Dam concrete anti-ageing method

A concrete, anti-aging technology, applied in water conservancy projects, marine engineering, construction and other directions, can solve the problems of easy aging, discoloration, shedding, cracking and curling, etc., to achieve stable thermal insulation and moisturizing properties, enhanced freeze-thaw resistance, and beautiful appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Raw material preparation: polymer powder preparation: take rubber powder 10-20, cellulose ether 1, starch ether 1 in parts by weight, and mix to obtain polymer powder.

[0032] Preparation of polymer mortar: according to weight, take sand 0.5-0.6, cement 0.2-0.3, water 0.1-0.2, polymer powder 0.01-0.02, and polymer mortar is obtained after mixing, and the polymer mortar can be compressive The strength is 31Mpa, and the bending resistance is up to 6.0Mpa.

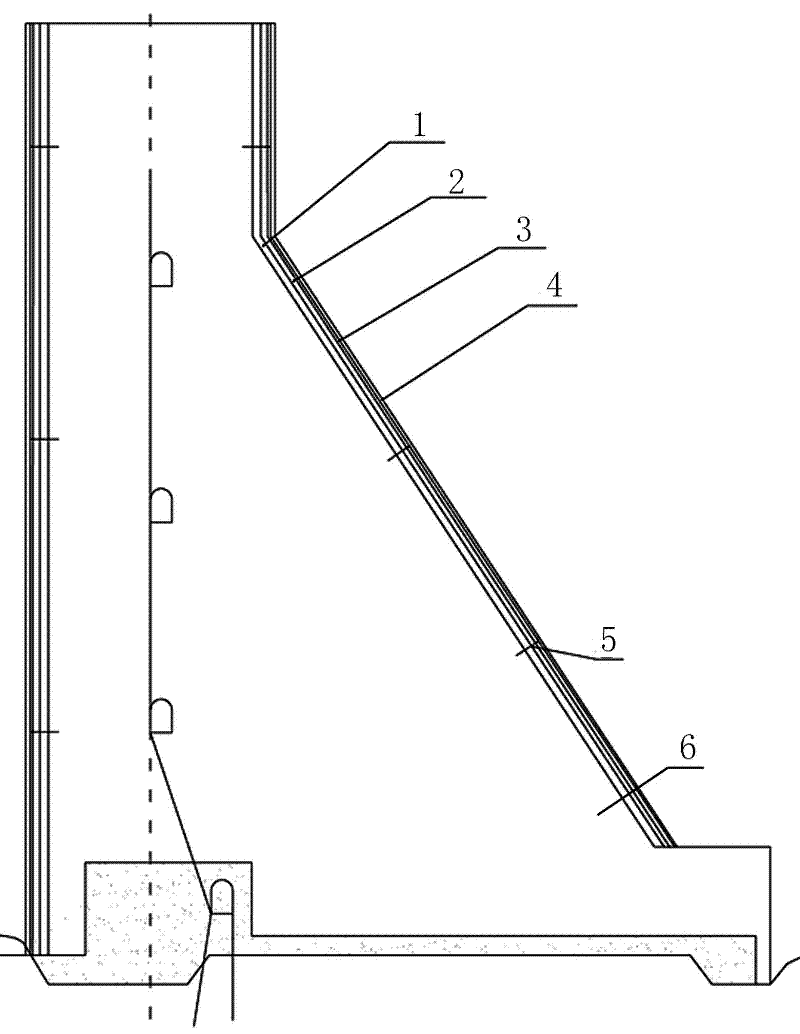

[0033] The concrete surface of the concrete dam 6 is covered with a layer of polyurethane foam. The polyurethane foam layer can be realized by spraying, pasting, and pouring. The thickness of the polyurethane foam layer is determined according to the climatic conditions of the dam location and the needs of dam concrete temperature control. The layer thickness should be in the range of 1cm~15cm. Form the dam insulation and moisture-retaining layer 1.

[0034] Polymer mortar is used to lay the surface of the dam insulation a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com