Automatic sowing machine for culturing seddlings in plastic tray

The technology of a seeder and a plastic disc is applied in the field of seeding machinery, which can solve the problems of large density of seed pots, small diameter, uneven number of bells, etc., and achieve the effects of reducing labor intensity, improving seeding efficiency, and improving seeding uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

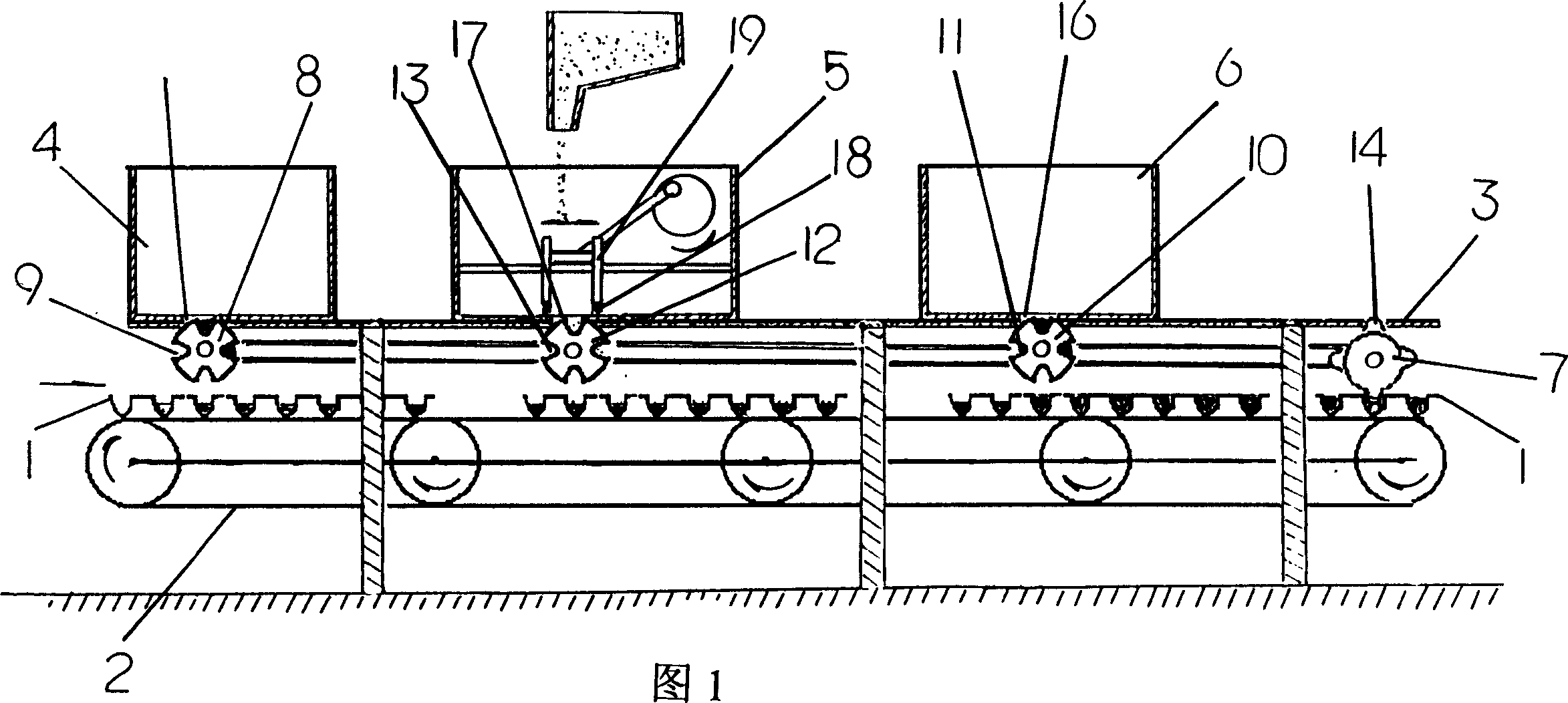

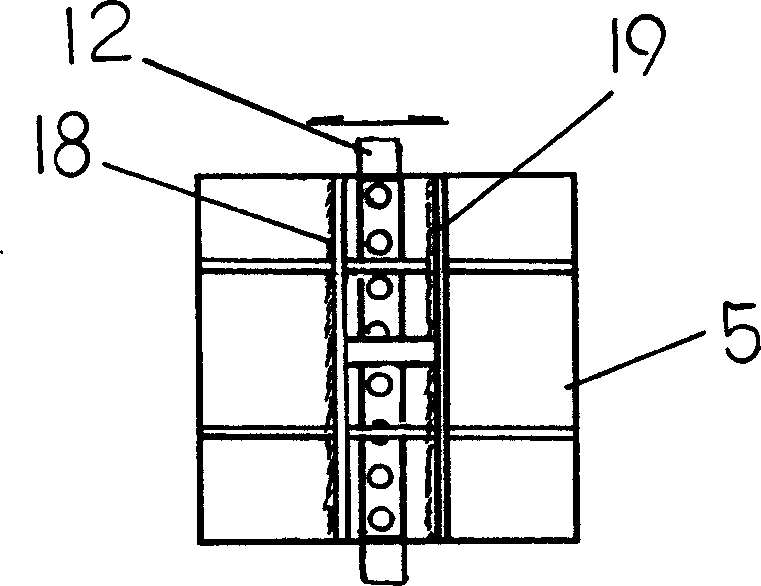

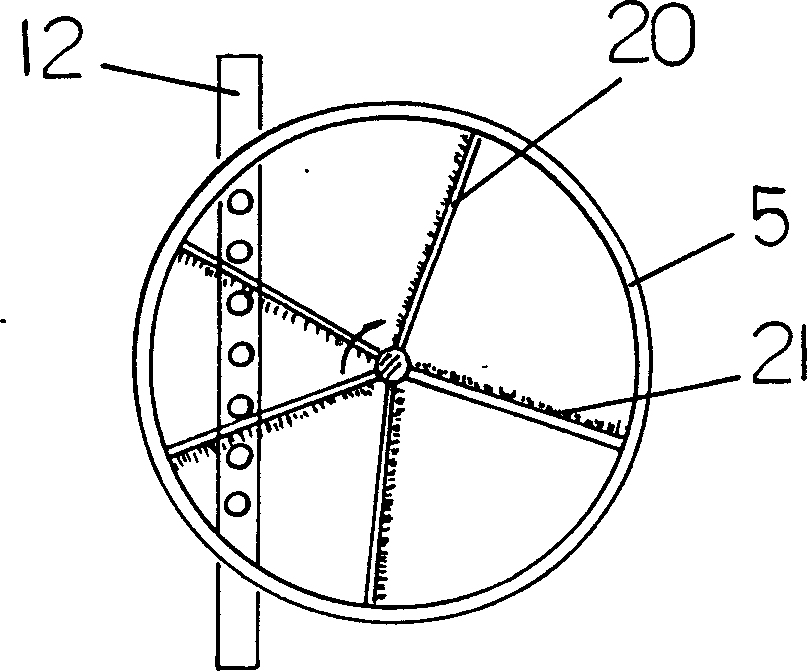

[0012] Referring to accompanying drawing 1, in the present embodiment, the assembly line device that is made of conveyor belt is set, and plastic tray 1 is placed on conveyor belt 2, and on the frame 3 above plastic tray 1, foundation soil spreader is arranged successively along plastic tray 1 advancing direction 4. Seed applicator 5, cover soil applicator 6 and soil pressing roller 7.

[0013] Shown in the figure, foundation soil applicator 4 is that soil application bar-shaped notch 15 perpendicular to plastic plate 1 advance direction is set at the bottom of foundation soil box, and base soil application bar-shaped notch 15 is provided with the foundation that rotates synchronously with conveyor belt 2. Soil application soil roller 8, base soil soil application roller 8 presses the spacing of seed bowl on the plastic tray 1, the number of holes is provided with corresponding base soil soil hole 9, and the volume of base soil soil hole 9 is 2 / 3 of seed bowl volume.

[0014] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com