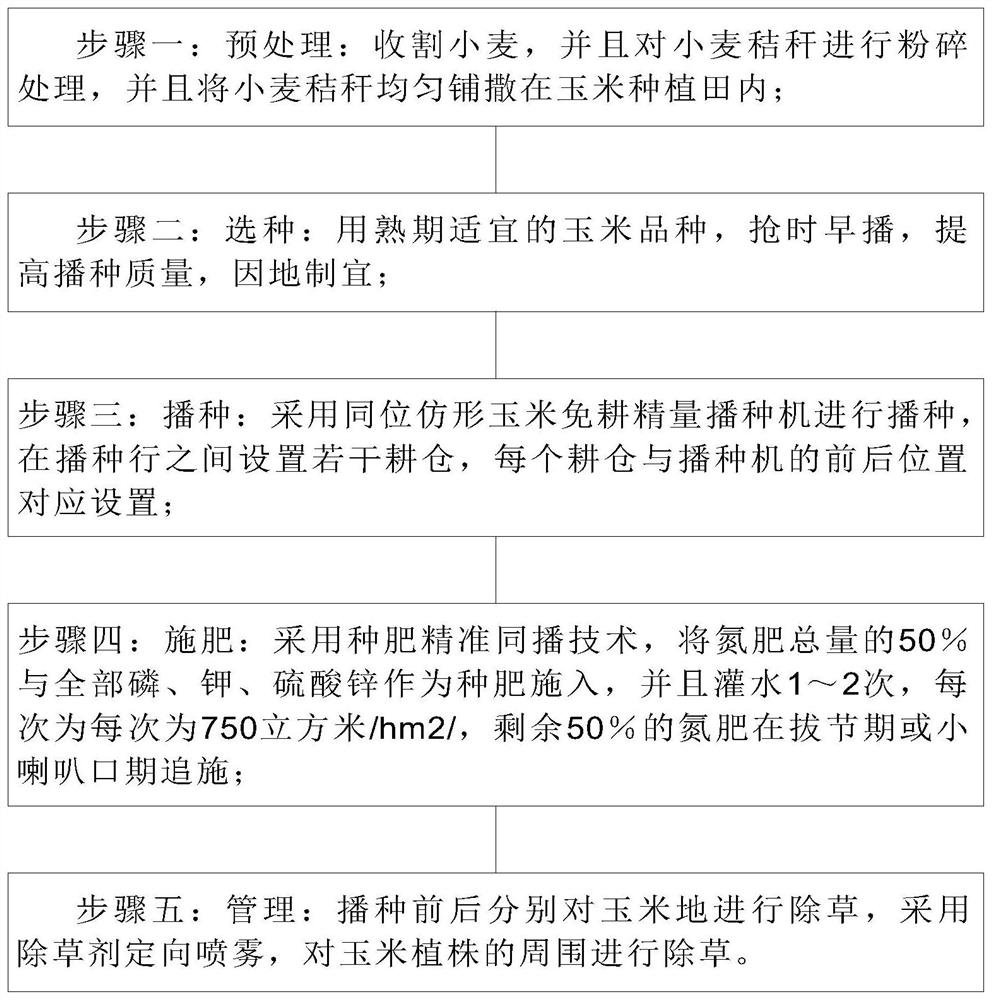

Planting method for realizing close planting and yield increasing of summer corn

PendingCN114568227AIncrease productionPlanting method saves timeSowingCereal cultivationSeederTillage

The invention discloses a planting method for realizing close planting and yield increase of summer corn, which comprises the following steps: step 1, pretreatment: harvesting wheat, crushing wheat straws, and uniformly spreading the wheat straws in a corn planting field; 2, seed selection: using a corn variety with a proper ripening period, early sowing in time, improving the sowing quality, and adjusting measures to local conditions; step 3, sowing: sowing by adopting an in-situ profiling corn no-tillage precision sowing machine, arranging a plurality of tillage bins between sowing rows, and arranging each tillage bin corresponding to the front and rear positions of the sowing machine. According to the planting method for realizing close planting and yield increasing of summer corn, a'in-situ profiling and air suction precision seeding 'technology and a'seedling strip arrangement and deep scarification fertilization' compound operation technology are adopted, and precise information regulation and control are assisted, so that precise regulation and control of seeding depth, single-grain precise seeding and layered deep fertilization are completed, and row spacing, seeding depth and fertilization depth are consistent.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

Direct sowing and rapid breeding method of bletilla striata

InactiveCN109089851AReduce configuration difficultyLower acquisition costsGrowth substratesCulture mediaBletilla striataZoology

The invention discloses a direct sowing and rapid breeding method of bletilla striata. Only wood blocks and saw dust are used as a seedbed matrix, a Huaduoduo No.1 liquid fertilizer diluent is used asa nutrient substance, through bletilla striata seed collection, seedbed manufacturing, direct sowing, moisturizing seedling raising and other steps, bletilla striata seeds sown directly on the matrixgerminate rapidly to achieve industrialized rapid breeding of bletilla striata seedlings.

Owner:四川千草生物科技股份有限公司

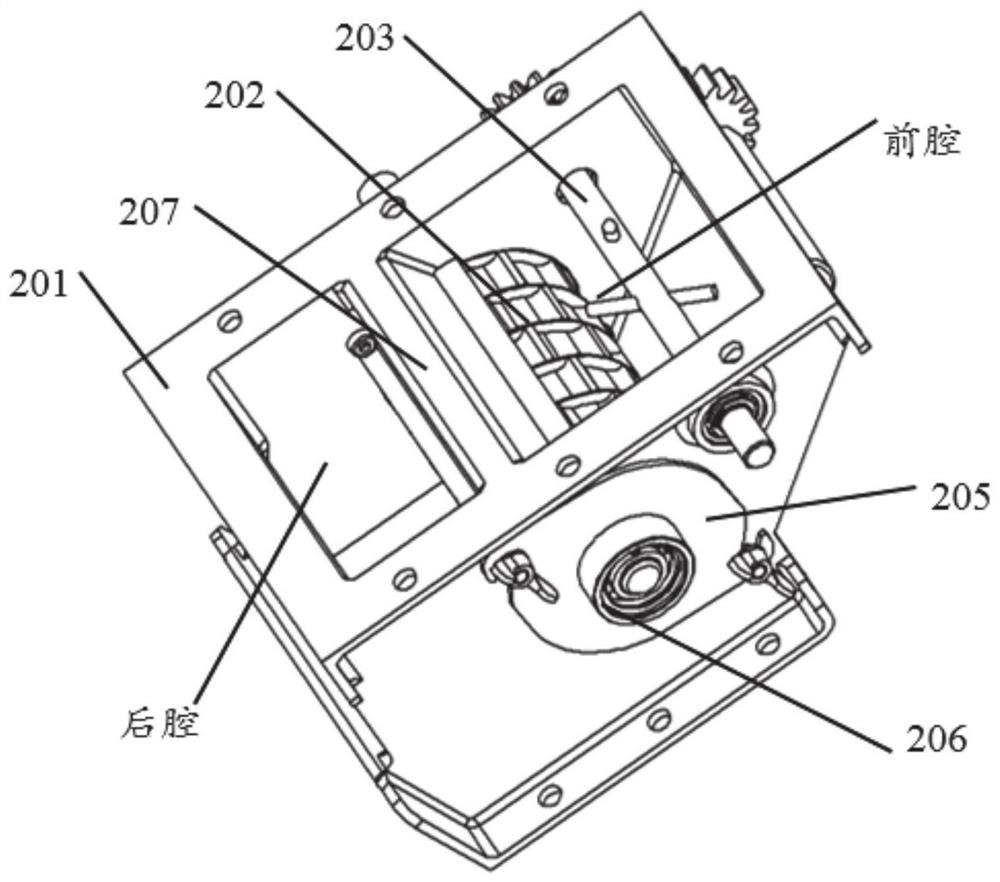

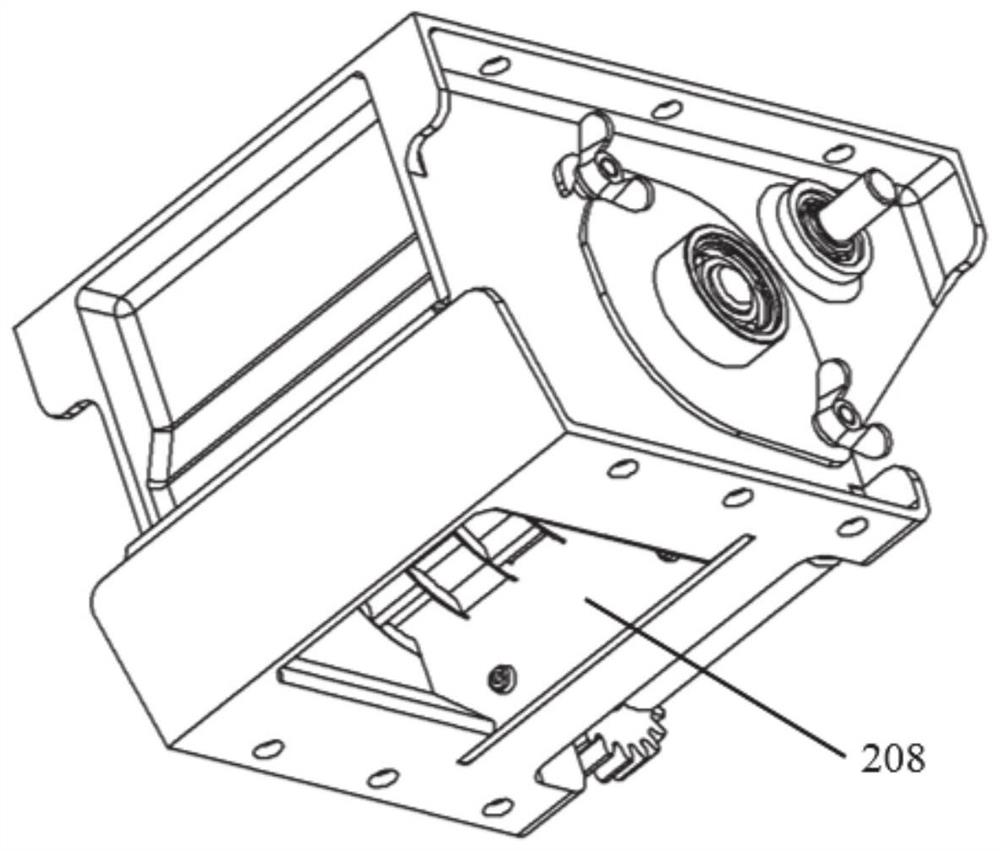

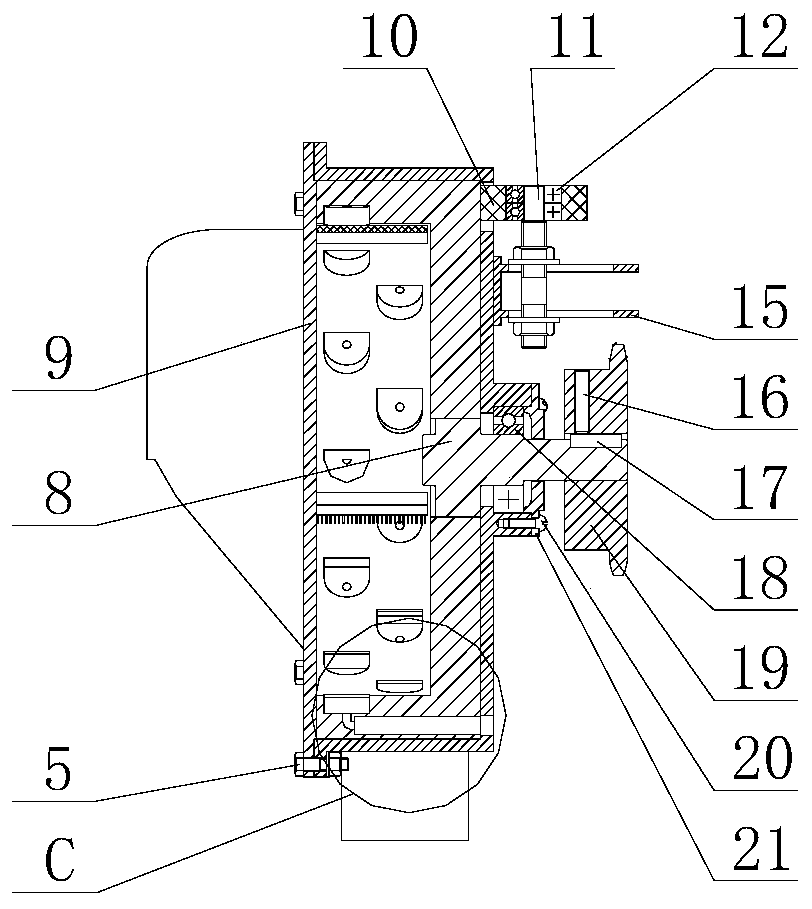

An inner positive pressure combined seed metering device

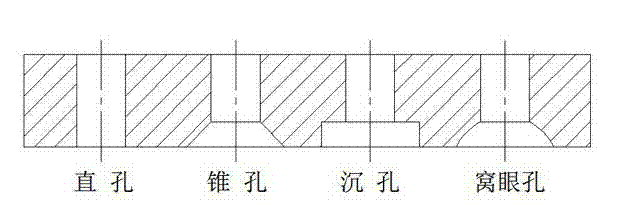

InactiveCN110199632BGood filling performanceExtension of timeBroadcast seedersStomaMechanical engineering

The invention discloses an inner positive pressure combined seed metering device, which comprises a front housing, a rear housing, a seeding disc, a seed unloading wheel and a seeding shaft; the wall thickness of the seeding disc is evenly distributed along the circumferential direction A number of combined holes composed of filling grooves and inoculation holes; air holes are provided on the bottom of the filling groove of each combined hole, and an air hole channel is opened on the seeding tray at the position of each air hole, and the air hole channel includes a A curved channel and a horizontally arranged straight channel, the edge of the cover plate of the rear housing is provided with an arc-shaped through hole, and the other end of the straight channel runs through the rear and the arc-shaped through hole on the rear housing along the axial direction of the seed tray It is connected with the atmosphere through the arc-shaped through hole. The inner seed filling type is combined with the air pressure type. In the seed filling stage, the seeds are first filled into the filling groove, and then pressed onto the air holes. Due to the constraints of the applied force and the depth of the filling groove, the The seeds will not slip out within a certain range, which increases the time for the seeds in the filling groove to be pressed and attached to the air holes.

Owner:HUAZHONG AGRI UNIV

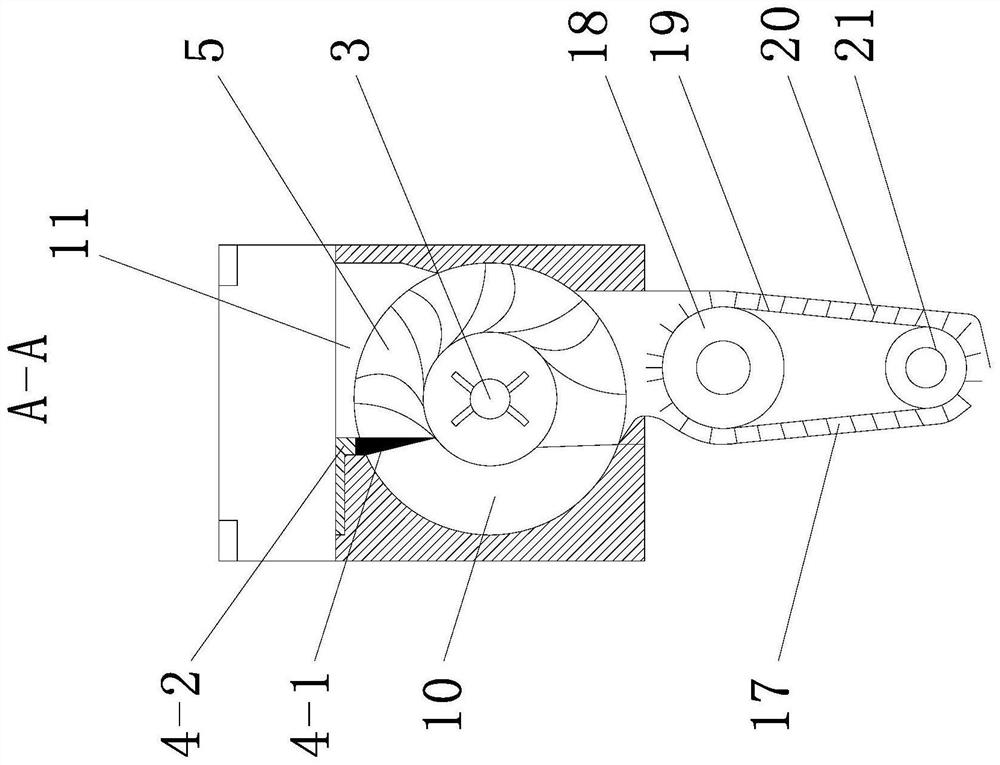

Spiral bevel-gear seed-metering device

InactiveCN111788911AImprove the pass rate of plant spacingSimple structureSeed depositing seeder partsSeederAgricultural science

The invention provides a spiral bevel-gear seed-metering device, belonging to the technical field of agricultural machinery seeding machinery. The spiral bevel-gear seed-metering device structurally comprises a shell, a blocking wheel end cover, a seed-metering shaft, a seed cleaning device, a seed-metering wheel, a first retainer ring, a seed-metering wheel end cover, a blocking wheel, a seed guiding unit, a seed protecting plate, a second retainer ring and a belt which are in connection. The spiral bevel-gear seed-metering device is simple in structure and clear in operating principle. Seedsfall into a seed filling area from a seed-metering opening; the seed-metering shaft drives a spiral bevel-gear seed-metering wheel to rotate; the seed protecting plate is tightly attached to the outer contour surface of the spiral bevel-gear seed-metering wheel; the seed-metering wheel rotates to a seed falling area; the seeds enter the seed guiding unit and fall into a seed guiding groove; a seed guiding driving wheel drives a seed guiding driving wheel belt through the seed-metering shaft to move; the seeds in the seed guiding groove are driven by a seed guiding conveying belt to reach a seed feeding position; and the seeds fall into a seed ditch under the action of gravity. The spiral bevel-gear seed-metering device provided by the invention has the following advantages: seed filling is facilitated; meanwhile, the uniformity of seed metering is improved; the problem of pulsation is effectively solved; and through arrangement of a belt type conveying seed guiding unit, the plant spacing after seed feeding can be guaranteed to be uniform and accurate, and the plant spacing qualified rate of the seeds is greatly improved.

Owner:YANGZHOU UNIV

Small potato seeding machine

PendingCN109362280AStructure miniaturizationImplement equidistant seedingFertiliser distributersPotato plantersTransmitted powerThree Dimensional Size

The invention provides a small potato seeding machine, and belongs to the technical field of agricultural machinery. The small potato seeding machine comprises a hanging frame, a seeding device, a fertilization device and a transmission device. The whole small potato seeding machine is mounted through the hanging frame, the structure is miniaturized and lightweight, and the small potato seeding machine is suitable for planting of potatoes in hilly and mountainous areas and small plot areas; the seeding device is arranged, and thus isometric seeding can be achieved; a stopping piece is arranged, and thus seeding uniformity can be effectively improved; the sizes of arc-shaped concave faces of a seeding wheel are designed according to the three-dimensional size of a single seed potato, only one seed potato is loaded, and thus re-seeding rate is decreased; in addition, during seeding and fertilization, land wheels transmit power through chain wheels and chain shafts for operation, and energy consumption is low; and continuous seeding operation of ditching, seeding, fertilization and earthing can be achieved through the whole machine, the manual labor intensity is reduced, and the seeding efficiency is improved.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

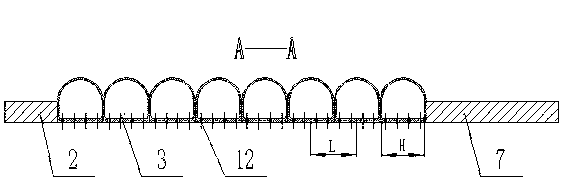

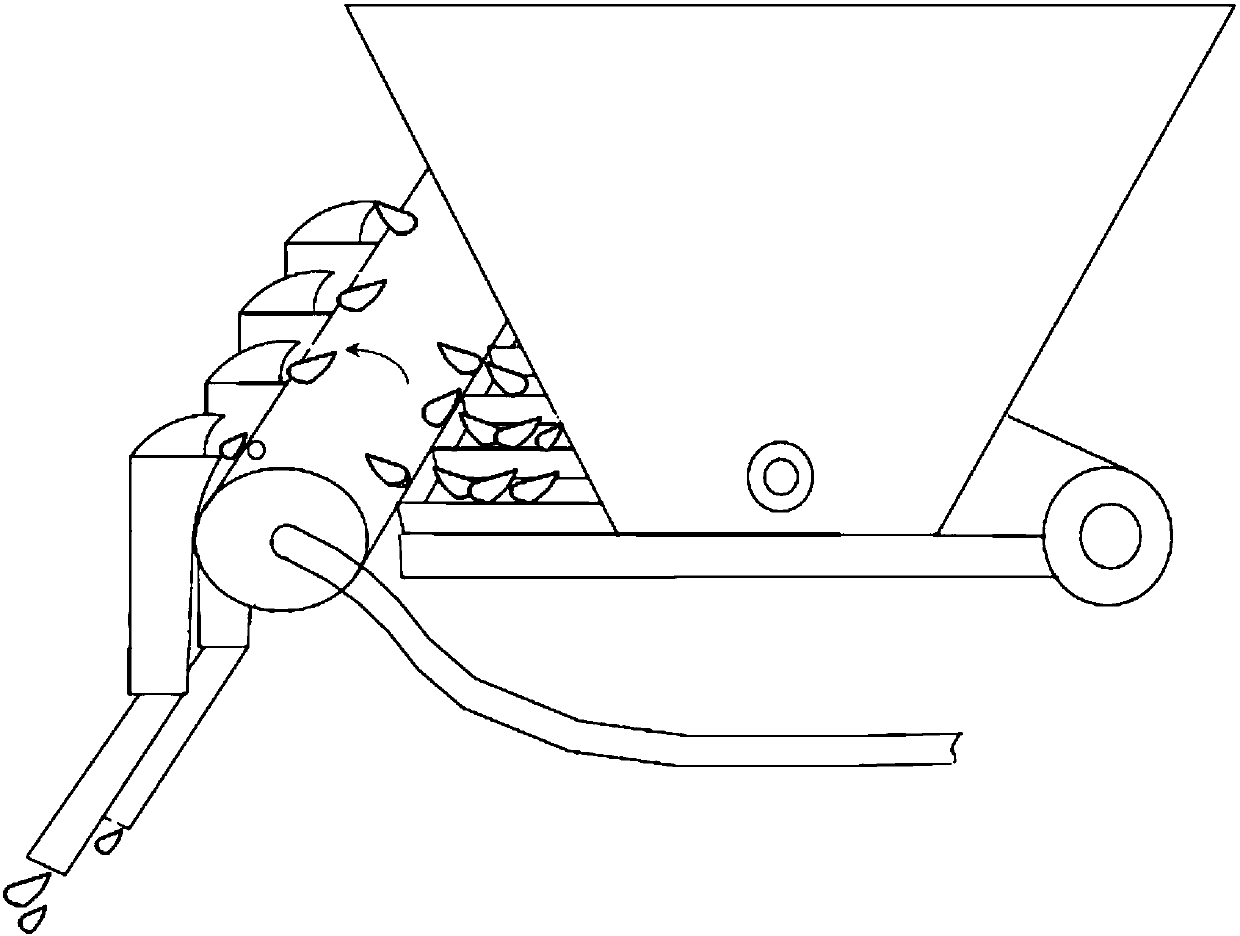

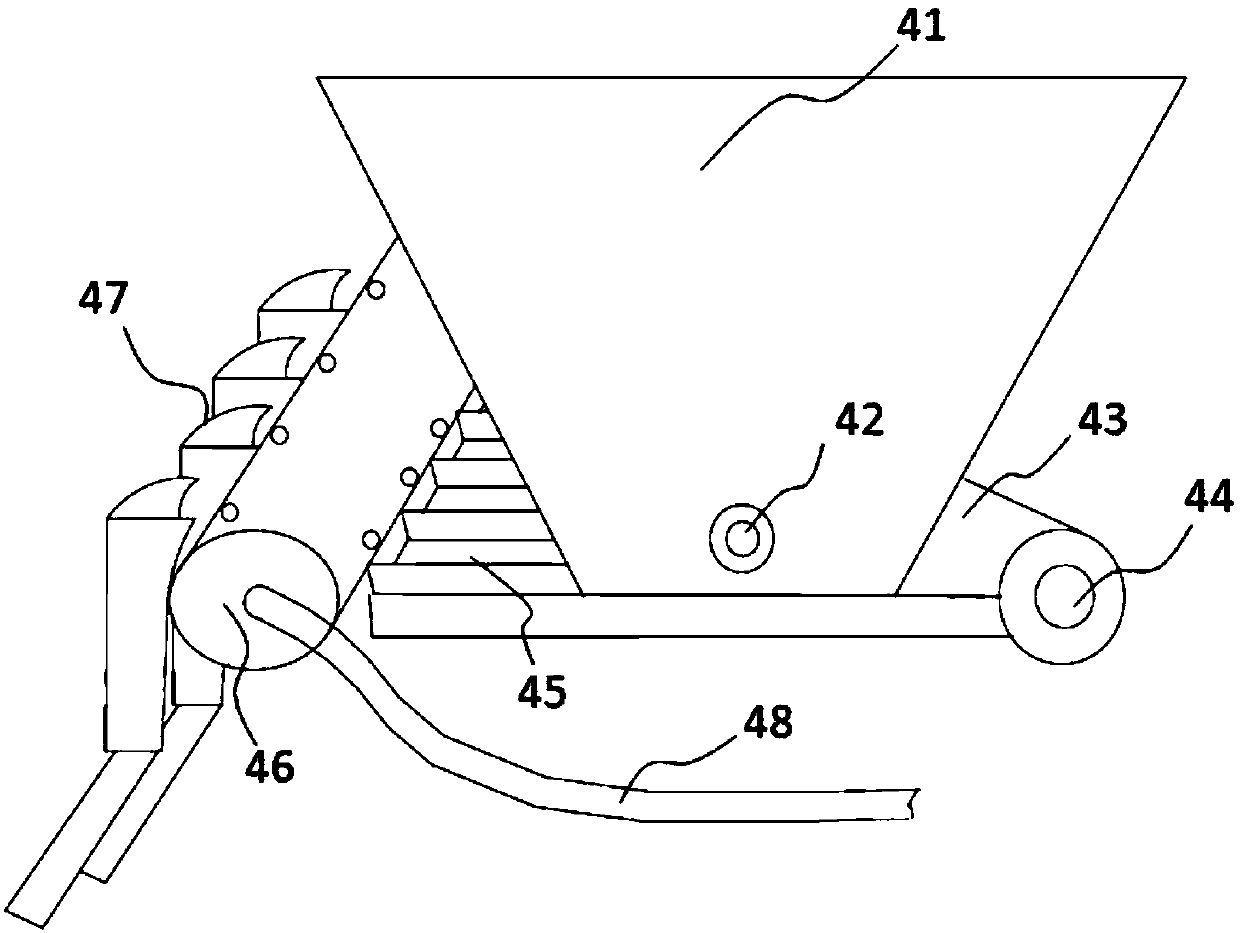

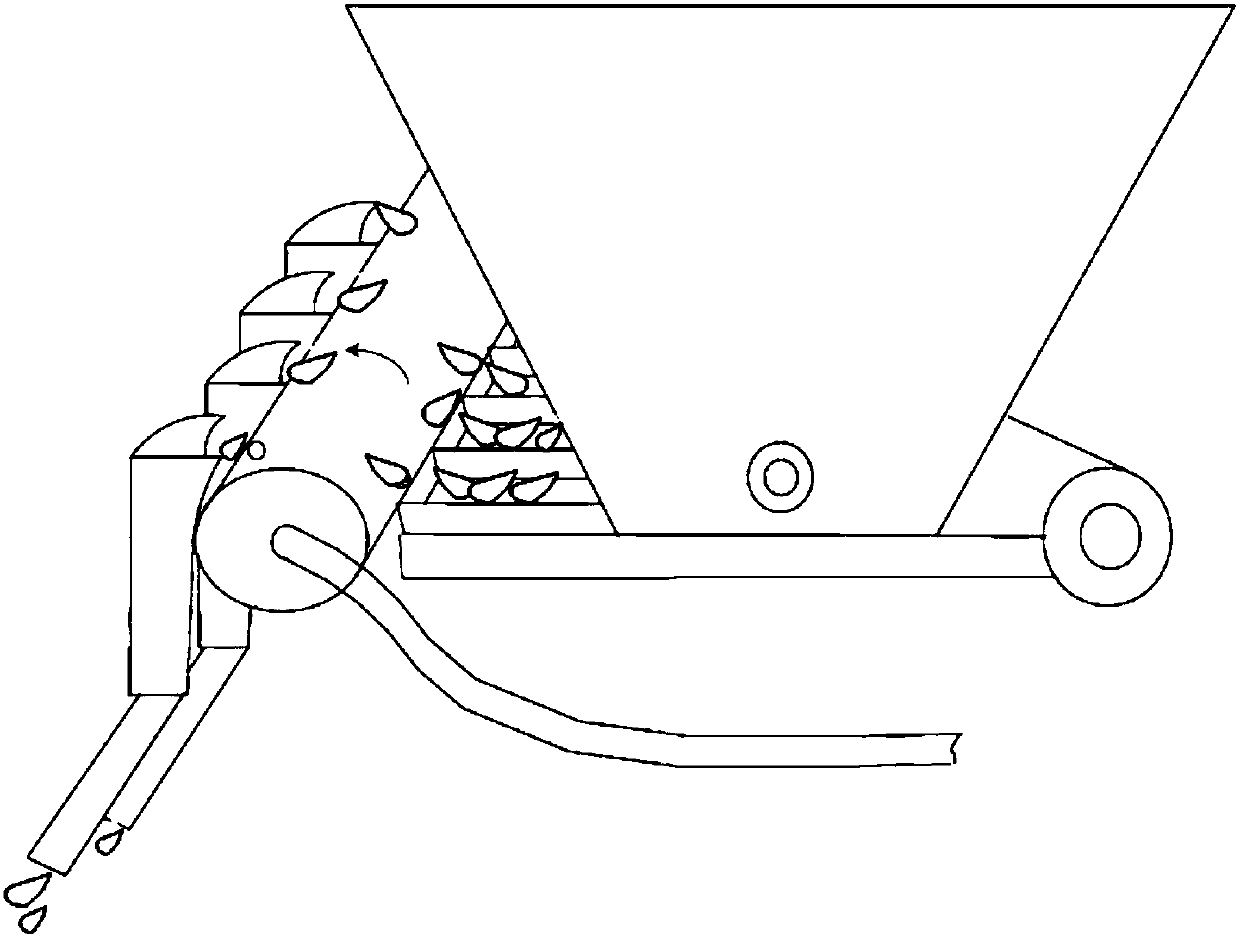

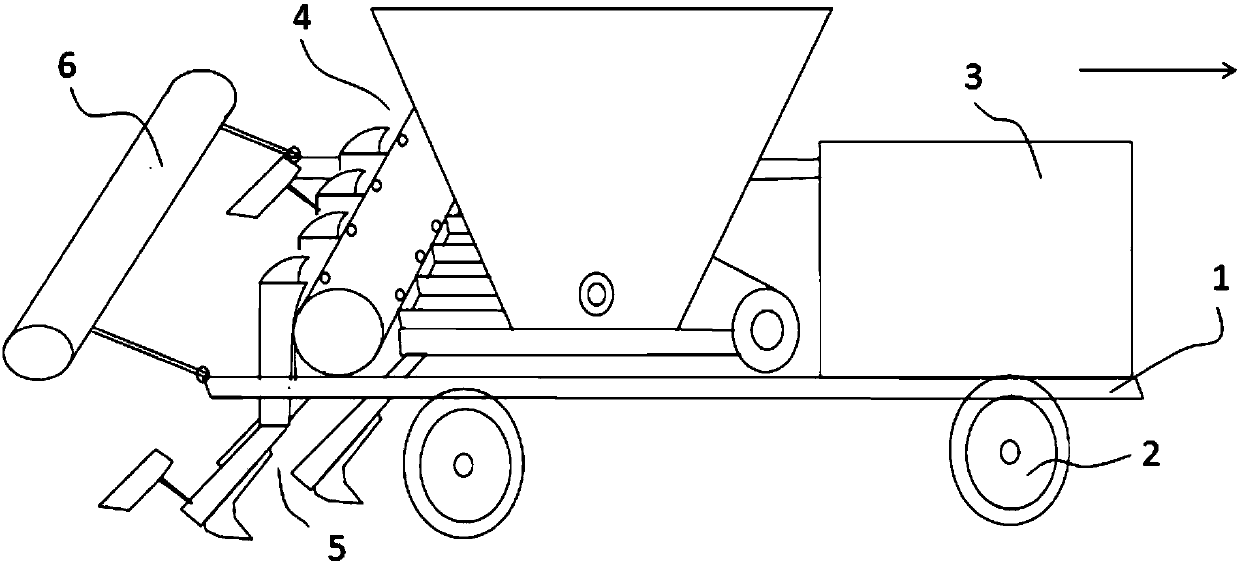

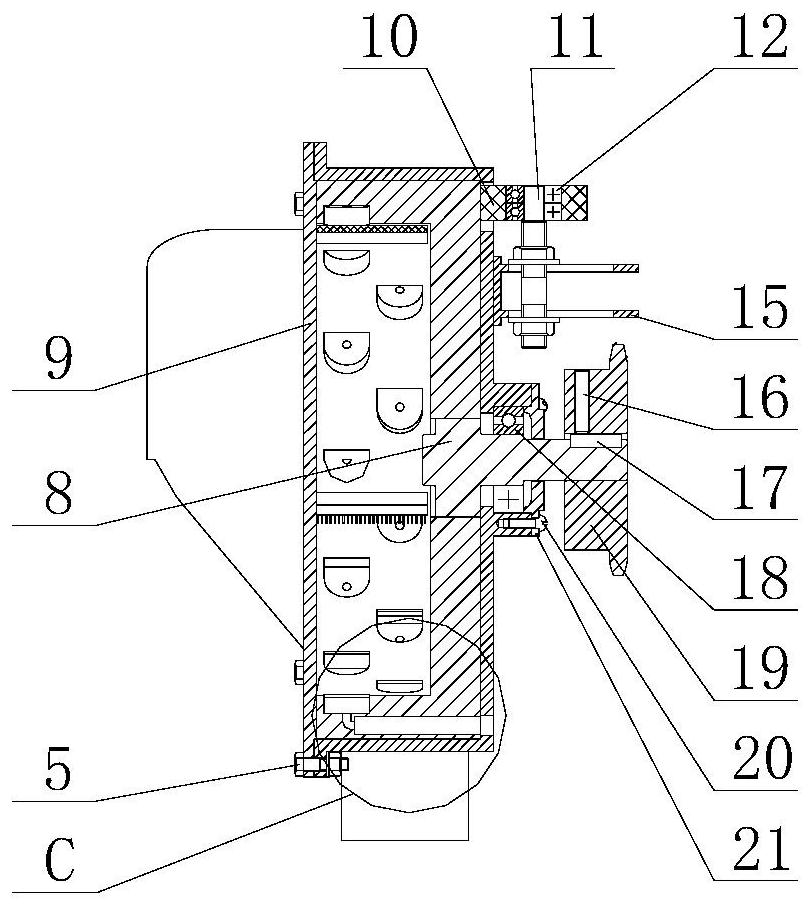

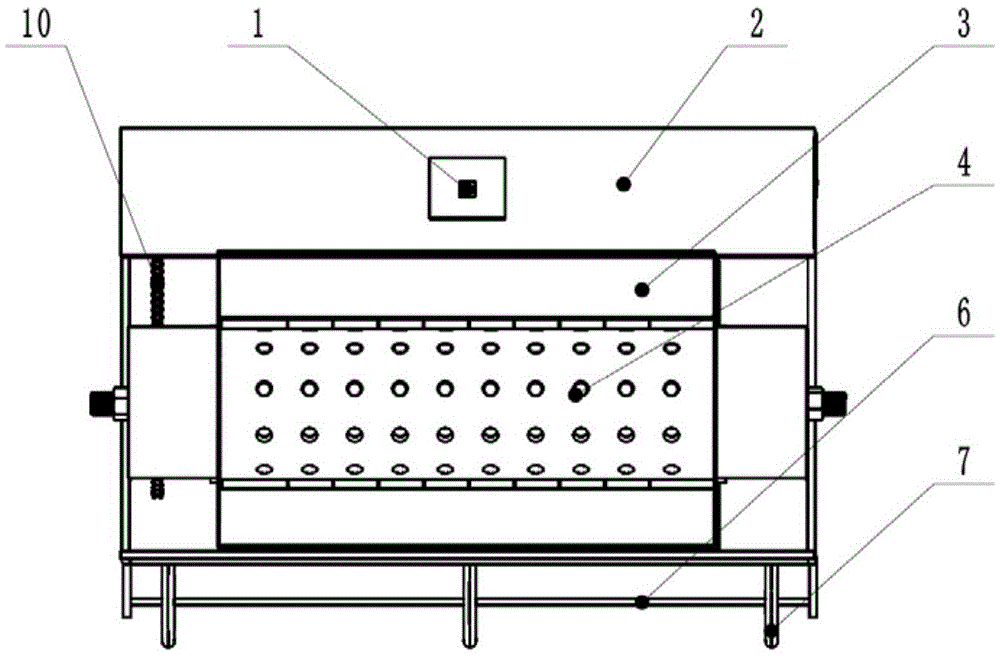

Air-suction vibration disk type field precise seeder for grain

InactiveCN102090184BFree adjustment of vibration amplitudeFree frequency adjustmentSeed depositing seeder partsSeederGasoline

The invention discloses an air-suction vibration disk type field precise seeder for grains, and the seeder provided by the invention is mainly used for precise field sowing and seedling culture for small and medium particle grains of irregular shapes, such as super rice and the like. The air-suction vibration disk type field precise seeder for grains comprises a field travelling rack, a power source, a negative and positive air pressure source, a vibrated seed disk mechanism, a hand-held profiling sucking disk and a control unit, wherein the vibrated seed disk mechanism and the negative and positive air pressure source are installed on the field travelling rack; power is provided by a small gasoline engine; seeds are subjected to upward throwing movement to be mutually separated under theshock excitation of the vibrated seed disk; a seed disk vibration parameter is reasonably regulated, thus the seeds are in a 'boiling' moving state, thereby obviously enhancing the mobility, and reducing the seed adsorption resistance; a sucking disk panel is provided with profiling adsorption holes; and the shapes and arrangement modes of the adsorption holes can be changed according to different requirements of sowing objects. According to the invention, the precise field sowing and seedling culture for small-particle grains can be realized, the sowing effect and uniformity can be effectively improved, the seedling culture cost is lowered, requirements on seed sizes are low, and the seeds can be prevented from being damaged.

Owner:JIANGSU UNIV

A kind of mechanical seeding method for inoculating cistanche

ActiveCN107278440BImprove efficiencyAvoid serious wasteRegular seed deposition machinesAgricultural scienceGermplasm

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

Electric self-propelled CNC plot drill

ActiveCN104012222BPrecise Control of UniformityEasy to operateSeed depositing seeder partsBroadcast seedersNumerical controlAutomatic control

The invention relates to an electric self-propelled numerical-control plot drill seeder aiming to solve the technical problems that plot seeders in the prior art are nonuniform in seeding and not precise enough in row length control. The electric self-propelled numerical-control plot drill seeder comprises a walking mechanism, an automatic control device, a seed separation mechanism, a furrowing and seeding mechanism and a lifting mechanism, and the seed separation mechanism, the furrowing and seeding mechanism and the lifting mechanism are correspondingly arranged on the walking mechanism; the seed separation mechanism comprises a seed separation unit and a seed storage unit, the seed separation unit is arranged above the furrowing and seeding mechanism, and the seed storage unit is arranged above the seed separation unit; the walking mechanism is an electric walking mechanism; the seed separation unit comprises a seed separation disc, a seed separation servo motor or a seed separation stepping motor, and the seed separation servo motor or the seed separation stepping motor is arranged below the seed separation disc, and drives the seed separation disc to rotate; the electric self-propelled numerical-control plot drill seeder has the advantages of uniform between-row and in-row seeding, high degree of automation, stepless row length setting (arbitrary row length setting), high row length control accuracy, simple operation, high sowing efficiency and the like.

Owner:李延民

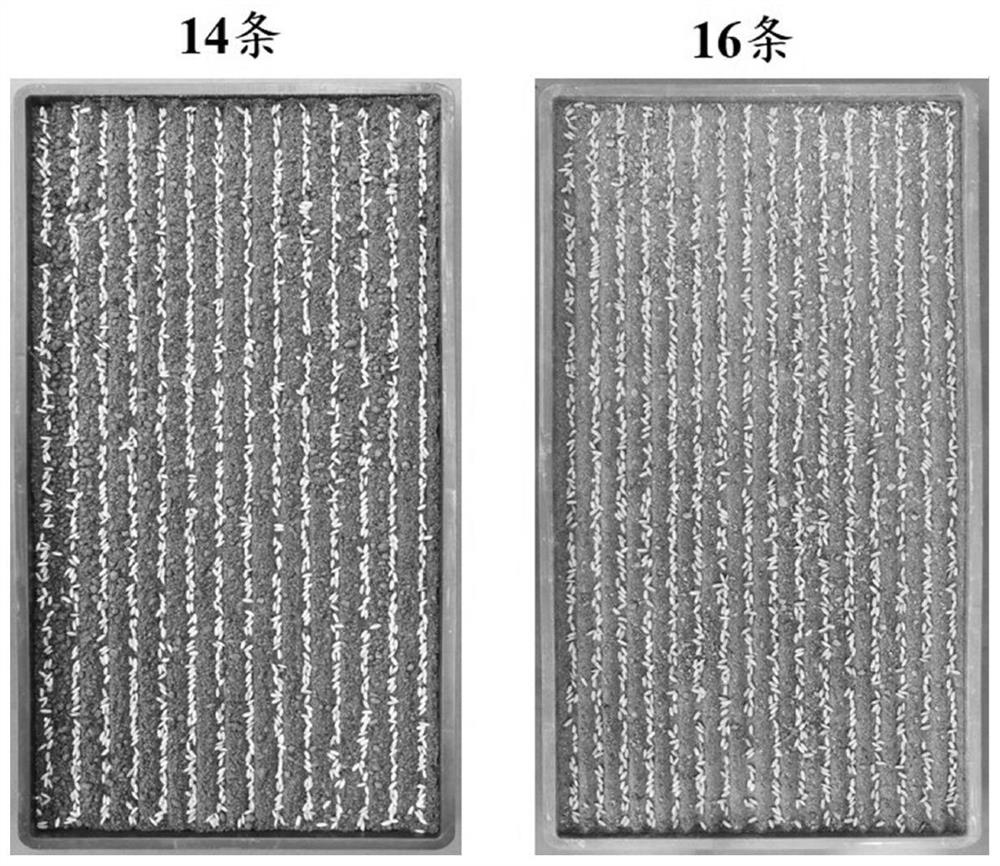

A kind of rice planting method by quantitative machine

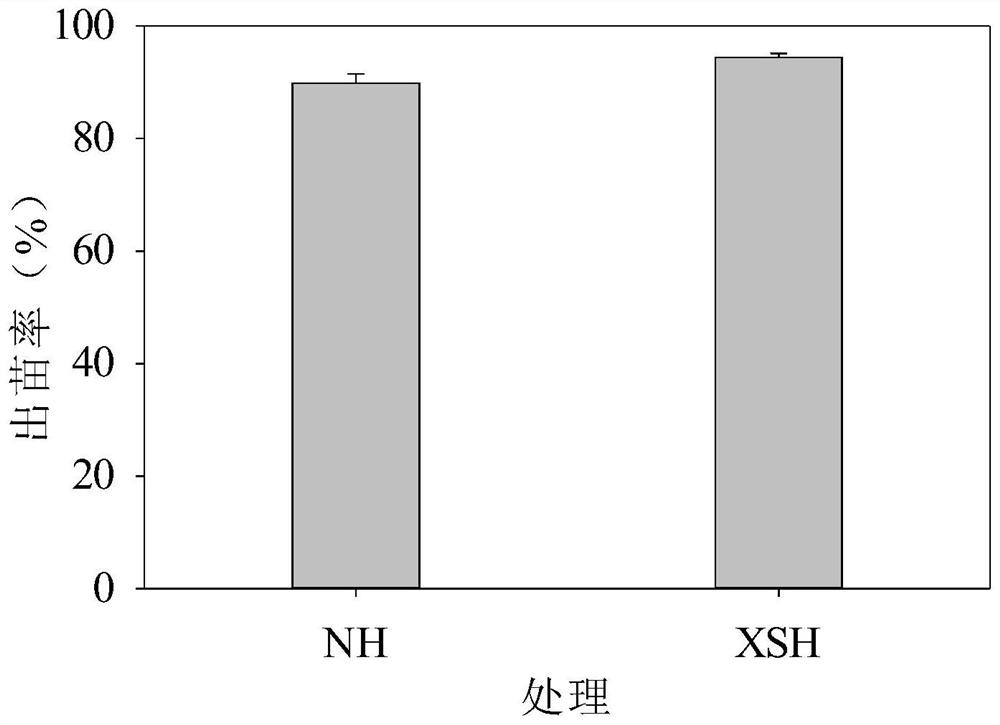

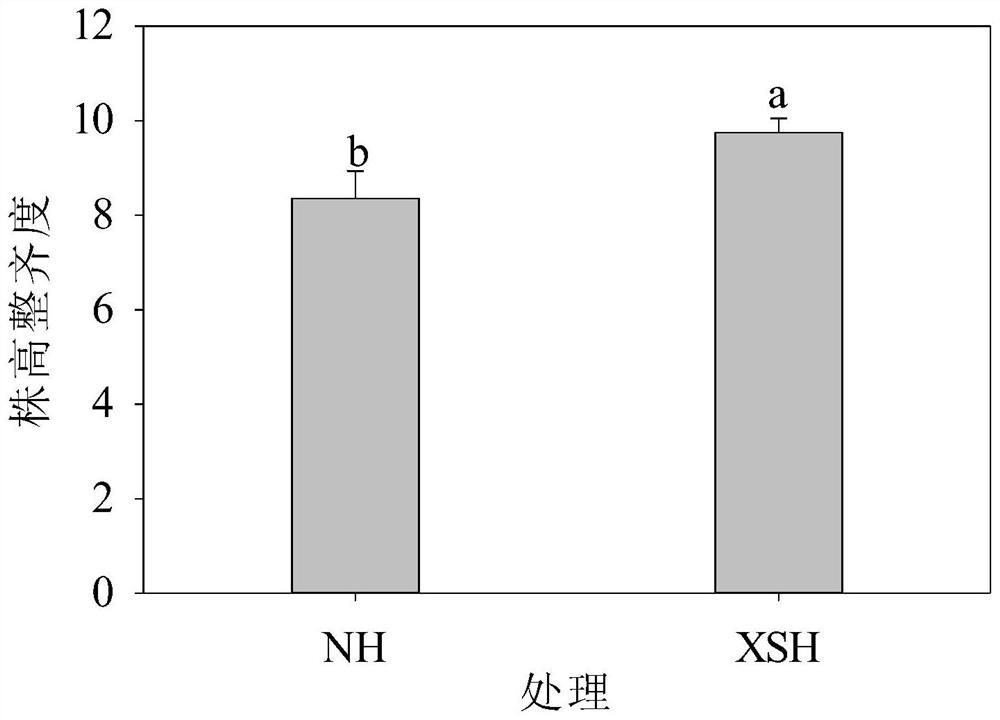

ActiveCN112913607BImprove uniformityImprove seeding uniformityRice cultivationAgricultural engineeringSeedling

The invention belongs to the technical field of rice machine-planting and planting, and discloses a quantitative machine-planting method for rice. According to the basic number of machine-planted seedlings per hole (cluster) under a specific yield target, according to the sowing method, the survival rate of machine-planted seedlings is calculated and the machine-planted seedlings are The utilization rate and the seedling rate of the seedlings in the seedling trays are used to determine the number of seeds sown in the trays. Positioning, quantitative and uniform sowing are carried out by means of hole seeding and drill seeding, and the machine-planting method of corresponding horizontal seedling times is matched. Realize the accurate digitization of seeding rate and improve the uniformity of the distribution of machine-planted seedlings.

Owner:CHINA NAT RICE RES INST

Caterpillar band recess next-to-ground precise seed discharging device

InactiveCN112913396AControl spatial distributionControl seeding rateSeed depositing seeder partsRegular seed deposition machinesAgricultural scienceAgricultural engineering

Owner:NORTHWEST A & F UNIV +1

Electric drive type seed sowing device, device and method

InactiveCN111642194AImprove uniformityImprove reliabilitySeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringElectric drive

The invention discloses an electric drive type seed sowing device, device and method. According to the technical scheme, the electric drive type seed sowing device comprises a shell, a spiral seed sowing wheel set and a stirring shaft set, wherein the spiral seed sowing wheel set and the stirring shaft set are installed in the shell and connected with a driving device, and the spiral seed sowing wheel set and the stirring shaft set can rotate in the same direction according to the set transmission ratio under the action of the driving device; and a seed clearing plate is installed at the bottom of the shell and tightly attached to the outer edge of the spiral seed sowing wheel set, and the upper end face of the seed clearing plate is higher than the lower end face of the spiral seed sowingwheel set. By means of the electric drive type seed sowing device, device and method, the sowing amount can be accurately adjusted, the uniformity and reliability of seed sowing are effectively improved, seed sowing can be achieved by replacing different seed sowing wheels for different planted crops, and operation is easy.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Internal-inflation positive-pressure combined seed metering device

InactiveCN110199632AGood filling performanceExtension of timeBroadcast seedersPositive pressureEngineering

The invention discloses an internal-inflation positive-pressure combined seed metering device, which comprises a front shell body, a rear shell body, a seed metering disc, a seed discharging wheel anda seed metering shaft, wherein a plurality of combined holes formed by filling grooves and inoculation holes are uniformly distributed on the wall thickness of the seed metering disc along the circumferential direction; an air hole is formed in the groove bottom of the filling groove of each the combined hole; an air hole channel is formed in the seed metering disc at the position of each air hole; each the air hole channel comprises a bent channel and a transversely-arranged straight channel; an arc-shaped through hole is formed in the edge of a cover plate of the rear shell body; and the other end of the straight channel penetrates through the axial direction of the wall thickness of the seed metering disc and is connected with the arc-shaped through hole on the rear shell body and is communicated with the atmosphere through the arc-shaped through hole. The combination of the inner inflation type and the air pressure type is adopted, in the filling stage, seeds are filled into the filling grooves first, and then are pressed and attached to the air holes, and because the seeds filled into the filling grooves cannot slide out within a certain range under the restriction of the acting force and the depth dimension of the filling grooves, the time for the seeds in the filling grooves to be pressed and attached to the air holes is increased.

Owner:HUAZHONG AGRI UNIV

A rice precision live seeding device

ActiveCN107124942BChange speedEnhanced cavitationDibble seedersAgriculture gas emission reductionCavitationDrive shaft

The invention discloses a rice precise direct-seeding and cavitating device, which comprises a shell, a cavitating disk and a transmission shaft, wherein a disk cavity is formed in the shell, and the cavitating disk is arranged in the disk cavity; the cavitating disk comprises a connecting portion connected with the transmission shaft and a plurality of cavity partition plates radially extending out of the outer side of the connecting portion, a seed cavity is formed among every two adjacent partition cavity plates and a cavity wall of the disk cavity, a seed inlet for seeds to enter the seed cavities is formed in the upper portion of the disk cavity, and a seed output opening for the seeds in the seed cavities to be output is formed in the lower portion of the disk cavity; when the seed inlet is communicated with the seed cavities, the seeds can enter the seed cavities through the seed inlet; when the seed cavities are communicated with the seed output opening, the seeds in the seed cavities are output from the seed output opening. The rice precise direct-seeding and cavitating device disclosed by the invention is simple and reliable, convenient and quick to install, capable of effectively improving cavitation of sowing in line and capable of meeting different requirements of rice precise hole sowing.

Owner:SOUTH CHINA AGRI UNIV

Seedling sowing equipment with high efficiency

InactiveCN107980292AImprove efficiencyAvoid wastingSeed depositing seeder partsBroadcast seedersSeedlingSowing

The invention provides seedling sowing equipment with high efficiency. The equipment can complete bottom soil spreading and rice sowing in one time, the sowing speed is increased, the quantity and thequality of sowing can be clearly observed, and surface soil needs to be spread on the top layer only after bottom soil spreading and sowing by the seedling sowing equipment with high efficiency, so that the sowing uniformity is greatly improved, and the quality of seedlings is greatly improved; moreover, the waste of soil and seeds can be prevented through the arrangement of a soil outlet door and a seed outlet door, soil or seeds can be accurately scattered on a nursery seedling plate through the control of a controller, the waste of seedling soil and seeds is avoided, and the equipment hasthe advantages of simple structure, high sowing efficiency, high quality of planted seedlings and the like.

Owner:新昌县汉良苗木专业合作社

A drum-type precision seeding device for hole sowing of vegetable seeds

ActiveCN104620735BAvoid damageSame distanceSeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringSprocket

The invention discloses a drum-type precise sowing device for hole sowing of vegetable seeds. The device comprises a switch, a stander, a feed hopper, a seed metering device, a brush, a rear walking wheel axle, wheels, a blanking hopper, an overrun clutch, a plurality of chains, a plurality of chain wheels, a front walking wheel axle and a motor, wherein the motor, the front walking wheel axle and the wheels are arranged at the front end of the stander; the rear walking wheel axle and the wheels are arranged at the rear end of the stander; the feed hopper, the seed metering device, the brush and the blanking hopper are arranged in the middle of the stander; the motor can be used for controlling the front walking wheel axle, the rear walking wheel axle and the seed-metering device by chain transmission. The drum-type precise sowing device has the characteristics of being simple in structure, convenient to operate and the like, and can be used for precisely and evenly sowing seeds at equal intervals.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com