Air-sucking vibration plate type precision seeder for field seedling raising

A seeder and vibrating disc technology, applied in the direction of spaced quantitative sowing machinery, seeder parts, etc., can solve the problems of not meeting the requirements of agronomy, not suitable for production needs, and poor sowing uniformity, so as to improve the sowing uniformity and The effect of operating efficiency, reducing the cost of raising seedlings, and not hurting the seeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

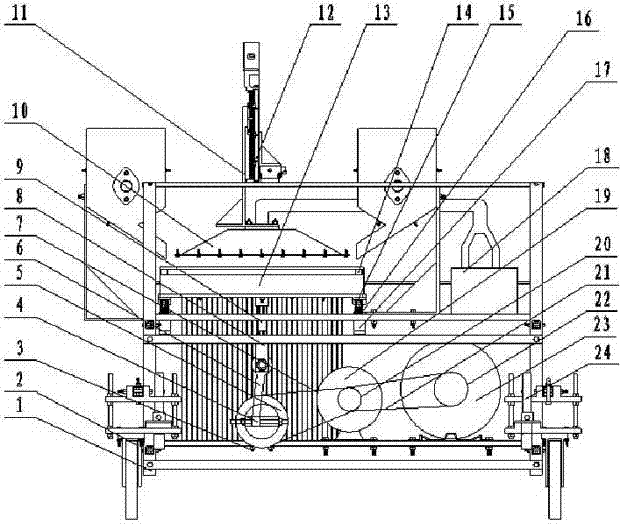

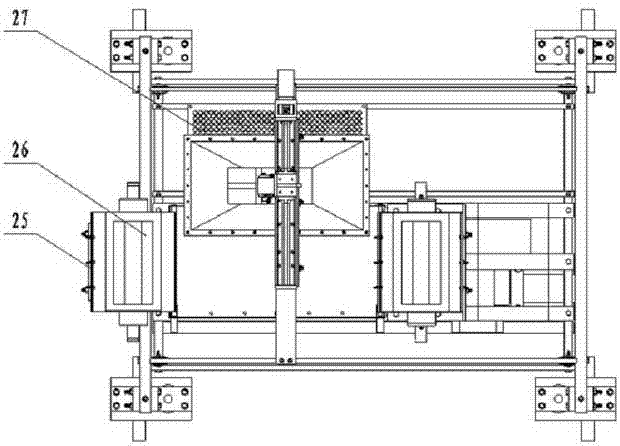

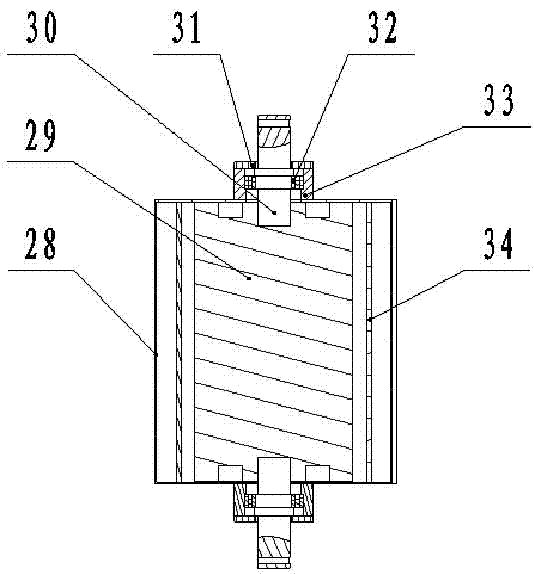

[0013] For device layout and transmission, please refer to figure 1 , figure 2 , image 3 . The planter stand 1 is divided into upper, middle and lower three-layer decks, and the traveling wheels 2 are connected to the lower panel of the leveling mechanism 24 by bolts, and are mainly used for walking in paddy fields. The base one 3 is connected to the lower deck of the planter frame 1 by bolts. The eccentric adjustment mechanism 4 is installed on the belt pulley one 5. Belt pulley one 5 is connected on the base one 3, and the axis of rotation of belt pulley one 5 is parallel with the axis of small gasoline engine 19 and positive and negative pressure fan 23 output shafts. One end of the connecting rod 6 is installed on the linear needle bearing 9 through the base 2 8, and the other end is installed on the eccentric adjustment mechanism 4. The suction cup 10 is connected to a two-degree-of-freedom manipulator 12 through a robot flange 11 . The two-degree-of-freedom manip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com