Caterpillar band recess next-to-ground precise seed discharging device

A kind of seed metering device and pit technology, which is applied in the field of precision seed metering device with crawler pits attached to the ground, which can solve the problem that it is difficult to achieve single-grain on-demand seeding of small seeds in one ditch, difficult to realize precision seeding, and inability to accurately control the space of seedlings Distribution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

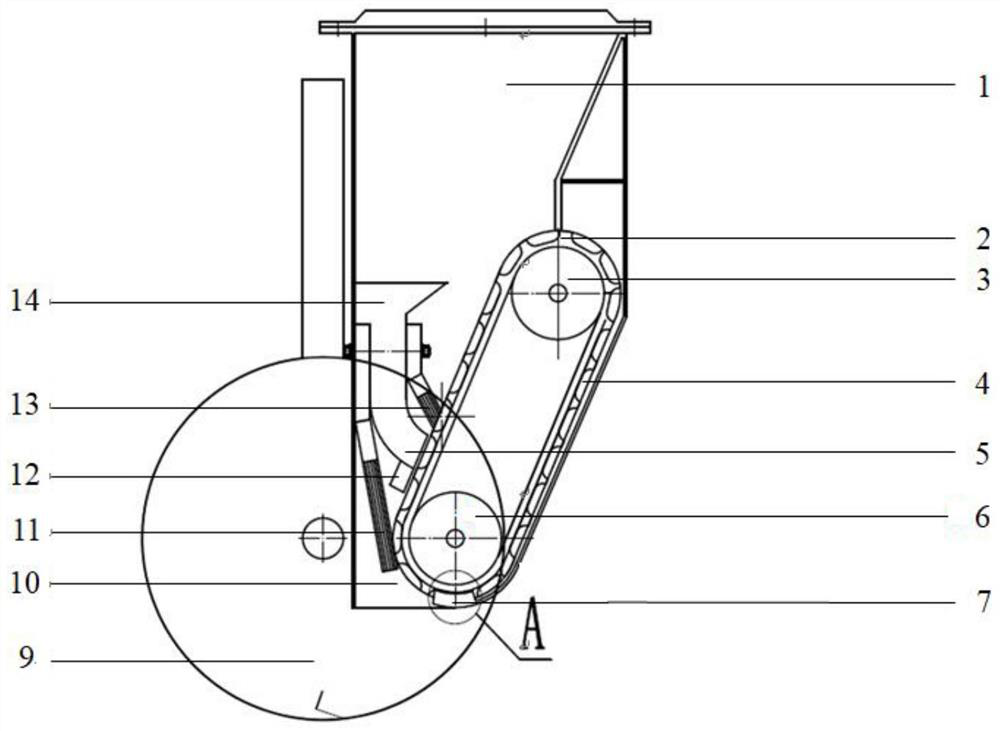

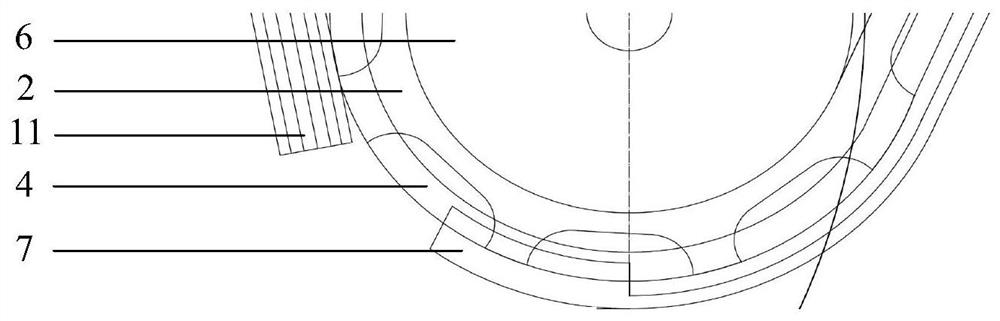

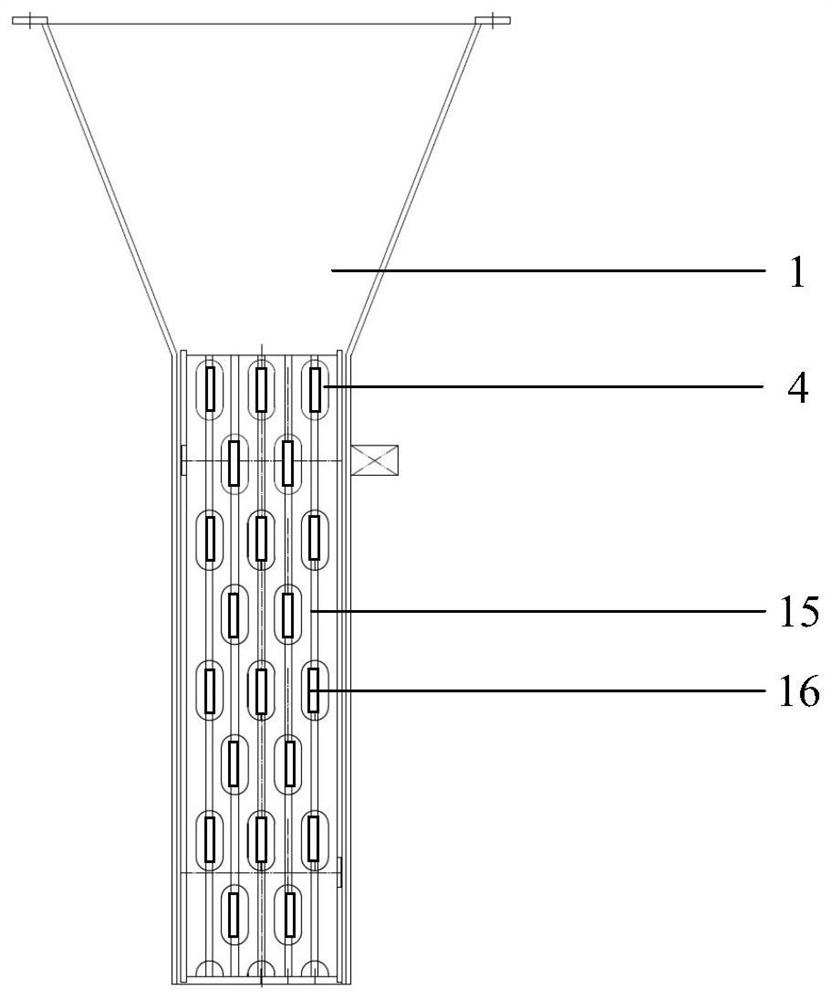

[0028] As shown in the figure, the present embodiment includes a frame, and a ditch opener 9 is installed through a shaft at the lower end of the frame, behind the position of the 9 shafts of the ditch opener, a seeding bin 1 is installed on the frame, and a seeding bin 1 The upper end is the seed inlet, and the upper cover can be installed; the lower end of the seed discharge bin 1 is provided with a seed distribution port 10 . Seed bin 1 is a vertical vertical plate near the front bin of ditch opener 9, and the bottom of rear bin gradually inclines toward front bin, and front and rear bins form a seed distribution opening at the lower end of seed bin. The seeding crawler belt 2 is arranged on the inside of the inclined part of the rear warehouse plate. The mounting structure of the seed-discharging crawler belt 2 is: a driving shaft and a driven shaft are respectively housed on the side walls of the seed-discharging bin 9, and the driving shaft can be connected with an exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com