Multi-resonance-cavity cavitating jet nozzle

A jet nozzle and multi-resonance technology, applied in the direction of injection devices, injection devices, etc., can solve the problems of low cavitation efficiency, small flow rate, and difficulty in forming cavitation effects, and achieve the effect of improving cavitation efficiency and enhancing cavitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

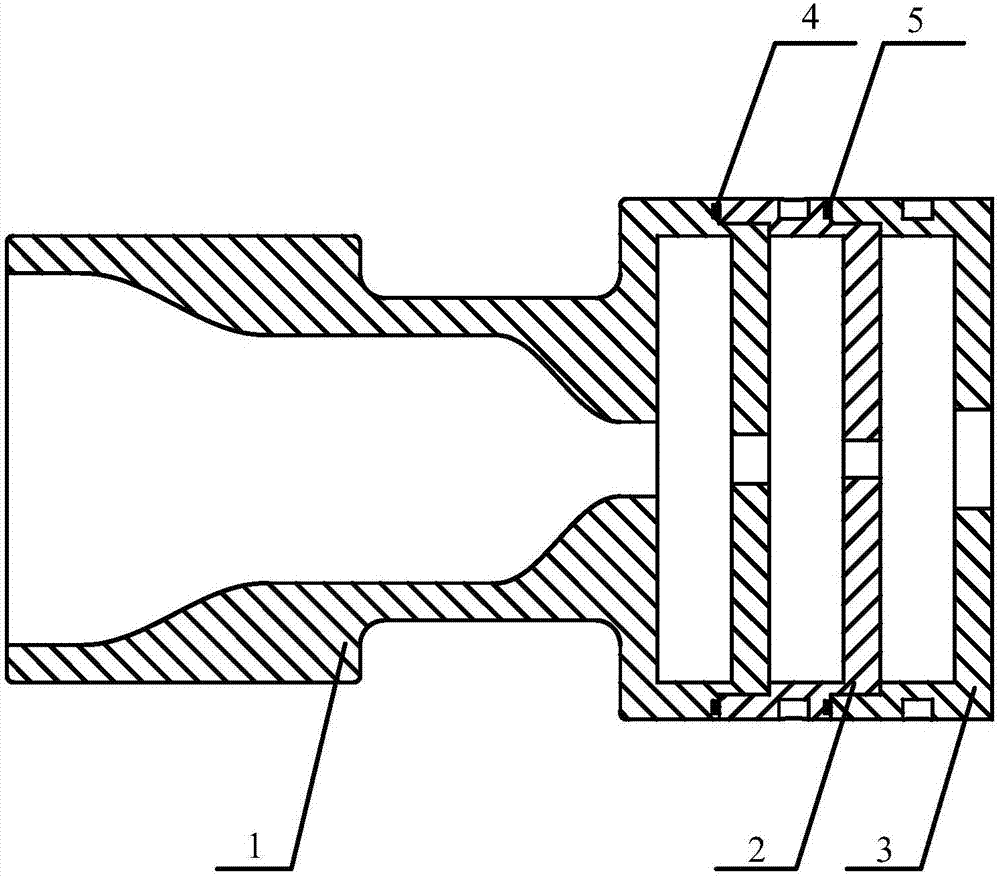

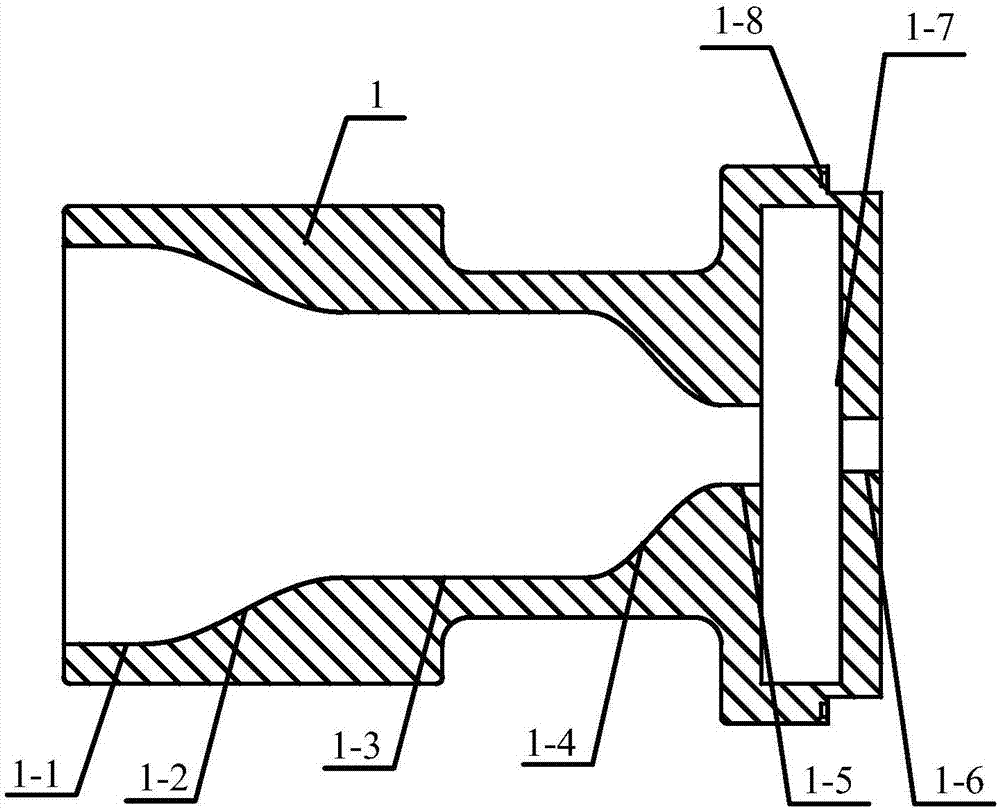

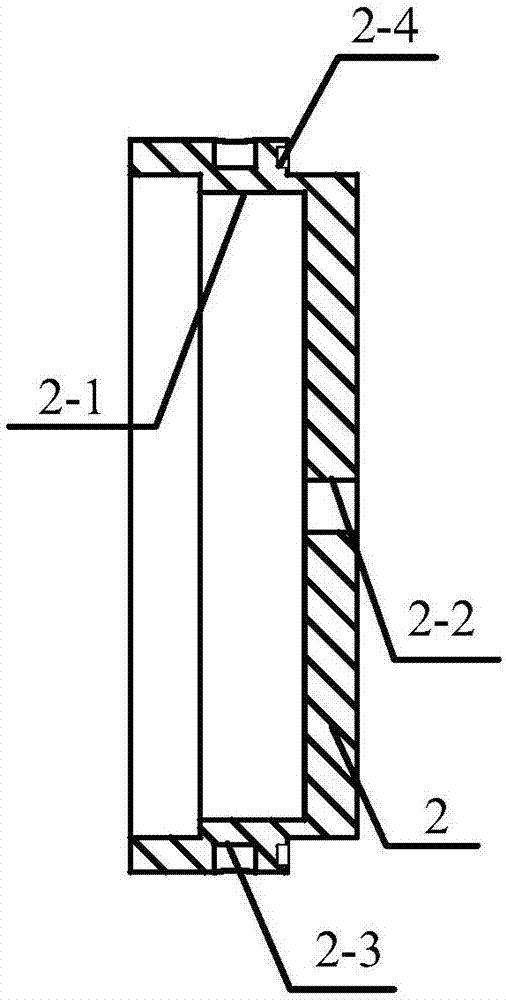

[0012] Such as Figure 1~5 As shown, the multi-resonant cavity type cavitation jet nozzle of the embodiment of the present invention includes a left end body 1, a middle body 2 and a right end body 3, the end of the left end body 1 is screwed to the middle body 2 and the right end body 3 is screwed to the middle body 2 to form Three resonant cavities with the same structure. The first resonant cavity 1-7 is located at the end of the left end body 1, and the end of the left end body 1 is connected to the middle body 2 through threads, and four round holes 2-3 are evenly arranged on the outer surface of the middle body 2 so that the middle body 2 and the left end body 1 are threaded. The tightening of the left end body 1 and the middle body 2 is provided with a sealing ring 4, the sealing ring 4 is installed in the sealing groove 1-8, and then the second reson...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com