Venturi tube based high-flux hydraulic cavitation reactor and cavitation method

A Venturi, high-flux technology, applied in the direction of mechanical oscillation water/sewage treatment, etc., can solve the problem of insufficient triggering or strengthening of physical and chemical reactions, large pipeline structure of the treatment system, and the processing capacity of the cavitation reactor. Small problems, etc., to achieve the effect of improving energy utilization, low equipment manufacturing cost, and reducing turbulent non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

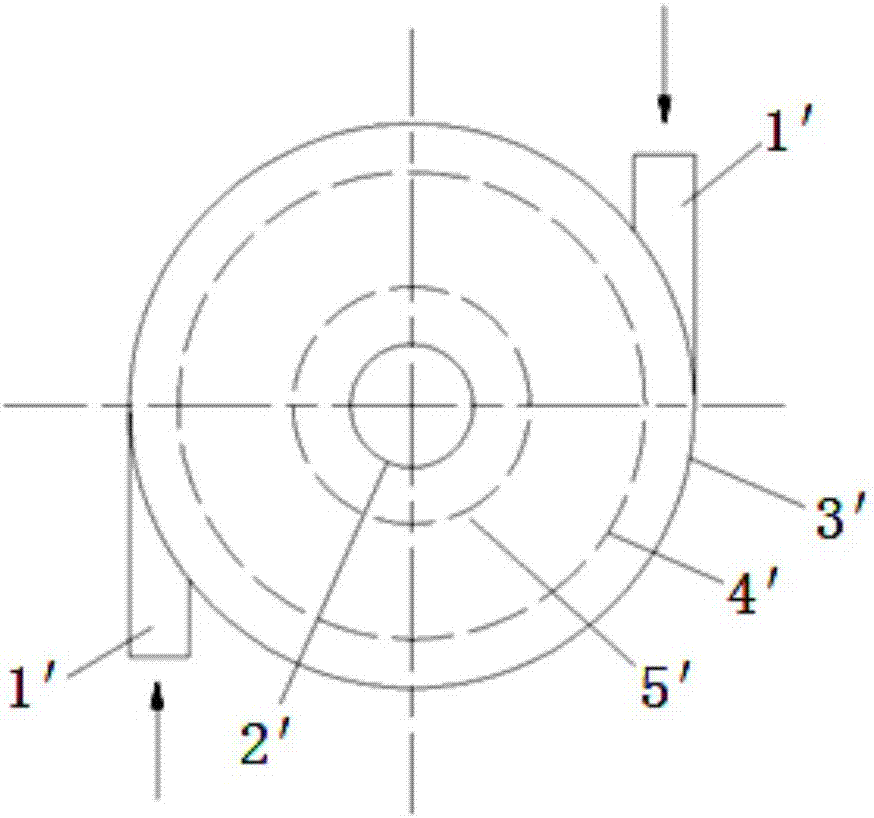

[0044] Such as figure 1 As shown, a large-flux hydraulic cavitation generator based on a Venturi tube includes a fluid inlet pipe (1'), a fluid outlet pipe (2'), a cylindrical cavity (3'), an annular orifice (including Class I annular orifice plate (4'), class II annular orifice plate (5', etc.) and cavitation enhancement module (6').

[0045] The first-level annular orifice plate (4') and the second-level annular orifice plate (5') are coaxially arranged in the cylindrical cavity (3'), and the center of the cylindrical cavity (3') is provided with a hollow Enhancement module (6'), two fluid inlet pipes (1') connected with the cylindrical cavity (3') are respectively arranged on the left and right sides of the cylindrical cavity (3'), and the two fluid inlets The tube (1') is arranged on the tangential direction of the outer edge of the cylindrical cavity (3'), and the fluid outlet tube (2') is arranged concentrically at the top or the upper and lower sides of the center of t...

Embodiment 2

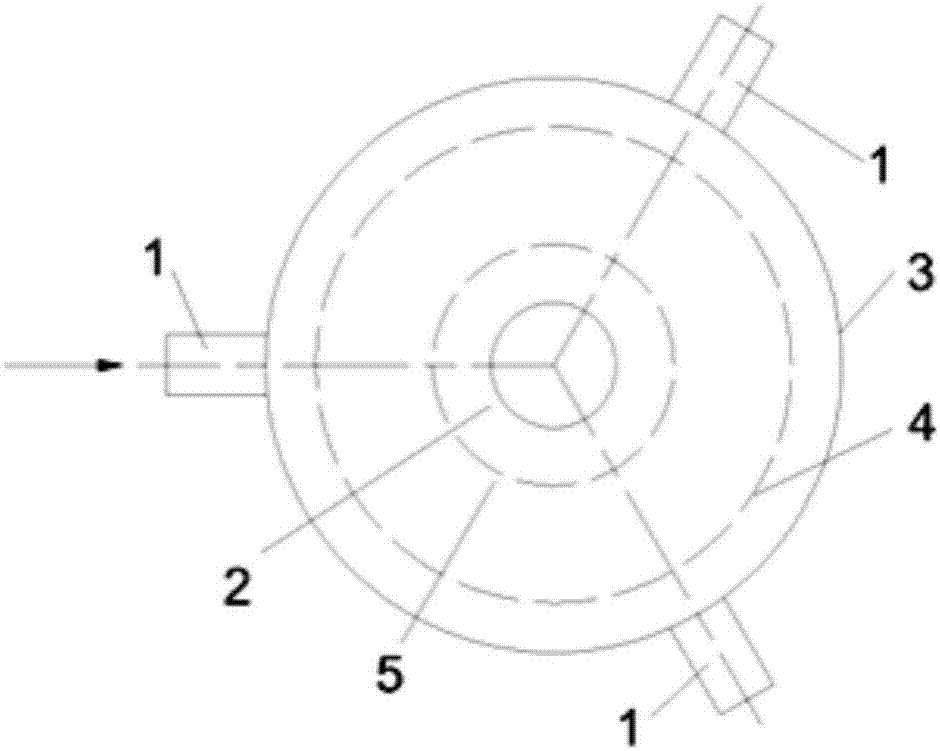

[0048] Such as Figure 2-4 , a large-flux hydraulic cavitation generator based on a Venturi tube, comprising a fluid inlet pipe (1), a fluid outlet pipe (2), a cylindrical cavity (3), an annular orifice (including a first-stage annular orifice (4), a second-level annular orifice plate (5), etc.) and a cavitation enhancement module (6).

[0049] The first-level annular orifice plate (4) and the second-level annular orifice plate (5) are coaxially arranged in the cylindrical cavity (3), and the center of the cylindrical cavity (3) is provided with a cavitation enhancement module ( 6), three fluid inlet pipes (1) are evenly arranged on the normal direction of the outer edge of the cylindrical cavity (3), and the fluid outlet pipes (2) are arranged concentrically on the cylindrical cavity (3) The upper end or upper and lower ends of the center position.

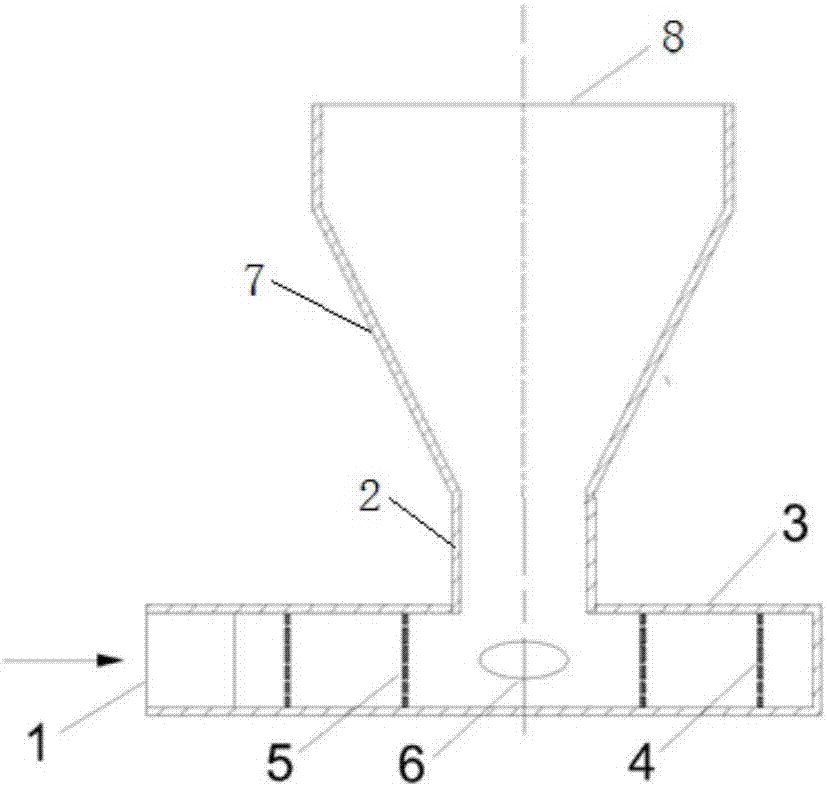

[0050] Venturi tube structure, including expansion section (7) and liquid outlet section (8), the small-diameter end of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com