Lip and spread angle variable efficient duct

A diffusion angle, variable technology, applied in the lip and diffusion angle variable high-efficiency duct, the duct that generates thrust on the aircraft, and the duct field, which can solve the response delay, difficult to achieve, and reduce the size of the lip. Negative pressure value and other problems to achieve the effect of improving efficiency, improving accuracy and reducing coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

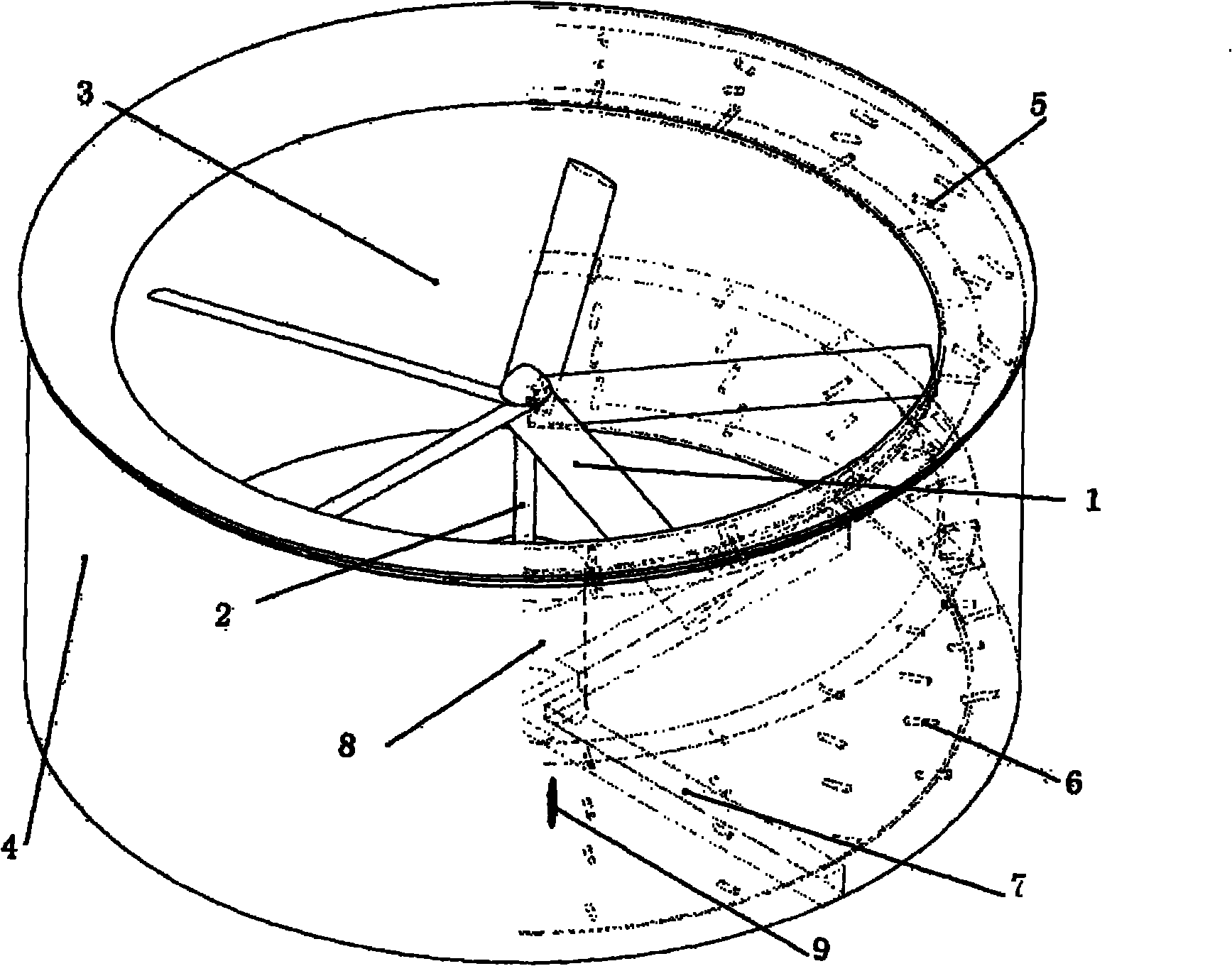

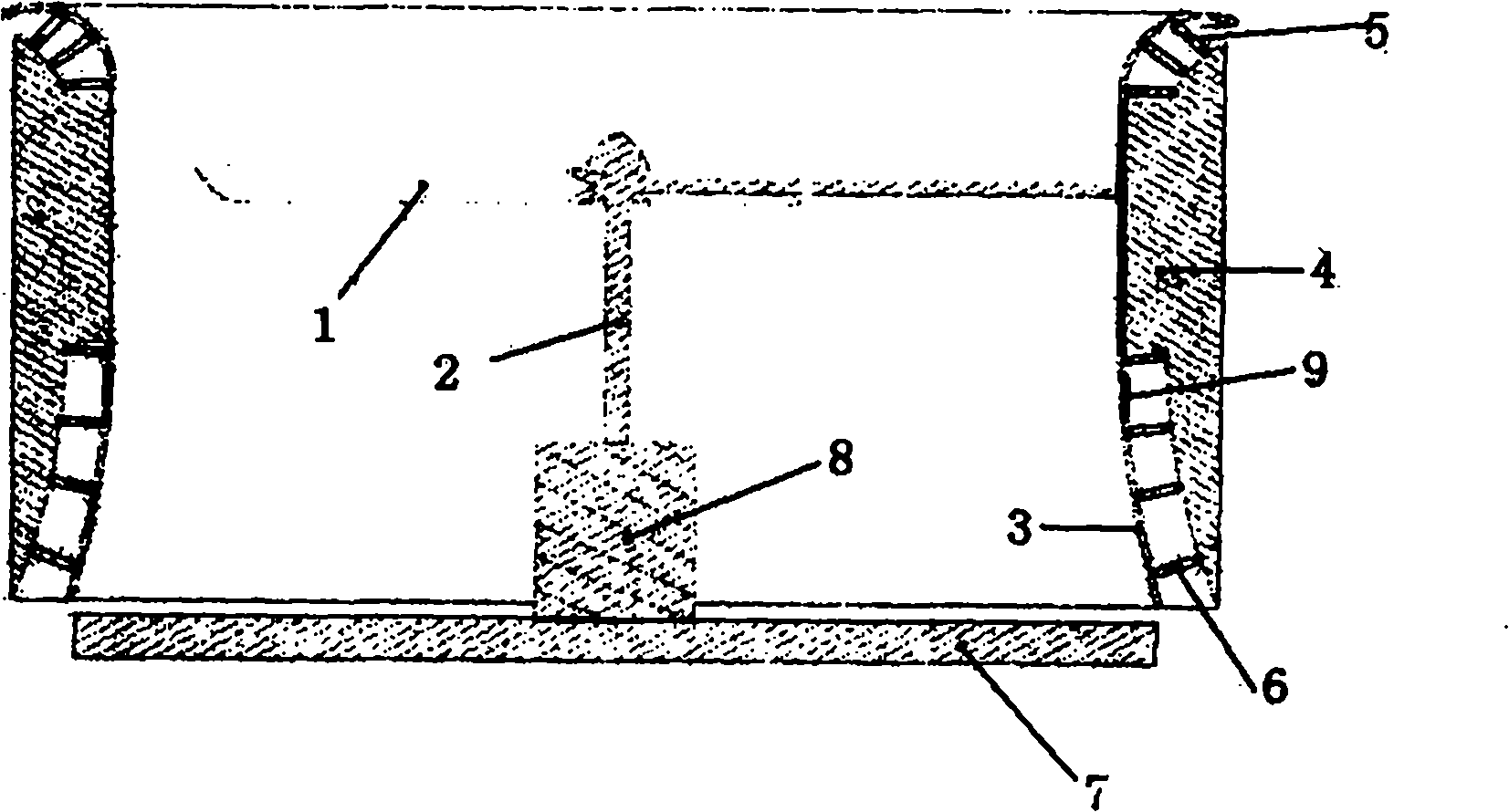

[0017] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

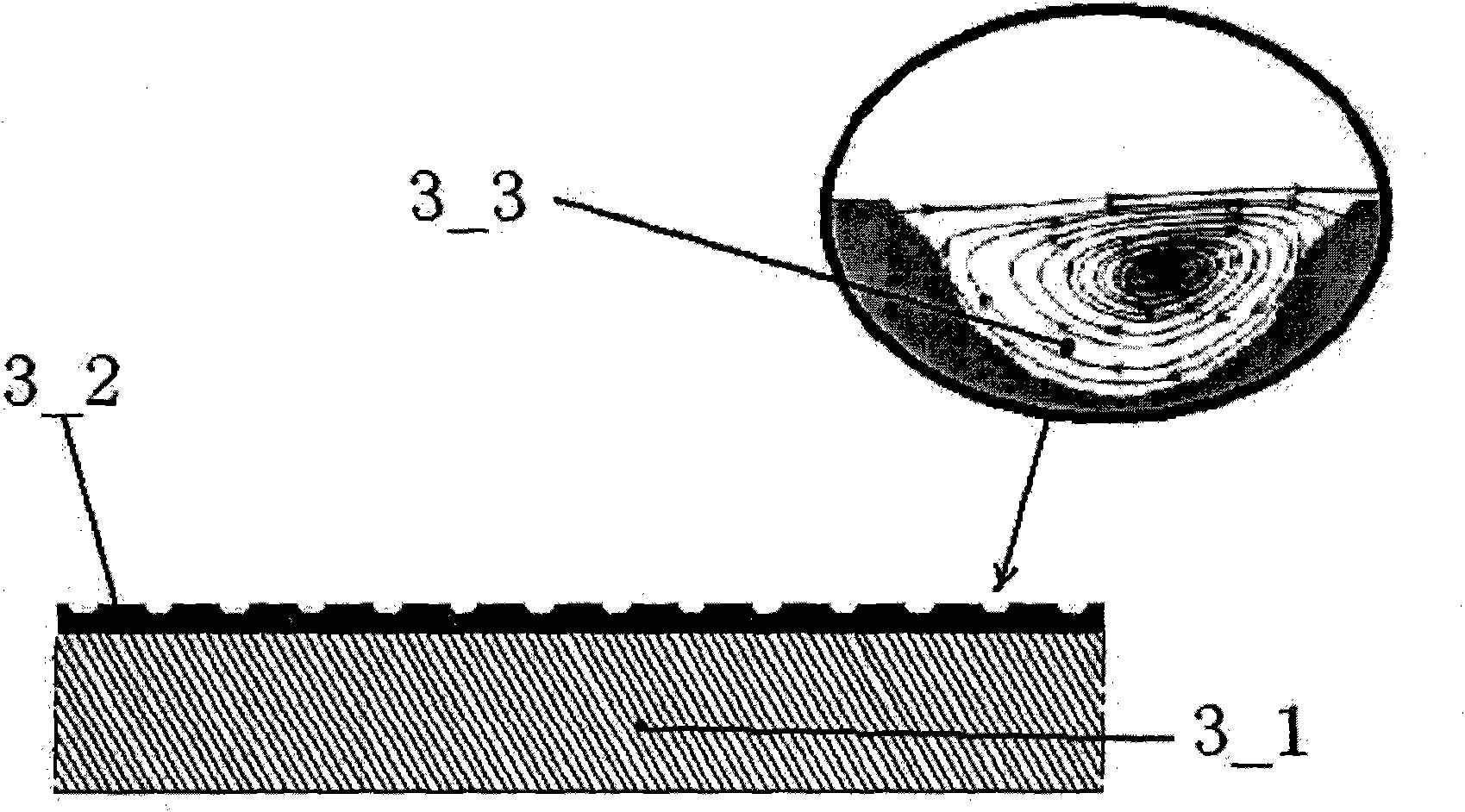

[0018] Figure 1 to Figure 3 Shown is a high-efficiency duct with a variable lip and divergence angle realized according to the present invention. The material used for the duct wall 3 is a flexible material with a certain strength. The upper and lower ends of the duct wall 3 are respectively fixed with multiple lip actuators 5 and diffuser actuators 6. The actuators 5 and 6 are separately fixed. One end is connected on the positioning platform 4. The flexible material may be rubber or other materials with certain elasticity that can form a thin-walled structure. The actuators 5 and 6 can use hydraulic cylinders, or stepper motors and lead screws to perform linear reciprocating motions under control signals to change the distance between the two ends of the actuators 5 and 6 . One end of the actuators 5 and 6 is hinged to the duct flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com