Type hole plate-type seed sowing and replanting device for alfalfa

The technology of alfalfa and seed metering device is applied in the directions of planter parts, etc., which can solve the problems of difficult control of wind pressure, high power and high manufacturing cost, and achieve the effect of improving the uniformity of sowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

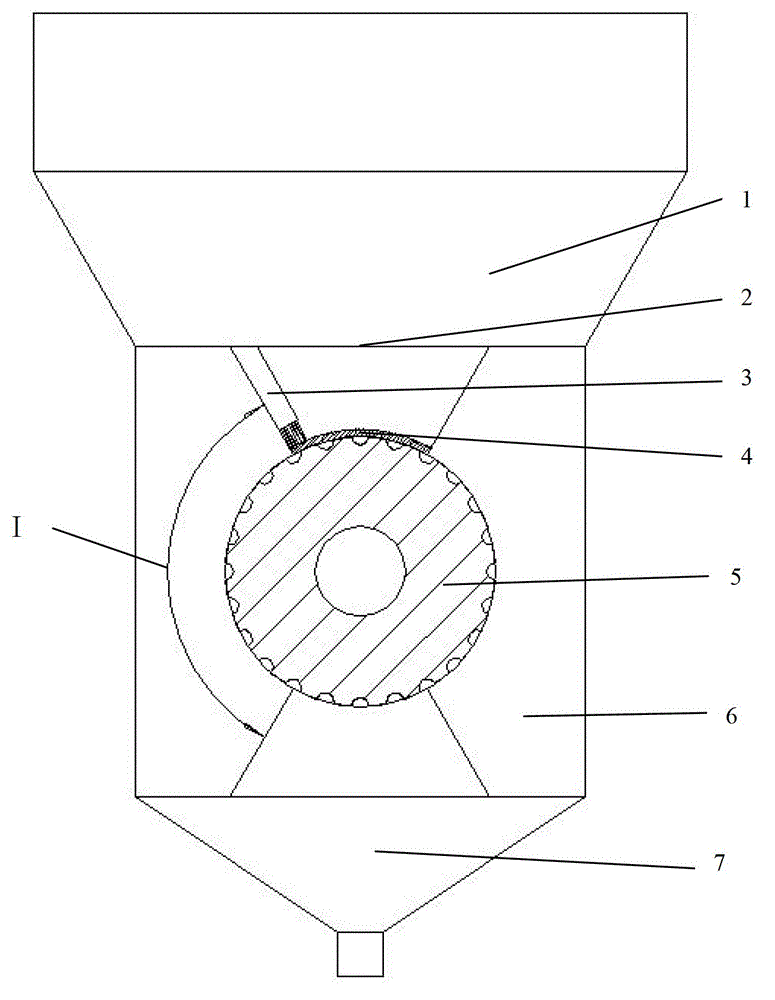

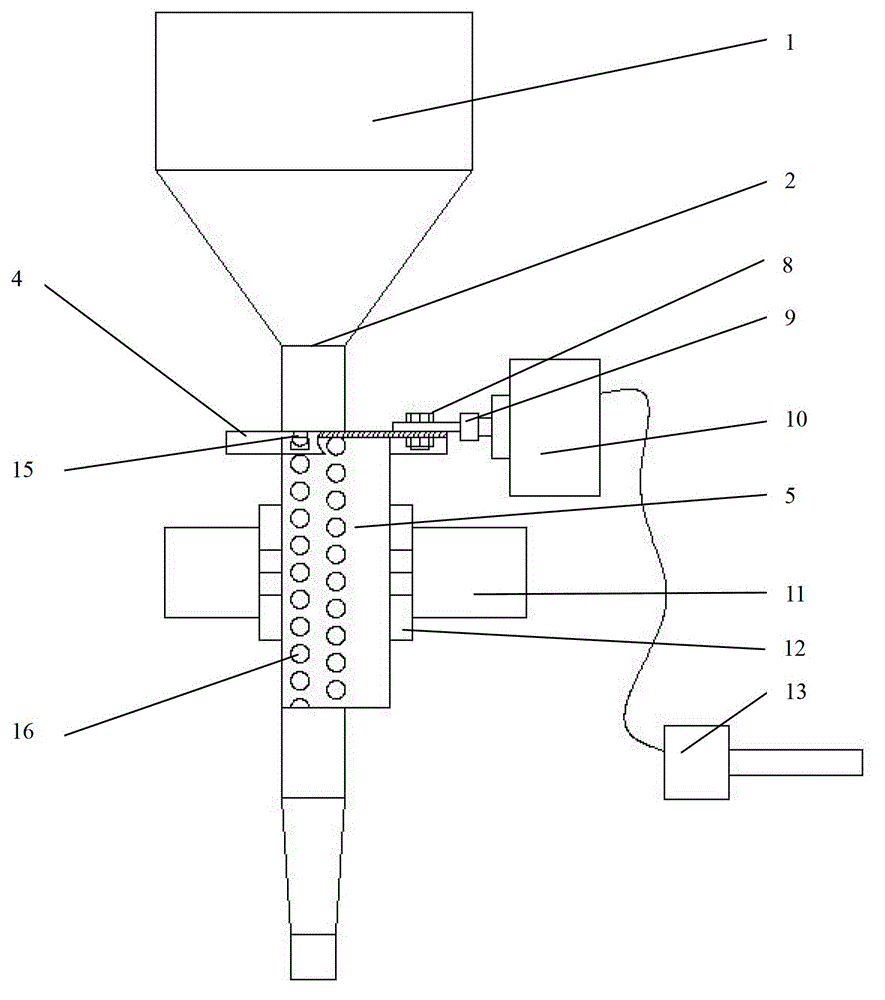

[0033] The present invention will be further described below according to accompanying drawing.

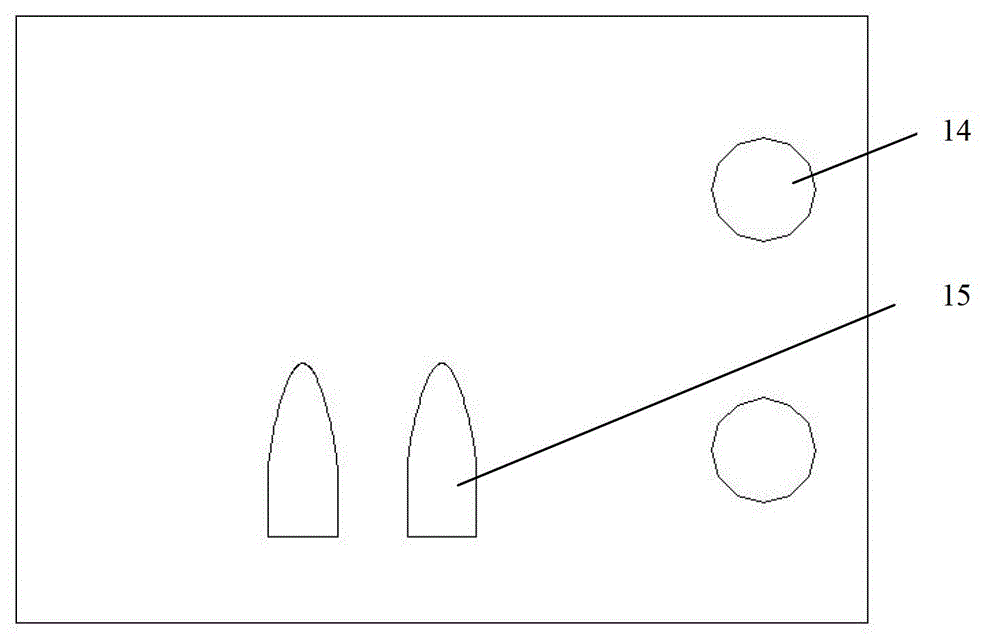

[0034] Please refer to Figure 1-Figure 7 , the alfalfa type orifice type supplementary seed metering device of the present invention comprises a seed box 1, the bottom of the seed box 1 is provided with a seed inlet 2, and a type orifice plate 4 is installed below the seed inlet 2, and a type hole plate 4 is provided on the type hole plate 4. Hole 15, the type orifice plate 4 below is the pocket wheel 5. Grooves 16 are distributed on the circumference outer surface of the socket wheel 5, and the socket wheel 5 is locked on the rotating shaft 11 by the clamp 12, and rotates with the rotating shaft 11; The device housing 6 has a seed protection area I, and an inoculation cup 7 is arranged below the seed meter housing 6 corresponding to the socket wheel 5; along the rotation direction of the socket wheel 5, the socket 16 is about to be screwed into the seed protection area The see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com