Rice precise direct-seeding and cavitating device

A hole-forming and precise technology, applied in sowing, planter parts, hole-seeding planters, etc., can solve problems such as the inability to meet the requirements of rice planting, and achieve the effects of improving seeding uniformity, reducing seed damage rate, and convenient and quick installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

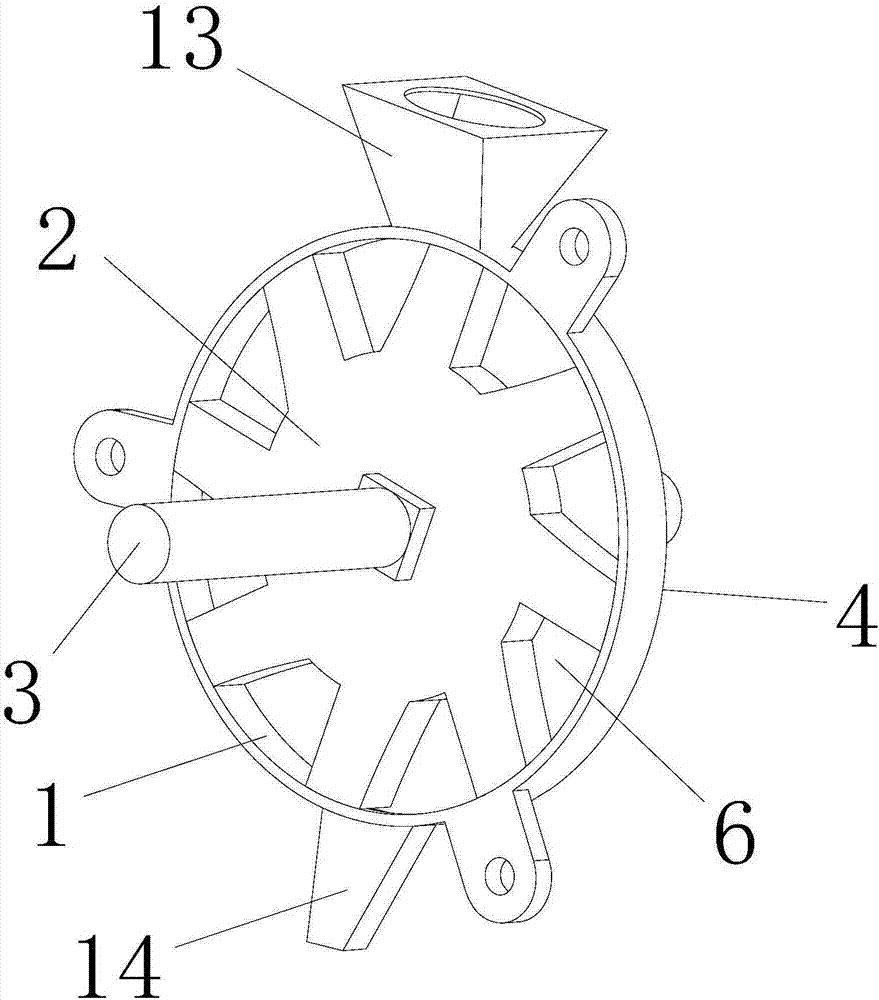

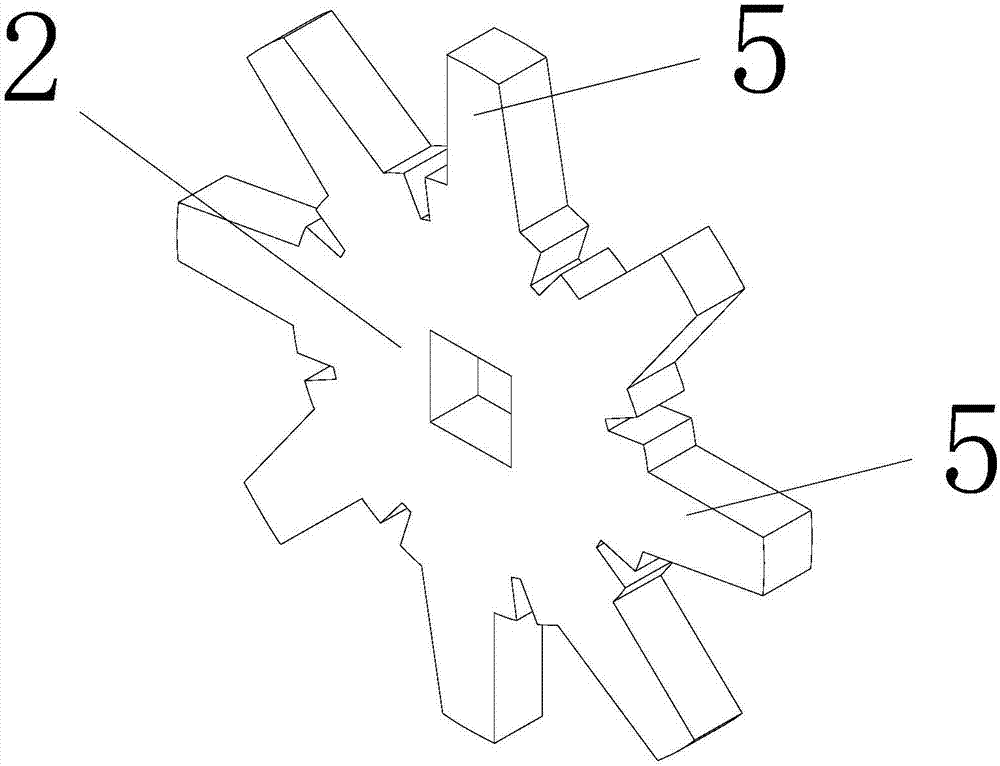

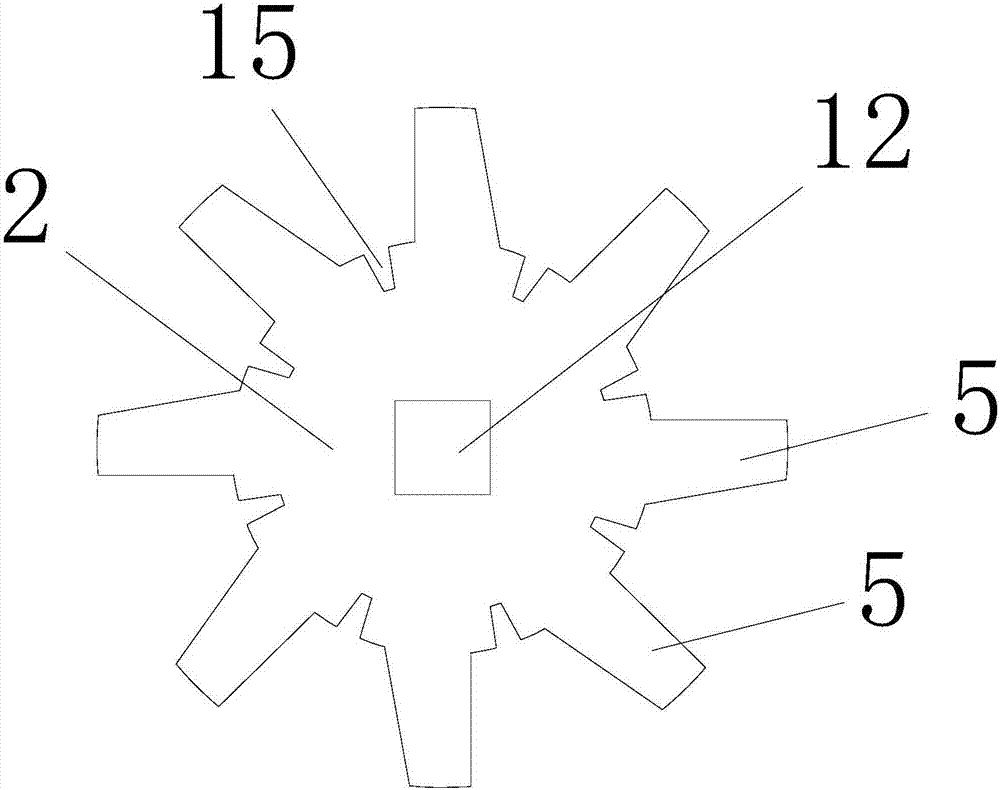

[0029] A caving device for precision direct seeding of rice, comprising a housing 1, a caving disc 2 and a transmission shaft 3, a disc cavity 4 is arranged in the housing, the caving disc is installed in the disc cavity, and the caving disc includes a transmission shaft The connecting part of the shaft connection and a plurality of compartment plates 5 protruding radially from the outside of the connecting part, a seed cavity 6 is formed between two adjacent compartment plates and the cavity wall of the disc cavity, and the upper part of the disc cavity is provided with The seed inlet for the seeds to enter the seed chamber, the lower part of the disc chamber is provided with the seed output port for the seed output in the seed chamber, when the seed inlet is connected with the seed chamber, the seeds enter the seed chamber through the seed inlet, when the seed When the cavity communicates with the seed output port, the seeds in the cavity are output from the seed output port....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com