Device for textile fabric padding

A textile fabric and padding technology, which is applied in the processing of textile materials, processing textile material carriers, liquid/gas/steam textile material processing, etc., can solve problems such as easy to forget, affect the effect of padding, and trouble, and reach the scope of application Wide, flexible effect of padding device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

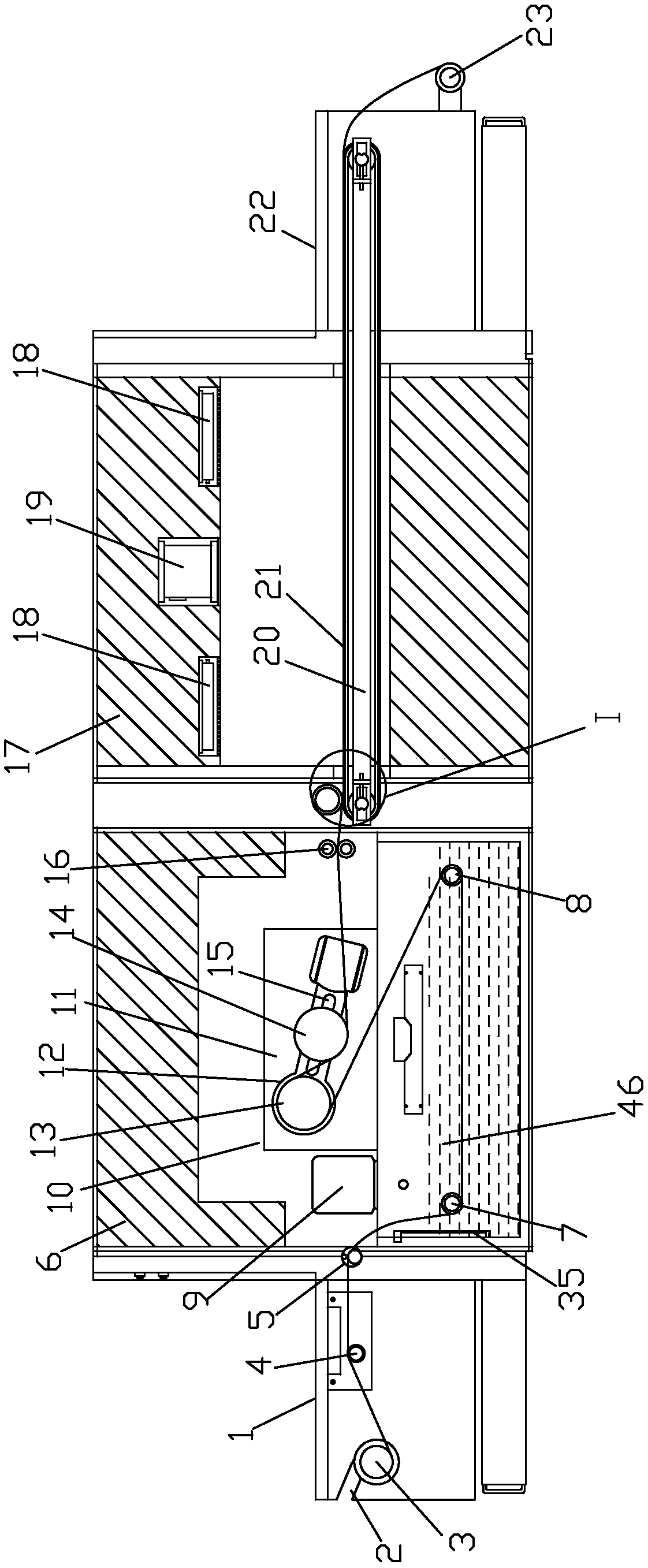

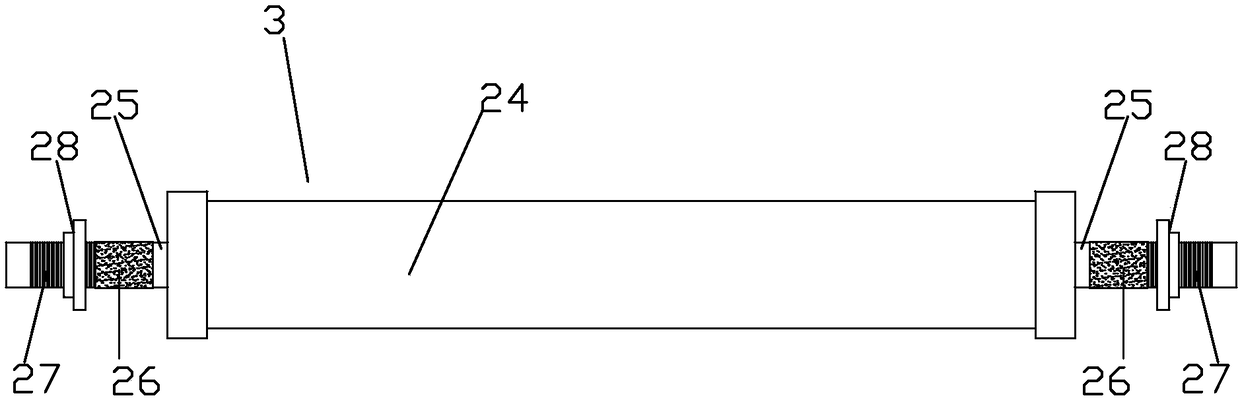

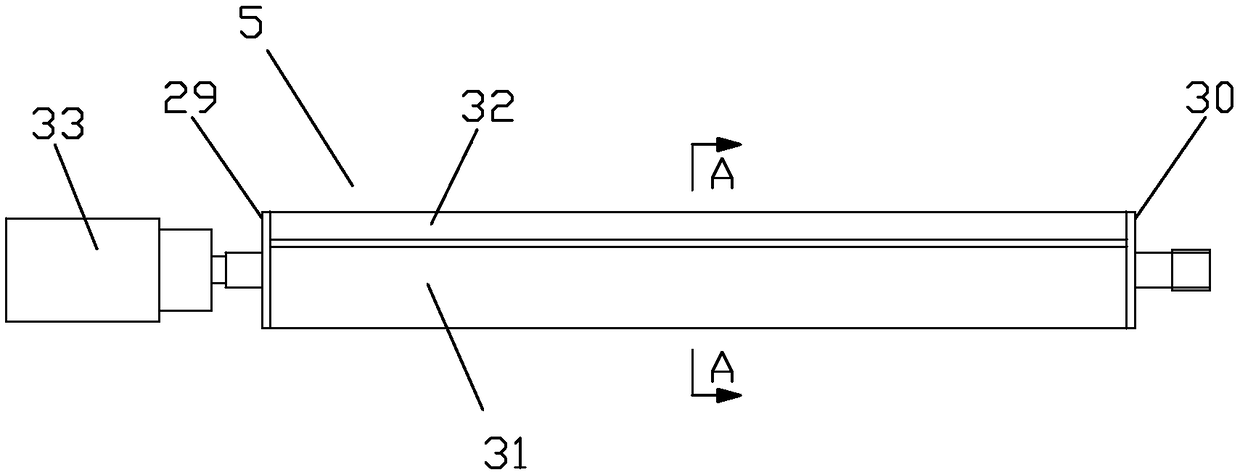

[0035] Such as Figure 1 to Figure 9As shown, a device for padding of textile fabrics includes a cloth feeding mechanism 1, a padding mechanism 6, a drying mechanism 17 and a cloth outlet mechanism 22, and the cloth feeding mechanism 1 is provided with a cloth releasing roller 3 and a cloth feeding mechanism Both sides of the roller 4 and the cloth feeding mechanism 1 are provided with rack openings 2 corresponding to each other, and the cloth roll roll 3 is installed by means of the rack openings 2 on both sides. The cloth rolling roller 3 includes a cloth rolling bar 24 and a frame bar 25, and the two ends of the cloth rolling bar 24 are provided with a frame bar 25, and the frame bar 25 and the frame mouth 2 match each other. The cloth releasing roller 3 is used for continuously feeding the cloth feeding roller 4, so as to realize a continuous and uninterrupted padding process, has a simple structure, and realizes directional conveying of the cloth. The frame bar 25 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com