Patents

Literature

98results about How to "Enhanced cavitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

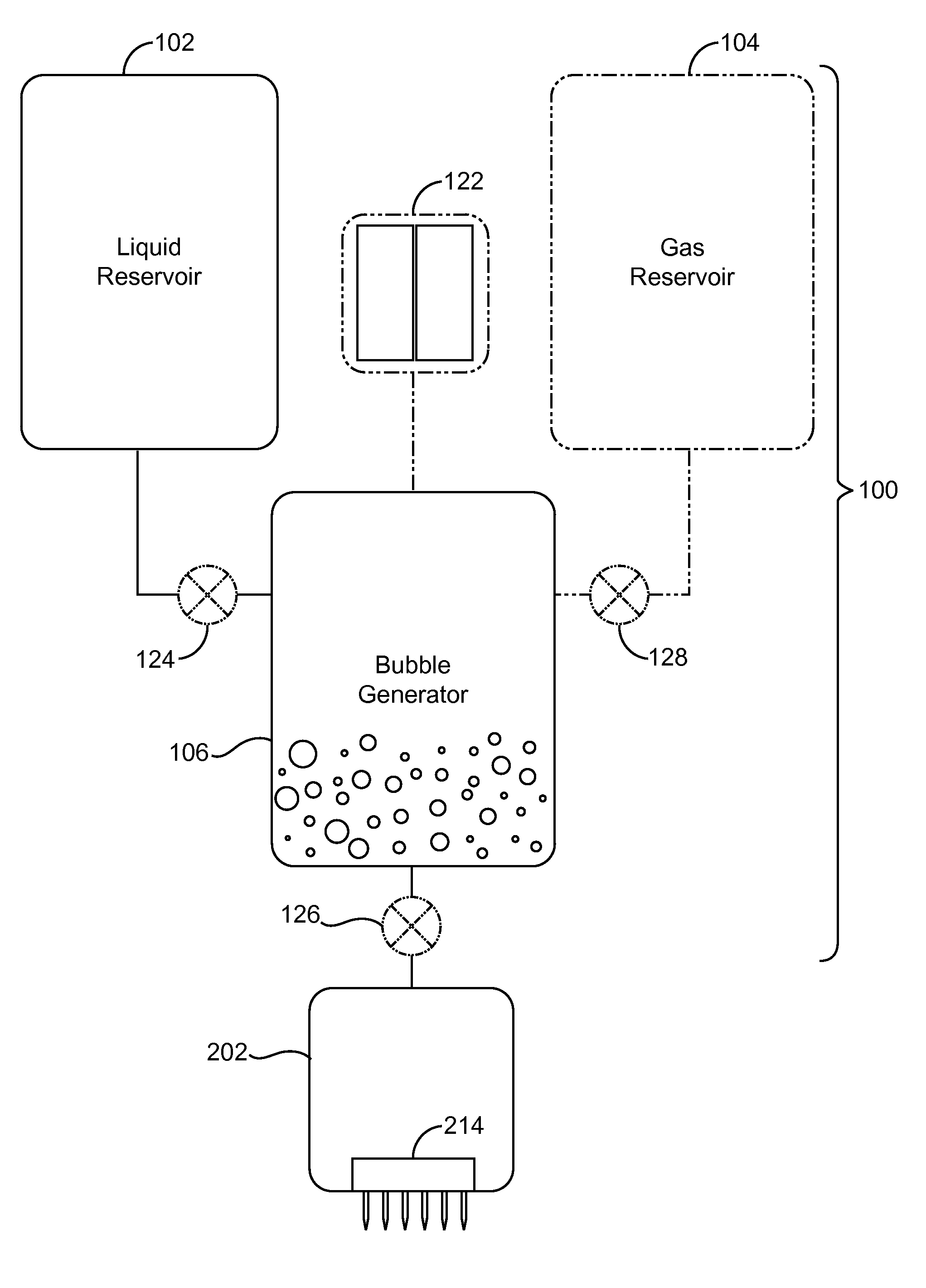

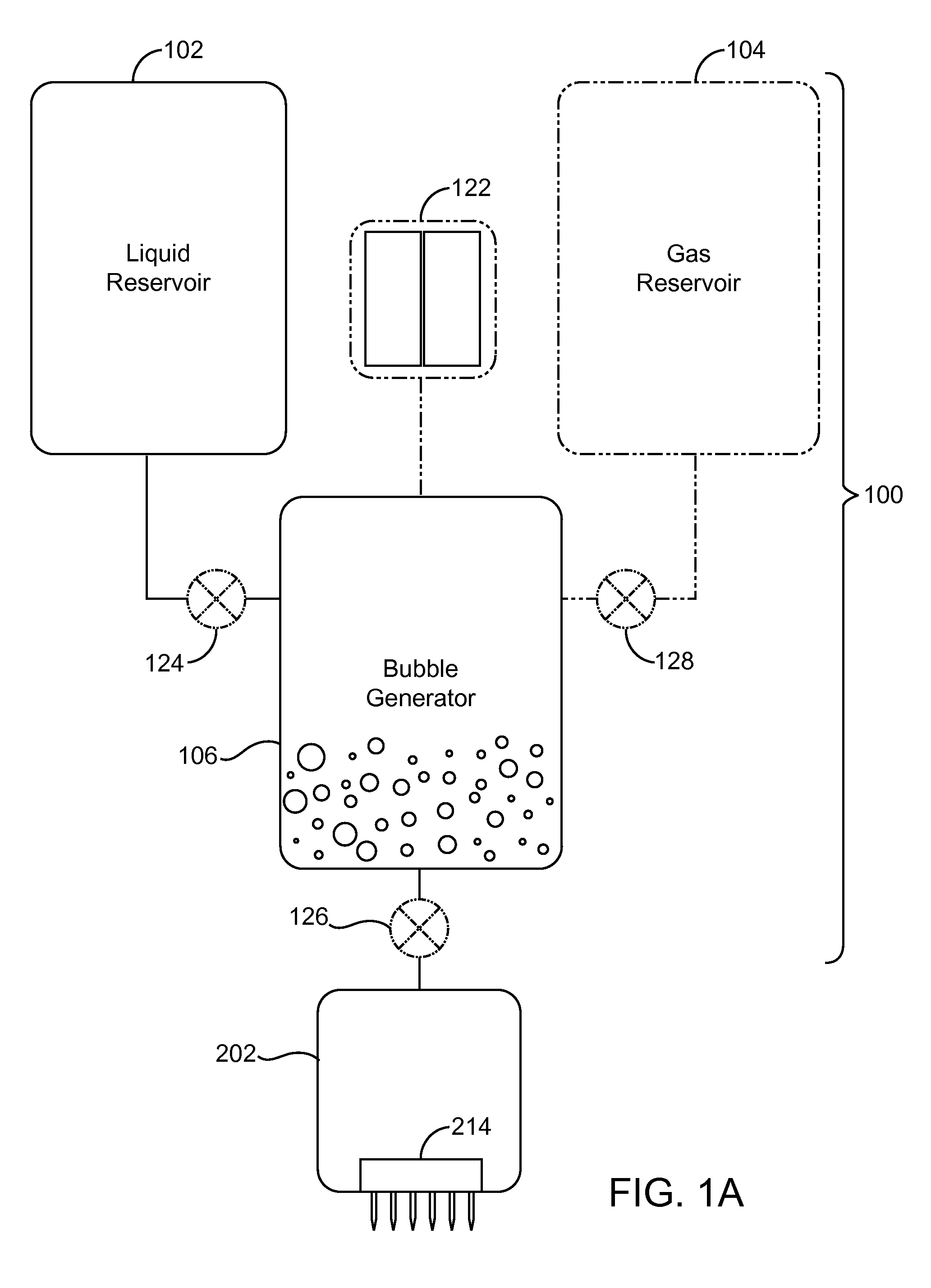

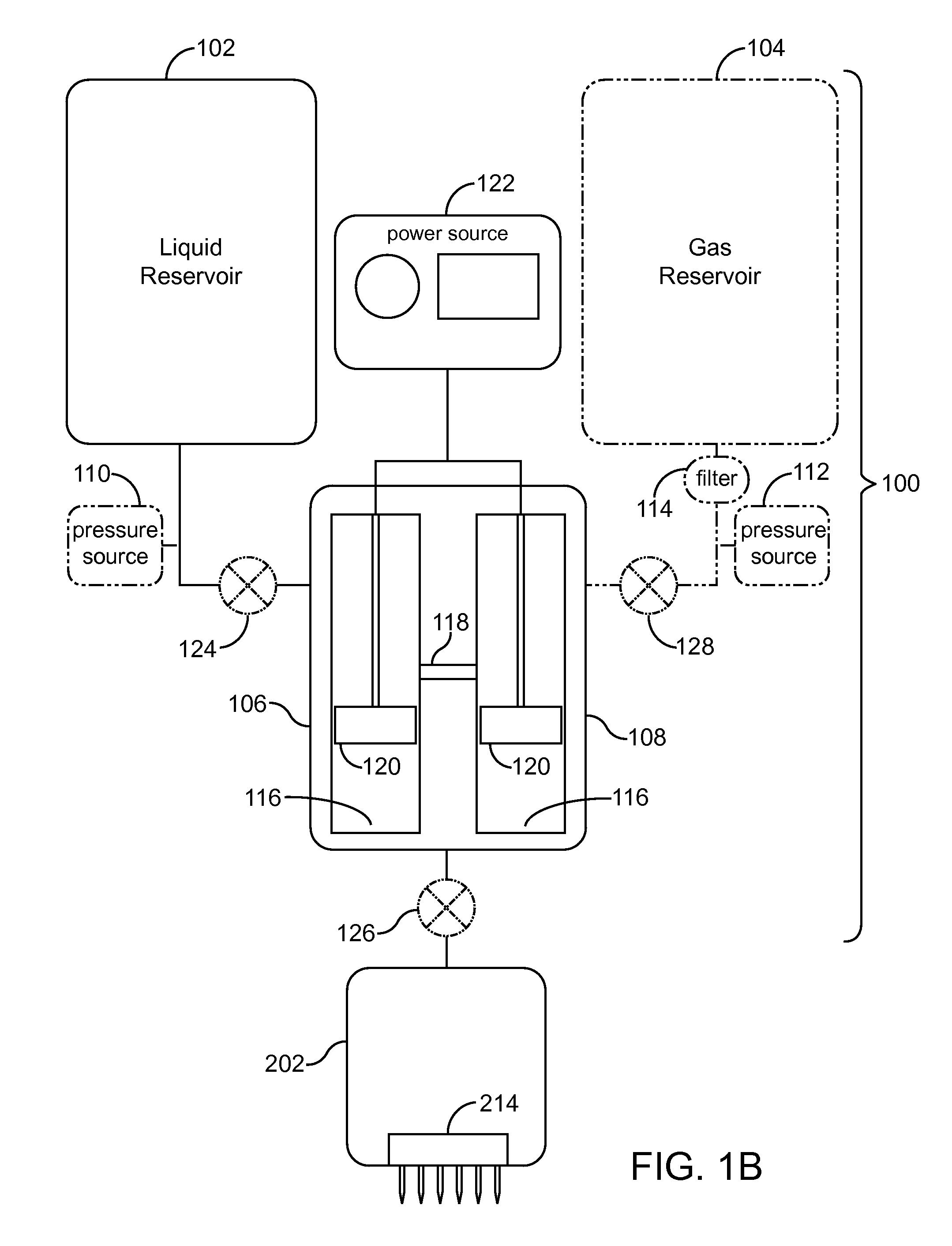

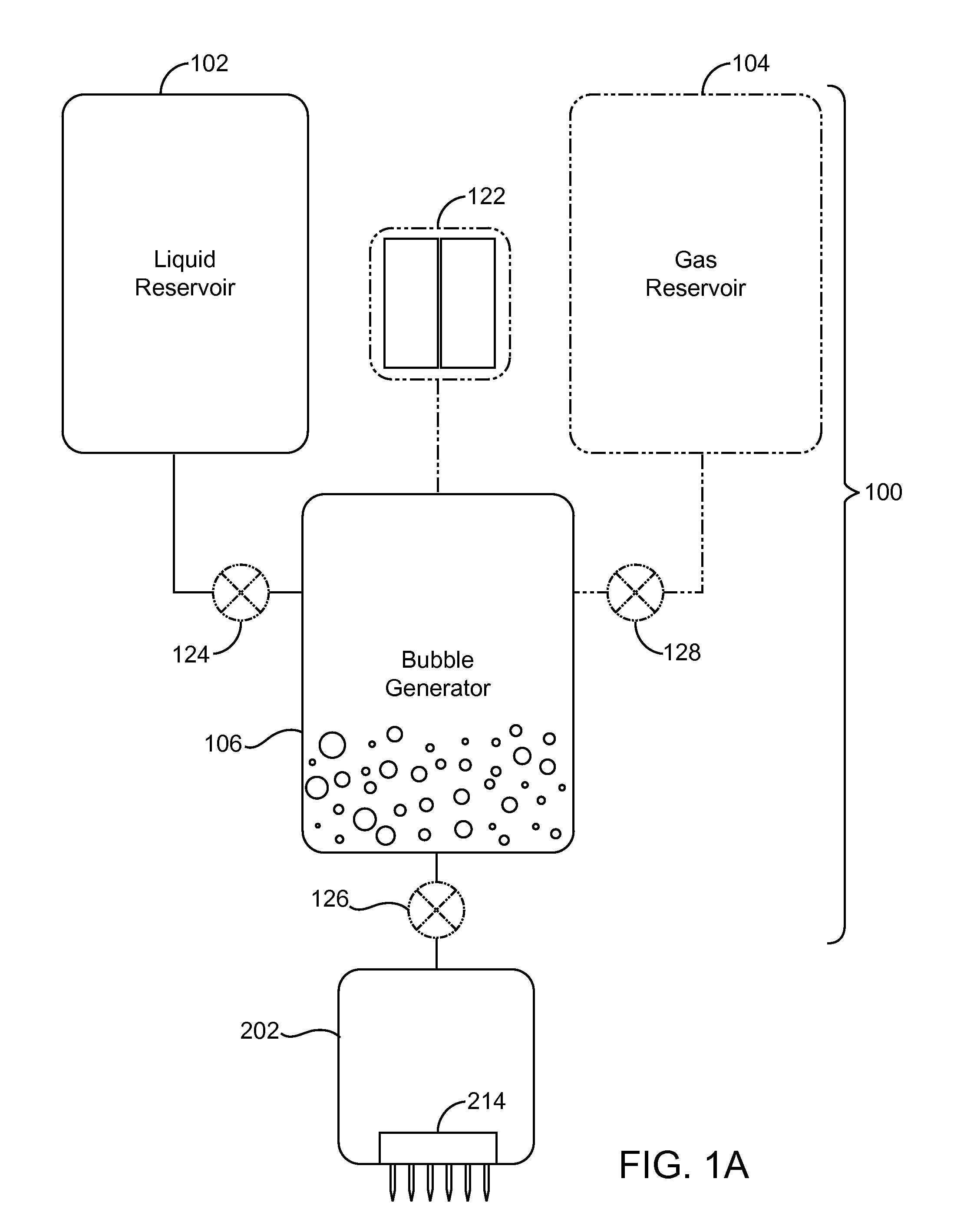

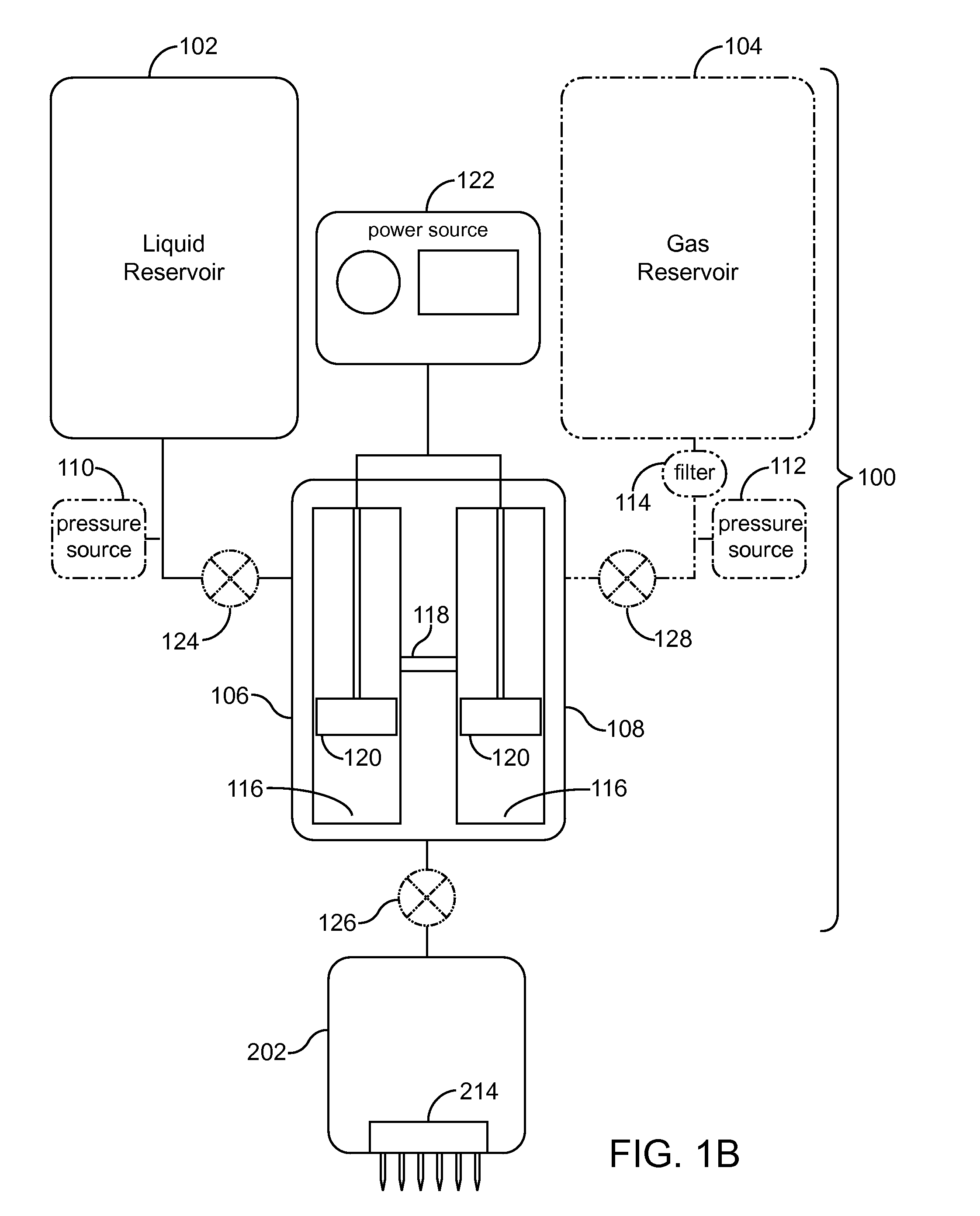

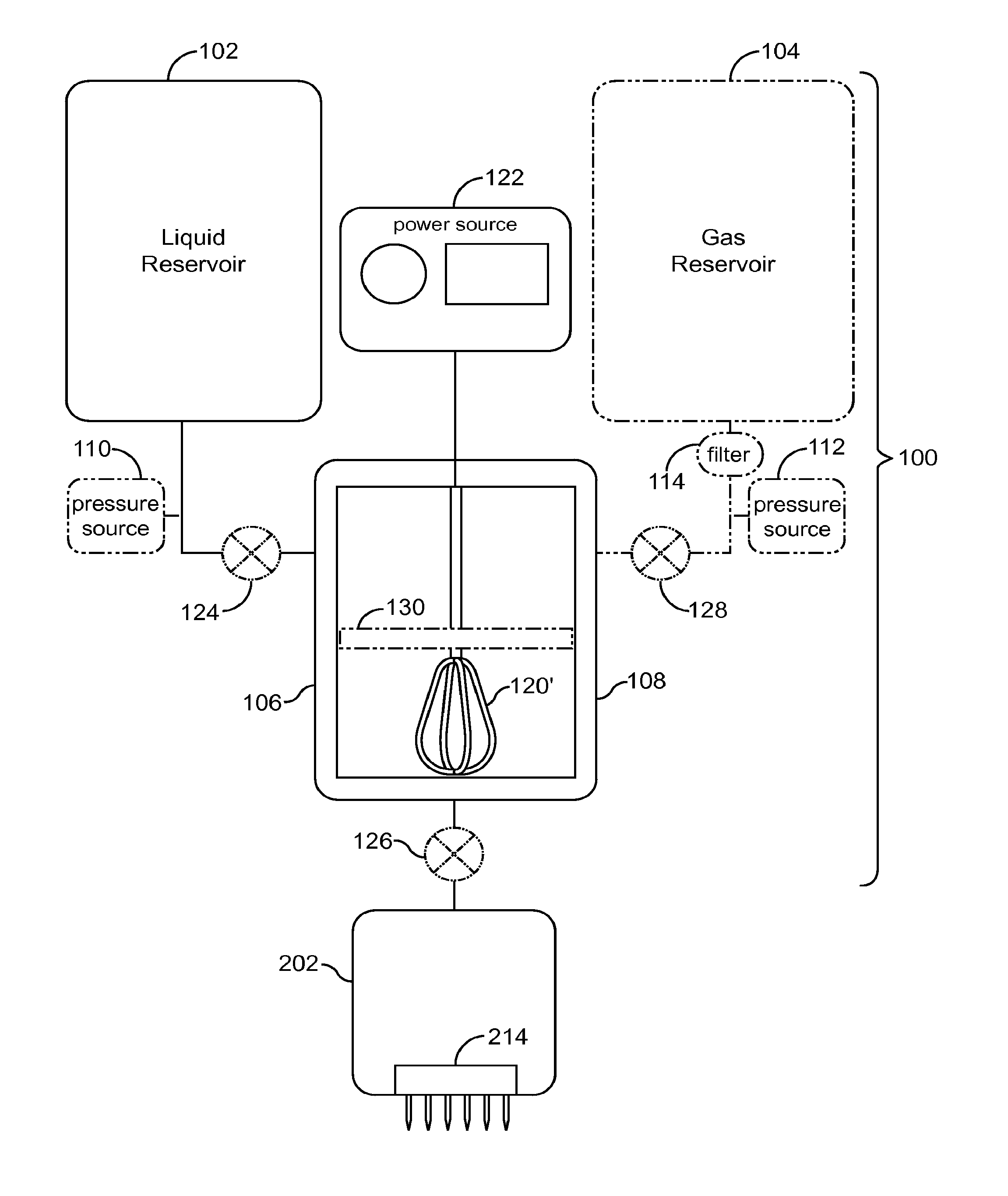

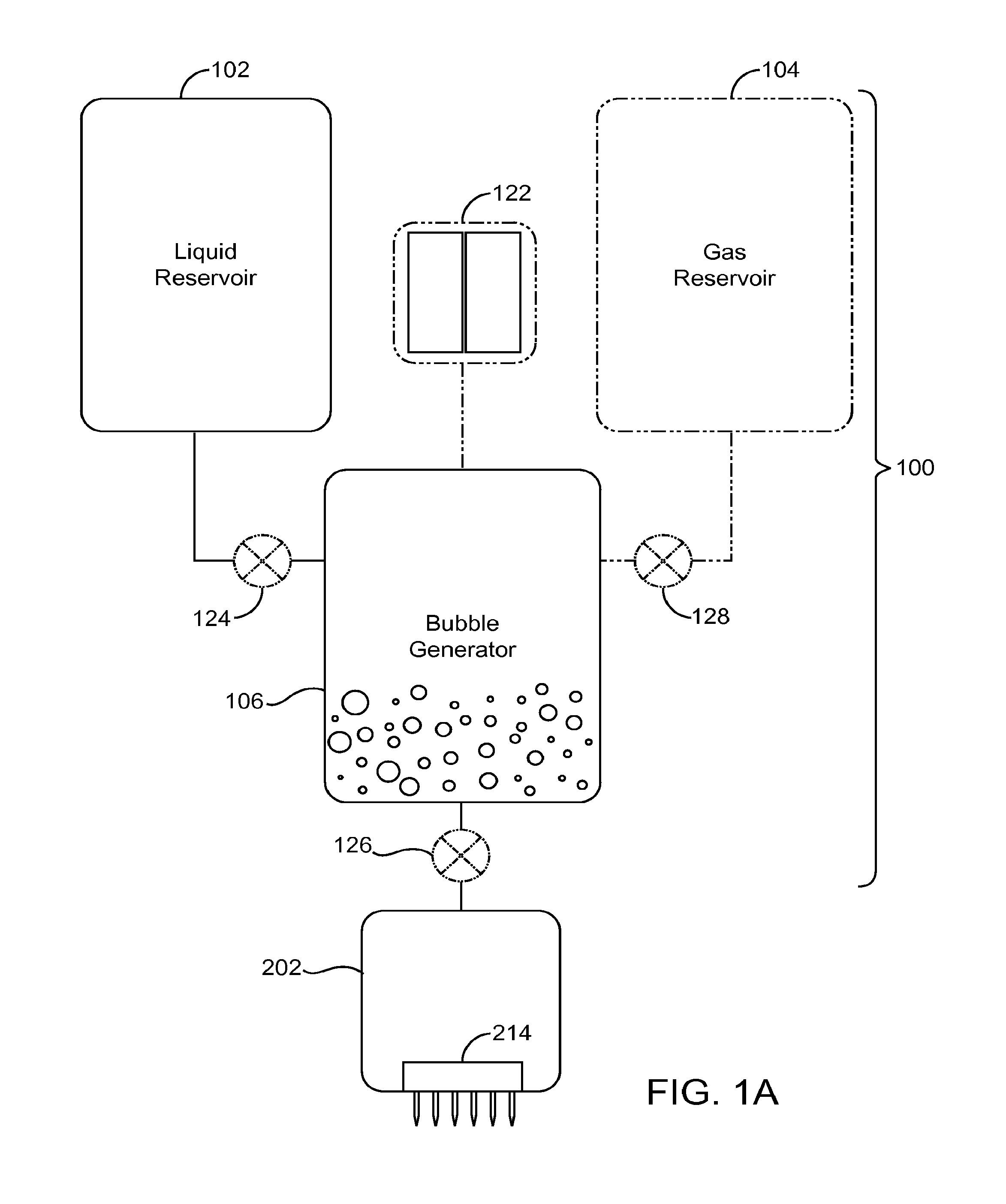

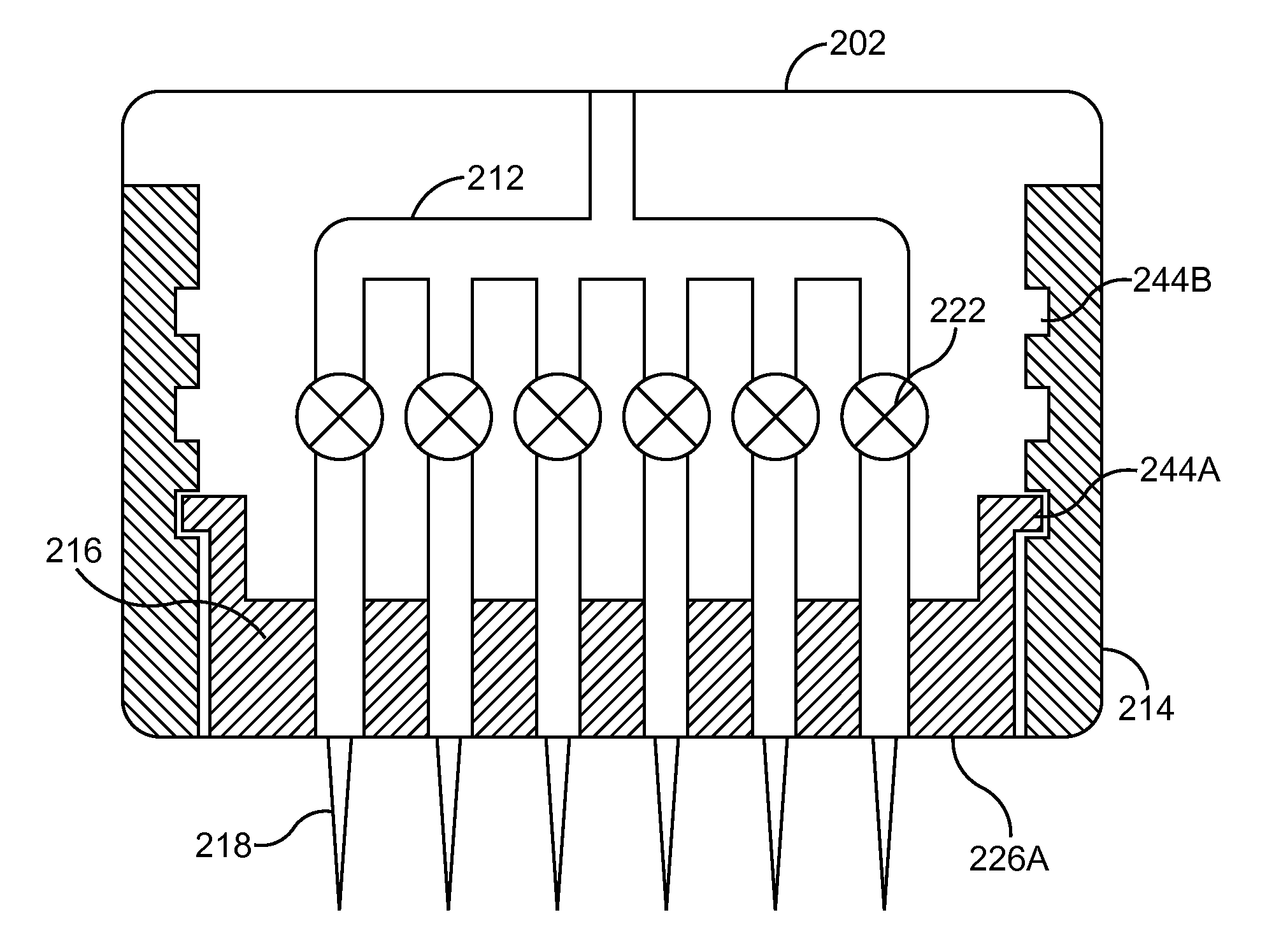

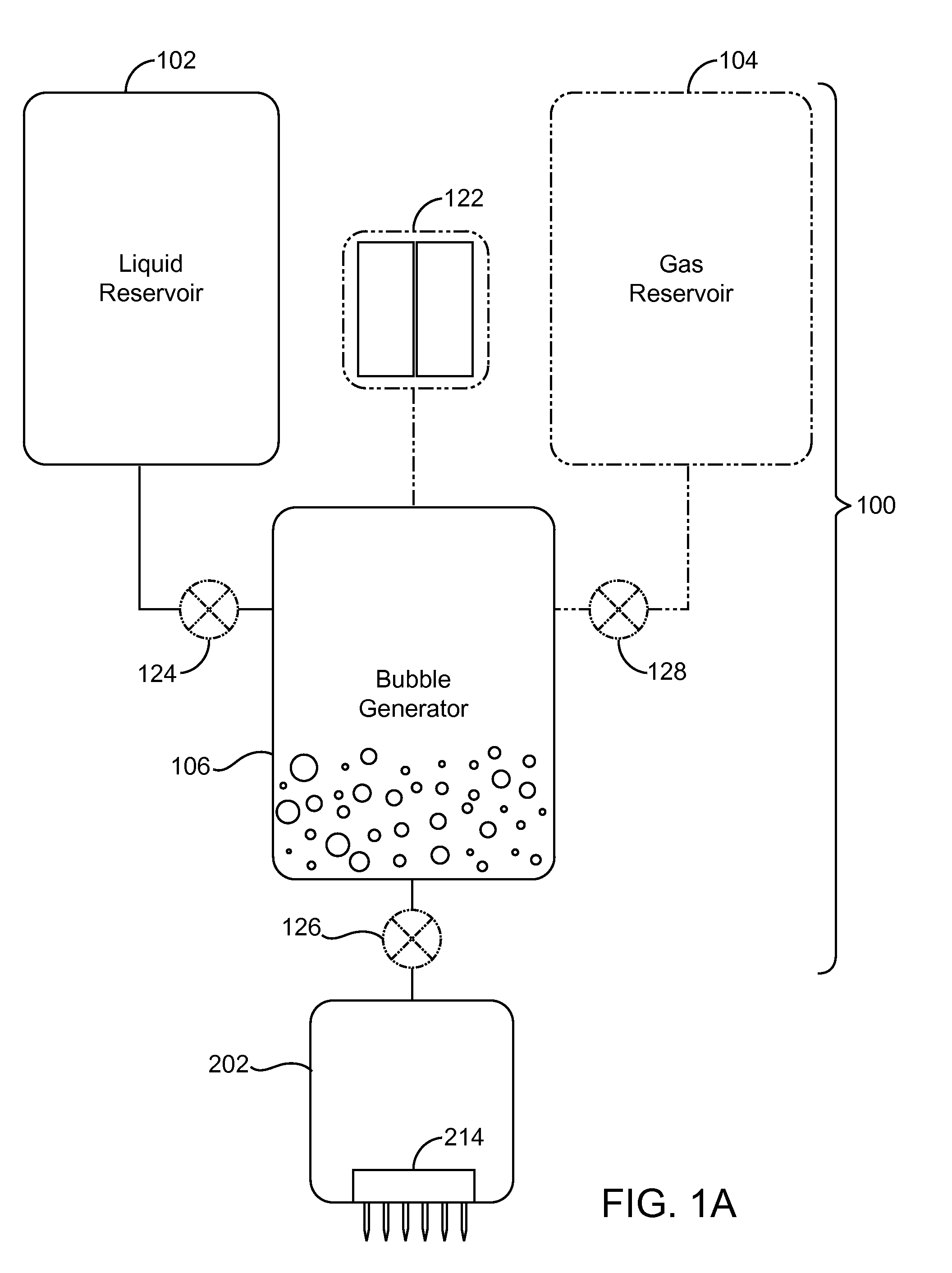

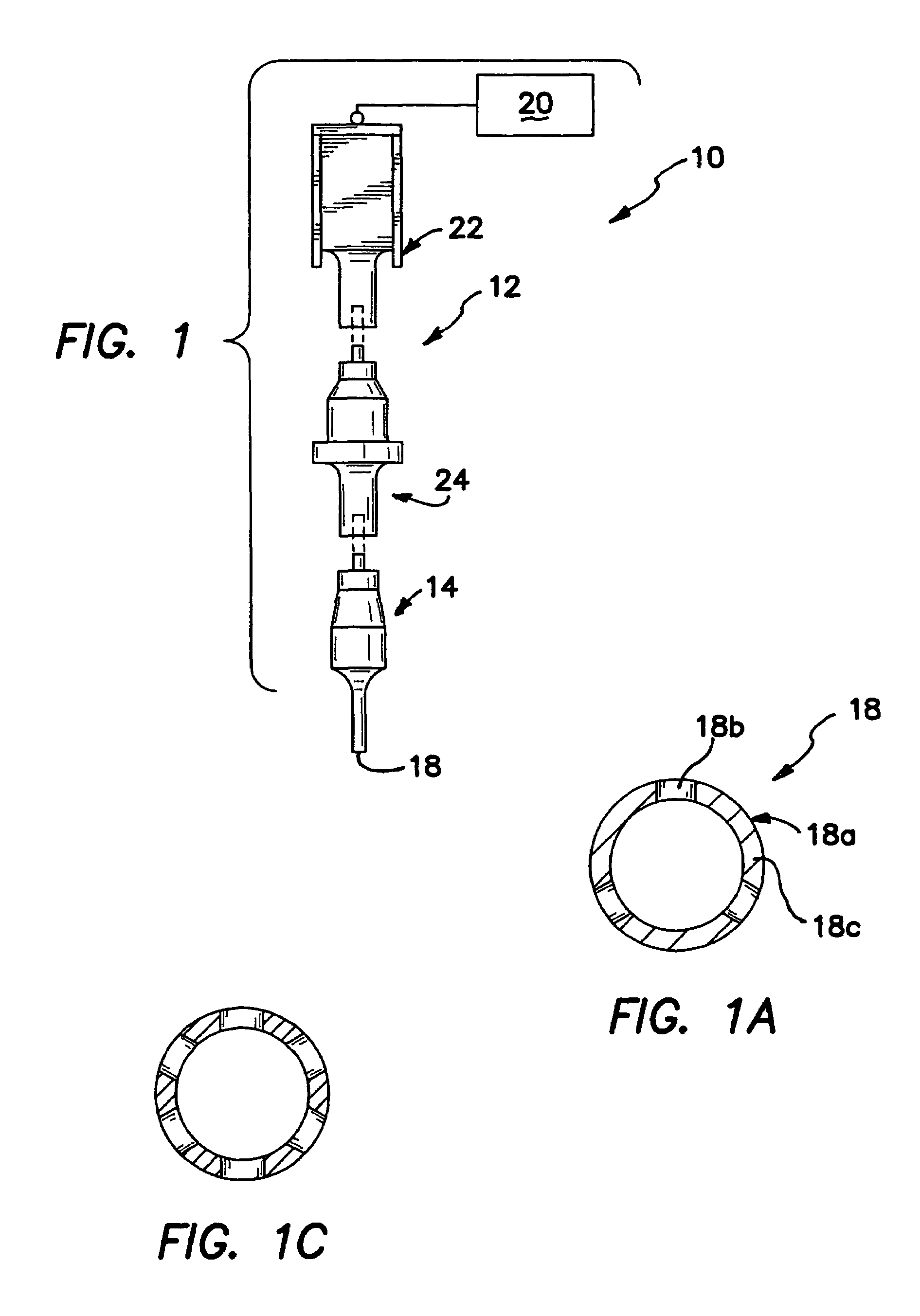

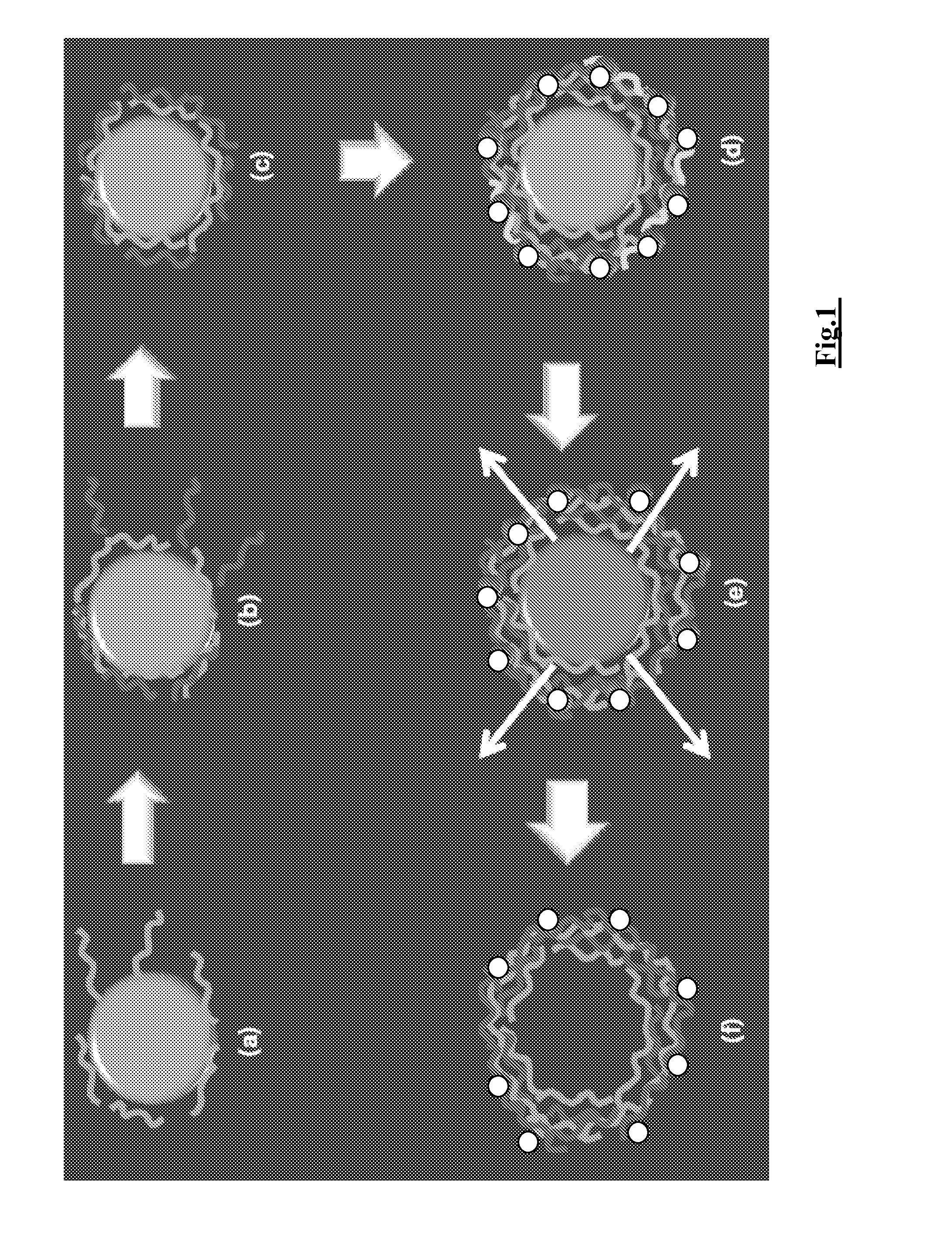

Devices and methods for selectively lysing cells

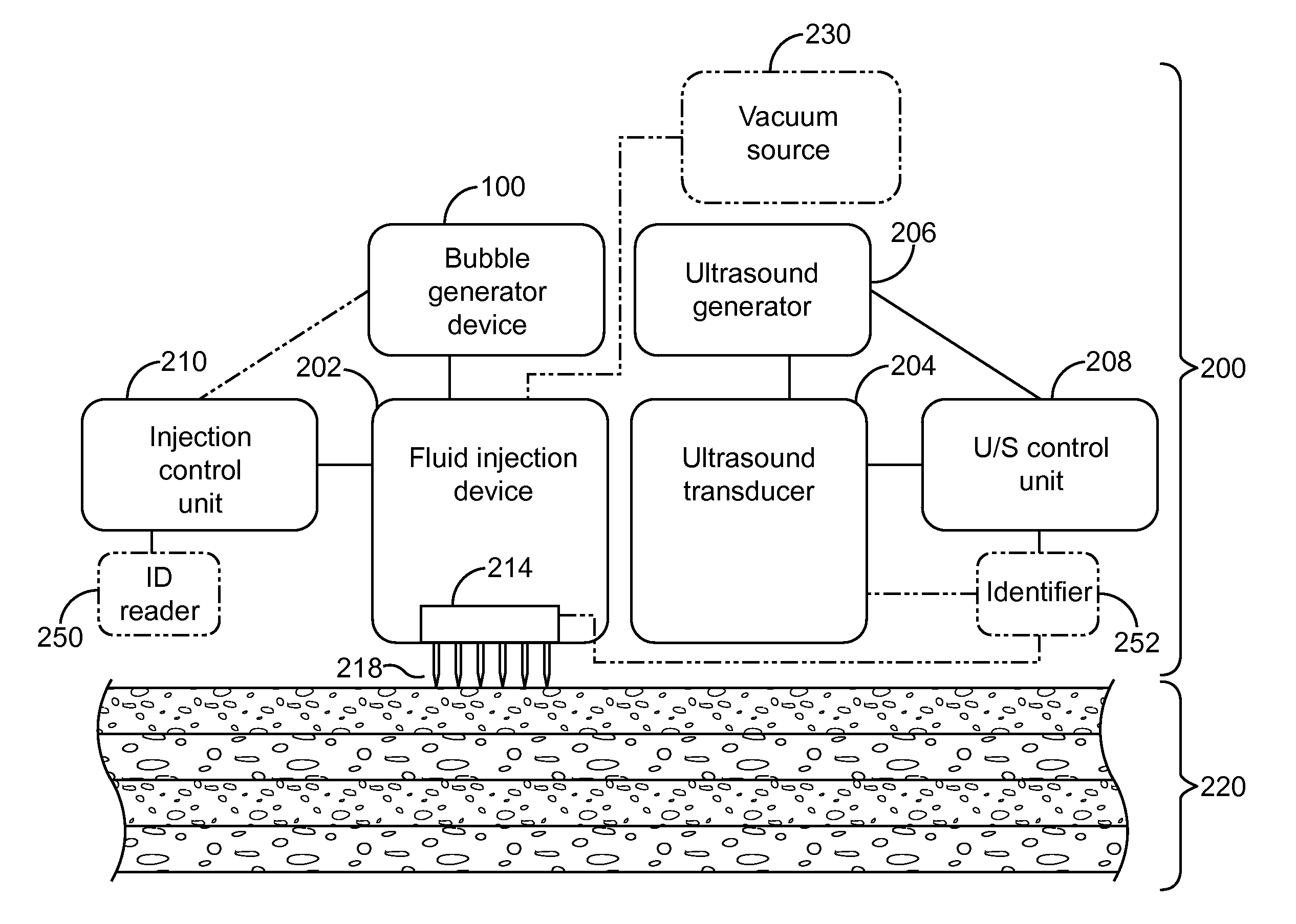

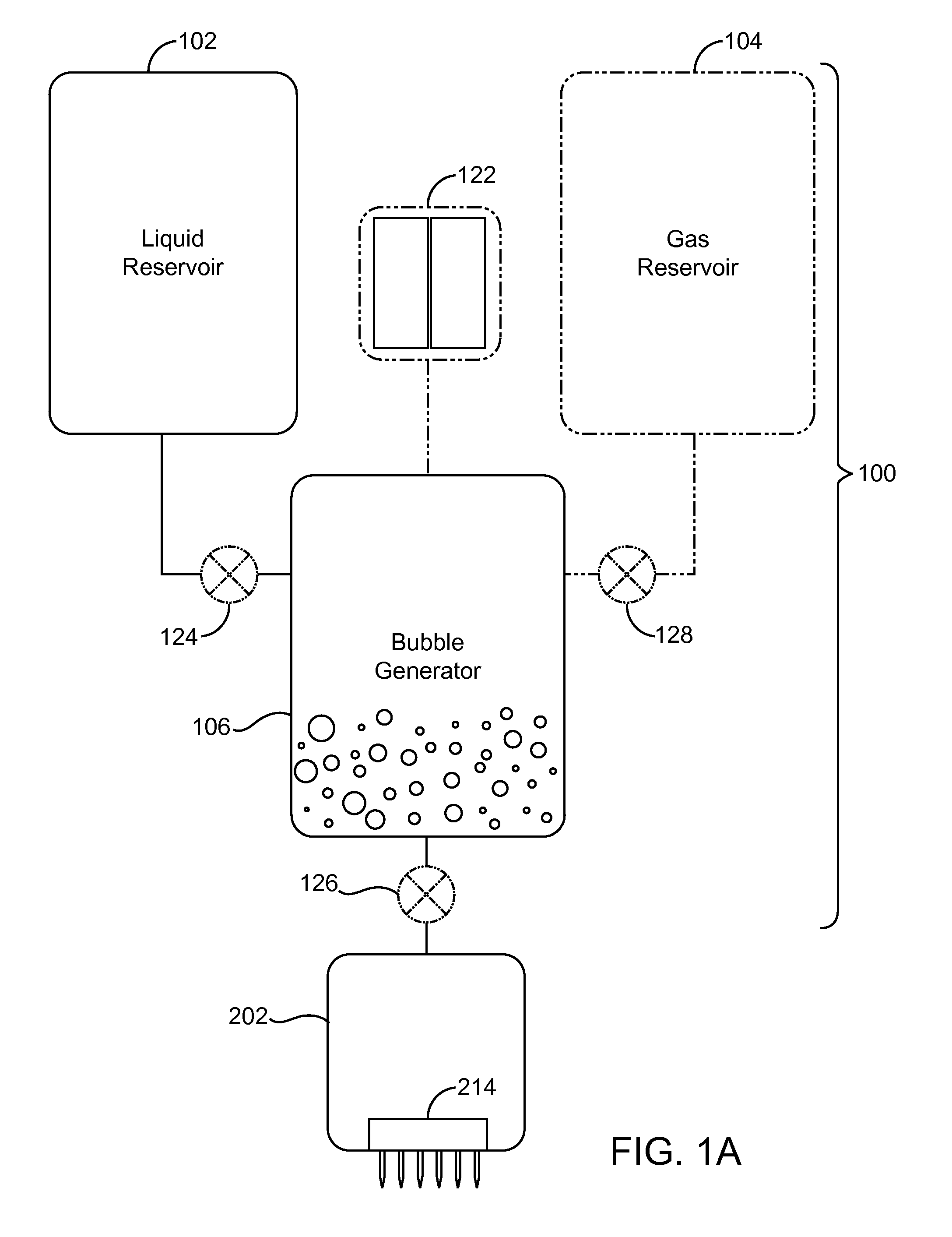

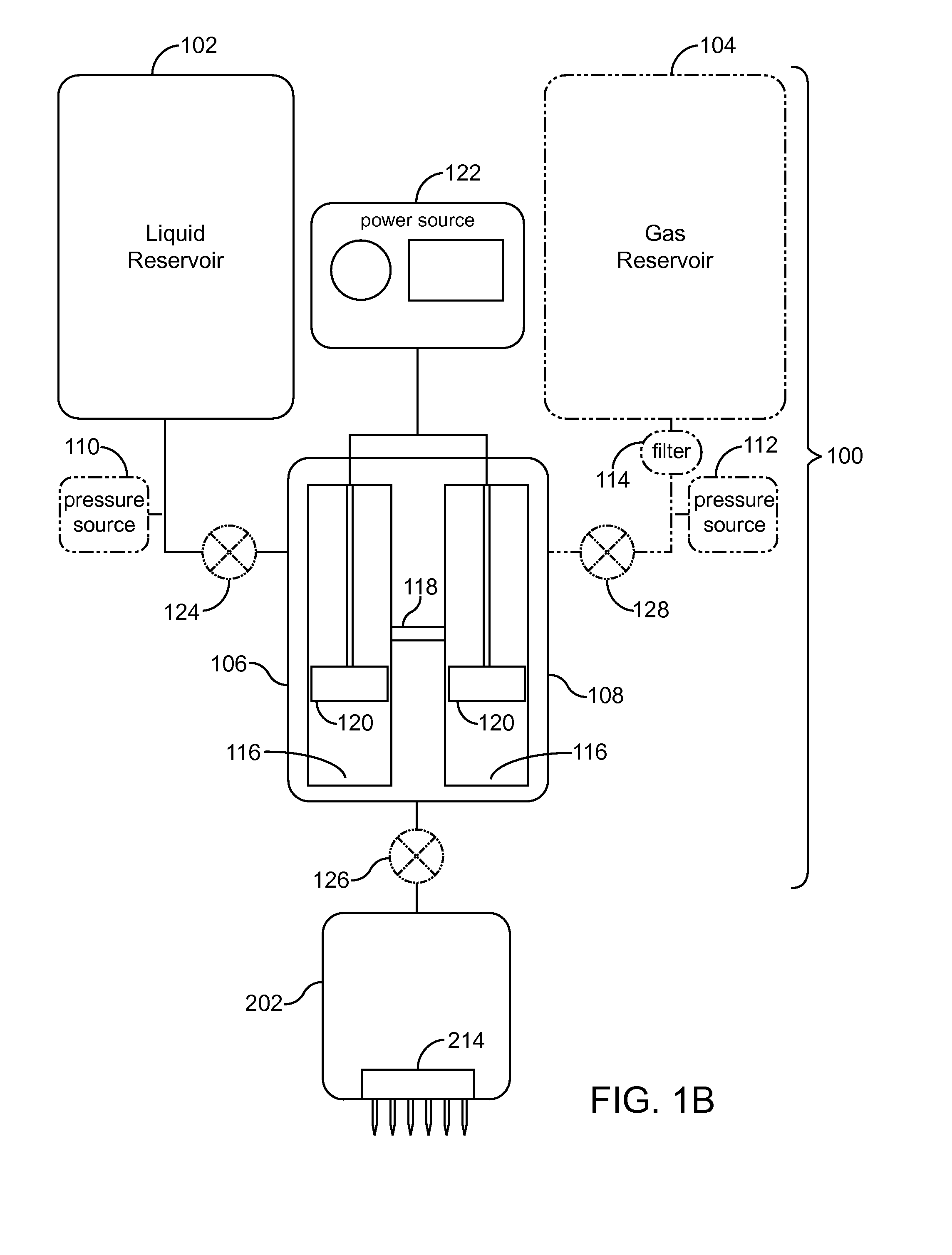

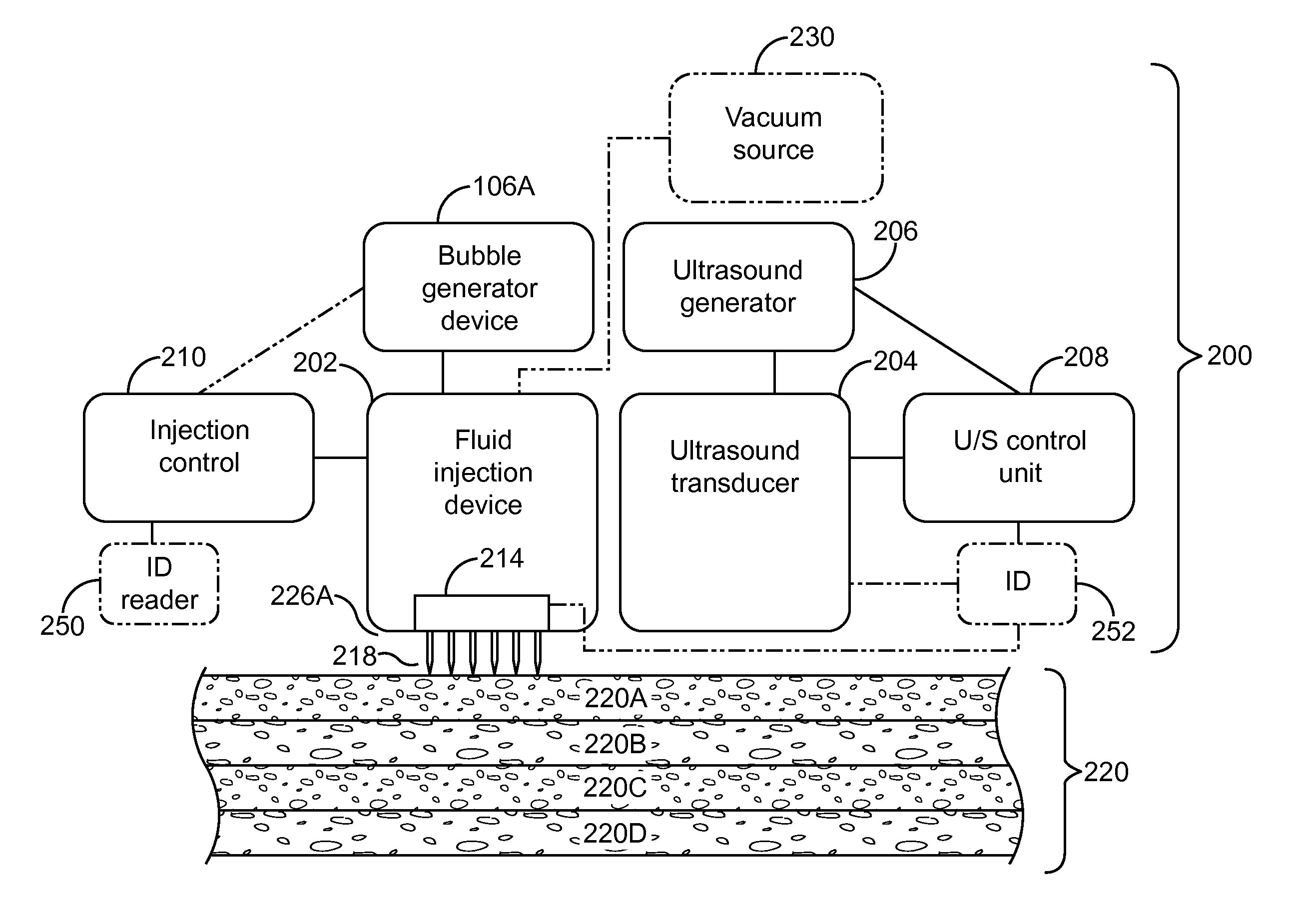

InactiveUS20080014627A1Promote absorptionFacilitates popping of bubblesMicroorganism lysisMedical devicesMicrobubblesBiomedical engineering

A device for generating microbubbles in a gas and liquid mixture and injection device, the device comprising a housing defining a mixing chamber; means for mixing solution contained in the mixing chamber to generate microbubbles in the solution; and a needle array removably attached to the housing and in fluid connection with the mixing chamber, the needle array including at least one needle.

Owner:ULTHERA INC

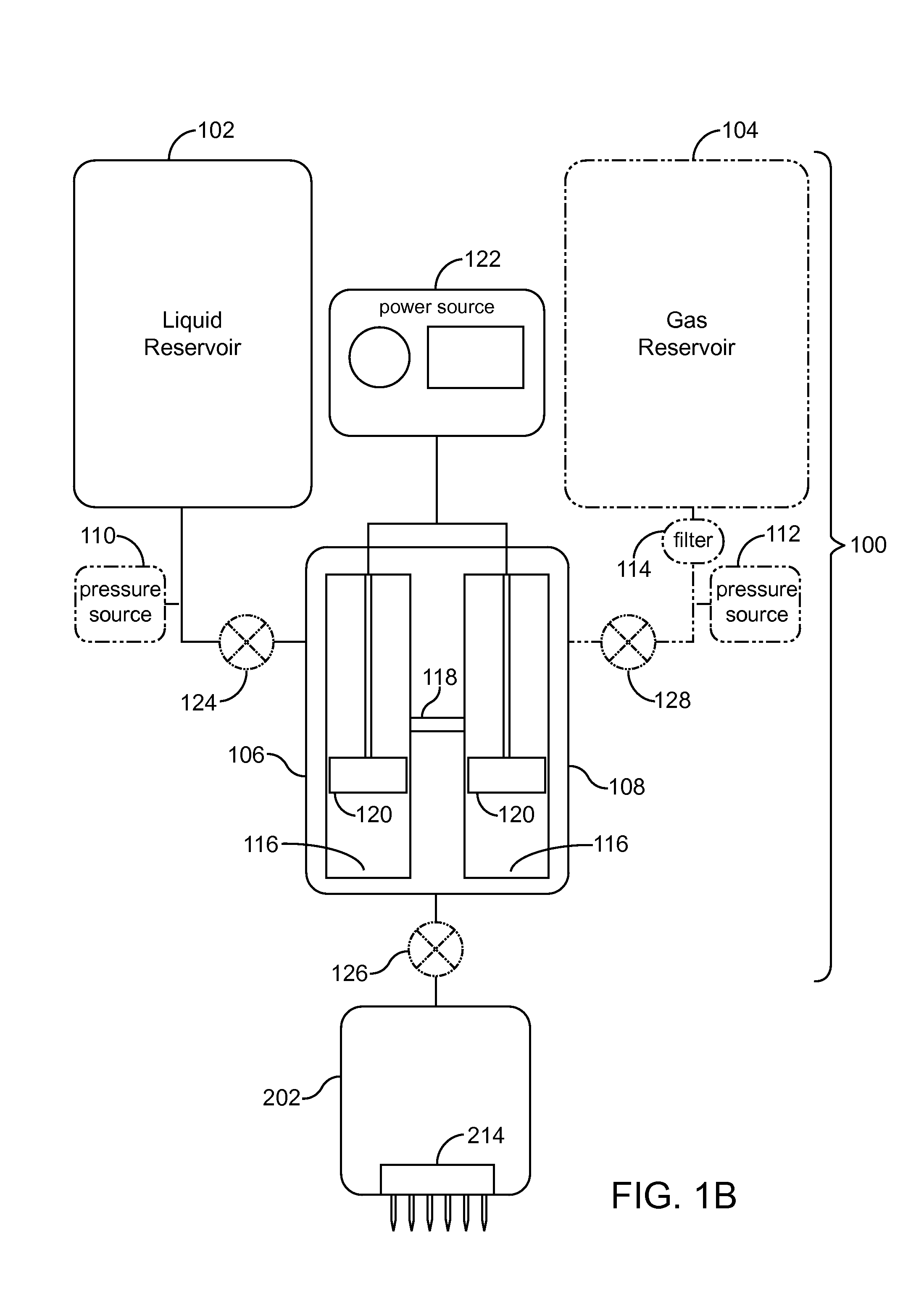

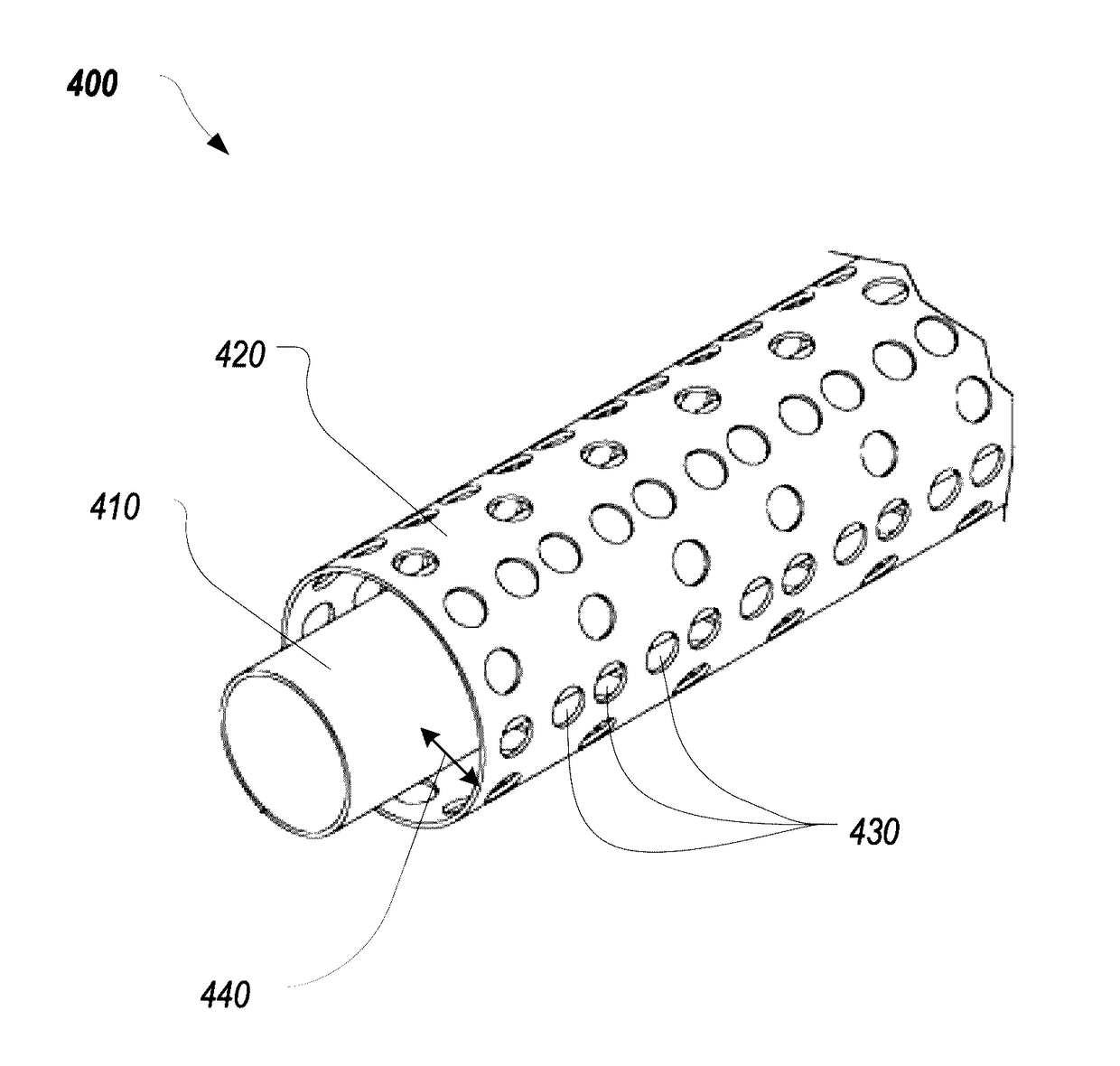

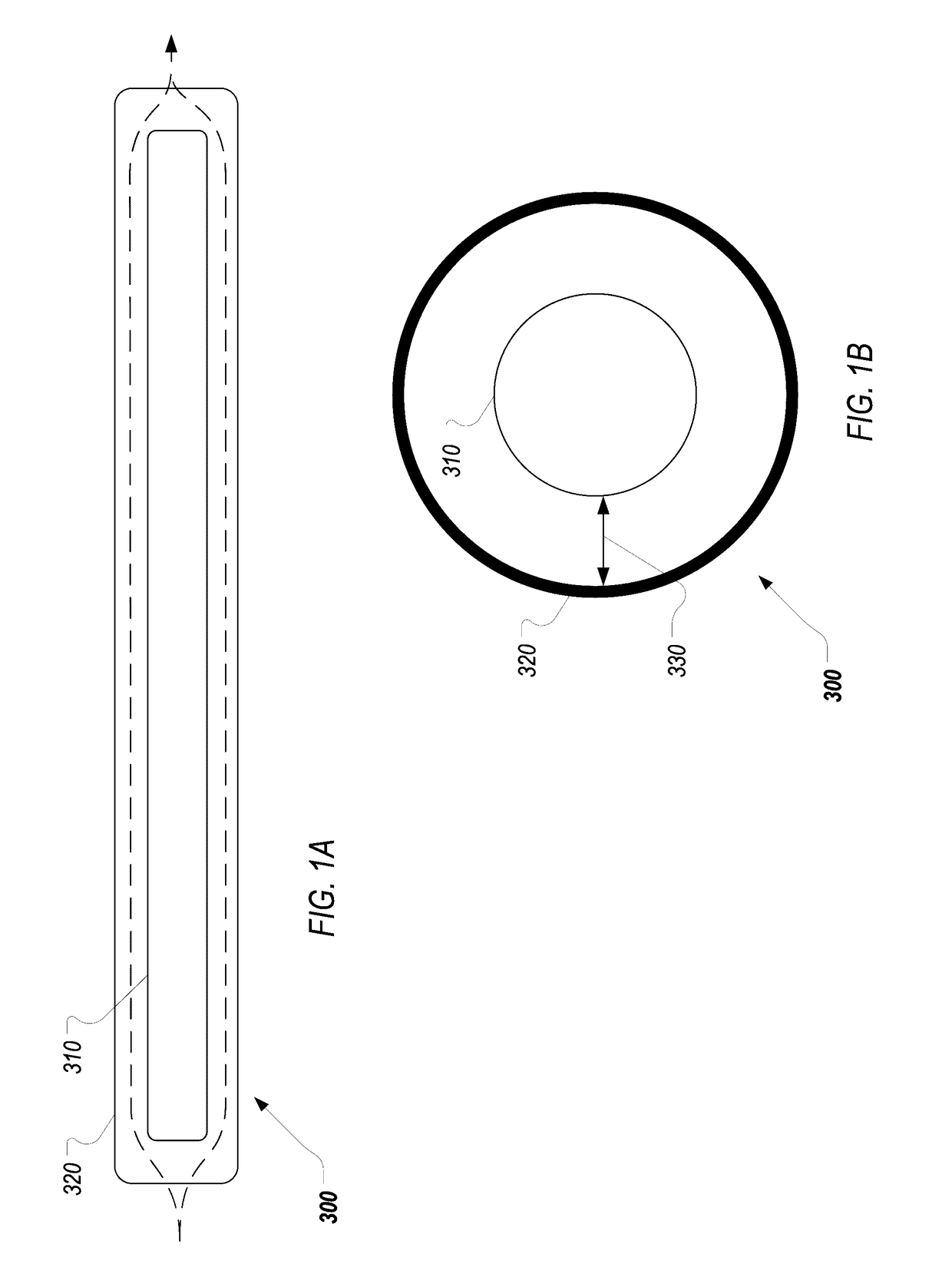

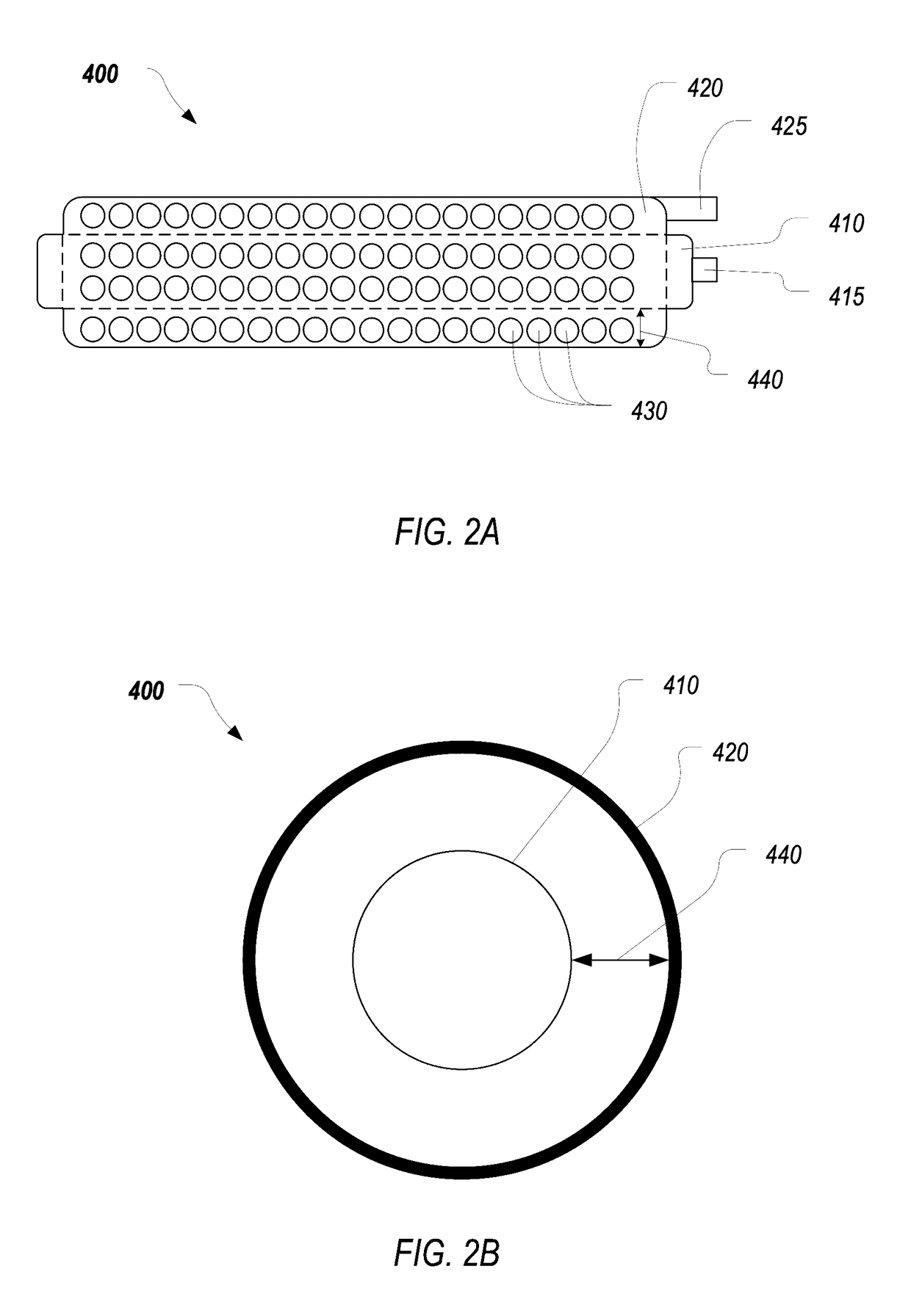

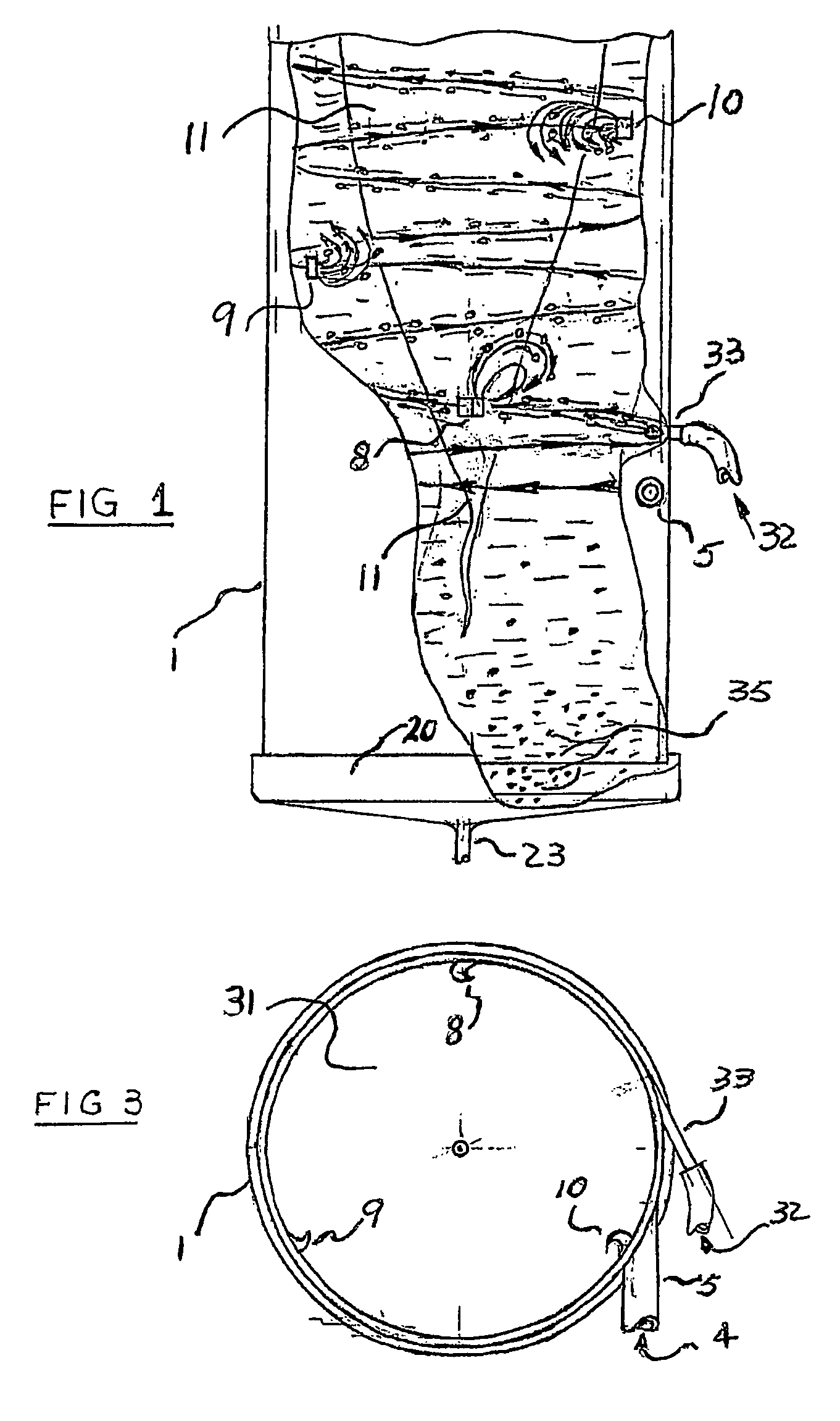

Produced water treatment method and apparatus

InactiveUS20080156709A1Improve filtration efficiencyEnhanced cavitationUltrafiltrationLoose filtering material filtersCavitationWaste collection

The present invention discloses a method and apparatus for separating particles and dissolved matter from a produced water fluid stream. Specifically, the present invention includes a first pressure source which transports untreated produced water or contaminated aqueous fluid into a separator annulus with a filter element disposed therein. The untreated fluid is placed under appropriate pressure sufficient to produce turbulent flow, increased particle kinetics and / or cavitation allowing the desired fluid to penetrate and pass into and through the filter media. The treated fluid is then transported to a collection tank. The contaminant matter retained by the filter media may be removed by the nearly instantaneous reverse pressurization of the separator annulus by a second pressure source thereby removing the contaminant particles away from contact with the filter media, and which may then be transported to a waste collection tank or a separator for further treatment.

Owner:TERVITA +1

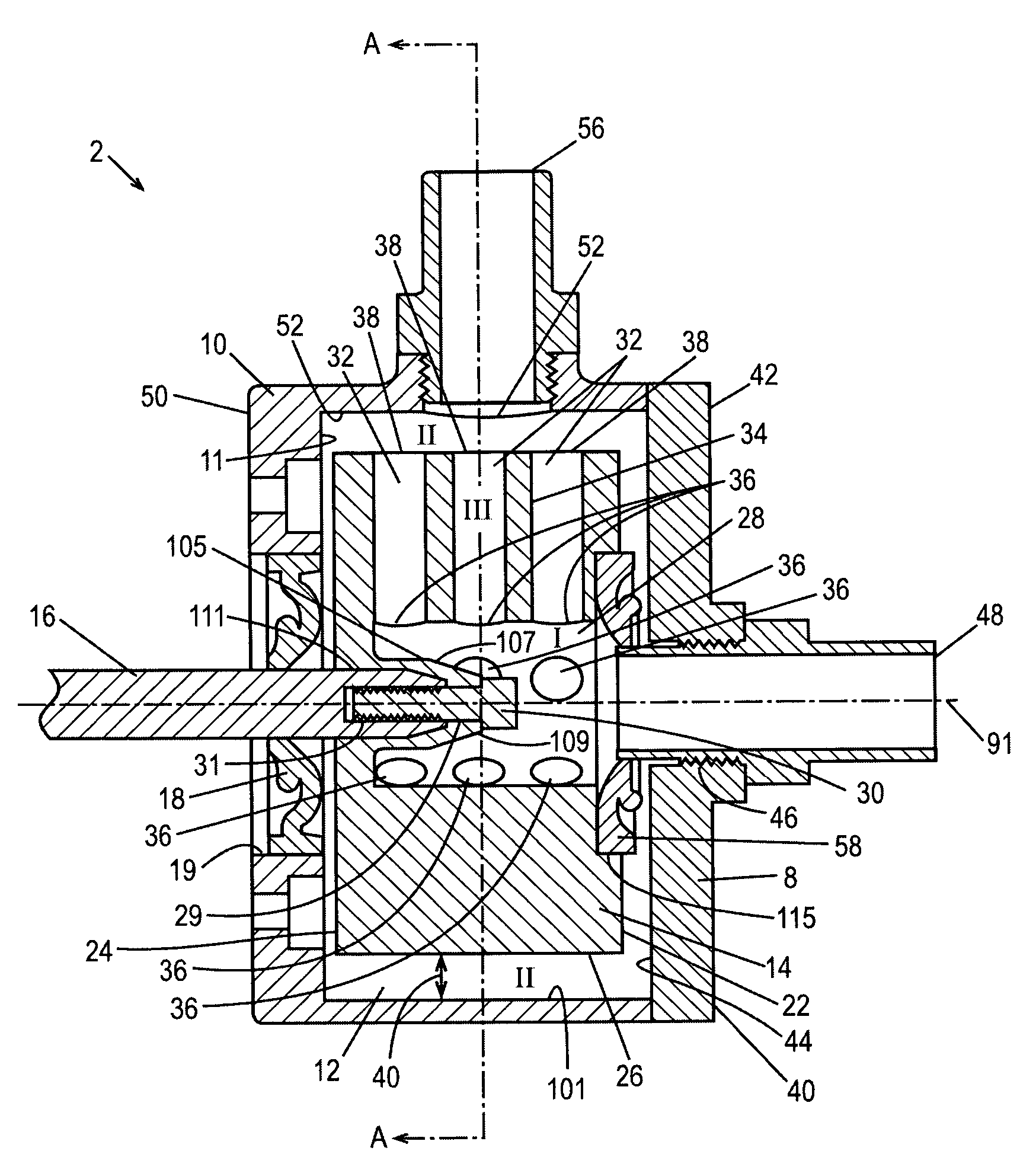

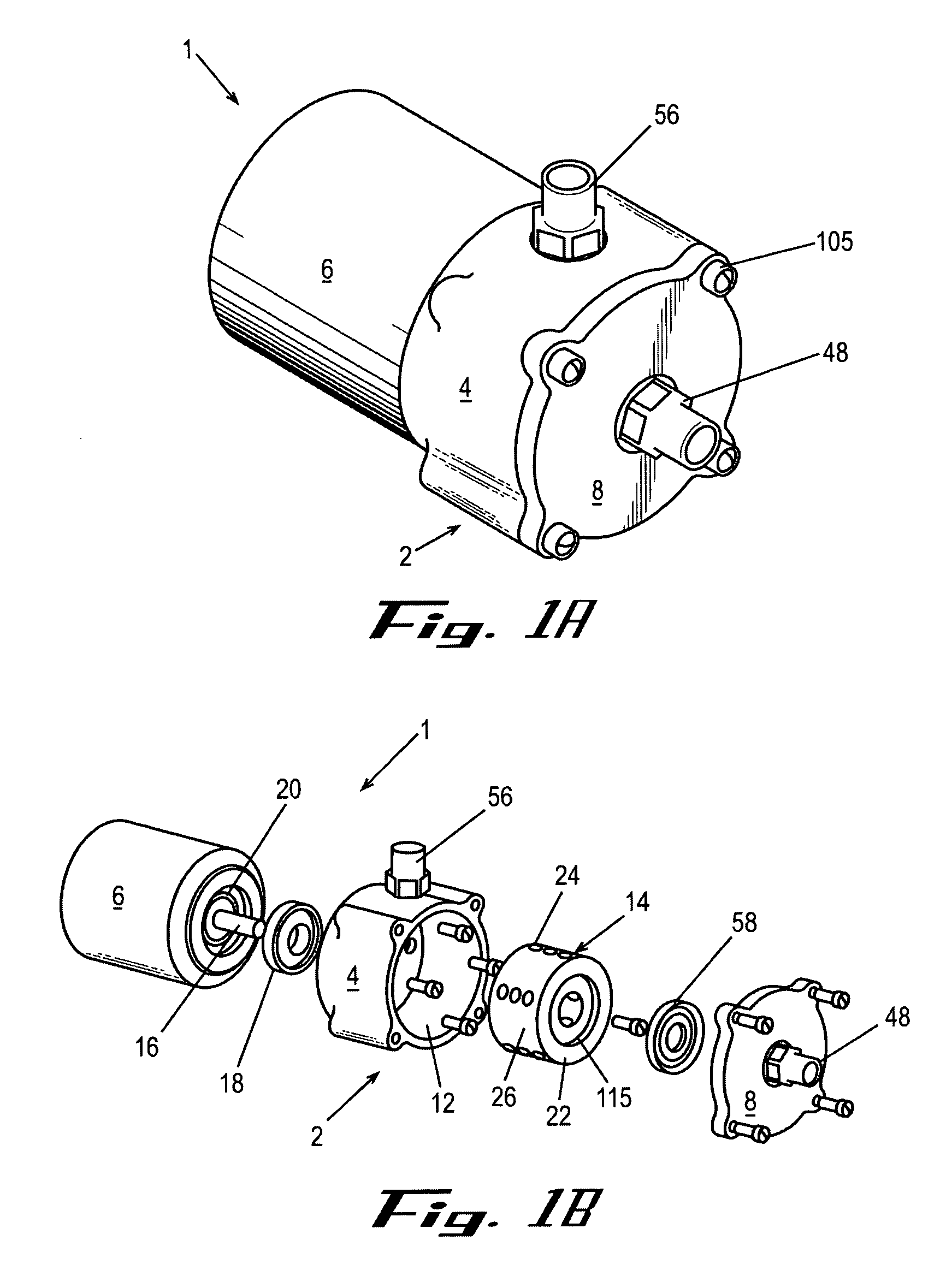

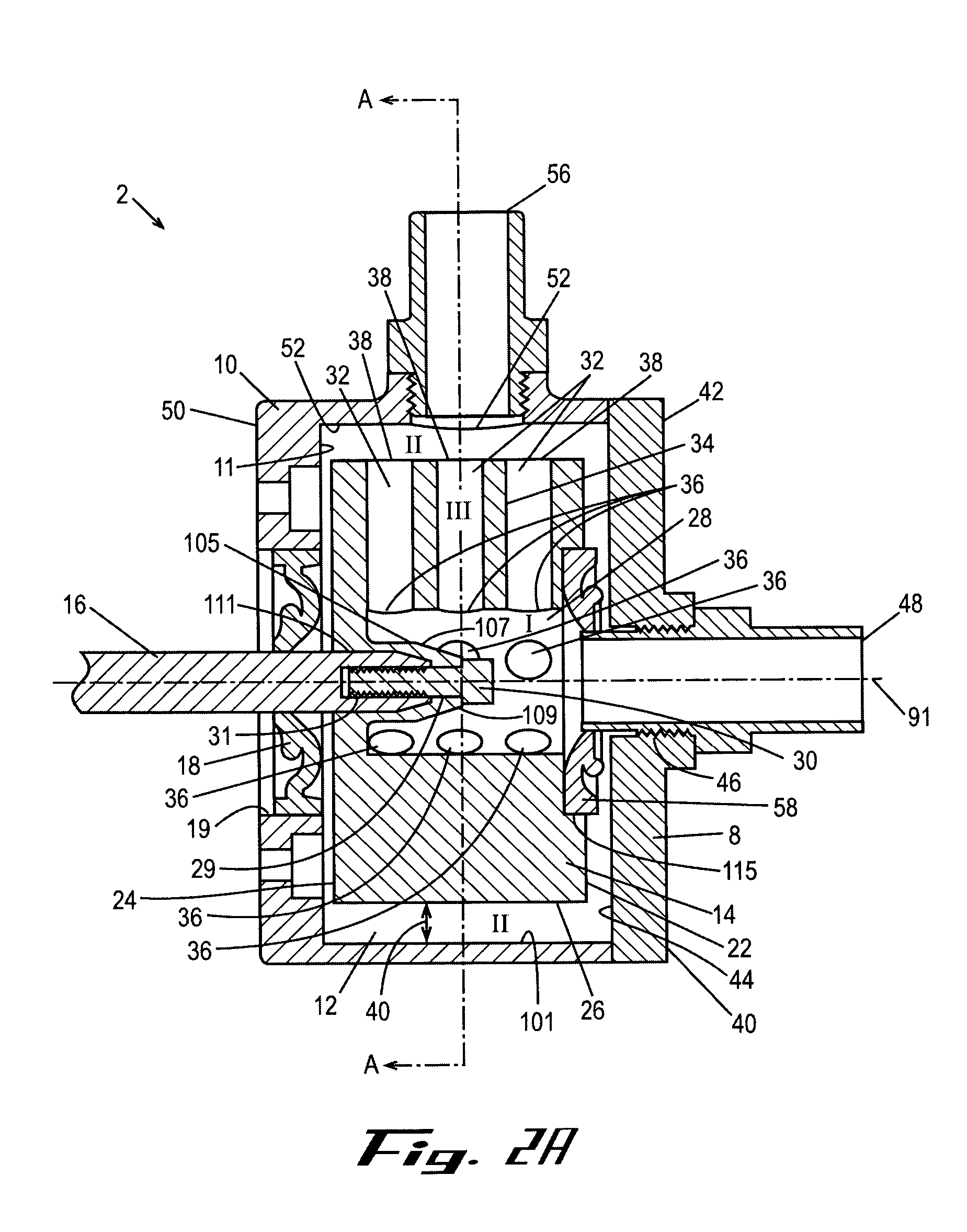

Roto-dynamic fluidic systems

An apparatus and method for generating cavitation in fluids is disclosed. The apparatus includes a housing for receiving a rotor, which is driven by a motive force. Multiple embodiments of the rotors are disclosed including, but not limited to, centrally feed, centrally drained, face feed, and face drained rotors. In one preferred embodiment, cavitation is enhanced by inducing tensile stress in the fluid by subjecting the fluid centrifugal force or centripital force depending upon the flow of the fluid.

Owner:GARRETT III NORMAN H

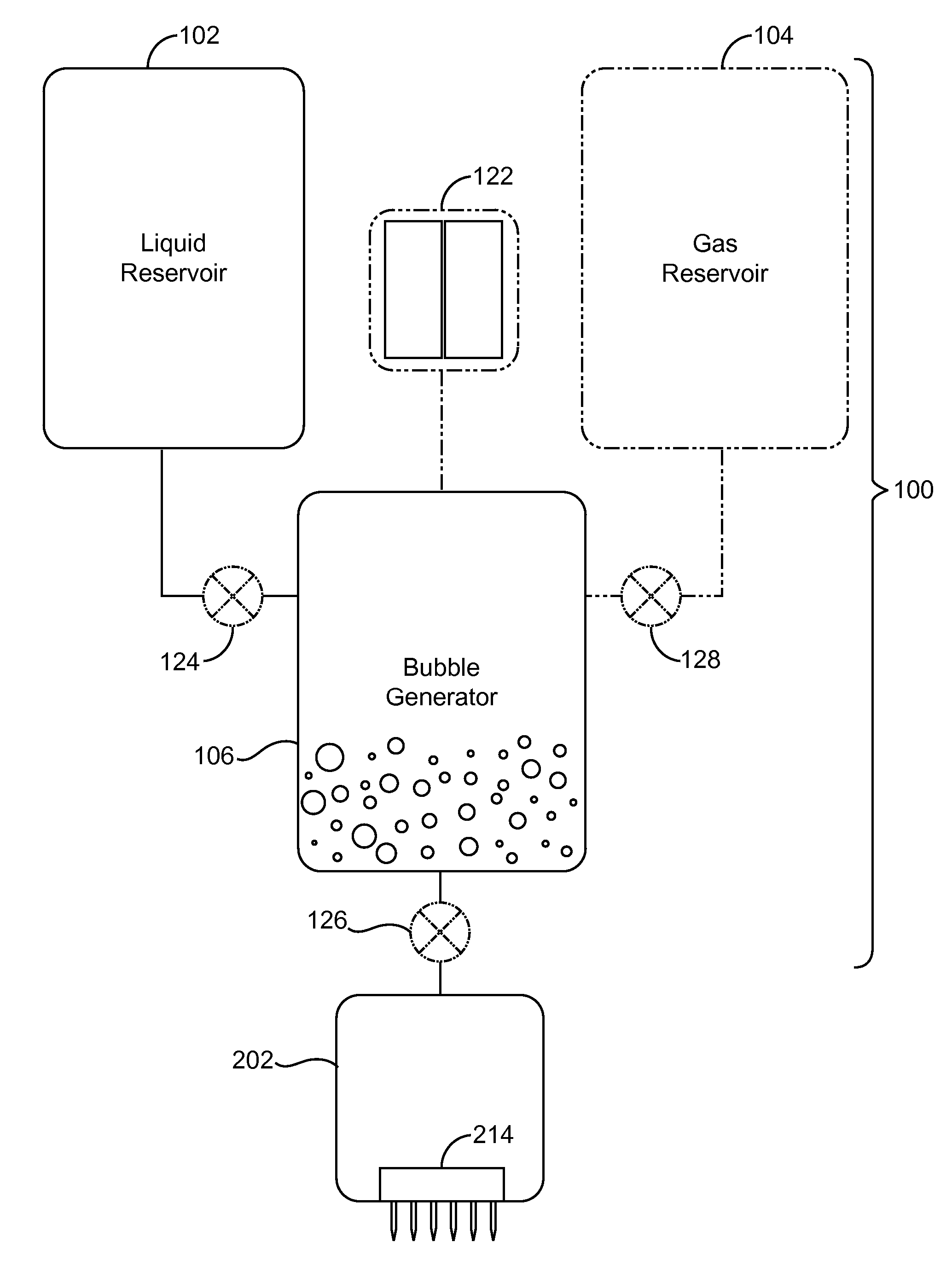

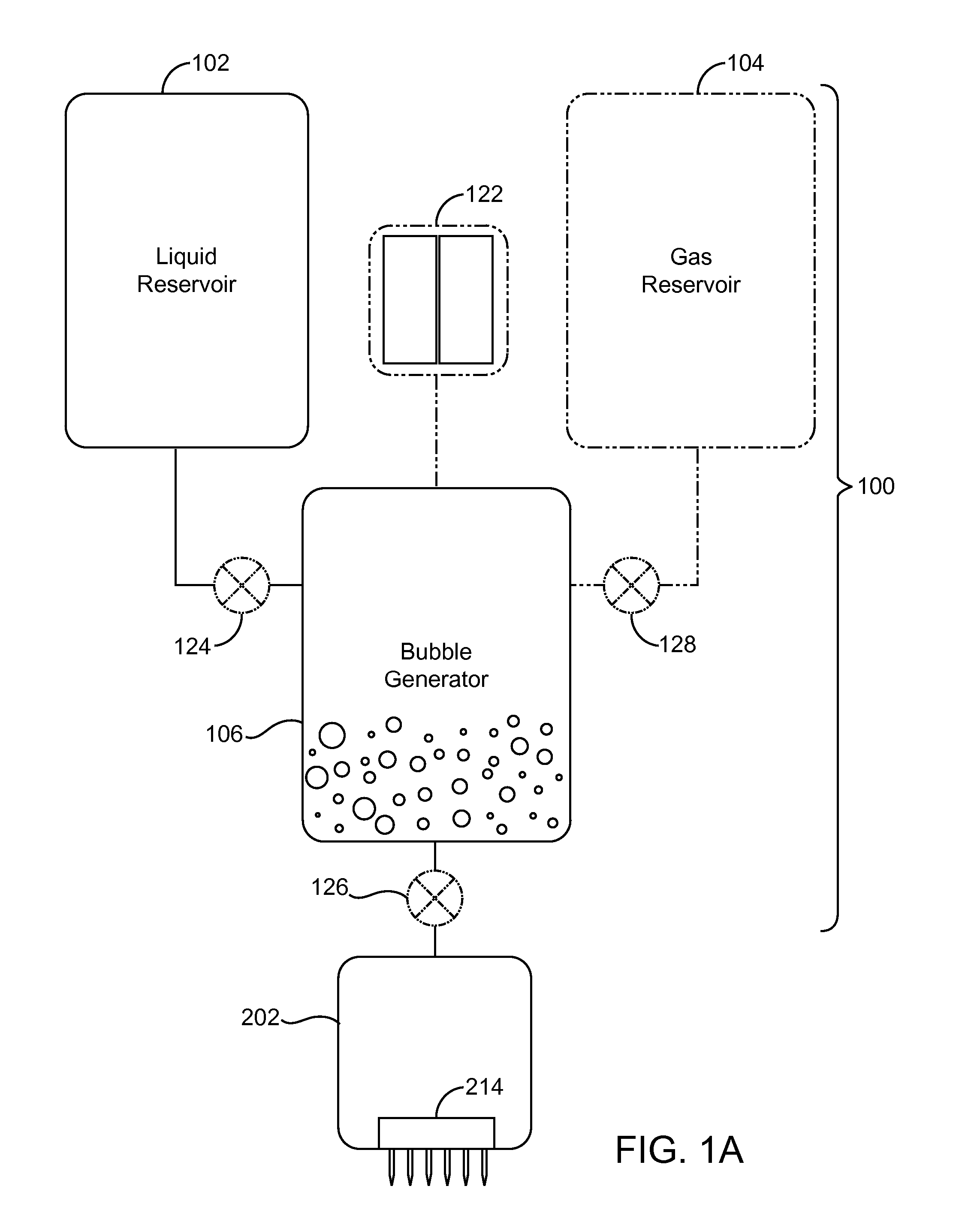

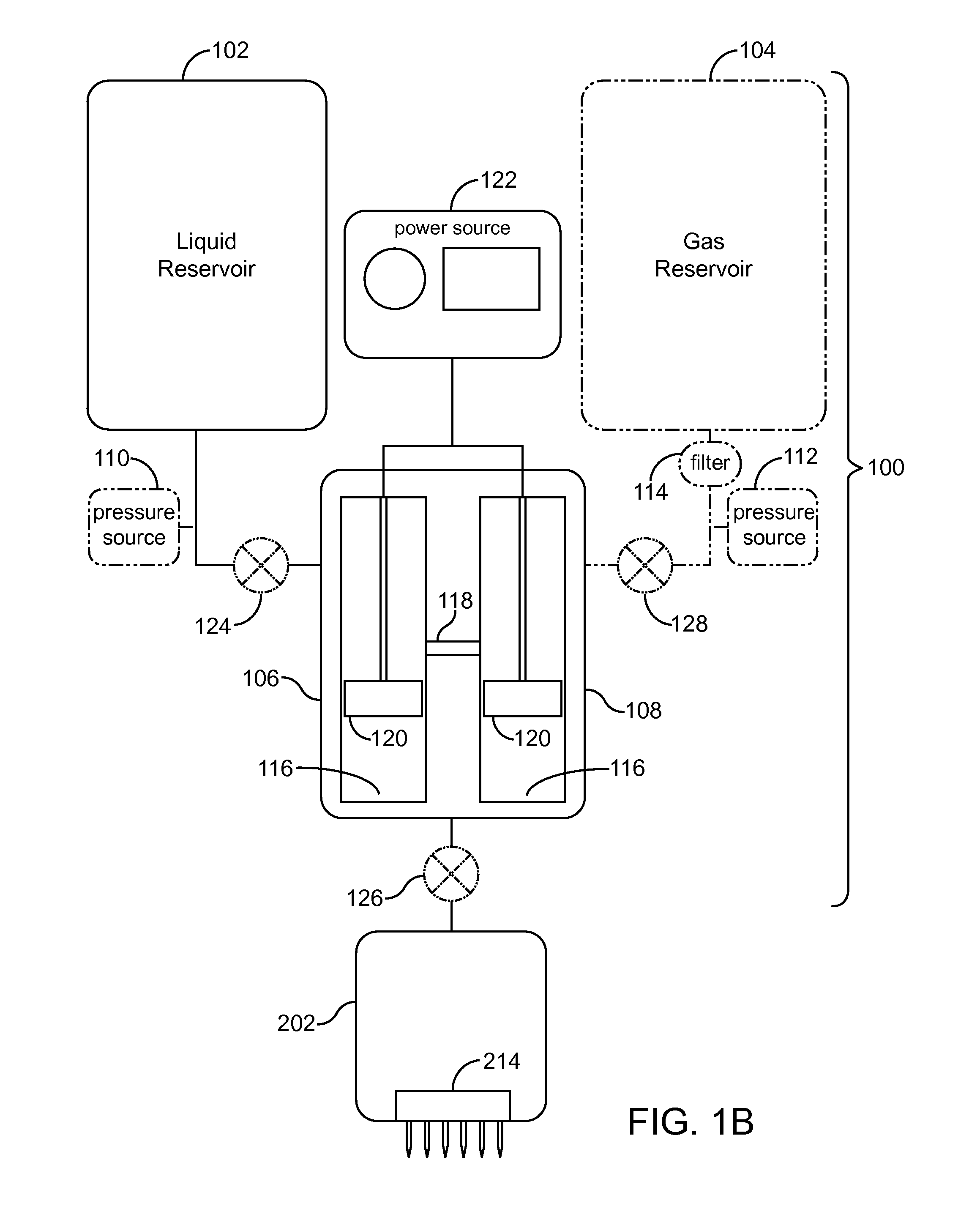

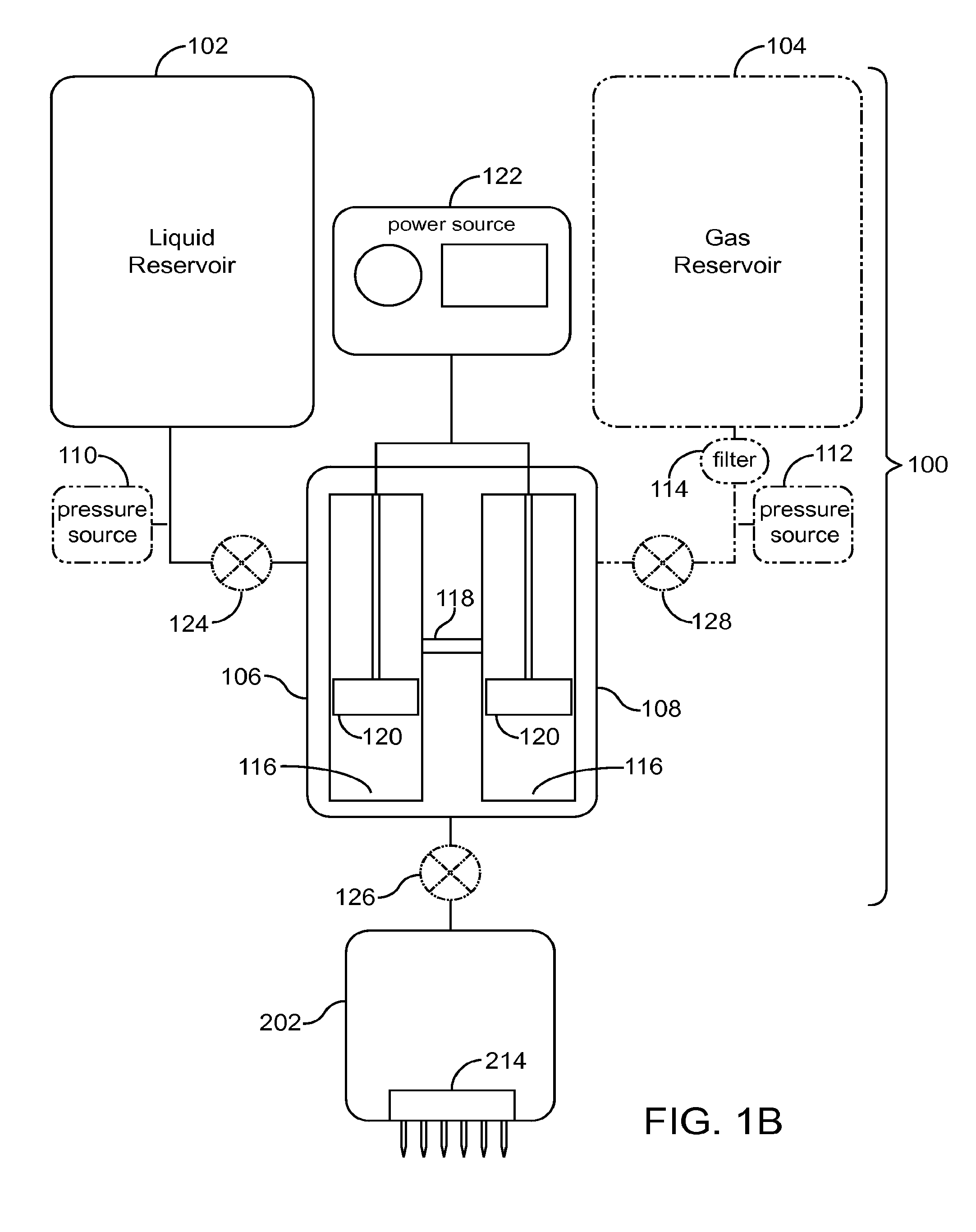

Devices and methods for selectively lysing cells

ActiveUS20080248554A1Promote absorptionFacilitates popping of bubblesUltrasound therapyElectrotherapyMicrobubblesBiomedical engineering

A device for generating microbubbles in a gas and liquid mixture and injection device, the device comprising: a housing defining a mixing chamber; means for mixing solution contained in the mixing chamber to generate microbubbles in the solution; a needle array removably attached to the housing and in fluid connection with the mixing chamber, the needle array including at least one needle; and a machine readable identifier on the needle array.

Owner:ULTHERA INC

Devices and methods for selectively lysing cells

InactiveUS20080195036A1Promote absorptionFacilitates popping of bubblesUltrasound therapyElectrotherapyMicrobubblesBiomedical engineering

A device, comprising a housing defining a mixing chamber; means for mixing solution contained in the mixing chamber to generate microbubbles in the solution; a needle array removably attached to the housing and in fluid connection with the mixing chamber, the needle array including at least one needle; and tissue apposition means for pulling the needle array into apposition with tissue.

Owner:ULTHERA INC

Devices and methods for selectively lysing cells

InactiveUS20080200863A1Promote absorptionFacilitates popping of bubblesUltrasound therapyElectrotherapyAnesthetic AgentVasoconstrictor Agents

A system comprising: a container containing a measured amount of a solution including at least one of a vasoconstrictor, a surfactant, and an anesthetic, the solution comprising a liquid and at least one of a gas and a fluid; a needle array in fluid connection with the container, the needle array including at least one needle.

Owner:ULTHERA INC

Devices and methods for selectively lysing cells

ActiveUS20130197427A1Promote absorptionFacilitates popping of bubblesReservationsFiltering accessoriesMicrobubblesProduct gas

A device for generating microbubbles in a gas and liquid mixture and injection device, the device comprising: a housing defining a mixing chamber; means for mixing solution contained in the mixing chamber to generate microbubbles in the solution; a needle array removably attached to the housing and in fluid connection with the mixing chamber, the needle array including at least one needle; and at least one pressure sensor for measuring tissue apposition pressure, the pressure sensor being mounted on one of the housing and the needle array.

Owner:ULTHERA INC

Devices and methods for selectively lysing cells

InactiveUS20080200864A1Promote absorptionFacilitates popping of bubblesUltrasound therapyElectrotherapyMicrobubblesNeedle insertion

A device comprising a housing defining a mixing chamber; means for mixing solution contained in the mixing chamber to generate microbubbles in the solution; a needle array removably attached to the housing and in fluid connection with the mixing chamber, the needle array including at least one needle; and means for adjusting a needle insertion depth of the at least one needle.

Owner:ULTHERA INC

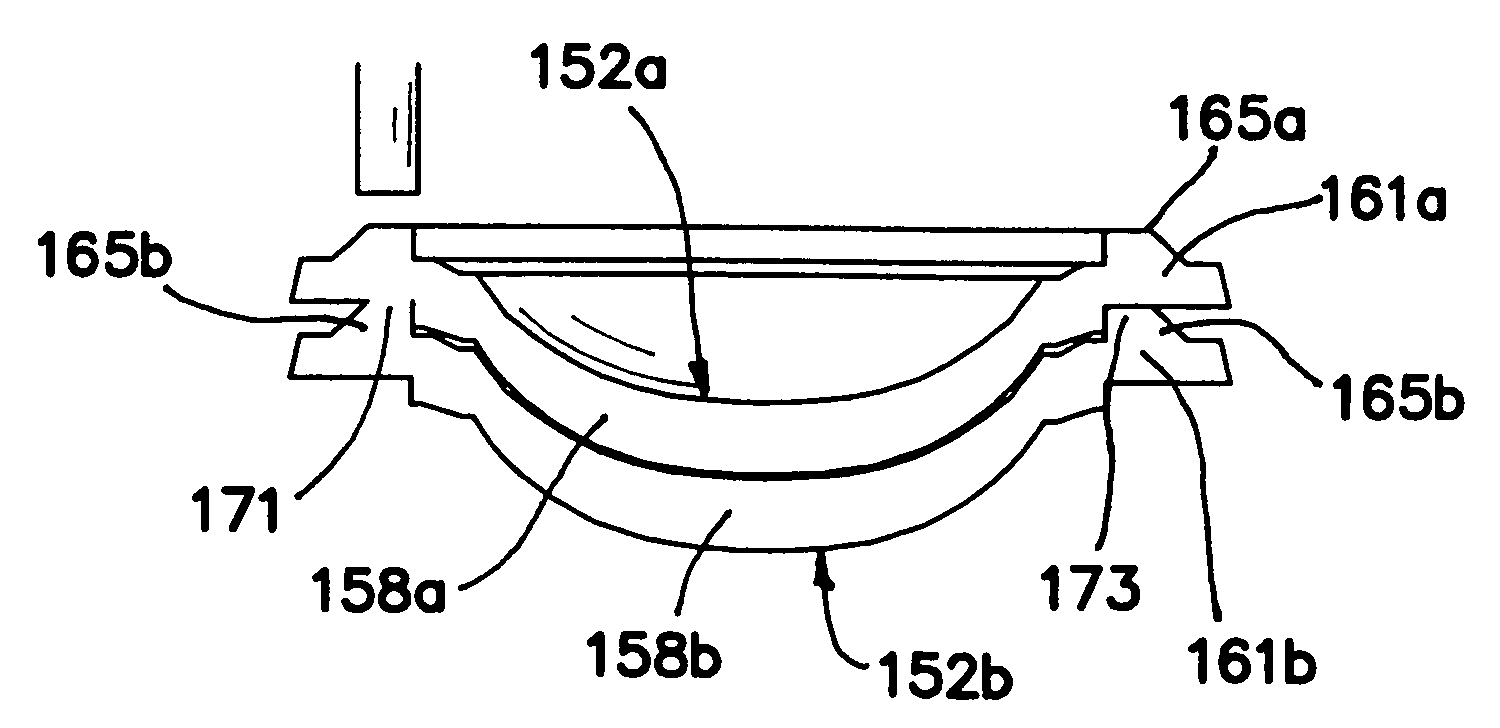

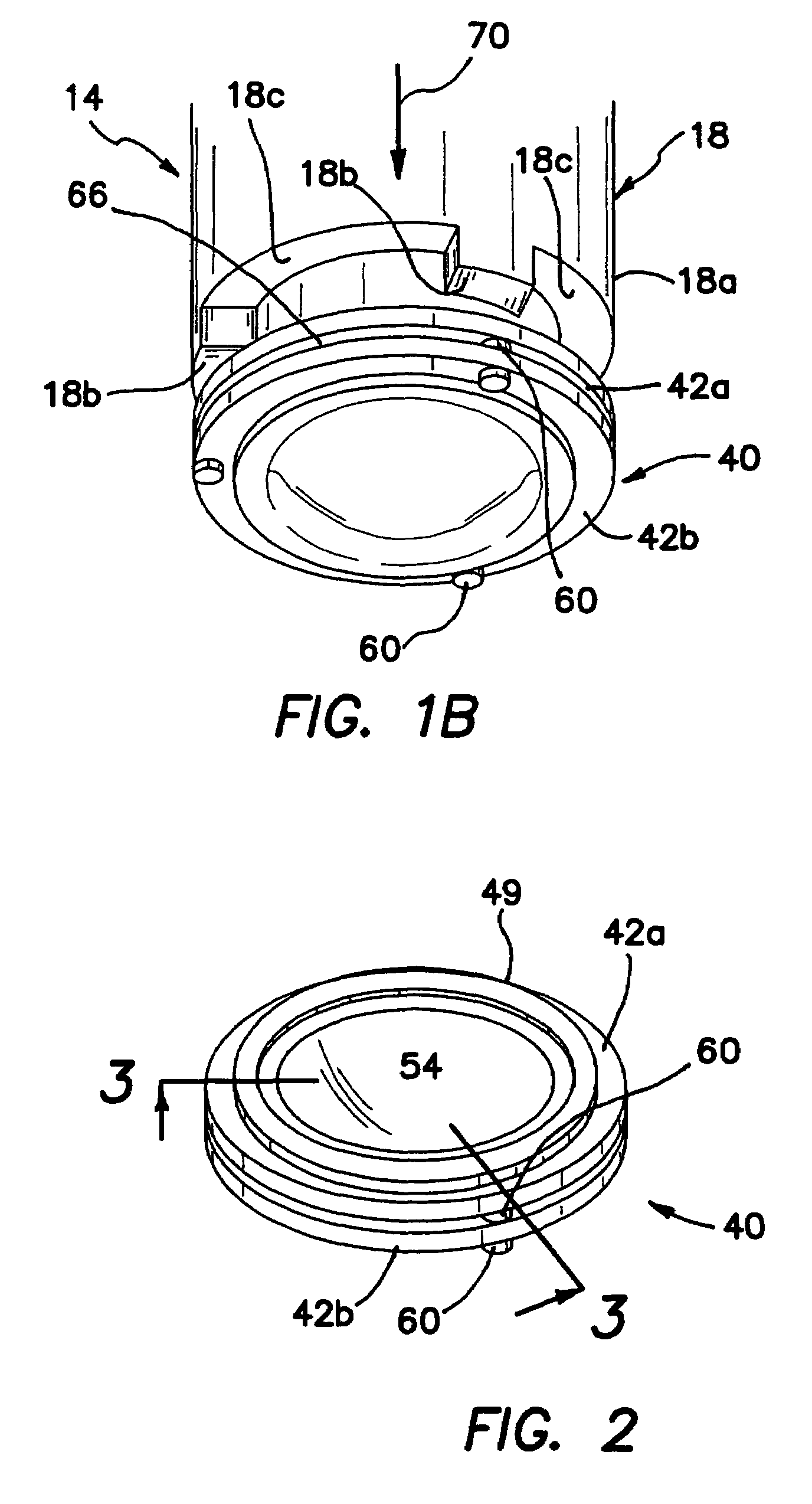

Contact lens mold assemblies and systems and methods of producing same

ActiveUS7731873B2For quick replacementPrecise and accurate amountOptical articlesStereotype platesEngineeringLens plate

Methods and apparatus are provided for making an ophthalmic lens. Apparatus are provided for filling contact lens shaped cavities of contact lens molding assemblies. Methods of coupling and fusing contact lens mold sections are also provided and generally include providing first and second mold sections which, when coupled together, are effective to form a lens-shaped cavity and contact regions between the mold sections. One or both of the mold sections may include one or more recessed regions or projections which provide areas of non-fusion and areas of fusion, respectively, when the mold sections have been filled with a contact lens precursor material and are fused together, for example, by focused ultrasound energy.

Owner:COOPERVISION INT LTD

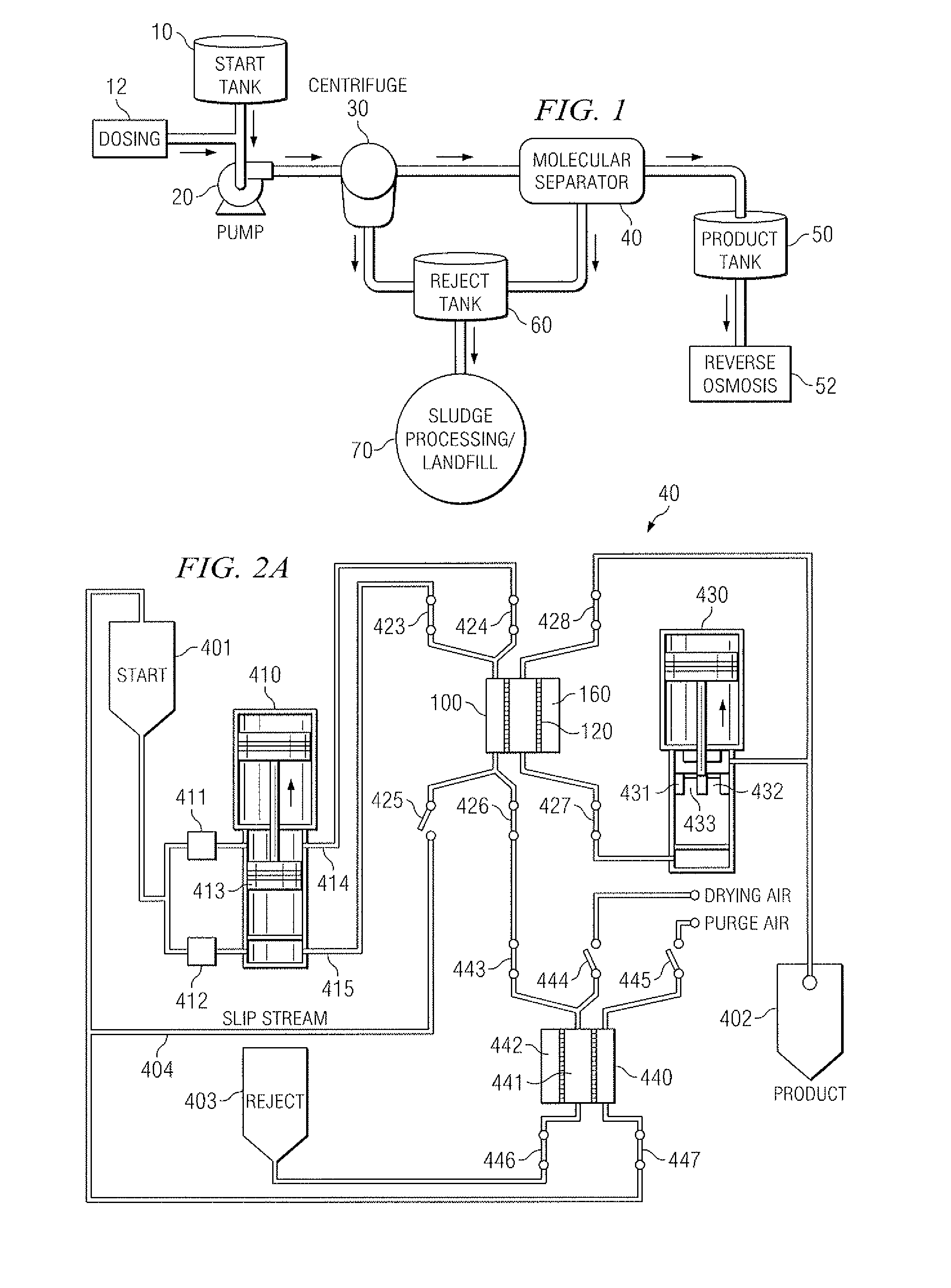

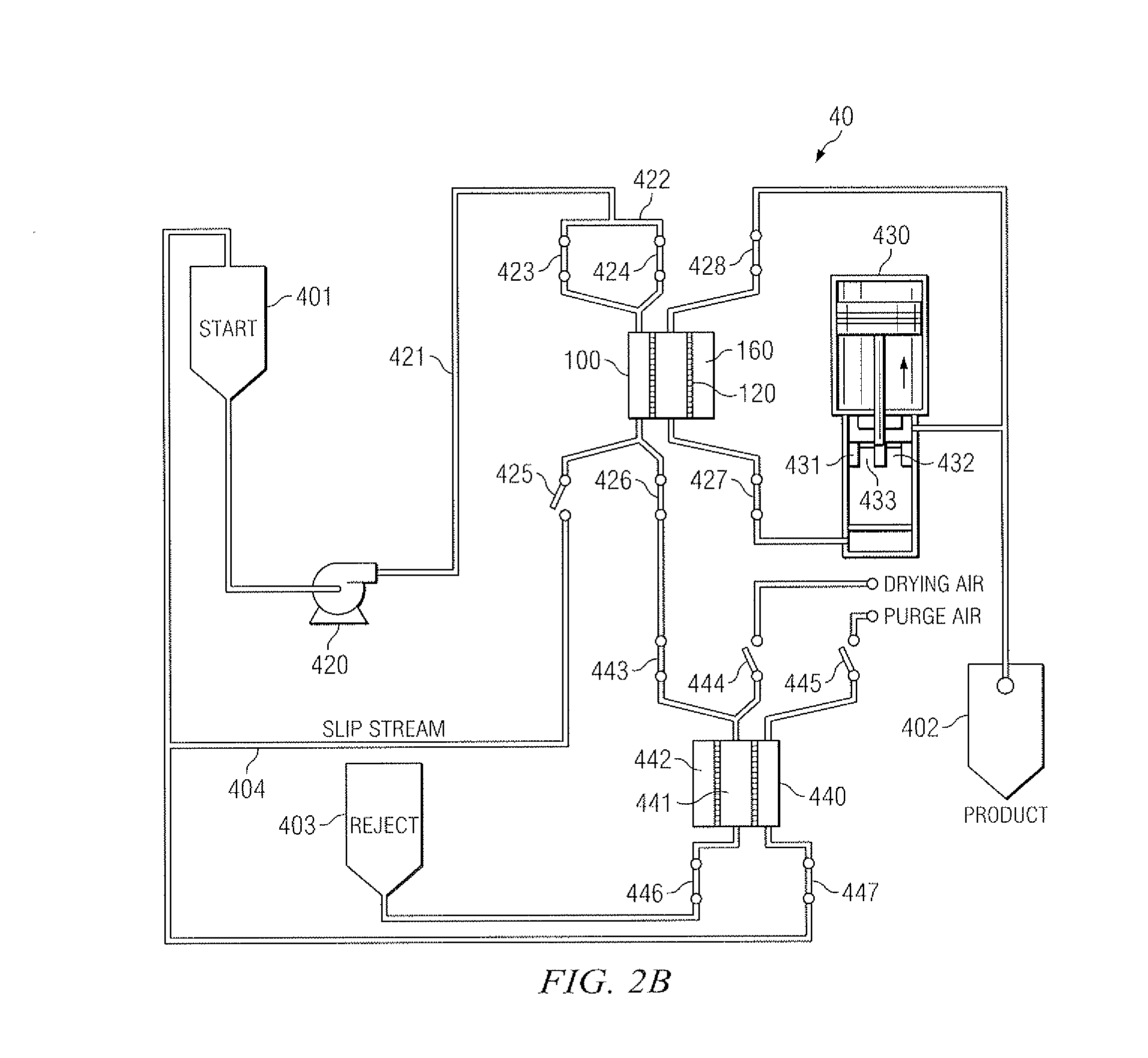

Systems and methods for reduction of total organic compounds in wastewater

InactiveUS20170113957A1Enhanced cavitationImprovement factorGeneral water supply conservationTreatment involving filtrationSimple Organic CompoundsNatural organic matter

A system for purifying wastewater comprising the reduction of total organic compounds in wastewater is disclosed. Chemical reducing agents are brought into contact with polluted water and through dynamically stable anode induced electro-coagulation and flotation removing natural organic material and biorefractory pollutants, decreasing competing organic matter for a secondary oxidizing step, where acids oxidize the processed wastewater through series of reactor tubes for the reduction of total organic compounds.

Owner:ORGINOIL INC

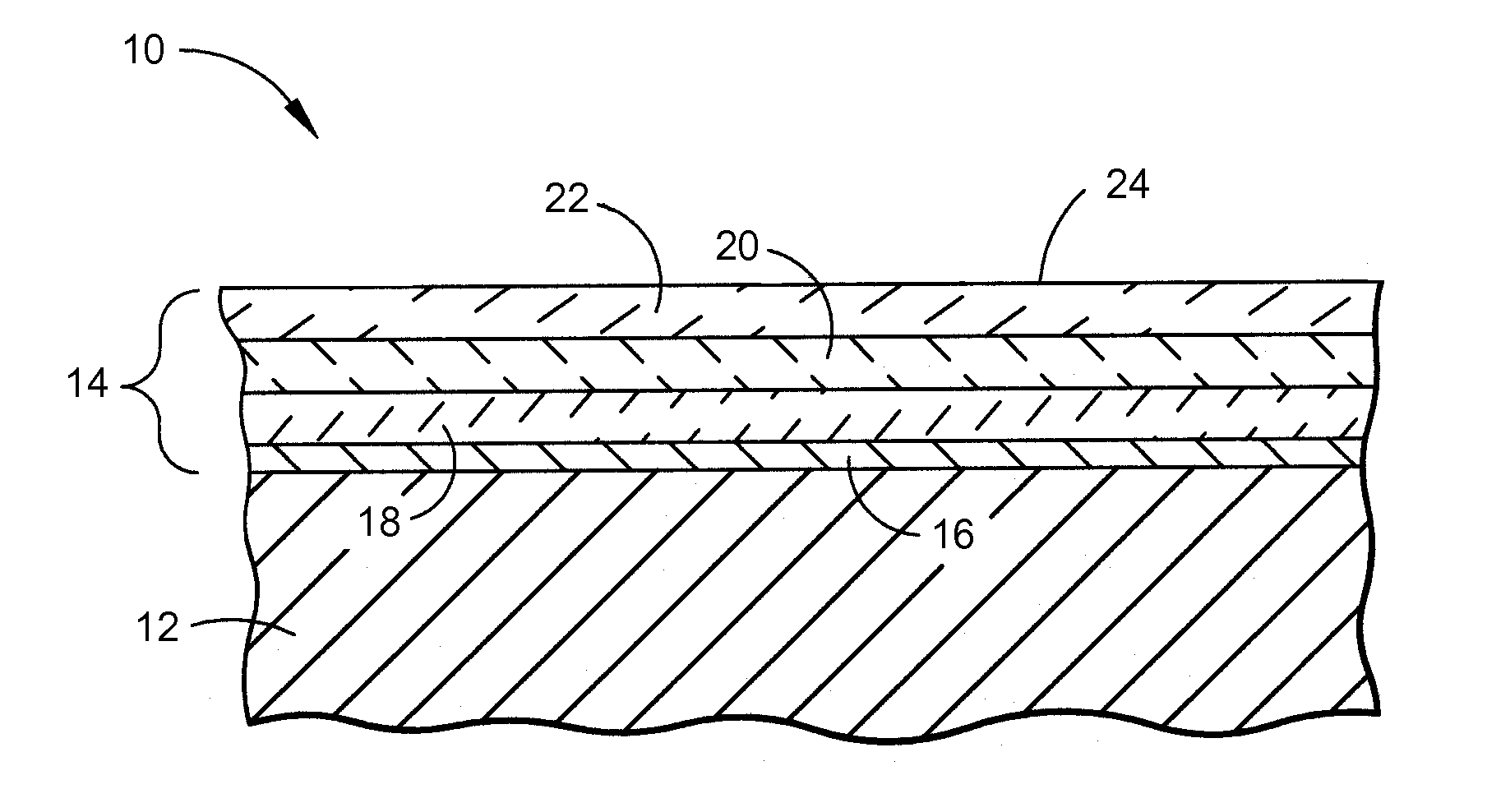

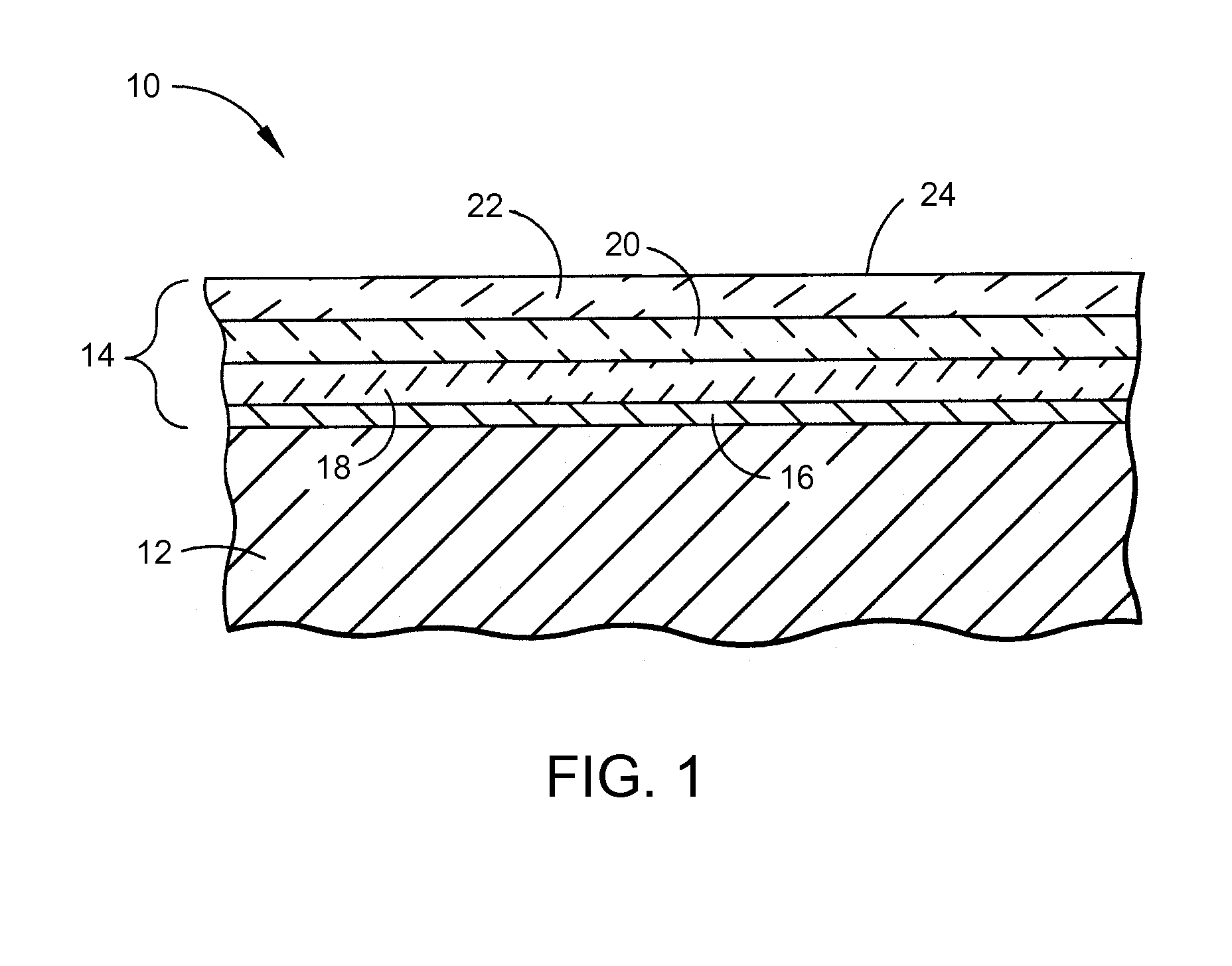

White Opaque Films With Improved Tensile And Barrier Properties

InactiveUS20090081474A1Light stiffnessLight transmission water vapor rateSynthetic resin layered productsThin material handlingPolyolefinCavitation

Provided are multi-layered white opaque films composed of at least two skin layers, at least one tie layer, and at least one core layer. The at least two skin layers are each composed of one or more polyolefins. The at least one tie layer is composed of one or more hydrocarbon resins. The at least one core layer is composed of a blend of one or more polyolefins and one or more cavitating agents. The multi-layered white opaque films described herein exhibit improvements in light transmission, stiffness, and water vapor transmission rate. Moreover, these films were found to exhibit improved cavitation as tested by optical gauge and light transmission.

Owner:EXXONMOBIL CHEMICAL CO INC

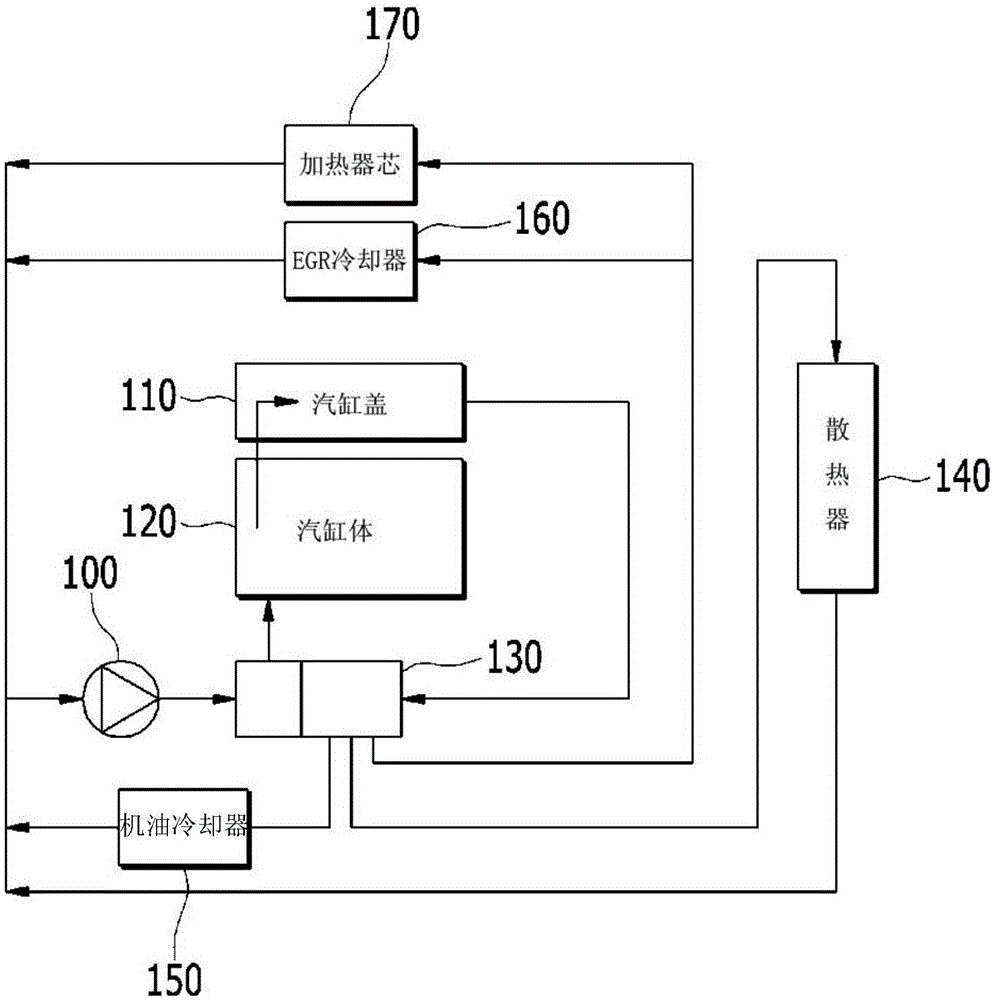

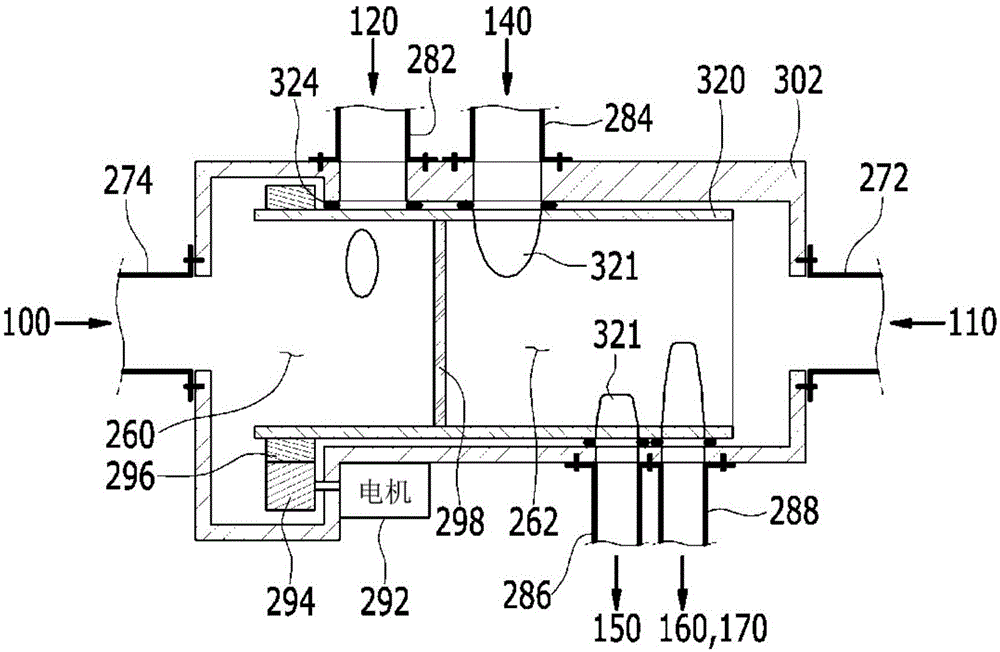

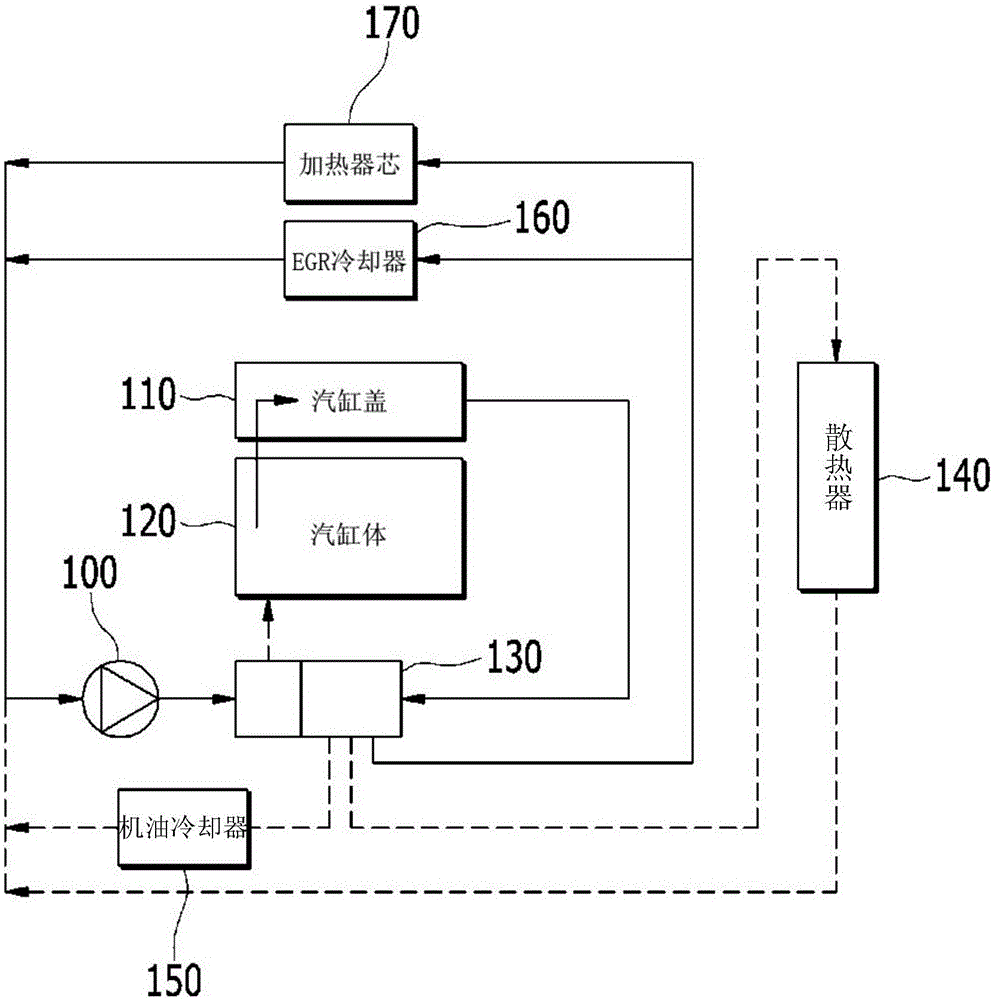

Engine system having coolant control valve

InactiveCN105604674AIncreased durabilityEnhanced cavitationLiquid coolingCasingsCylinder headEngineering

An engine system having a coolant control valve may include a cylinder block, a cylinder head, an exhaust gas recirculation (EGR) cooler, a heater core, an oil cooler or a radiator and a coolant control valve. The cylinder block is configured with cylinders; the cylinder head is sitting on top of the cylinder block and comprises exhaust ports and intake ports configured to lead to the cylinders, the Exhaust Gas Recirculation (EGR) cooler, the heater core, the oil cooler, or the radiator through which coolant circulates, and the coolant control valve configured to control a coolant supplied to the cylinder block, a coolant discharged from the cylinder block through the cylinder head, and a coolant supplied to the EGR cooler, the heater core, the oil cooler, or the radiator.

Owner:HYUNDAI MOTOR CO LTD

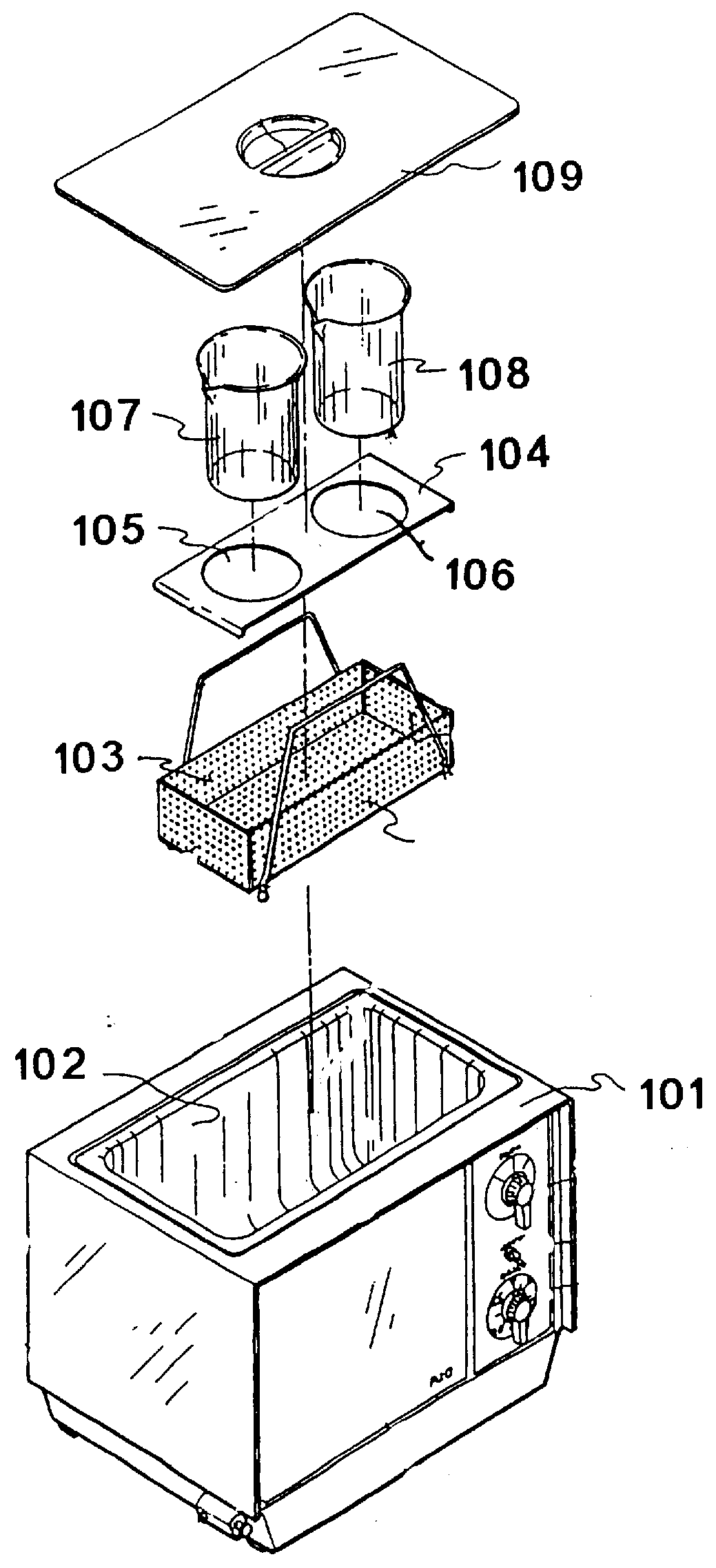

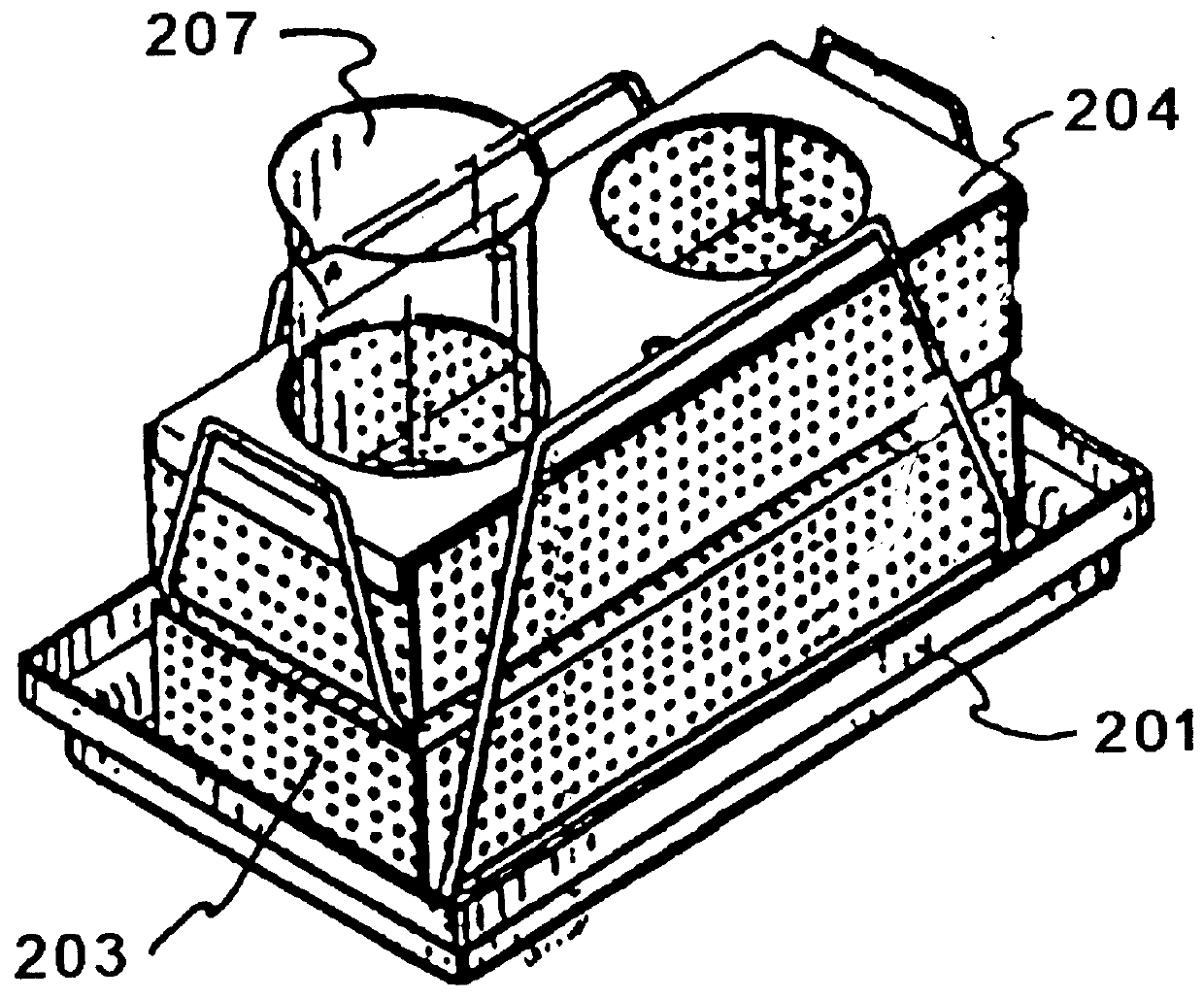

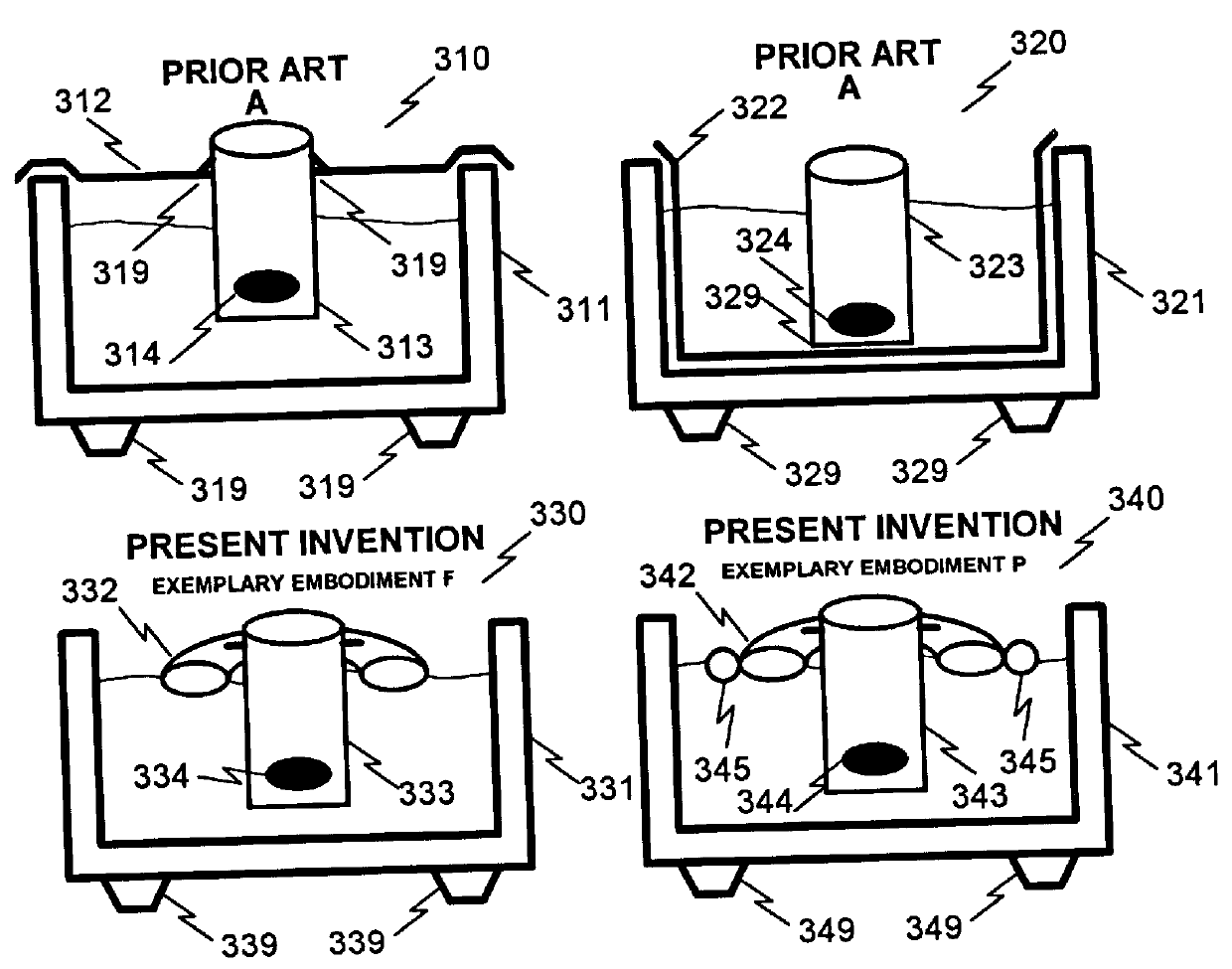

System and method for ultrasonic cleaning and degreasing

InactiveUS6030463AEnhanced cavitationAffect maximum cavitationElectrostatic cleaningCleaning using liquidsHarmonicBiomedical engineering

A system and method of performing ultrasonic cleaning is disclosed whereby a conventional ultrasonic cleaning bath is augmented via the use of a cleaning target support structure and an optional mechanical isolator whereby the cleaning target is mechanically isolated from the ultrasonic cleaning bath. This isolation permits ultrasonic harmonics which are normally damped (suppressed) in amplitude due to conventional mechanical connections between the bath and the containment vessel to be fully applied to the cleaning target, resulting in substantial reduction in overall cleaning time and an improvement in cleaning efficiency. Various embodiments of the proposed system and method are disclosed, with several being preferred. Namely, the use of a circular floating-ballast to support a glass or plastic beaker used as the containment vessel is preferred as well as the use of a circular floating-ballast to support a plastic bag used as the containment vessel. Either of these configurations isolates the cleaning target from the sides of the ultrasonic bath. This isolation reduces the effective mass of the structure comprising the cleaning target, the containment vessel, and the containment vessel support (ballast means) and permits ultrasonic harmonics to fully affect cleaning with minimal harmonic damping. Consistent cleaning time improvements of 20-80% over conventional prior art basket-type and containment vessel support cover methods has been observed.

Owner:RUSCZYK LESTER LEE

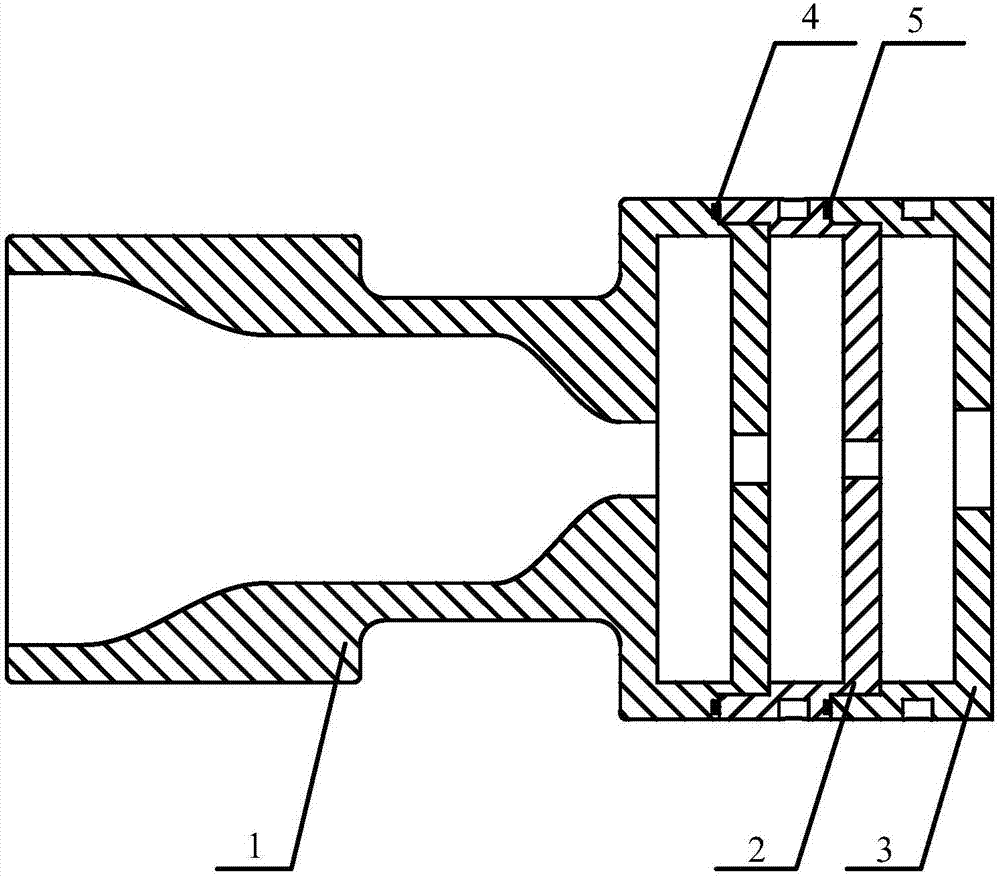

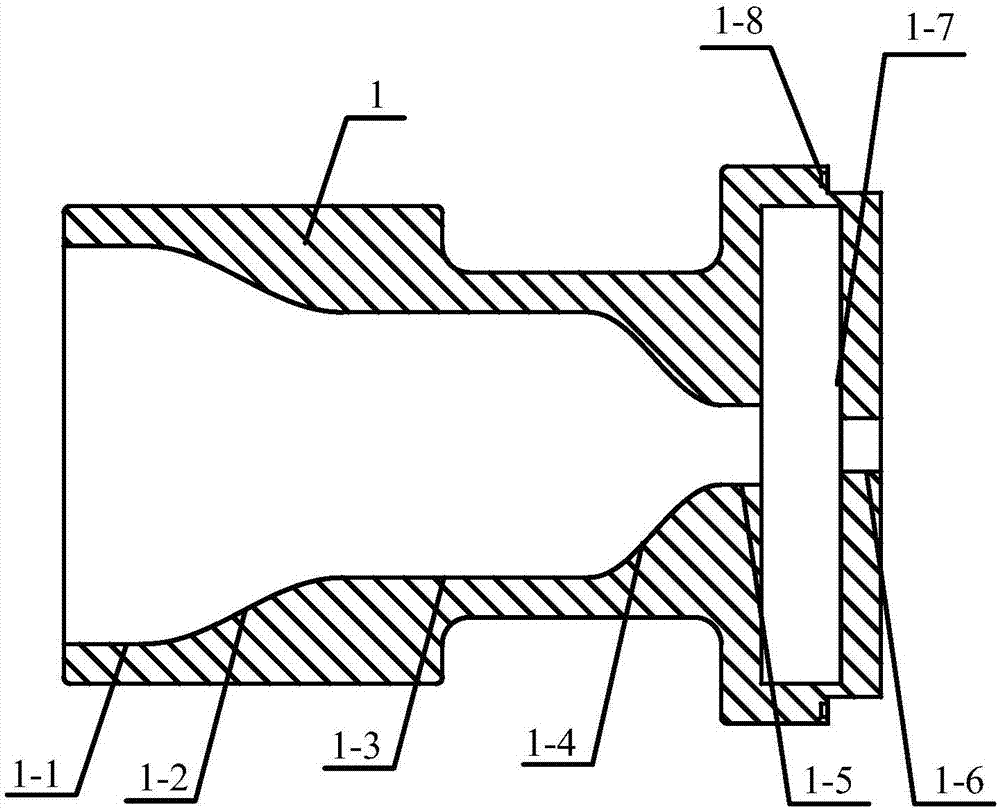

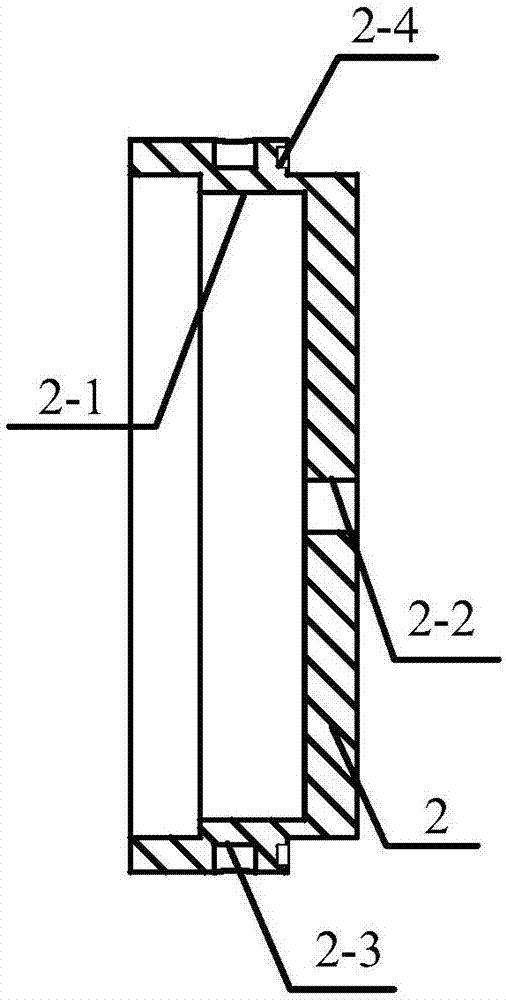

Venturi tube based high-flux hydraulic cavitation reactor and cavitation method

ActiveCN107162101AReduce turbulence inhomogeneitySimple structureWater/sewage treatment with mechanical oscillationsJet flowHigh flux

The invention discloses a venturi tube based high-flux hydraulic cavitation reactor and a hydraulic cavitation method. The reactor comprises a cylindrical cavity, a plurality of fluid inlet pipes, an annular porous plate, a fluid outlet pipe and a venturi tube structure. The fluid inlet pipes are uniformly arranged at the outer edge of the cylindrical cavity, the annular porous plate is coaxially arranged in the cylindrical cavity, the fluid outlet pipe is arranged at the axis position of the cylindrical cavity, and the venturi tube structure is arranged on the fluid outlet pipe. The hydraulic cavitation method includes steps: fluid enters a cavity between the annular porous plate and the outer wall of the cylindrical cavity along the fluid inlet pipes; the fluid penetrates the annular porous plate; after the fluid passes through the annular porous plate, a great quantity of cavitation bubbles are generated, and a strong cavitation phenomenon is generated by convergence and collision of cavitation fluid at the center of the cylindrical cavity; treated fluid enters an expansion section through the fluid outlet pipe and gradually recovered in pressure along with expansion of a flowing passage, and the cavitation bubbles collapse again to form micro jet flow and shock wave to generate instantaneous local high temperature and instantaneous high pressure. The venturi tube based high-flux hydraulic cavitation reactor and the hydraulic cavitation method have advantages of high flux and high cavitation efficiency.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

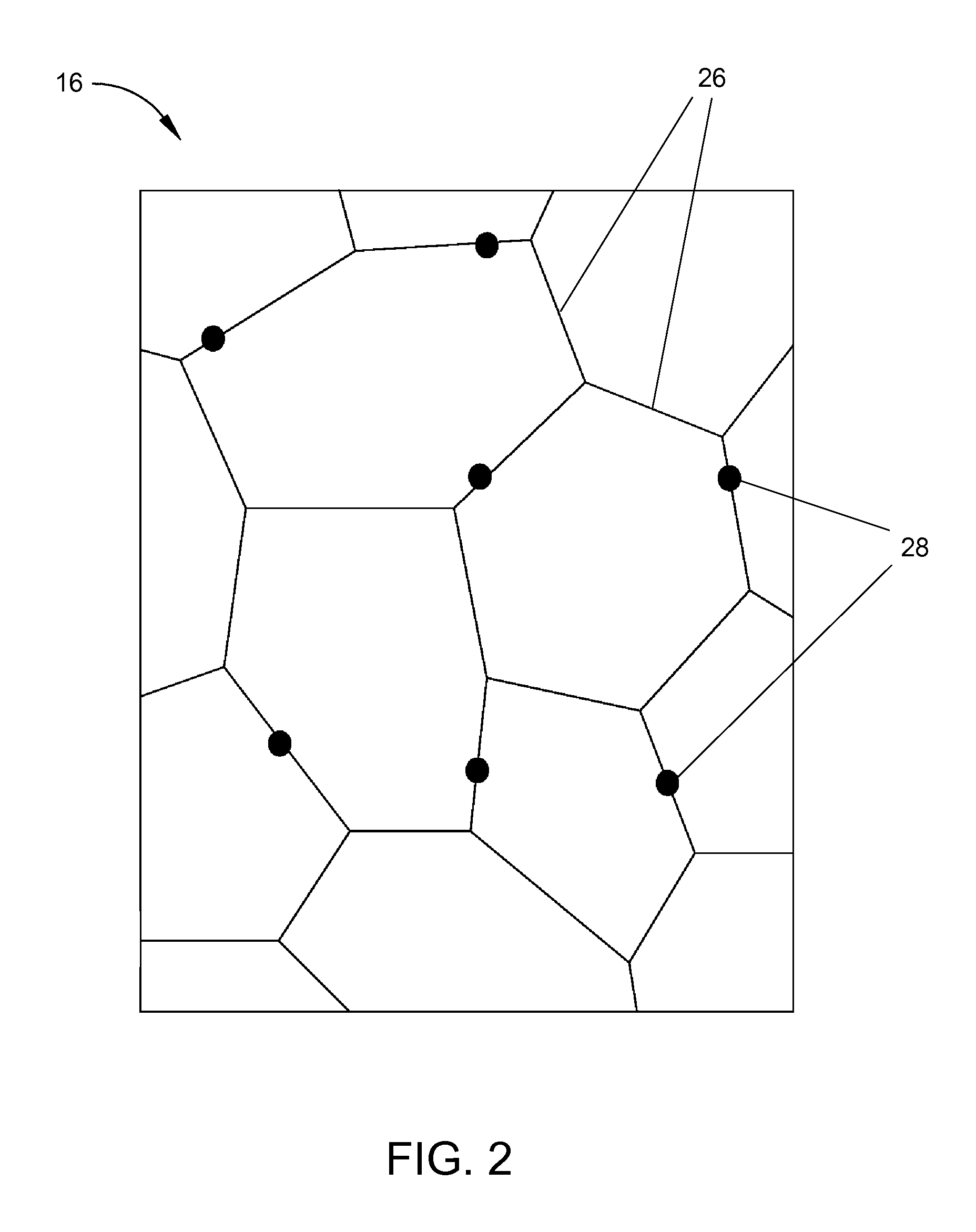

Cavitation-resistant environmental barrier coatings

InactiveUS20140050929A1Enhanced cavitationIncrease resistanceLiquid surface applicatorsLayered productsCavitationCoating system

An environmental barrier coating, a method of application thereof, and an article made thereby suitable for protecting components exposed to high-temperature environments with improved delamination resistance and cavitation resistance. The environmental barrier coating system for a silicon-containing substrate includes a bond coat layer on the silicon-containing substrate and at least one ceramic environmental barrier layer on the bond coat layer. The bond coat layer includes silicon and at least one doping material including elemental titanium. The doping material is located at grain boundaries within the bond coat layer in sufficient quantity to improve the delamination resistance and the cavitation resistance of increase the bond coat layer.

Owner:GENERAL ELECTRIC CO

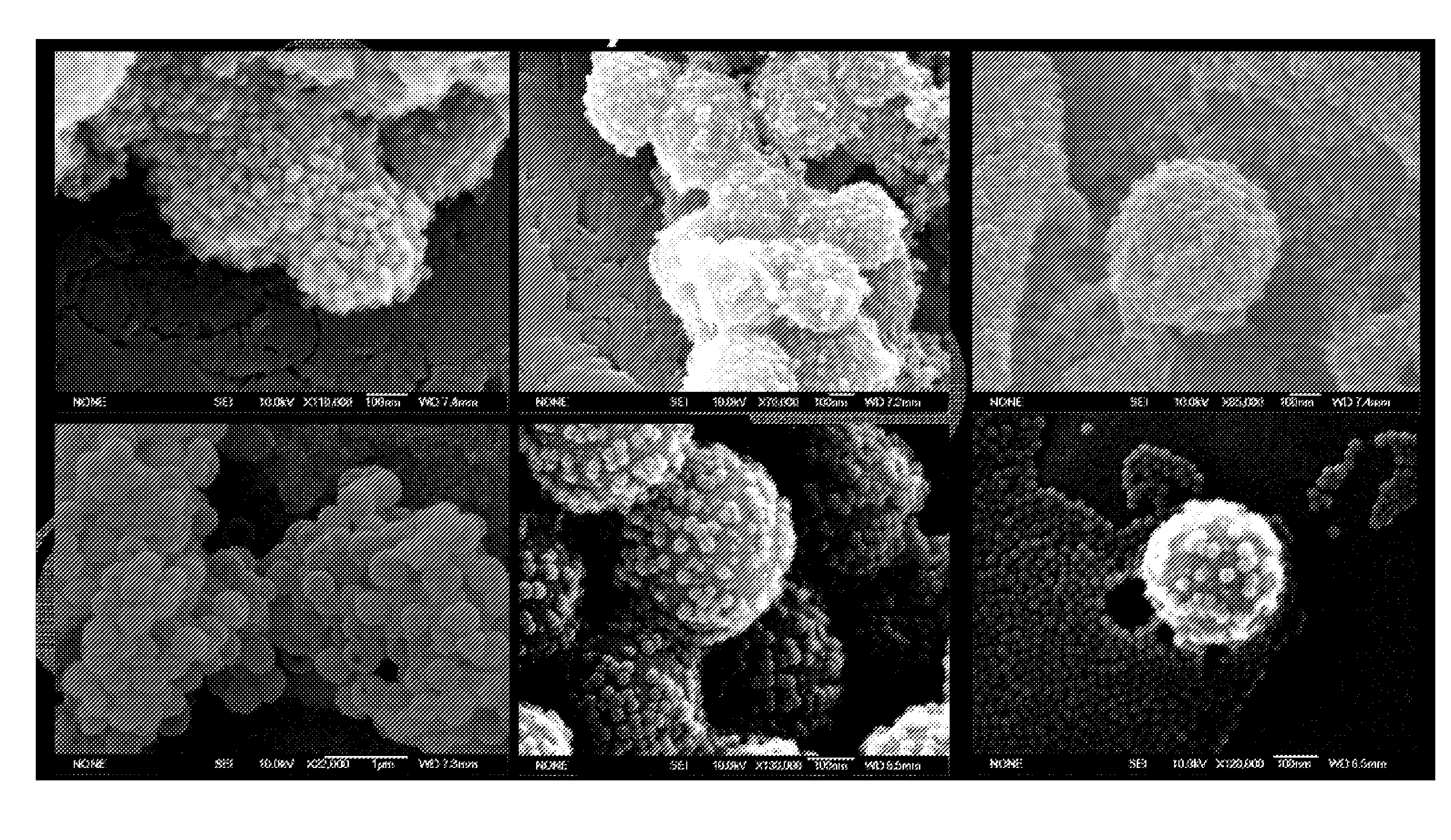

Sonosensitive nanoparticles

InactiveUS20130281916A1Facilitate initiationEasy to startPowder deliverySurgeryNanoparticleNanometre

A method of delivering a therapeutic substance to tissue comprises delivering the therapeutic substance and nanoparticles to the tissue, the nanoparticles having a diameter in the range from 10 to 1000 nm and surface features having a depth in the range from 5 to 50 nm, and insonating the tissue with pressure waves. Corresponding particles, and associated methods of controlling and imaging the treatment and delivery are also disclosed.

Owner:ISIS INNOVATION LTD

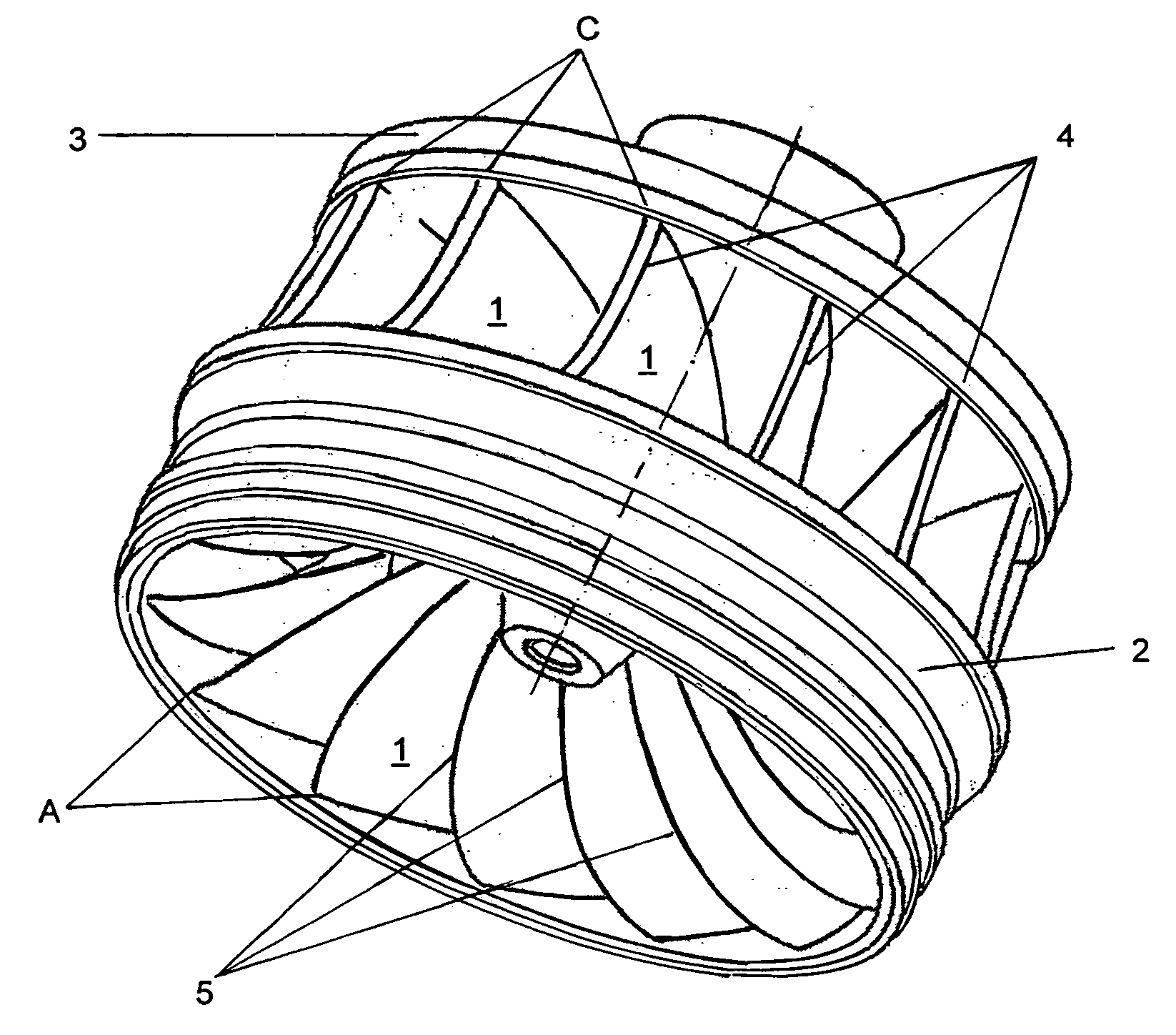

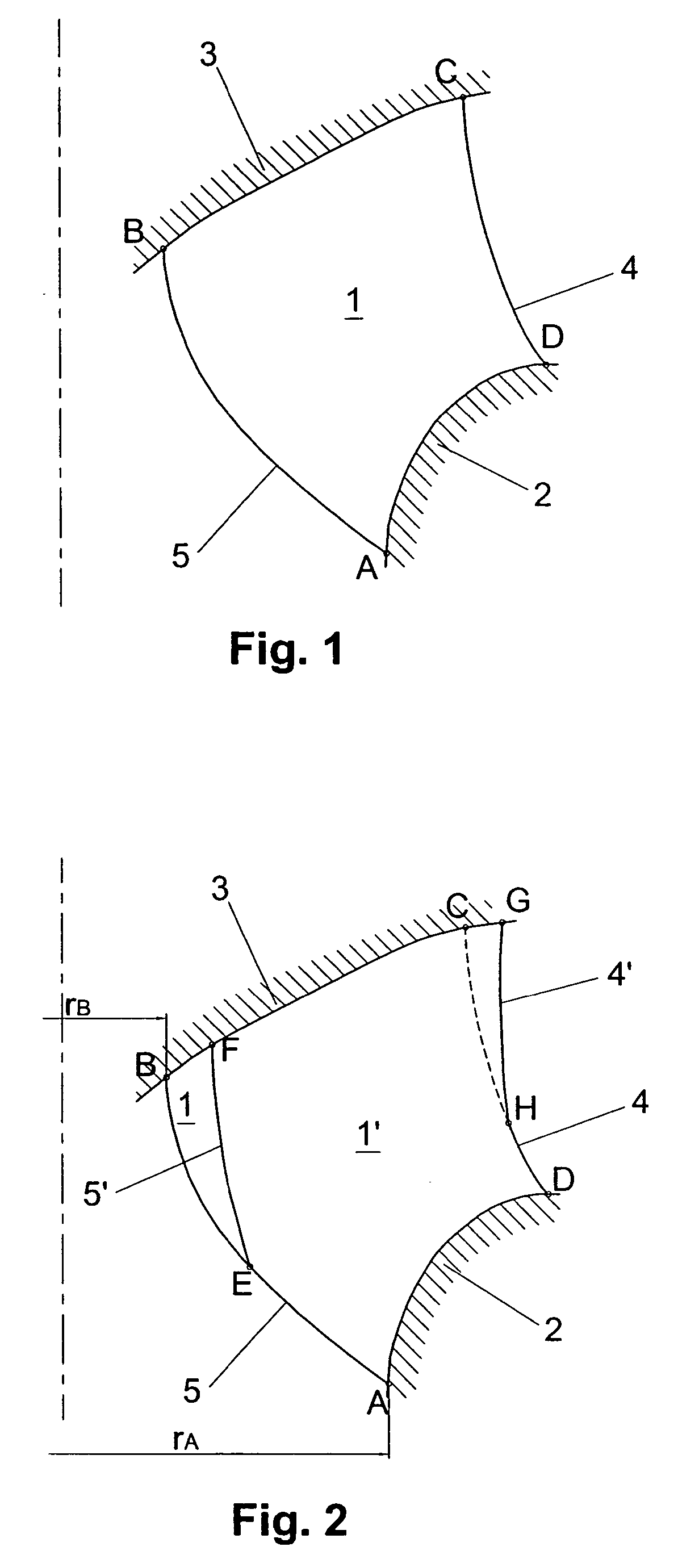

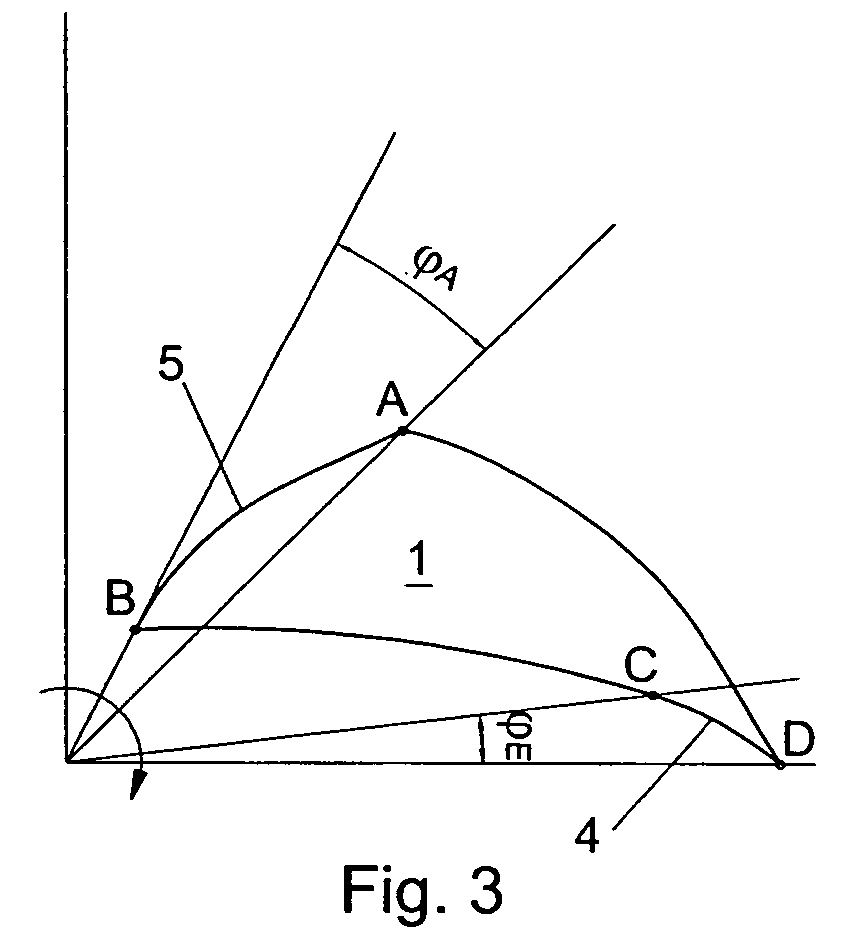

Hydraulic machine rotor

InactiveUS20050214115A1Good cavitation behaviorLoss in efficiencyPropellersHydro energy generationEngineeringMechanical engineering

Rotor blades of a hydraulic machine rotor are shaped such that the inlet edge and outlet edge of two adjacent rotor blades have varying profiles in different sections.

Owner:VA TECH HYDRO

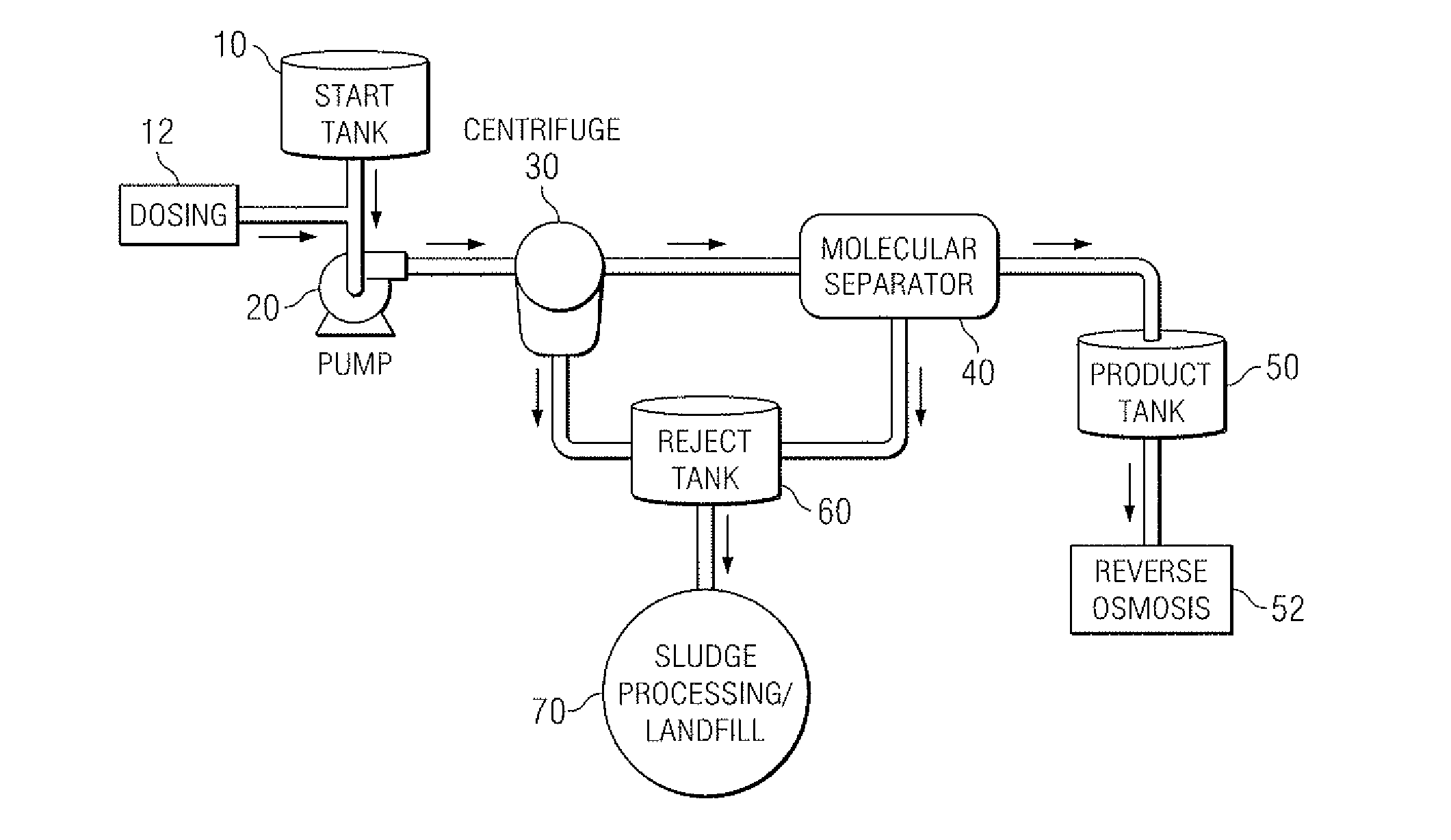

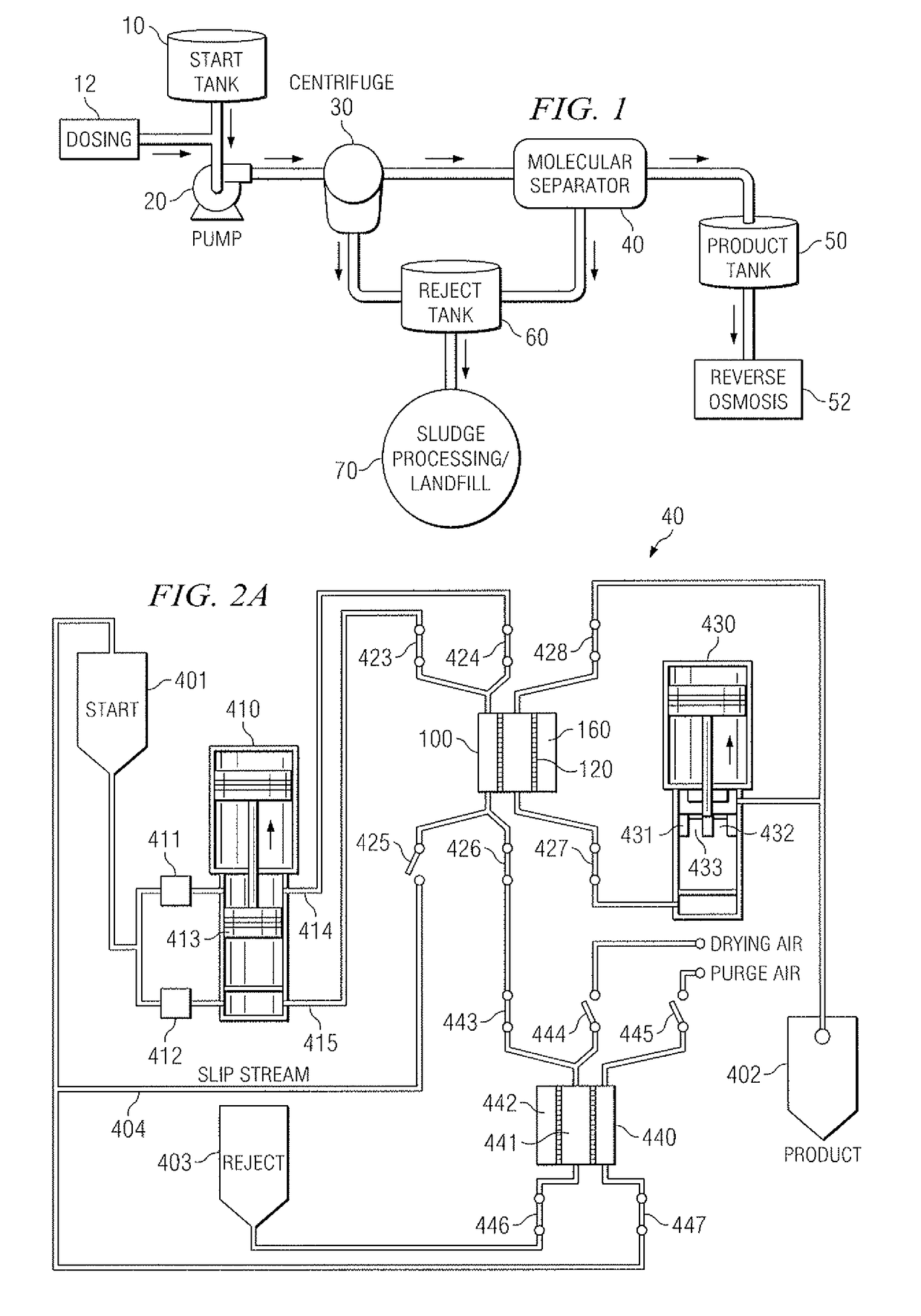

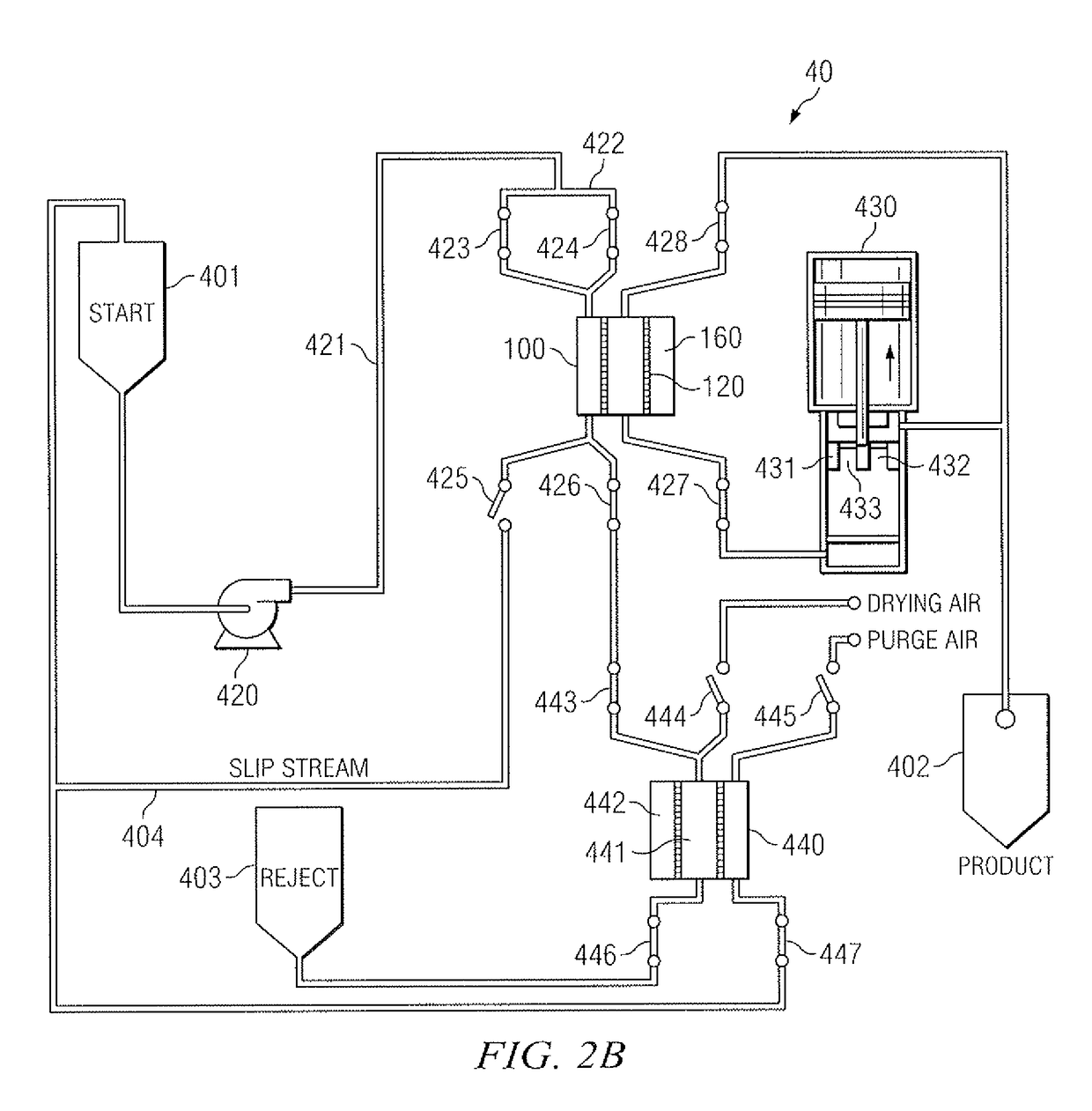

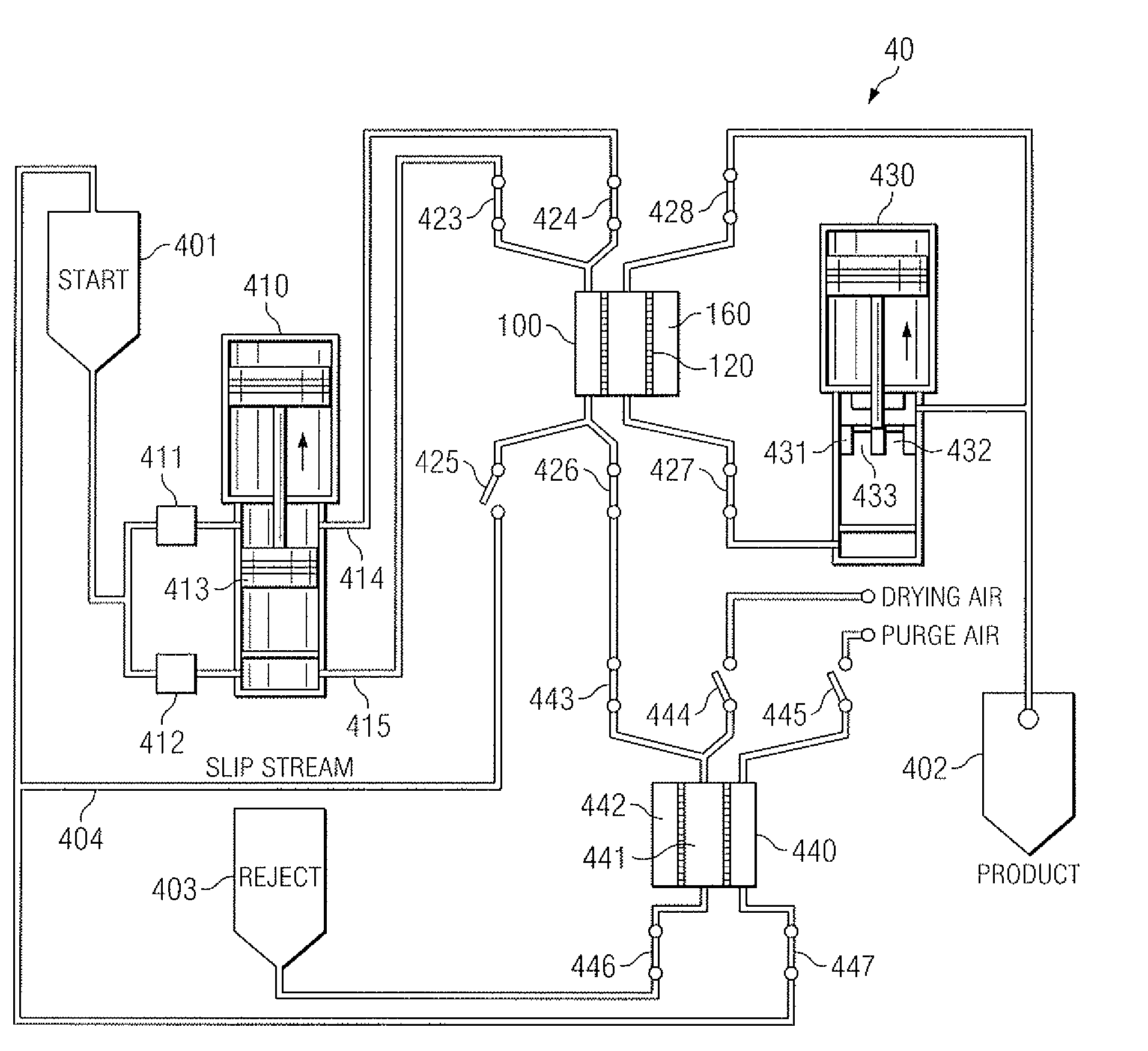

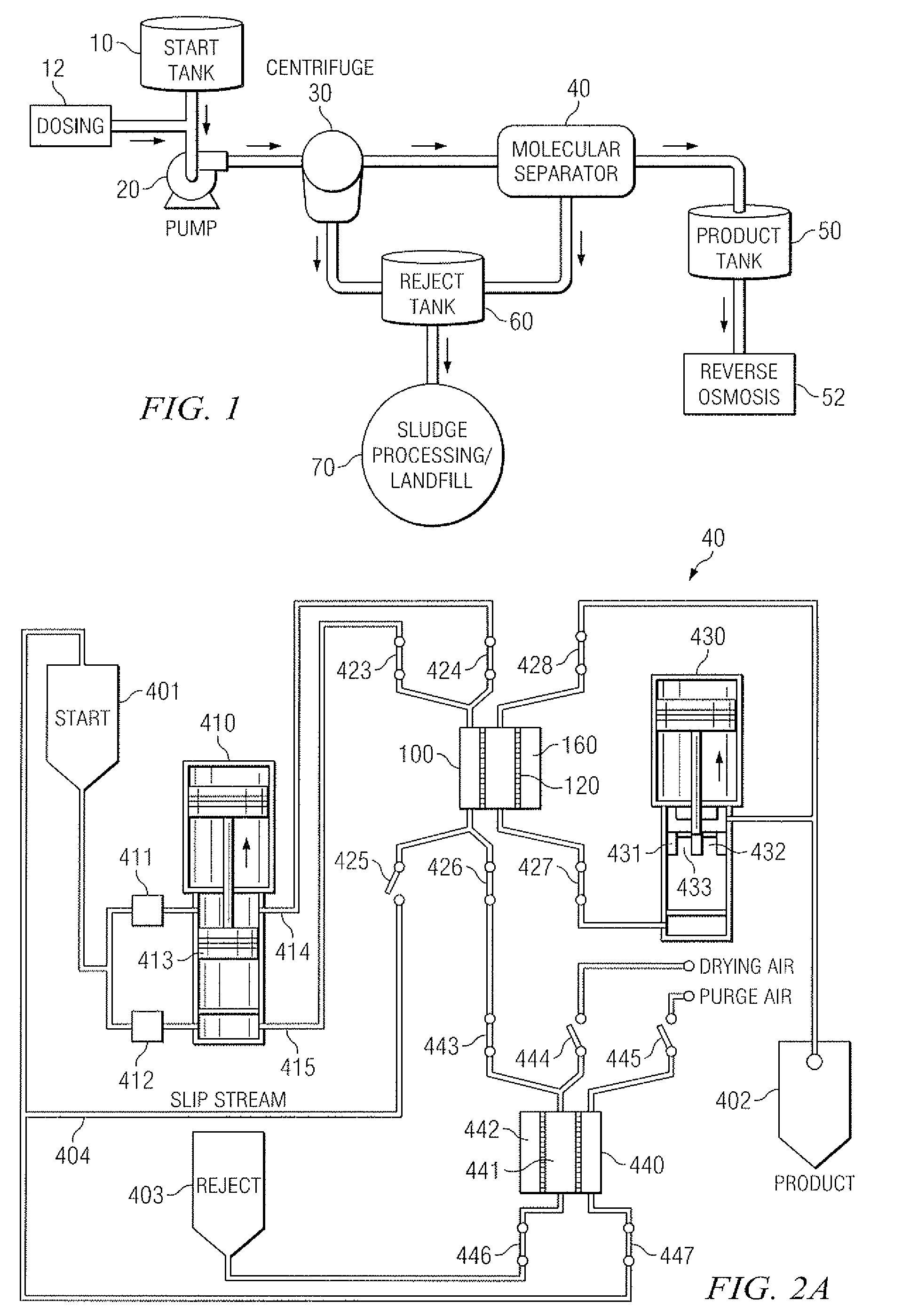

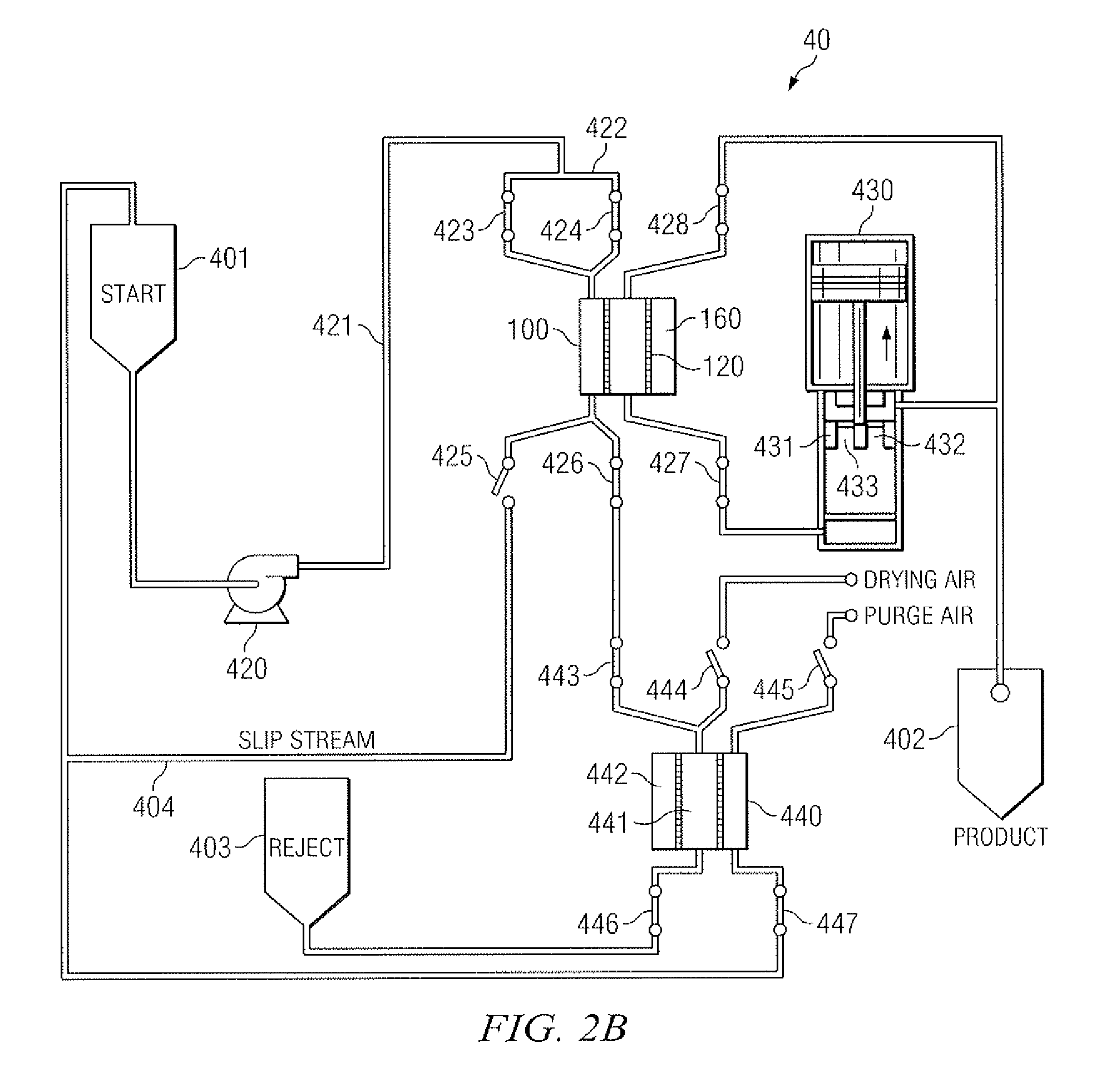

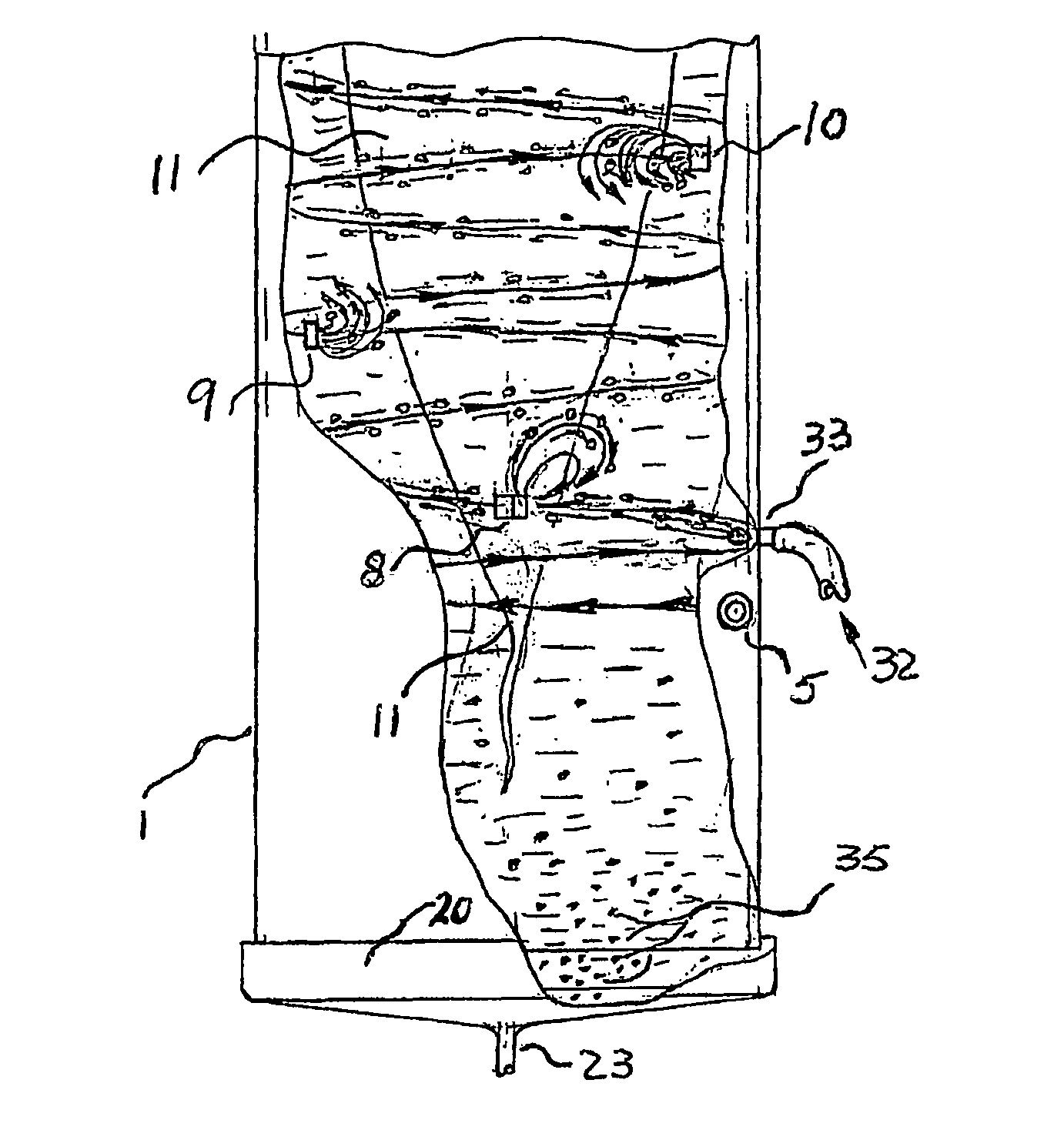

Wastewater treatment method and apparatus

InactiveUS7906023B2Easy to useEnhanced cavitationUltrafiltrationReverse osmosisCavitationFilter media

The present invention discloses a method and apparatus for separating particles and dissolved matter from a produced water fluid stream. Specifically, the present invention includes a first pressure source which transports untreated produced water or contaminated aqueous fluid into a separator annulus with a filter element disposed therein. The untreated fluid is placed under appropriate pressure sufficient to produce turbulent flow, increased particle kinetics and / or cavitation allowing the desired fluid to penetrate and pass into and through the filter media. The treated fluid is then transported to a collection tank. The contaminant matter retained by the filter media may be removed by the nearly instantaneous reverse pressurization of the separator annulus by a second pressure source thereby removing the contaminant particles away from contact with the filter media, and which may then be transported to a waste collection tank or a separator for further treatment.

Owner:TERVITA +1

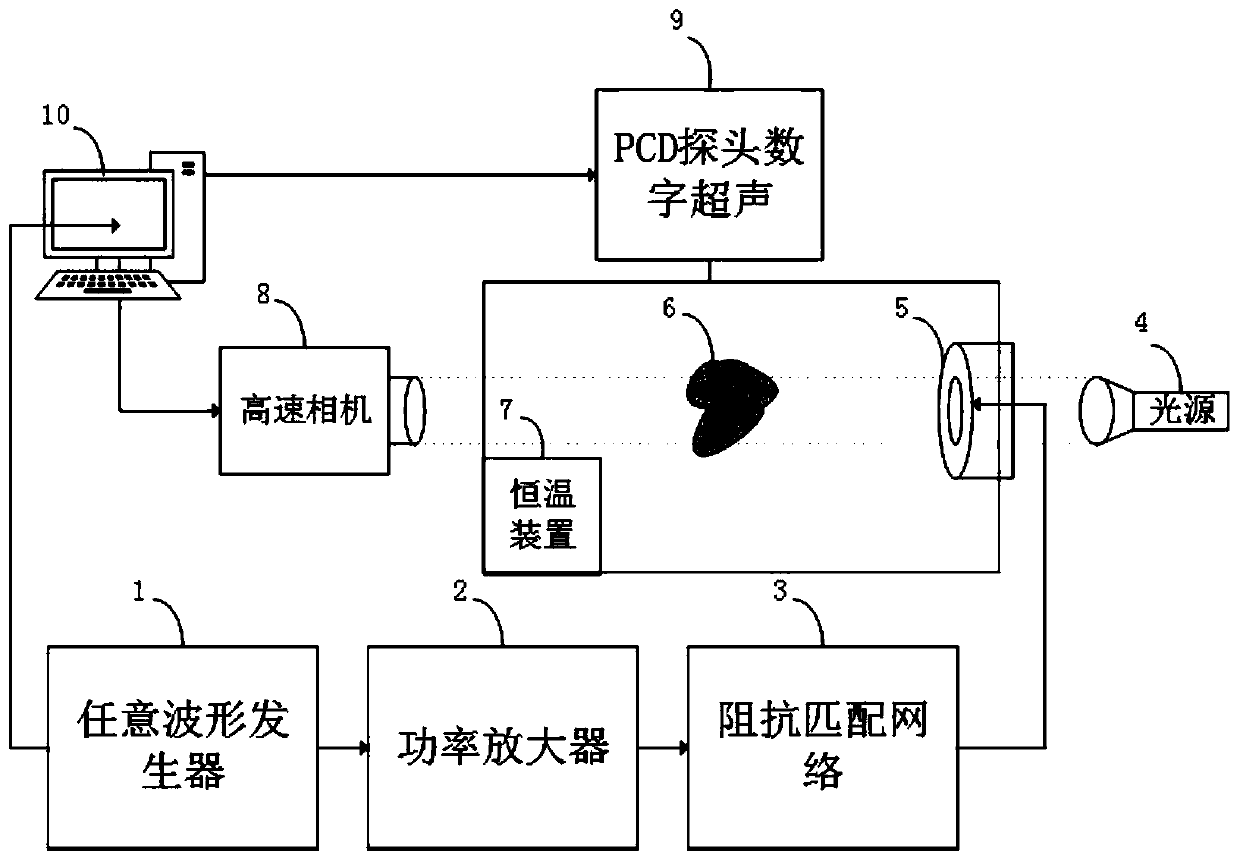

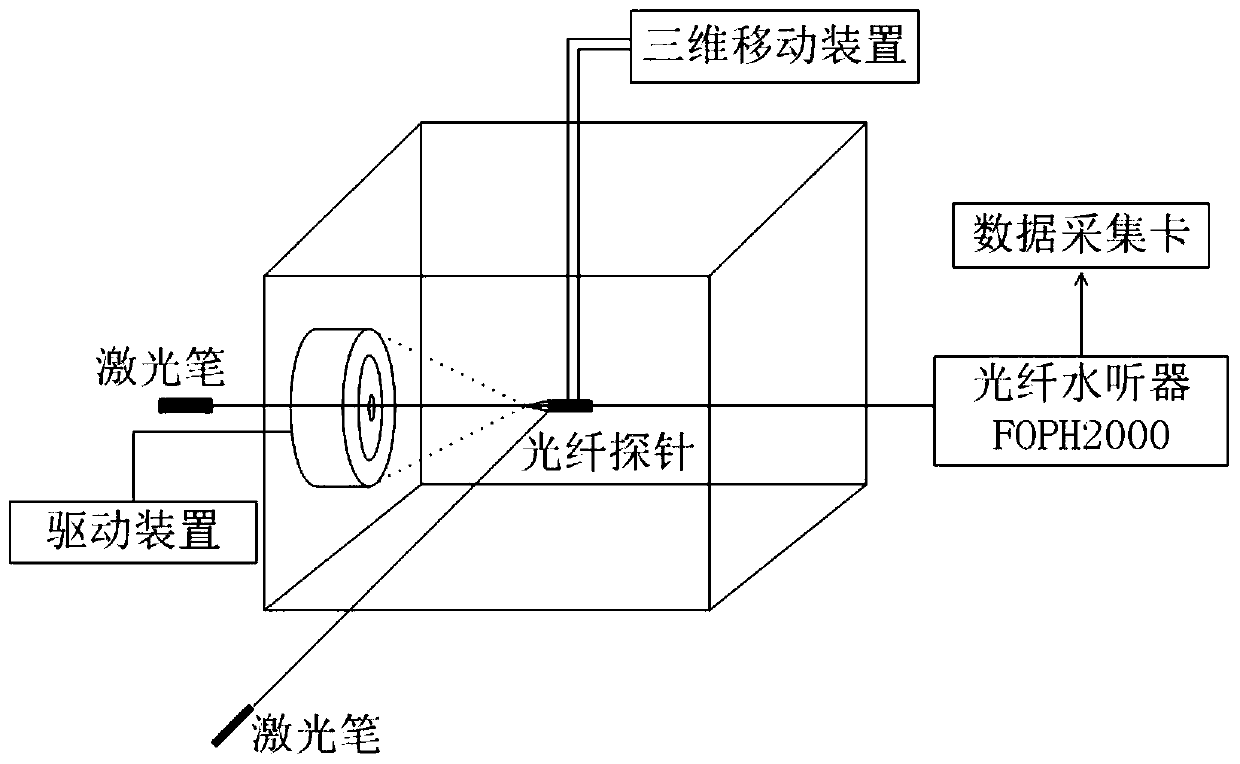

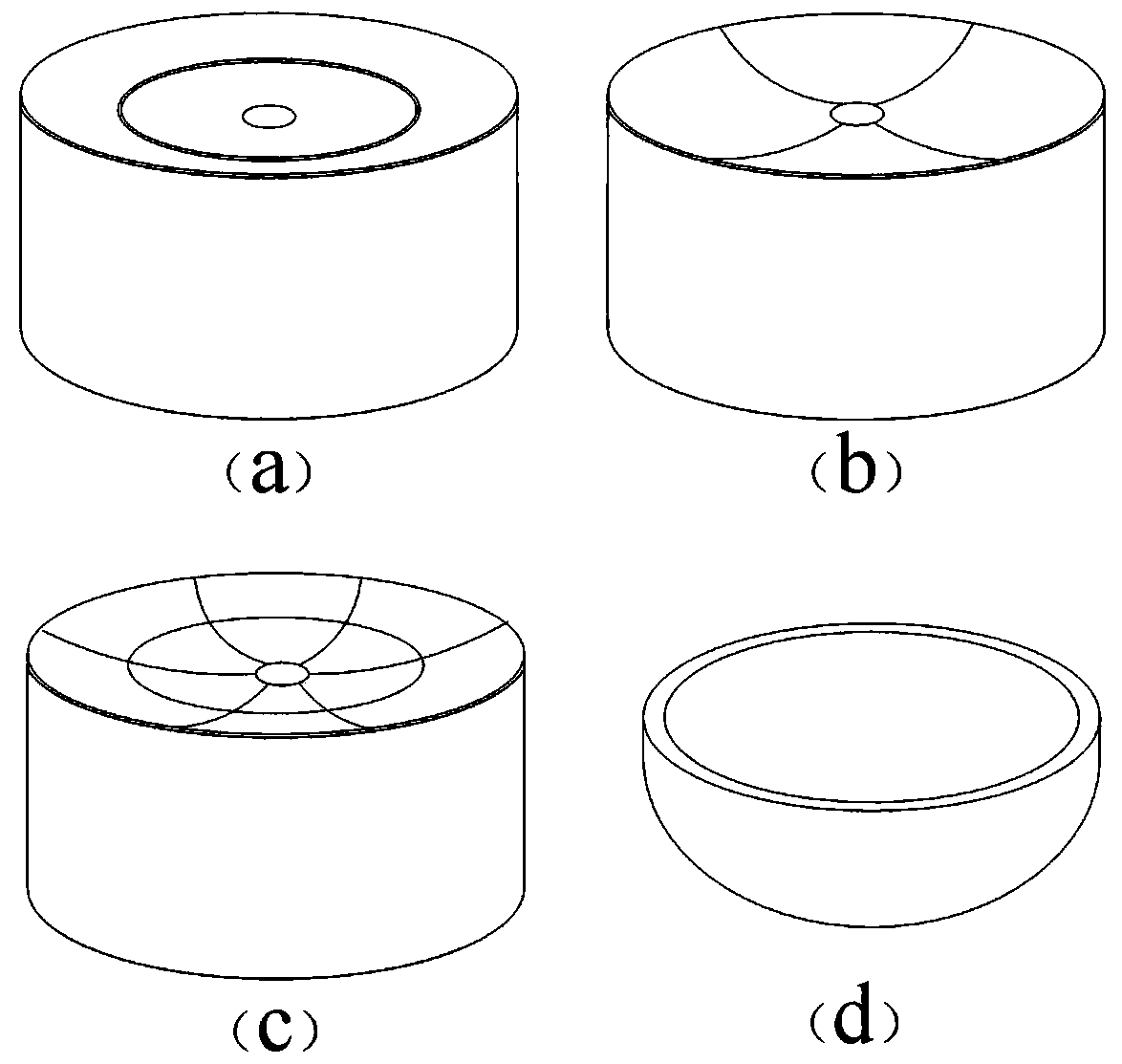

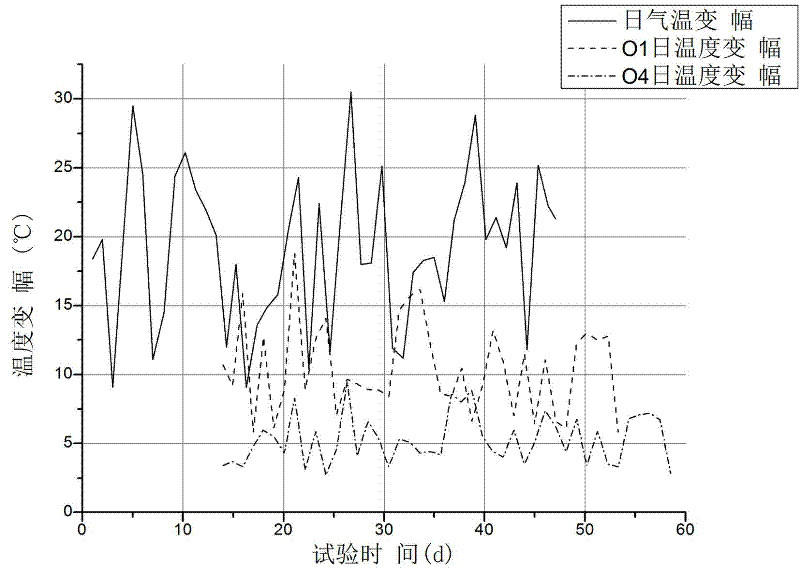

Microbubble synergistic dynamic experiment system based on double frequency superimposed ultrasonic pulse in viscoelastic medium and microbubble synergistic dynamic experiment method based on double frequency superimposed ultrasonic pulse in viscoelastic medium

ActiveCN110243454AImprove efficiencyImprove securitySubsonic/sonic/ultrasonic wave measurementDesign optimisation/simulationDynamic methodCavitation

The invention discloses a microbubble synergistic dynamic experiment system based on a double frequency superimposed ultrasonic pulse in a viscoelastic medium and a microbubble synergistic dynamic experiment method based on the double frequency superimposed ultrasonic pulse in the viscoelastic medium. The experiment method comprises the following steps 1) according to an actual waveform of a focal region sound field measured by a hydrophone, setting KZK equation parameters and establishing a microbubble nonlinear excitation waveform; 2) constructing a HIFU synergistic model according to viscoelasticity of a biological tissue and vibration characteristics of the microbubble in compressible fluid; 3) establishing a microbubble synergistic dynamic method based on double frequency superimposition; 4) in combination with simulation results of steps above, determining a HIFU waveform phase, sound pressure and frequency parameters to perform a thermal ablation or tissue damage experiment. According to the system and the method provided by the invention, the dynamic characteristics of the microbubble in the biological tissue are used fully to design the sound wave waveform and the phase parameter, maximum vibration of the microbubble is triggered at a focal region, a cavitation effect is enhanced, and safety and efficiency of HIFU thermal ablation and tissue damage are improved.

Owner:XI AN JIAOTONG UNIV

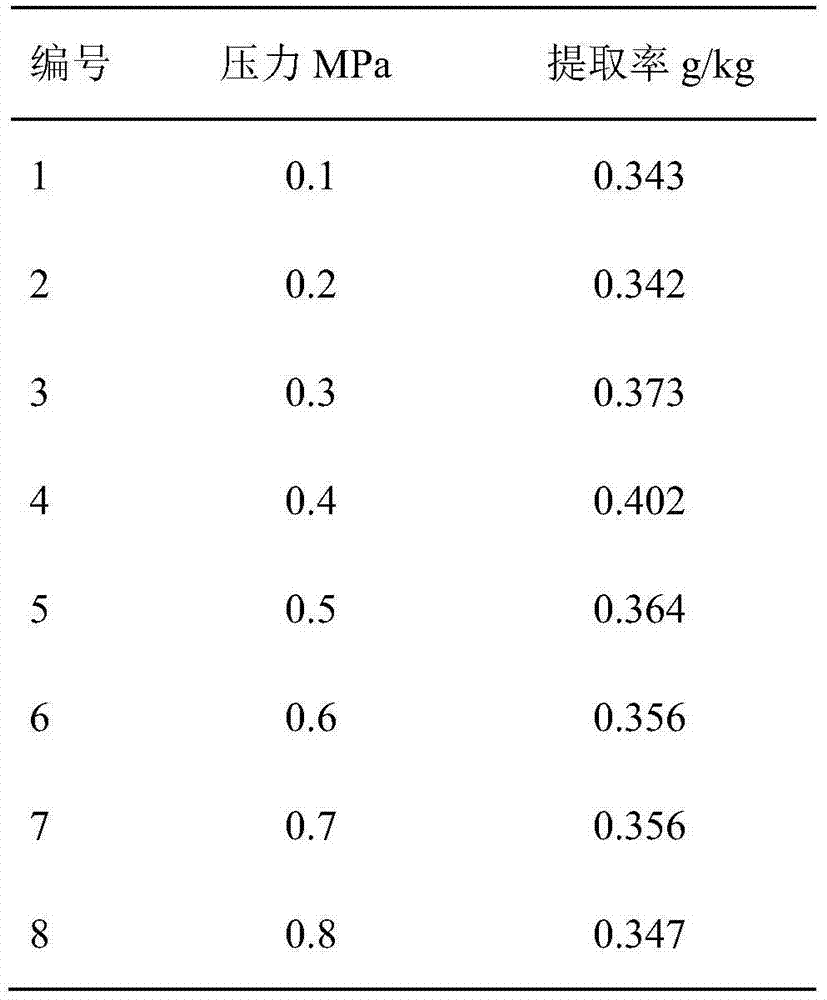

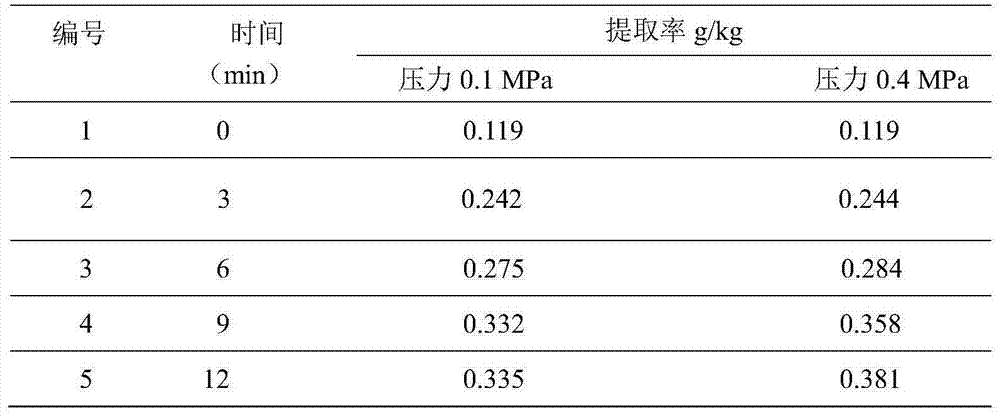

Method for extracting apple polyphenol by ethyl alcohol solvent with assistance of pressure ultrasound

InactiveCN104256635AHigh yieldReduce extraction costsCosmetic preparationsToilet preparationsUltrasound deviceAlcohol

The invention discloses a method for extracting apple polyphenol by ethyl alcohol solvent with the assistance of pressure ultrasound. The method comprises the following steps: (a) selecting crushed and juiced apple residues as raw materials; (b) putting the apple residue into a pressure ultrasound device, adding 40%-80% ethyl alcohol solution in the pressure ultrasound device, wherein the weight ratio of the apple residue to the ethyl alcohol solution is 1 to (15-30), and the pH value is adjusted to be between 3.0 and 4.5; carrying out pressurization ultrasound treatment, wherein the treatment conditions are that the pressure range is 0.20-0.50MPa, the ultrasound frequency is 20KHz, the ultrasound power is 150W-250W, the total ultrasound treatment time is 9-20 minutes, and the working temperature is 55 DEG C-85 DEG C. After the selected ultrasound time is reached, a feed liquid is taken out, and is centrifuged, and then the solvent is recycled, and dried, thereby obtaining a crude apple polyphenol product.

Owner:SHANDONG NORMAL UNIV

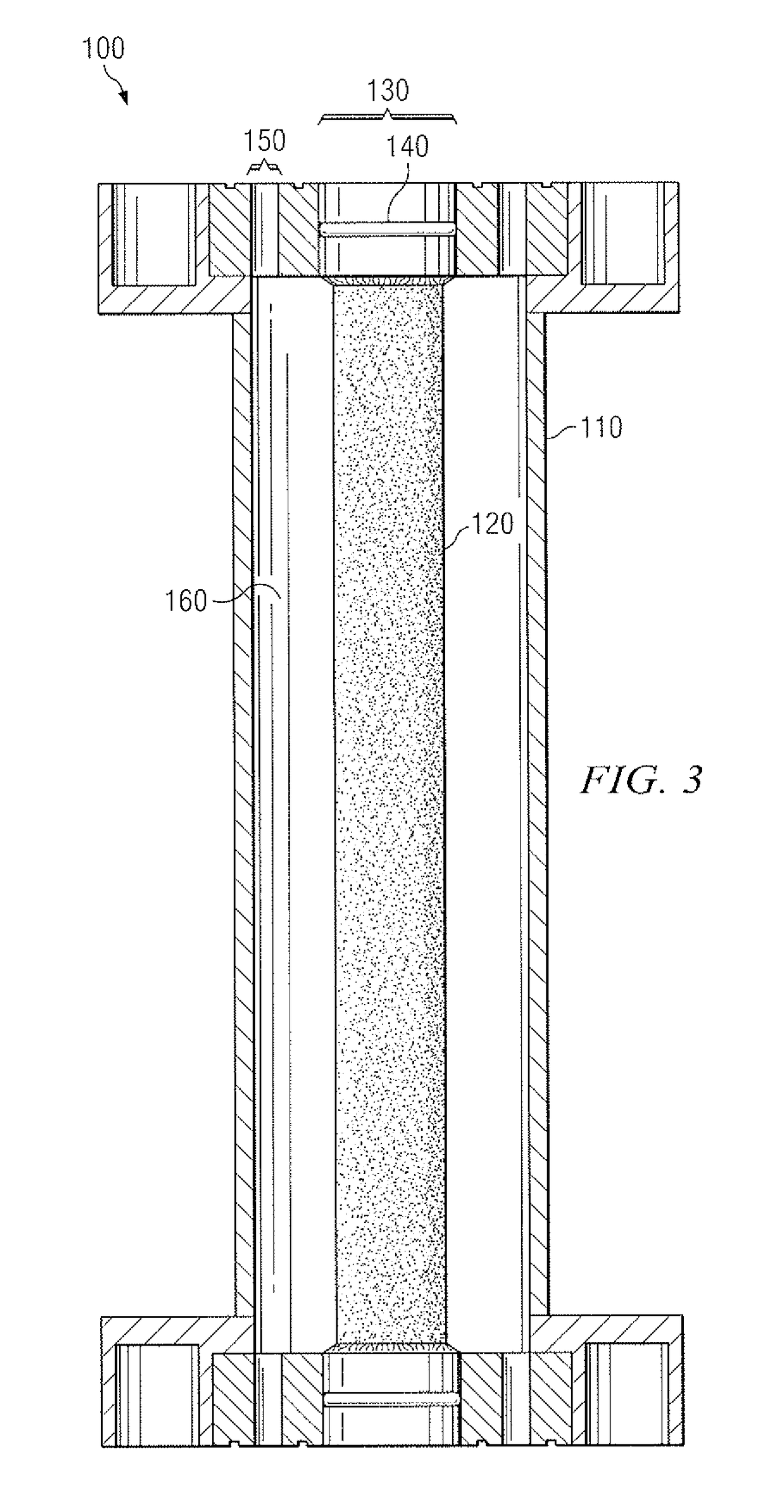

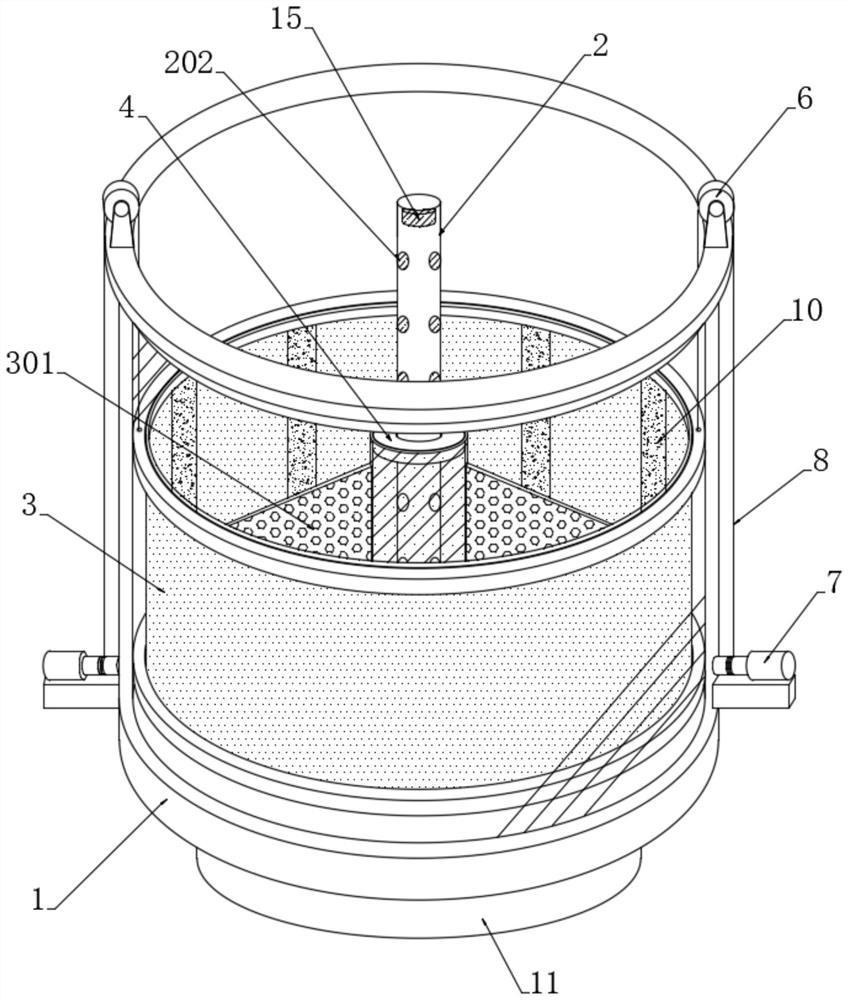

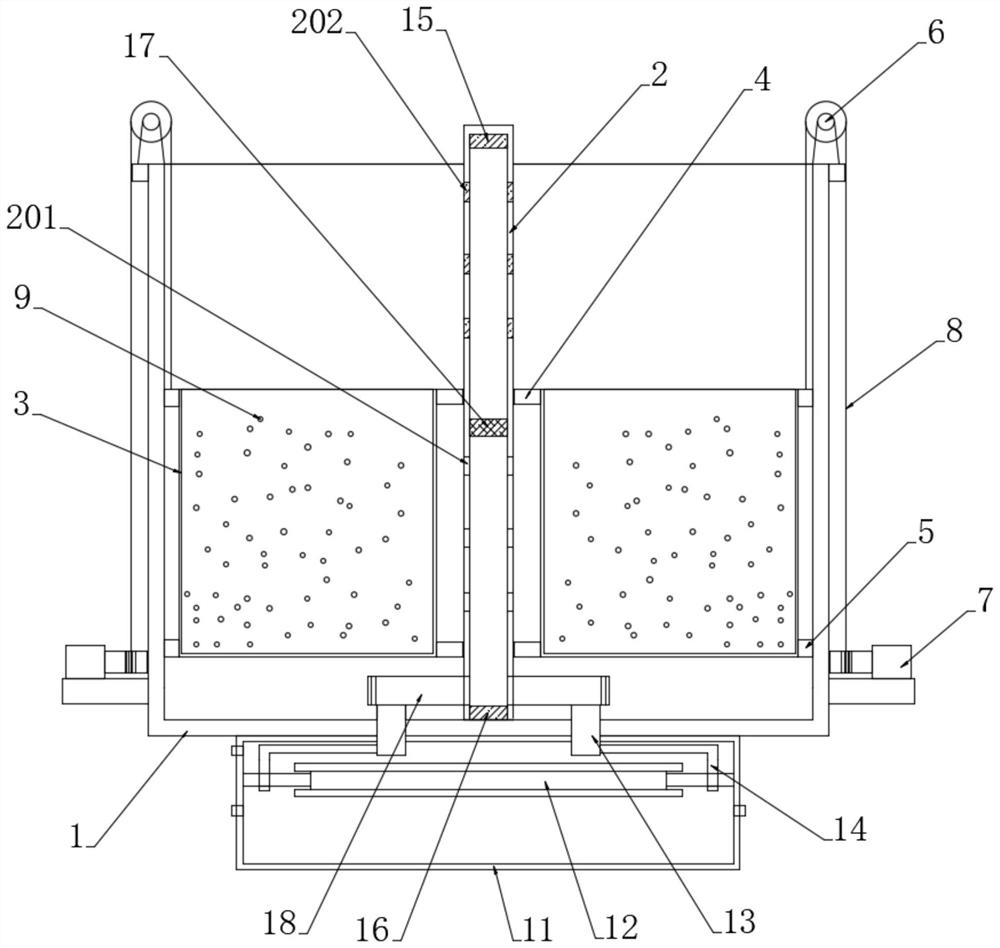

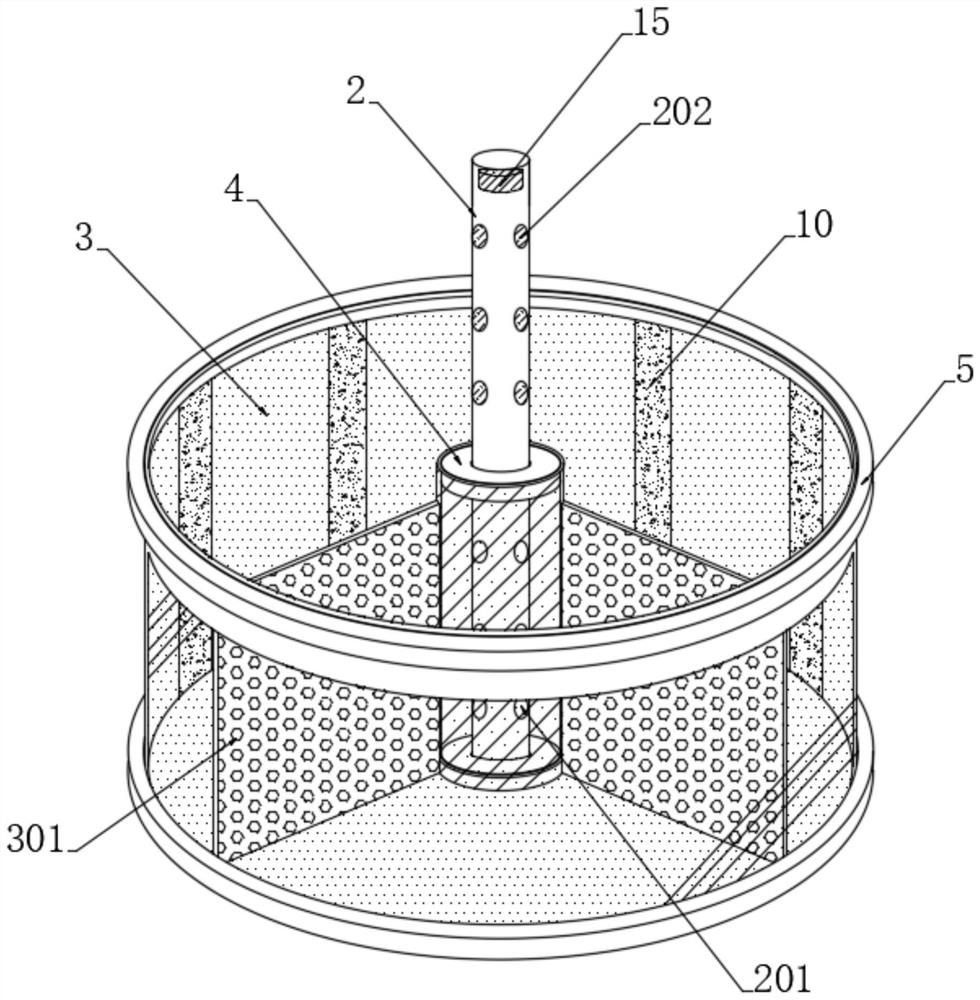

Molecular separator

ActiveUS8012355B2Easy to useEnhanced cavitationVolume/mass flow measurementUltrafiltrationCavitationFilter media

The present invention discloses a method and apparatus for separating particles and dissolved matter from an untreated fluid stream. Specifically, the present invention includes a first pressure source which transports untreated fluid or contaminated aqueous fluid into a separator annulus with a filter element disposed therein. The untreated fluid is placed under appropriate pressure sufficient to produce turbulent flow, increased particle kinetics and / or cavitation allowing the desired fluid to penetrate and pass into and through the filter media. The treated fluid is then transported to a collection tank. The contaminant matter retained by the filter media may be removed by the nearly instantaneous reverse pressurization of the separator annulus by a second pressure source thereby removing the contaminant particles away from contact with the filter media, and which may then be transported to a waste collection tank or a separator for further treatment.

Owner:TERVITA +1

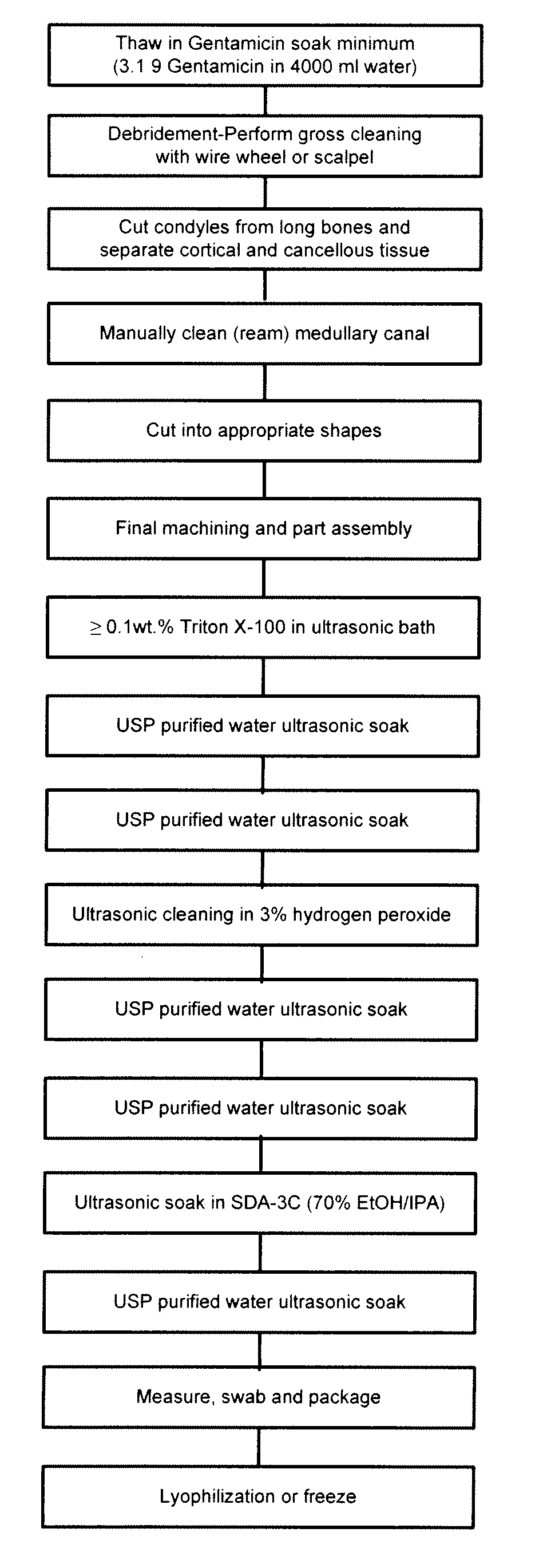

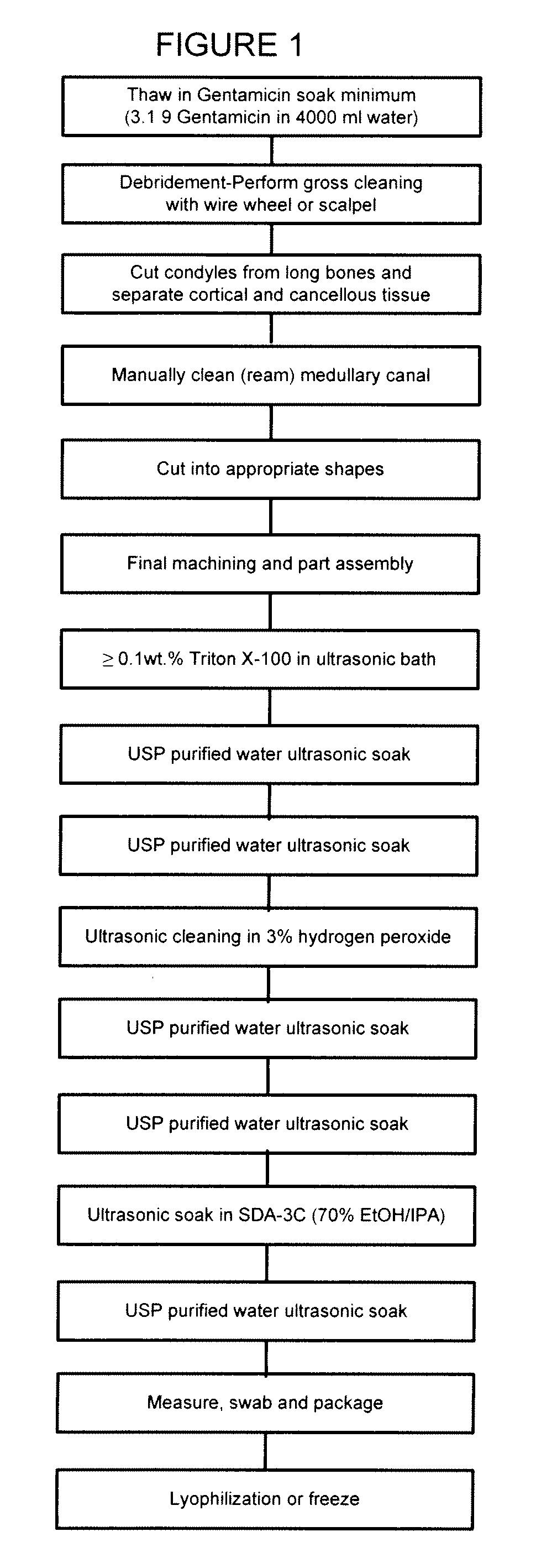

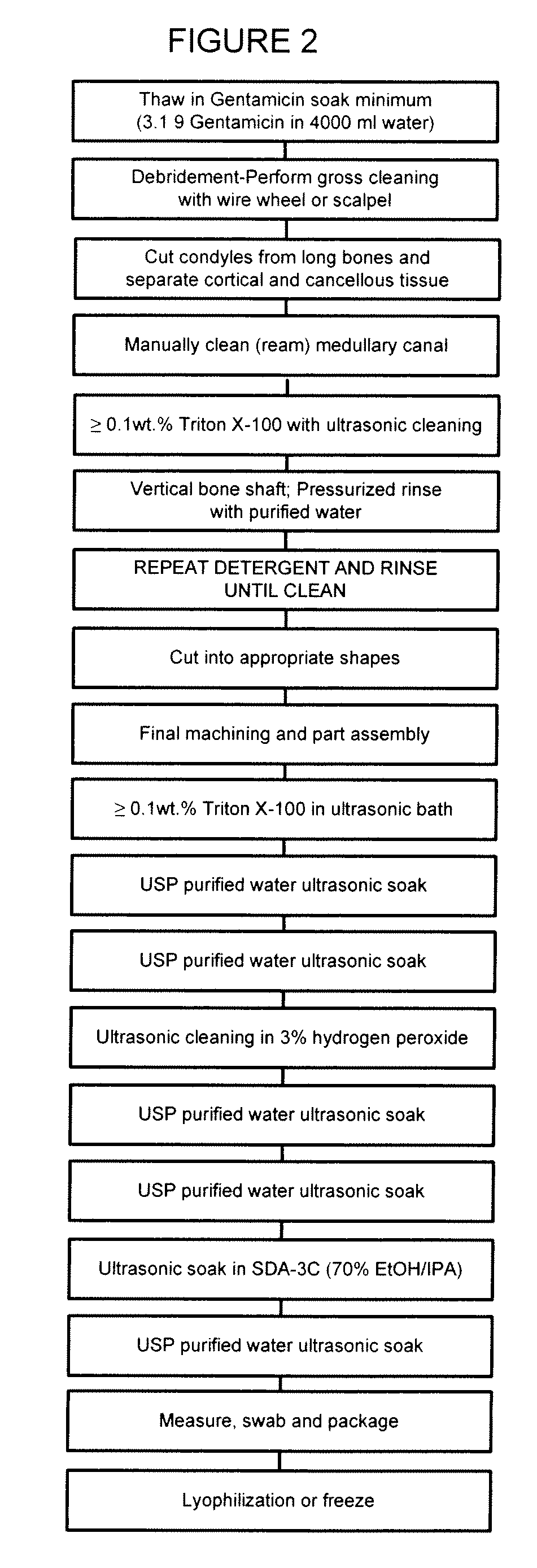

Allograft tissue purification process for cleaning bone

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

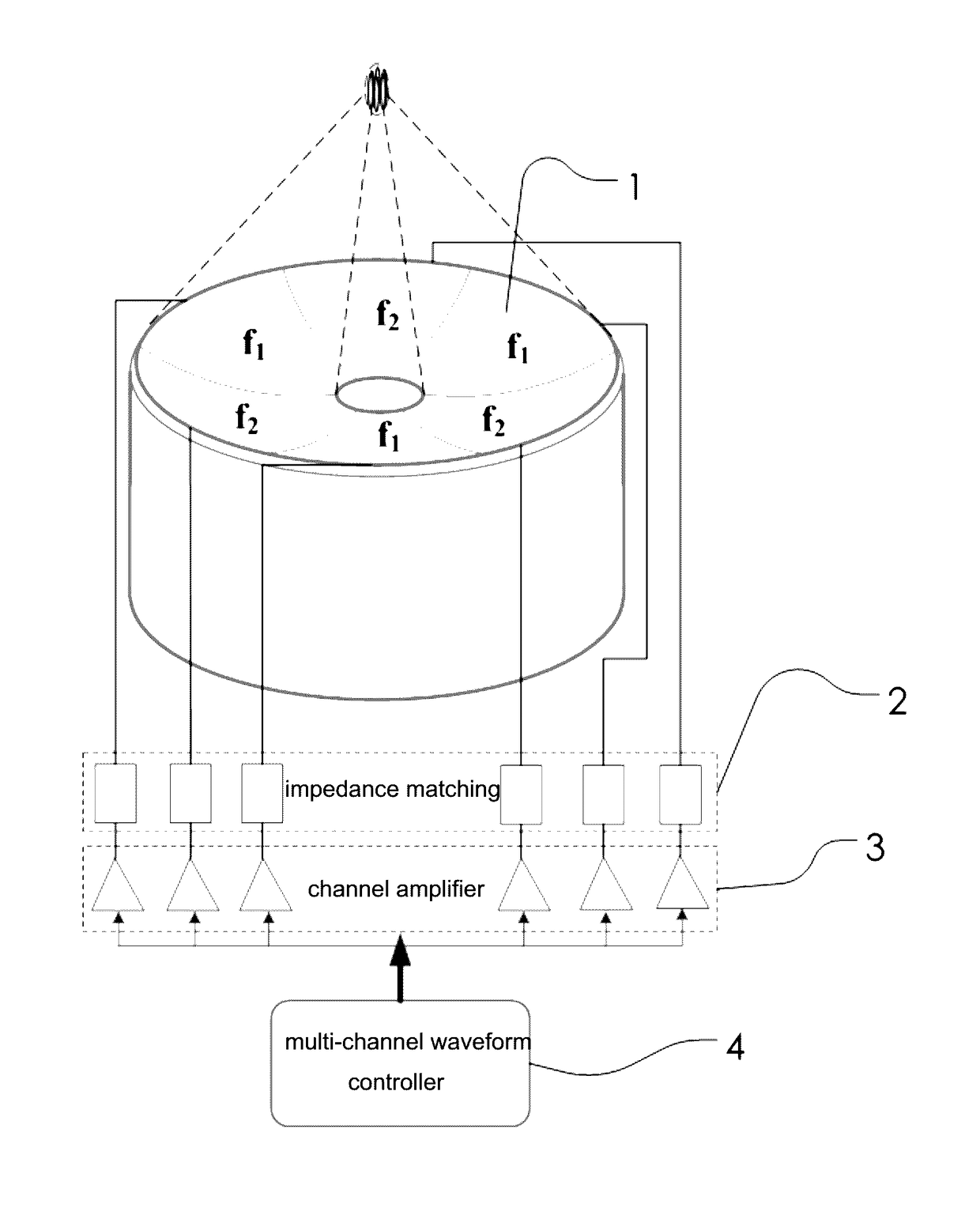

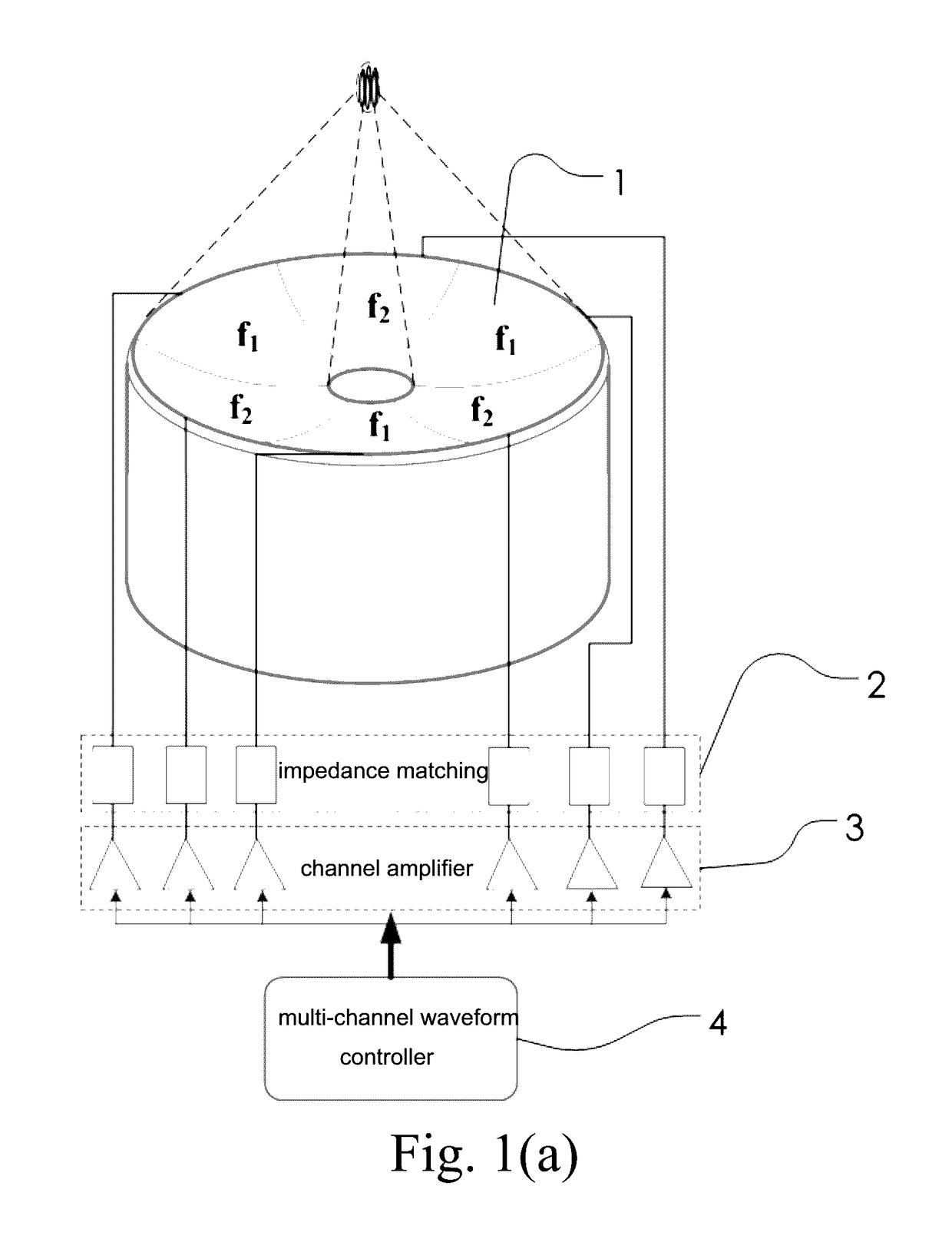

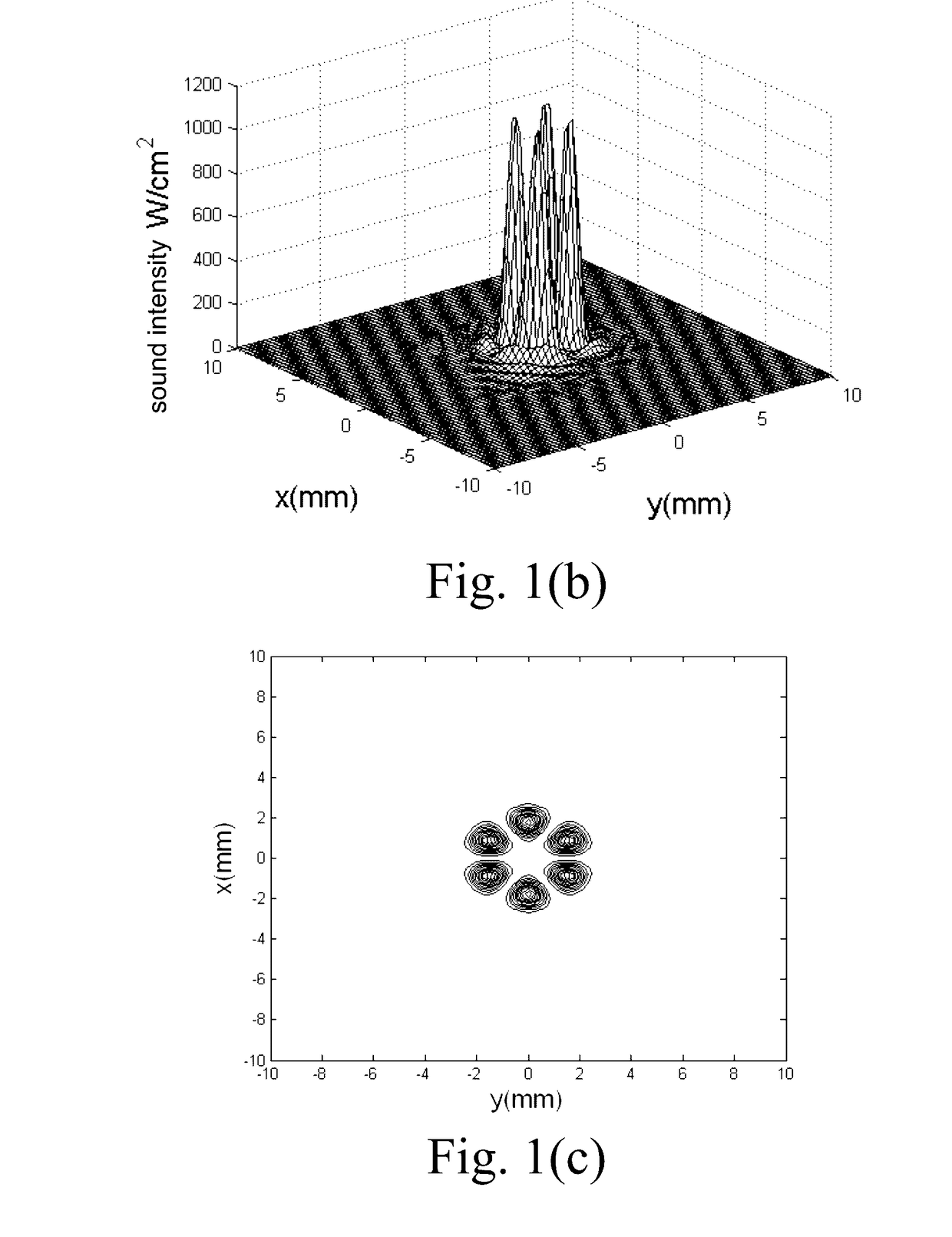

Focused ultrasound split-foci control using spherical-confocal-split array with dual frequency of fundamental and harmonic superimposition

ActiveUS20170080259A1Sufficient cavitation-transferred thermal efficiencyConducive to cavitation enhancementUltrasound therapySurgical instrument detailsCavitationSonification

A spherical-confocal-split array with dual frequency of fundamental and harmonic superimposition includes: array elements which are spherically confocal, whose quantity is an even number, wherein a half of the array elements operate with a lower frequency, and the other half of the array elements operate with a higher frequency; both the lower frequency and the higher frequency are MHz high-frequencies; each of the array elements corresponds to a frequency drive; array element beams don't superimpose outside the focal region; each of the array elements is connected to a channel amplifier (3) through corresponding impedance matching (2); and a multi-channel waveform controller (4) is connected to the channel amplifier (3) for controlling amplitudes and phases of all channels. The dual-frequency spherical sectorial split array is able to generate split multi-foci of the focal plane with the dual frequencies; and control strong interference of transient cavitation clouds at the adjacent foci.

Owner:XI AN JIAOTONG UNIV

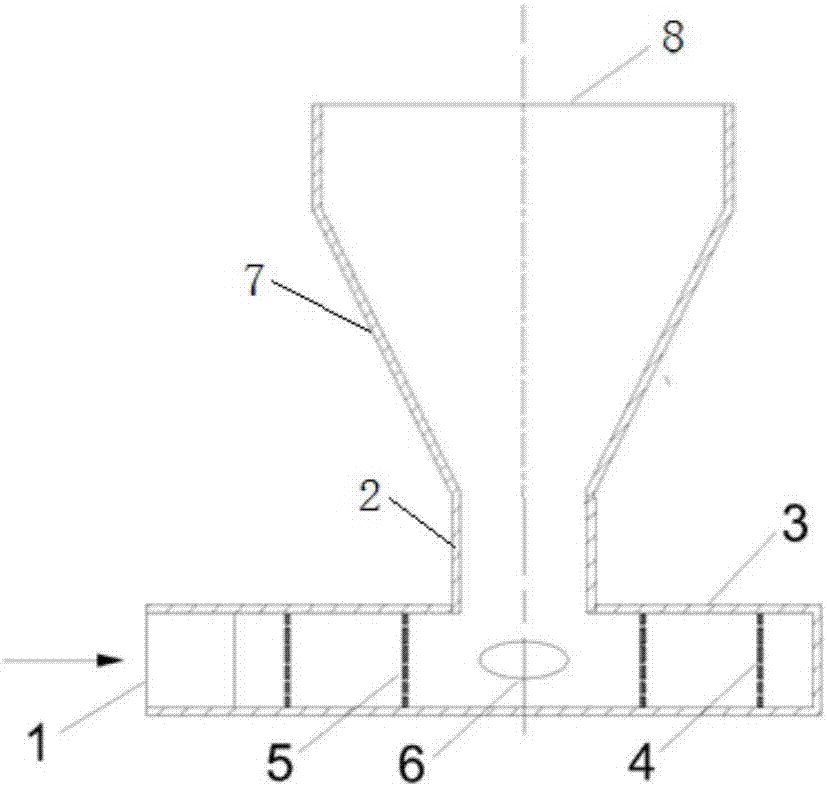

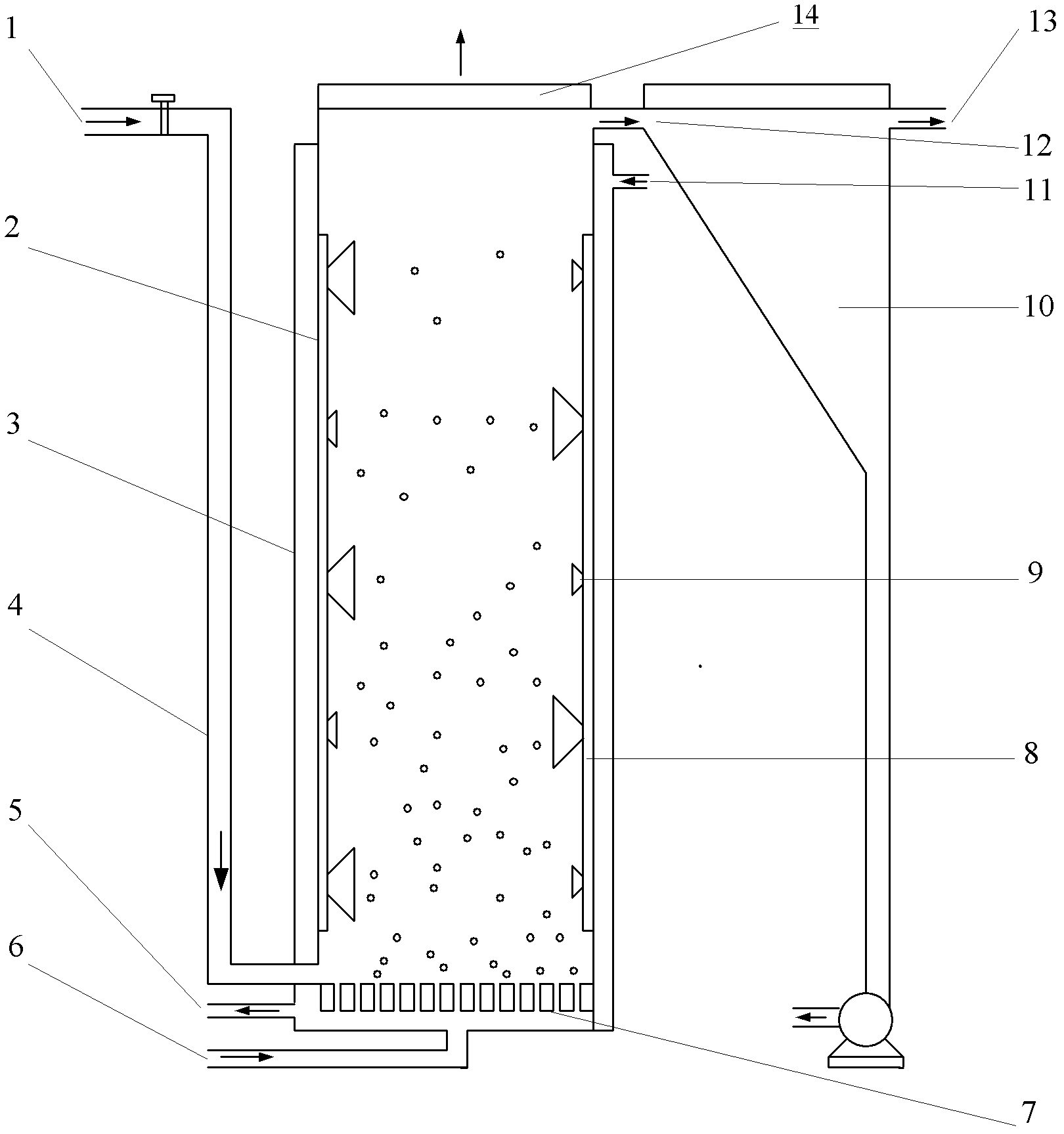

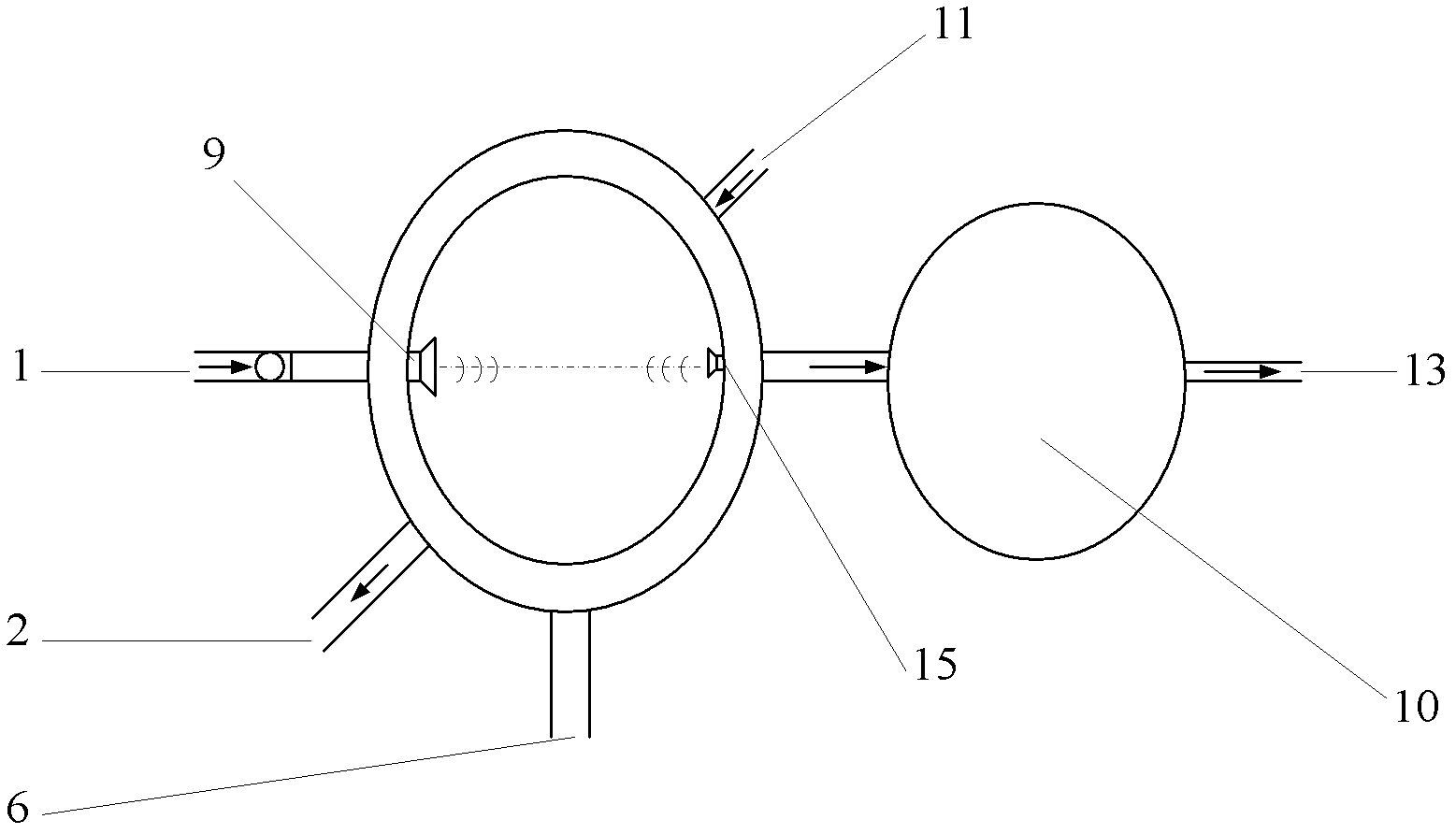

Airlift sonochemical reactor

InactiveCN102557231AAvoid Ultrasound Transmission LossUniform radiationWater/sewage treatment with mechanical oscillationsWater/sewage treatment by oxidationCavitationDistributor

The invention discloses an airlift sonochemical reactor, which is characterized in that: a vertical reacting cylinder is arranged; an ozone distributor with a gas outlet being upwards is arranged on the bottom of the reacting cylinder, a water outlet of a waste liquid tubing guide is close to the upper of the distributor, and keeps flow direction of water outlet being symmetrical with flow direction of ozone; energy transducers are arranged on the internal side wall of the reacting cylinder in an array manner, and a low frequency energy transducer and a high frequency energy transducer in a same horizontal plane are oppositely arranged on a same diameter line to form a energy transducer pair; and the number of the energy transducer pairs on a same horizontal plane is odd number, and the energy transducers uniformly distributed on a same circumference are arranged in an interval arrange manner of a low frequency energy transducer and a high frequency energy transducer. The airlift sonochemical reactor of the invention can high-efficiency utilize the synergism of ultrasonic wave and ozone, promotes acoustic cavitation effect, and can be used for treating industrial wastewater which is difficult to degrade.

Owner:HEFEI UNIV OF TECH

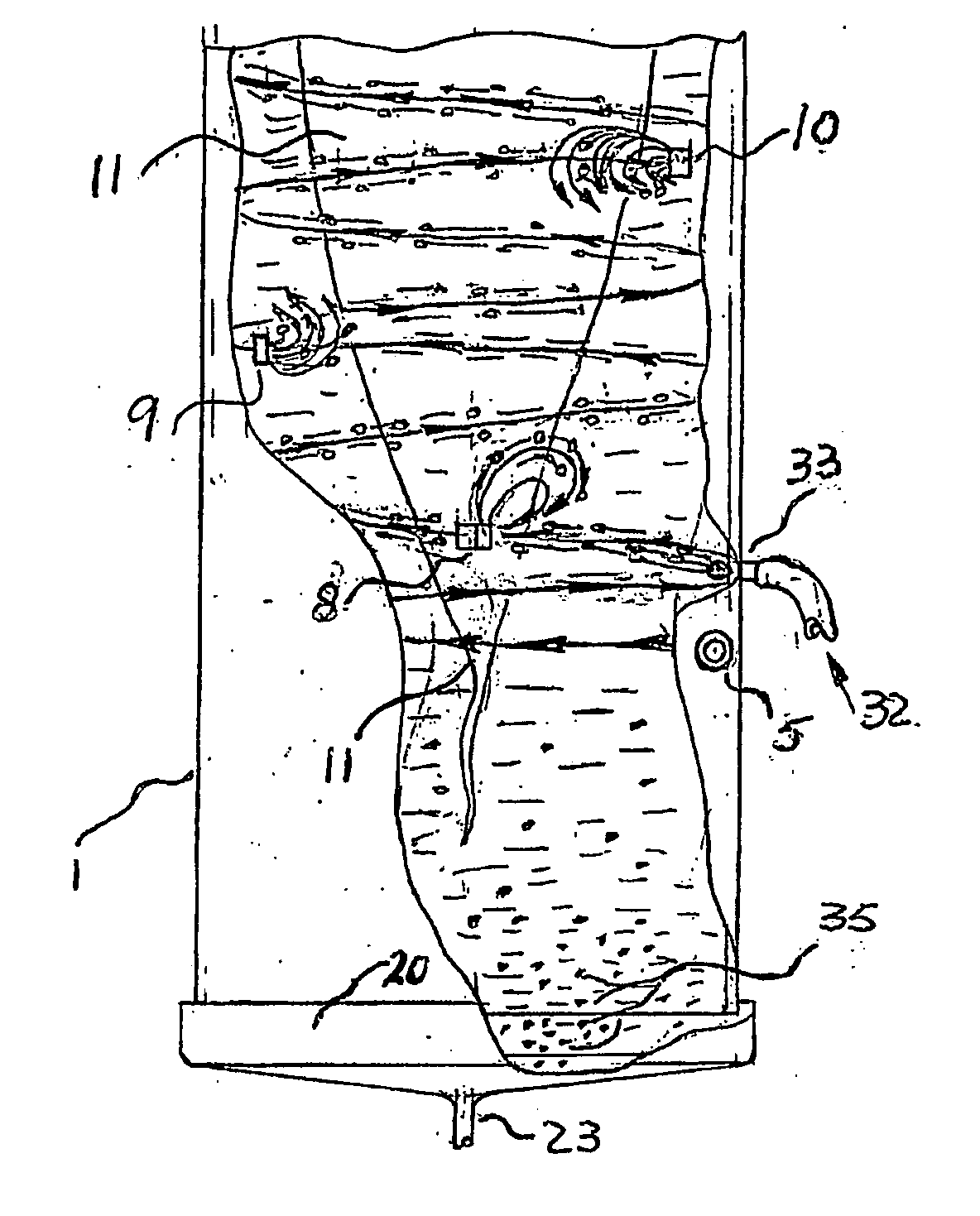

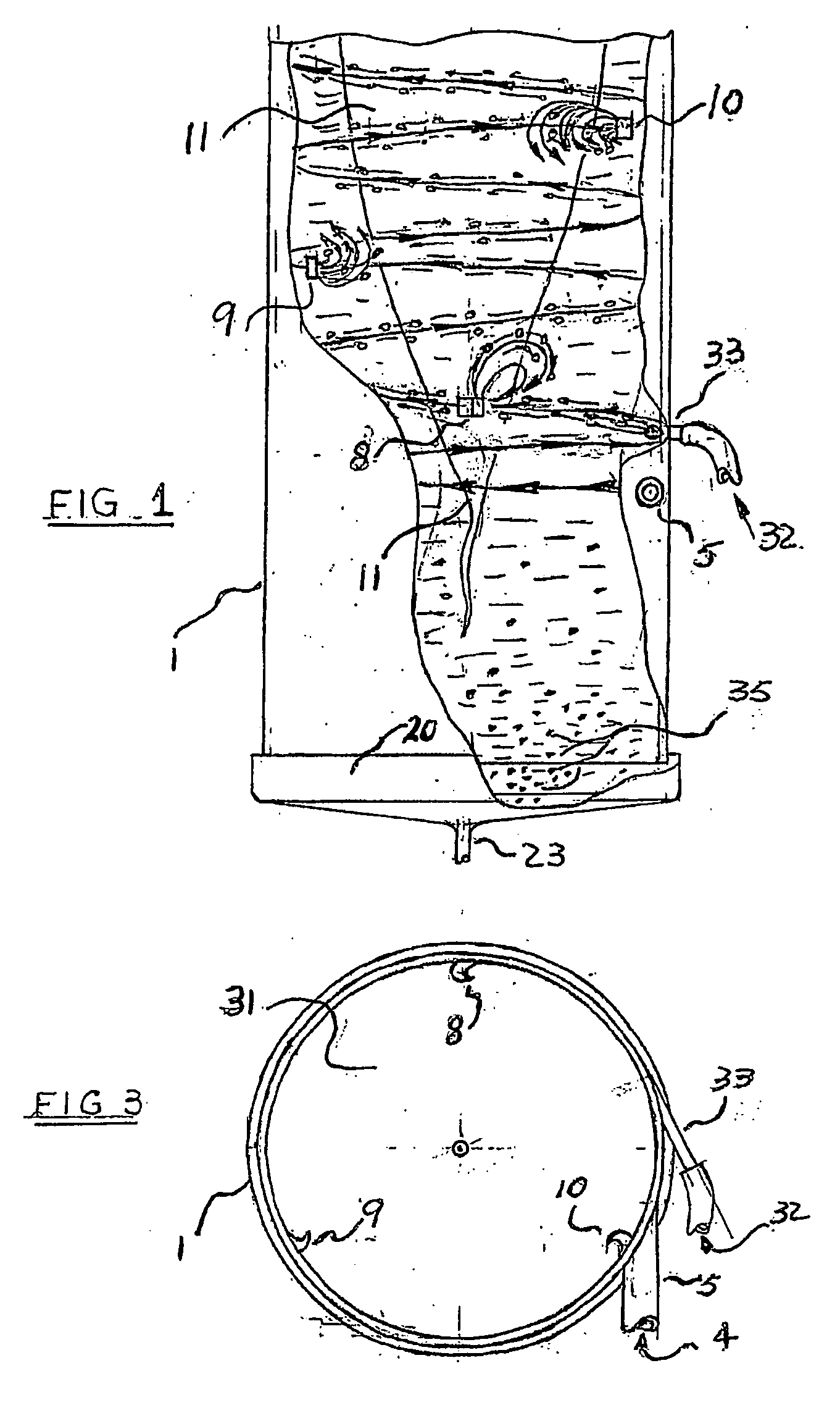

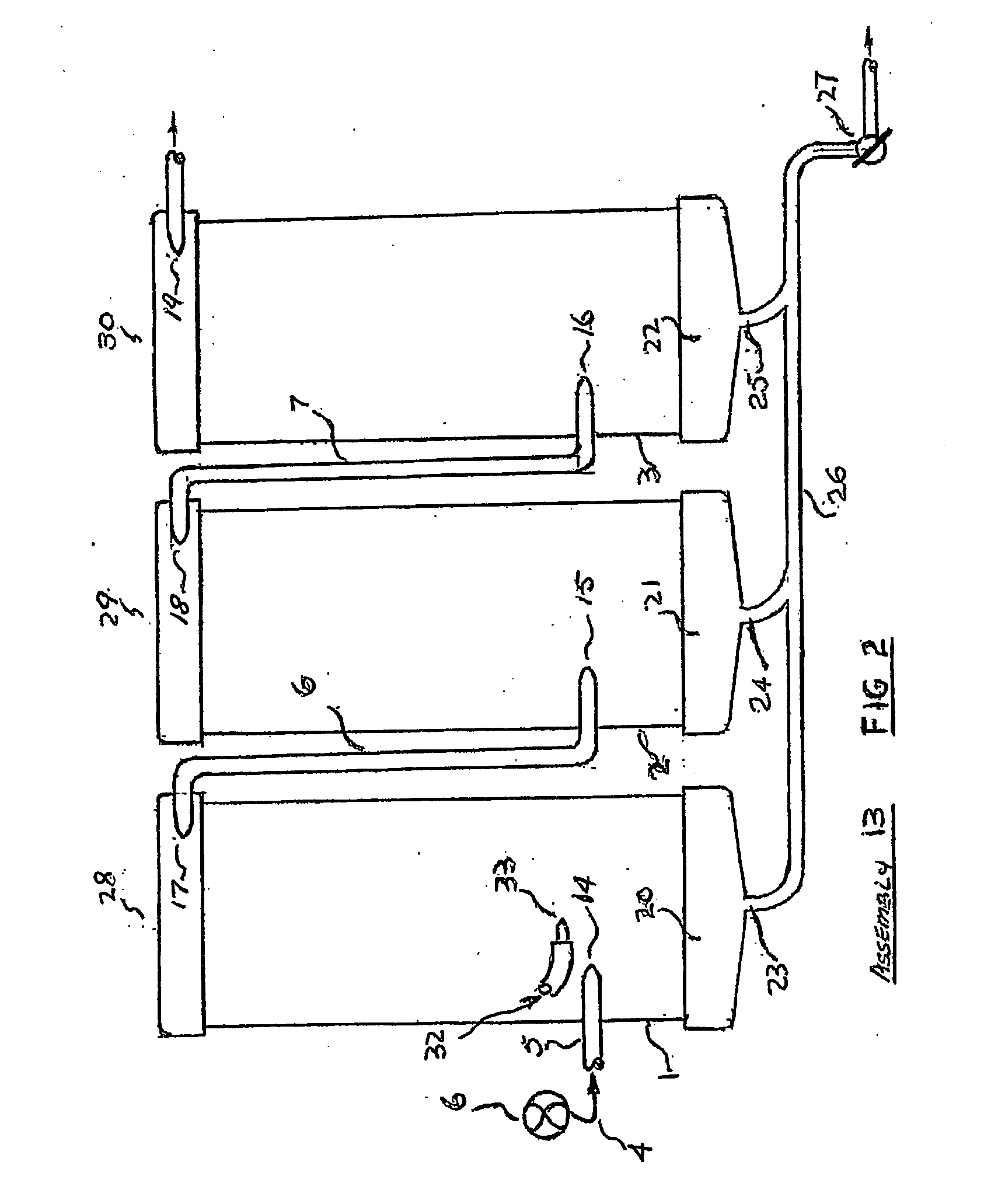

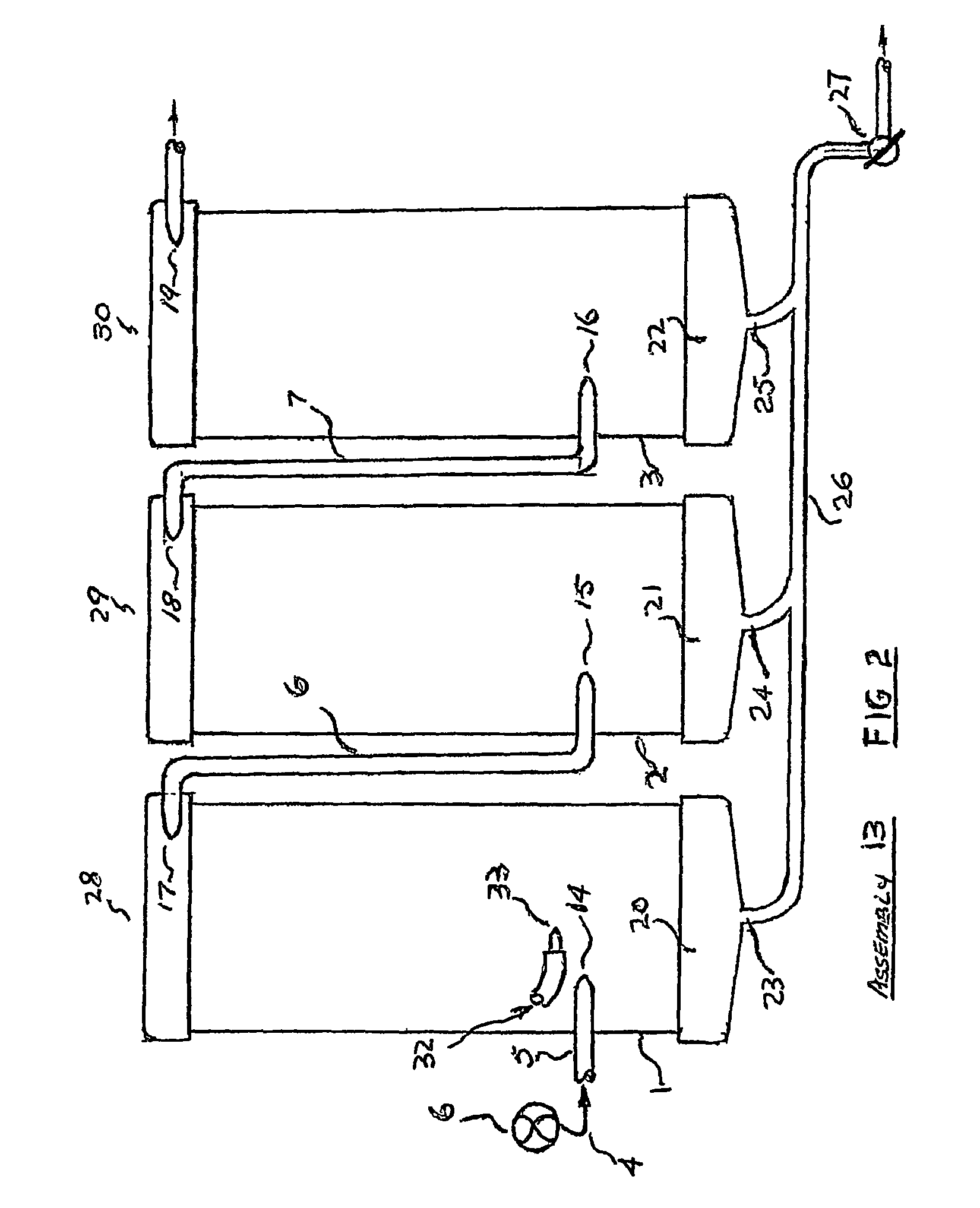

Fluid purification using hydraulic vortex system

InactiveUS20100237008A1Excellent decontaminationEnhanced cavitationWater/sewage treatment by centrifugal separationReversed direction vortexEngineeringFluid supply

An assembly for water purification comprising a series of vessels which allows fluid to communicate therebetween via fluid supply lines. The assembly is arranged so as to generate a plurality of co operating vortices generated by fluid impact on formations disposed on an inner surface of the vessels to cause an ascending fluid flow to be deflected back in the direction of fluid flow thereby creating local vortices. Water exiting said vessels has higher purity than water entering the vessel.

Owner:GONINAN BRIEN EDWARD

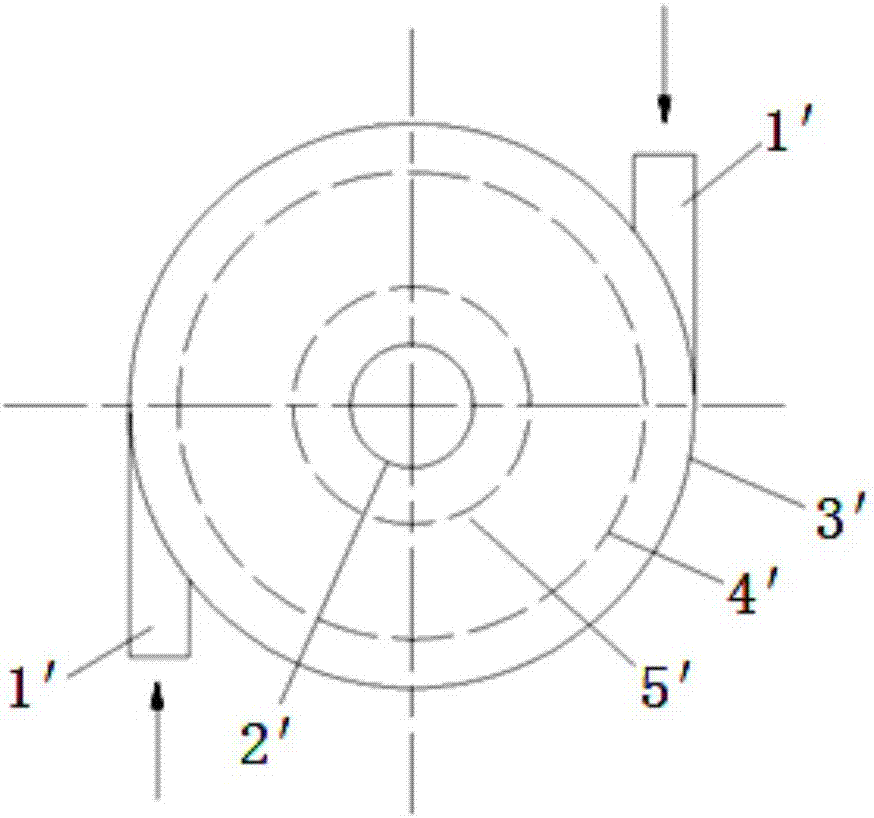

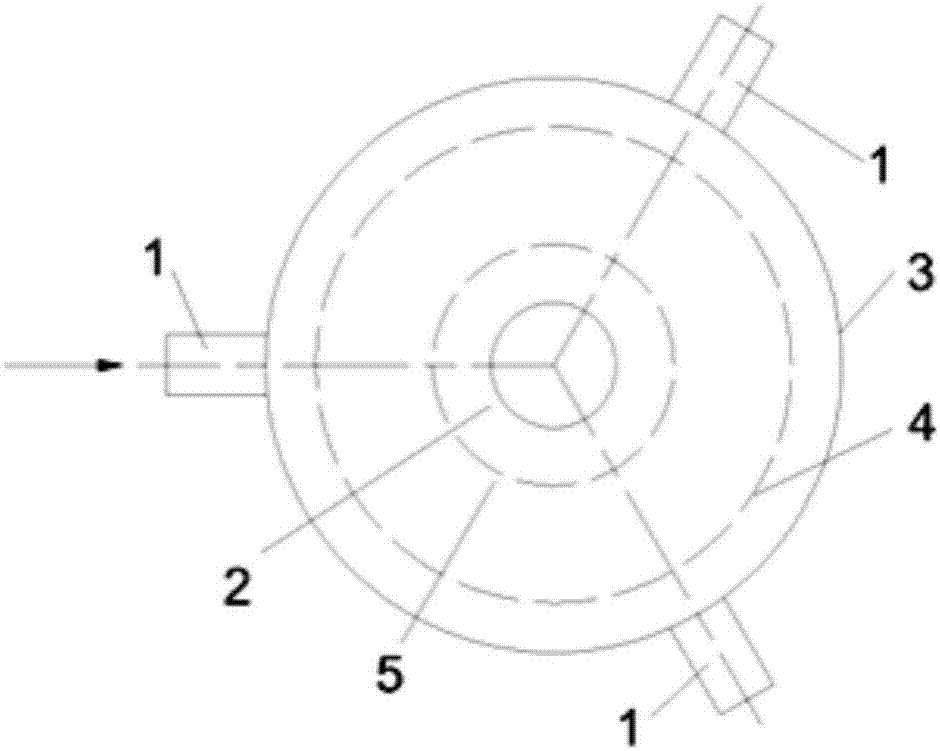

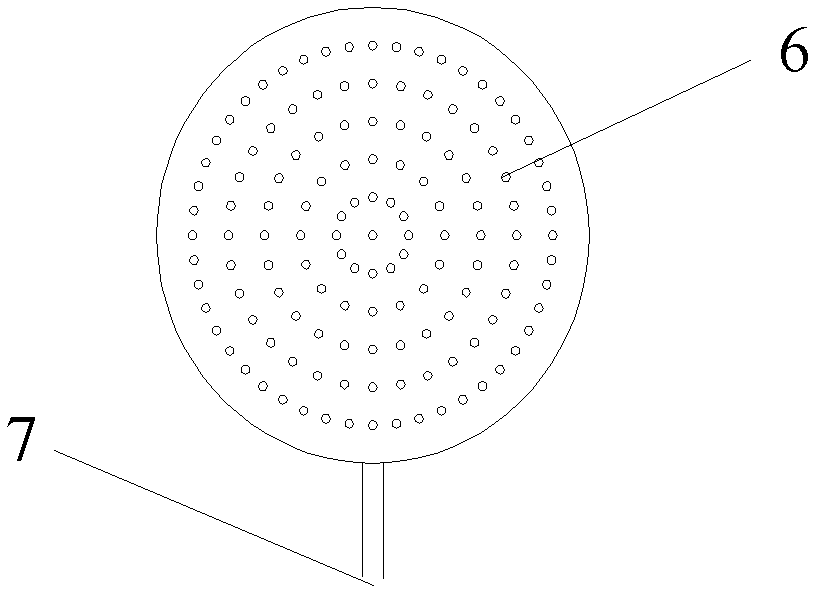

Multi-resonance-cavity cavitating jet nozzle

ActiveCN107051761AEnhanced cavitationHigh cavitation efficiencySpray nozzlesSpray nozzleMultiple stages

The invention discloses a multi-resonance-cavity cavitating jet nozzle which comprises a left end body, a right end body and at least one middle body, wherein the tail end of the left end body is in threaded connection with the first middle body, and the right end body is in threaded connection with the last middle body, thus forming at least three resonance cavities with identical structures; inlets and outlets of the resonance cavities are connected with different stages of necking openings; the tail resonance cavity and a spraying opening are formed in the right end body; the axial lines of the multiple resonance cavities, the different stages of necking openings and the spraying opening are overlapped with the axial line of the nozzle; and a first sine flow guide curved surface and a second sine flow guide curved surface are arranged at the front part of the left end body, so that liquid can quickly and stably enter the nozzle, is severely cavitated through the multiple stages of necking openings and the multiple resonance cavities, and is finally sprayed out from the spraying opening. Compared with the prior art, the multi-resonance-cavity cavitating jet nozzle disclosed by the invention can conform to influx of high-flow high-flowing speed liquid; and the sine flow guide curved surfaces, the multiple resonance cavities and the multiple stages of necking openings enhance the cavitating effect on the liquid and improves the cavitating efficiency.

Owner:YANSHAN UNIV

Fluid purification using hydraulic vortex system

InactiveUS8622225B2Excellent decontaminationEnhanced cavitationWater/sewage treatment by centrifugal separationReversed direction vortexEngineeringFluid supply

An assembly for water purification comprising a series of vessels which allows fluid to communicate therebetween via fluid supply lines. The assembly is arranged so as to generate a plurality of co operating vortices generated by fluid impact on formations disposed on an inner surface of the vessels to cause an ascending fluid flow to be deflected back in the direction of fluid flow thereby creating local vortices. Water exiting said vessels has higher purity than water entering the vessel.

Owner:GONINAN BRIEN EDWARD

Metal surface porcelainizing method

InactiveCN102051608AImprove corrosion resistanceEnhanced cavitationMetallic material coating processesCavitationMetal

The invention relates to a metal surface porcelainizing method which comprises the following steps: sequentially adding 40-60% of mineral oil, 35-50% of nano additive and 5-10% of stabilizer, and mixing to obtain an oil-base nano porcelain medium; and carrying out metal surface porcelainizing on a workpiece to be subjected to metal surface porcelainizing by using the oil-base nano porcelain medium. A dynamic protective film can be formed on the metal surface treated by using the method, and has favorable functions of resisting corrosion, cavitation corrosion and abrasion. The method provided by the invention can be used for porcelainizing the surface of a part in a complex structure.

Owner:KUNMING UNIV OF SCI & TECH

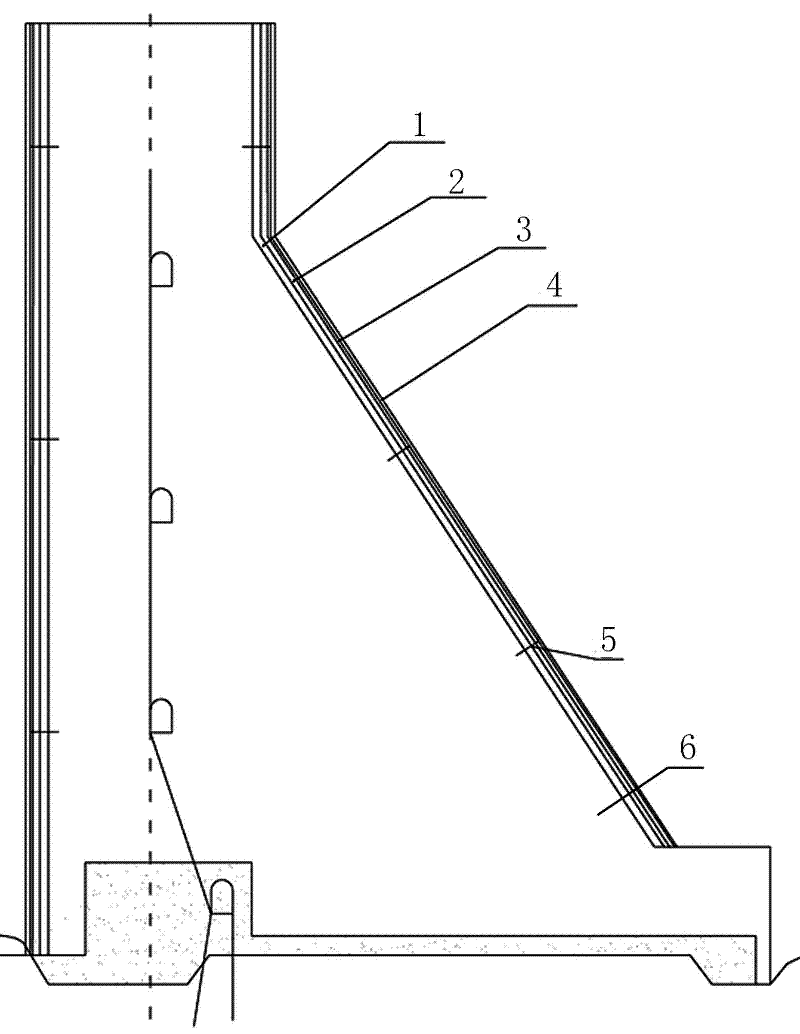

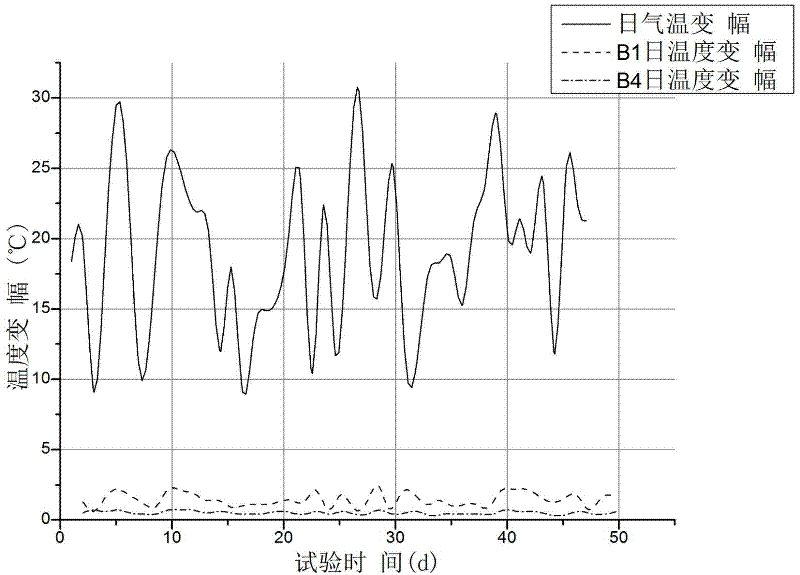

Dam concrete anti-ageing method

ActiveCN102505664AImprove freeze-thaw resistanceSpeed up leakageMarine site engineeringCrack resistanceCavitation

Disclosed is a dam concrete anti-ageing method. A polyurethane foam layer is coated on the surface of a concrete dam, after a dam heat-insulation and moisturizing layer is obtained, a polymer mortar layer is further covered on the concrete dam, and a dam heat-insulation moisturizing layer protecting layer is obtained; a layer of alkali-resistant fiberglass gridding cloth or an iron wire screen which is fixed by heat-insulation anchor bolts is laid outside the dam heat-insulation moisturizing layer protecting layer, another polymer mortar layer is covered on the alkali-resistant fiberglass gridding cloth or the iron wire screen, so that a protecting surface layer is obtained, and anti-ageing construction of a dam body is completed. In the technical scheme, the dam body is constructed, abilities including freezing and thawing resistance, leakage resistance, carbonized flow scouring resistance, abrasion resistance, cavitation resistance, durability, pressure resistance, crack resistance and impermeability of the dam body can be strengthened by the obtained protecting layer, and the protecting layer has the advantages that the protecting layer is attractive in appearance and fine in heat insulation and moisturizing performances, and does not pollute environments. The heat insulation and moisturizing performances are stable, and cannot be changed greatly along with weather change, and concrete cracks and concrete ageing due to change of weather conditions can be effectively controlled.

Owner:宜昌天宇科技有限公司

Polishing equipment for stainless steel products

ActiveCN111774942AEfficient removalImprove pickling and polishing effectEdge grinding machinesPolishing machinesPickling AgentsSS - Stainless steel

The invention discloses polishing equipment for stainless steel products, and belongs to the technical field of stainless steel production and processing. Through intermittent opening and closing cooperation of an upper electromagnet and a lower electromagnet, up-and-down lifting motion of a magnetofluid inside a jet-flow vertical pipe is achieved, therefore, a pickling agent is guided into the jet-flow vertical pipe, the extracted pickling agent is jetted into an annular polishing cavity through a lower jet-flow opening, fluid motion of the pickling agent is intensified, in addition, the multiple magnetic polishing particles are driven to do non-specification motion, the polishing equipment is simultaneously matched with intermittent opening and closing of a magnetic attraction plate, andthe motion of the magnetic polishing particles is intensified. Heat generated by the heating end of a semiconductor chilling plate is guided into the jet-flow vertical pipe and then diffuses into theannular polishing cavity along with the pickling solution, the pickling and polishing effect of the stainless steel products is effectively improved, oxide skin and the like at the gullies of the stainless steel products are effectively removed, and after polishing is completed and a polishing box is lifted upwards, the stainless steel products in a polishing box is dried through hot air flow andcold air flow.

Owner:揭阳市永乐五金电器厂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com