Patents

Literature

30results about How to "Tension effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

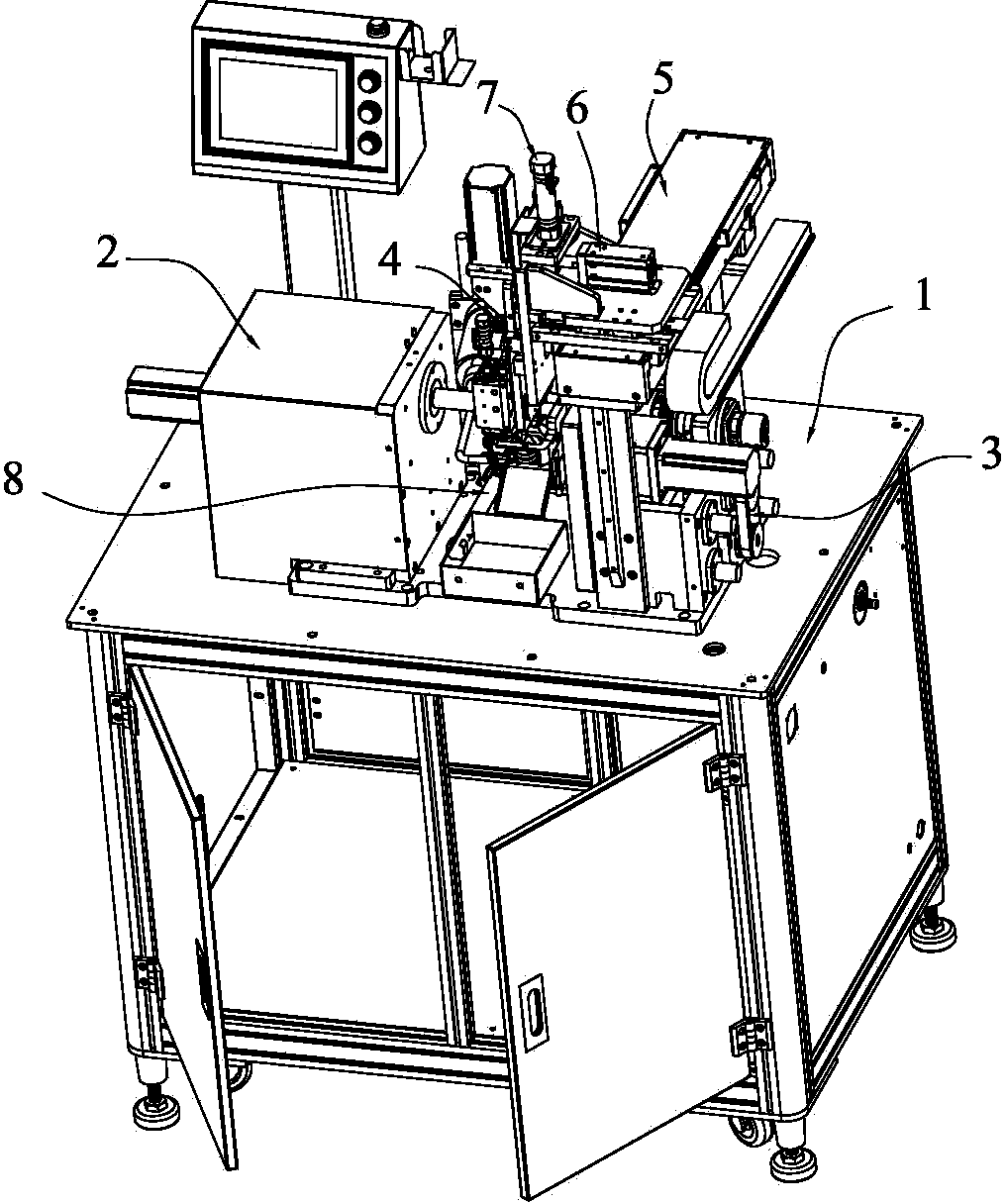

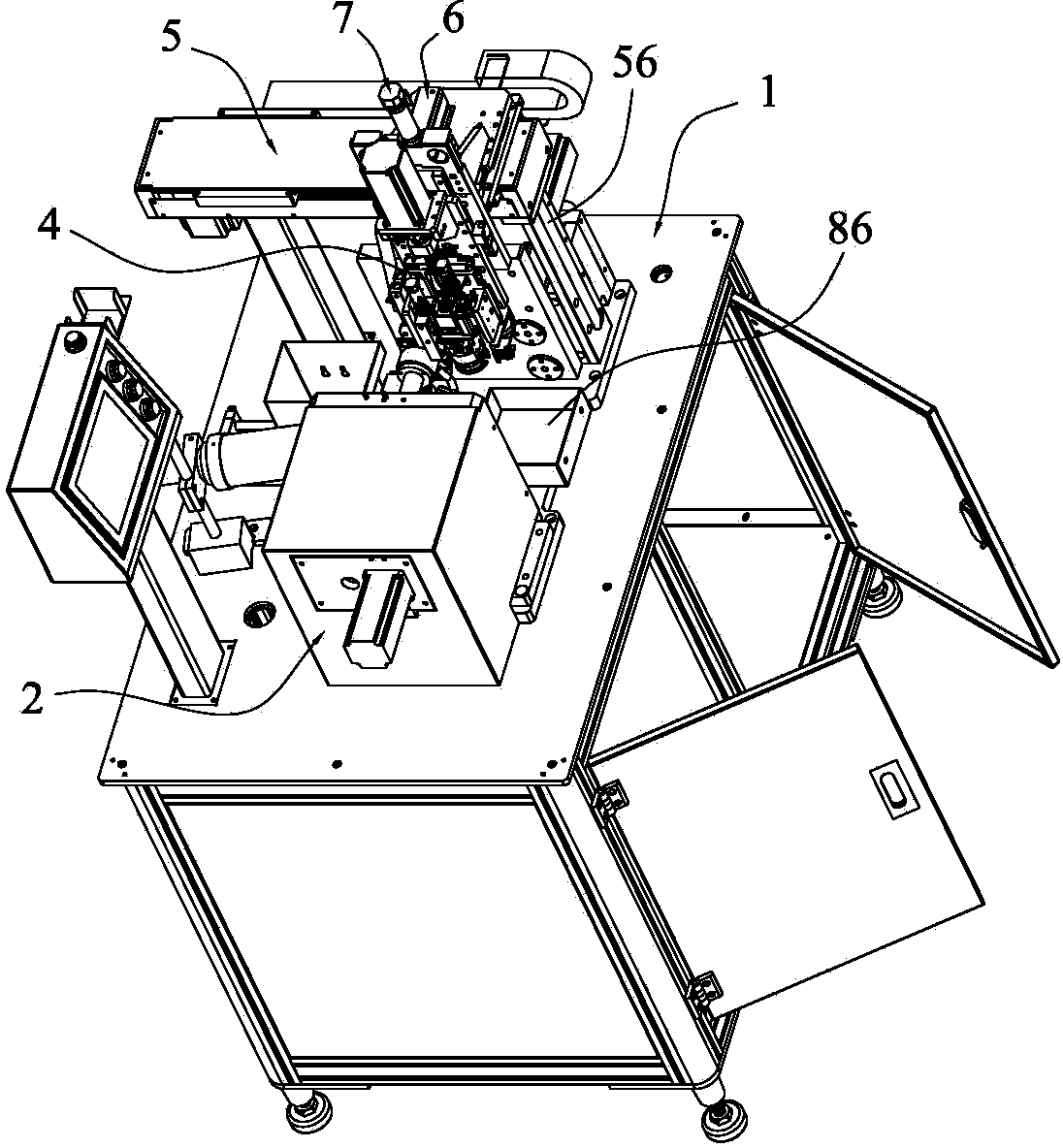

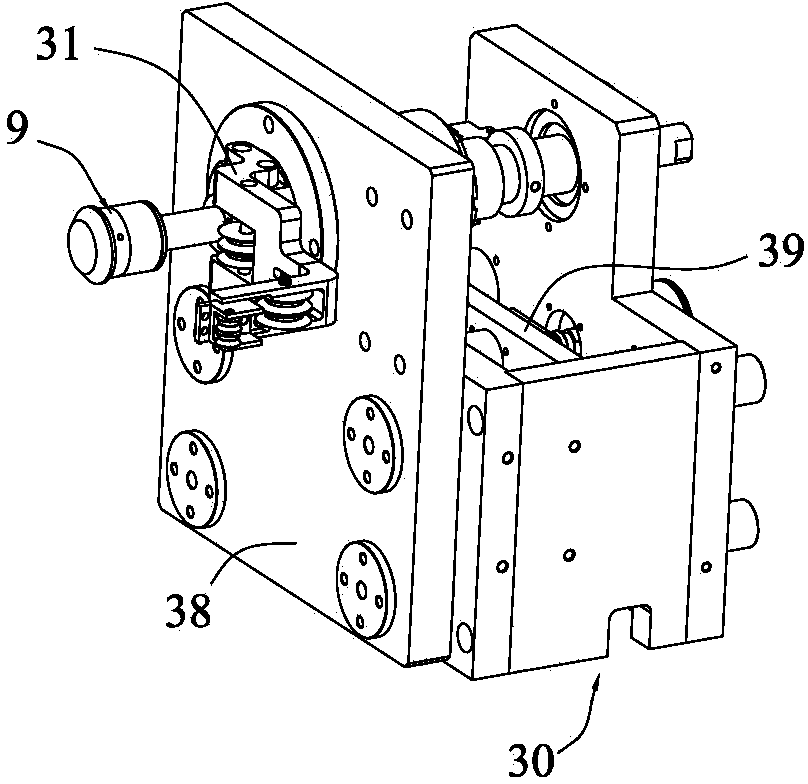

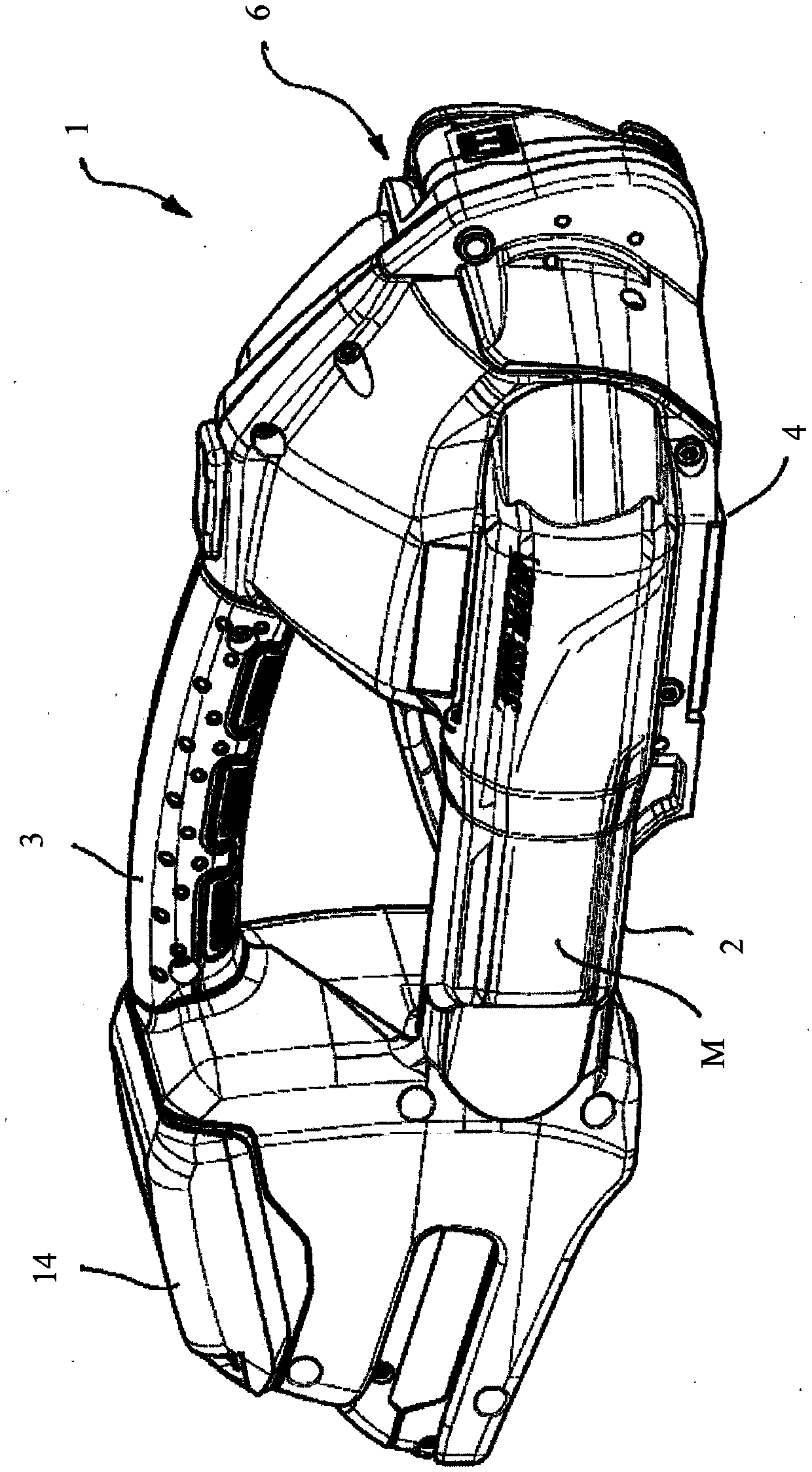

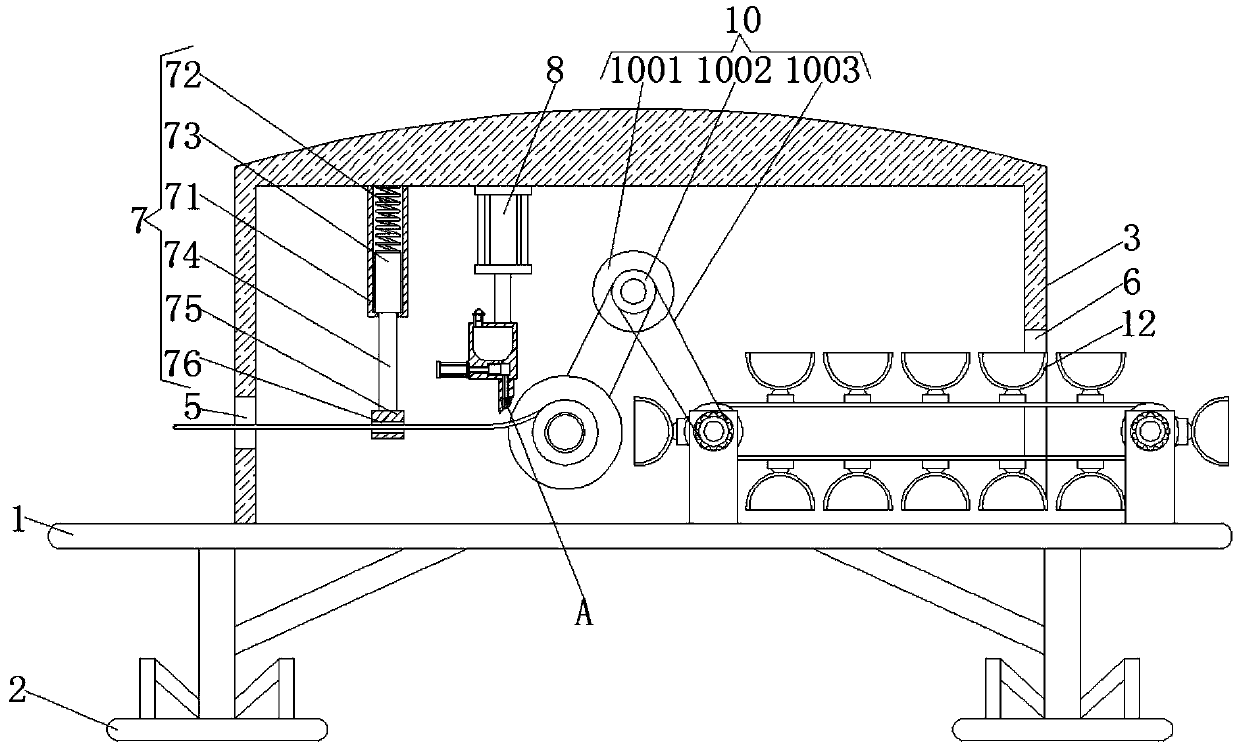

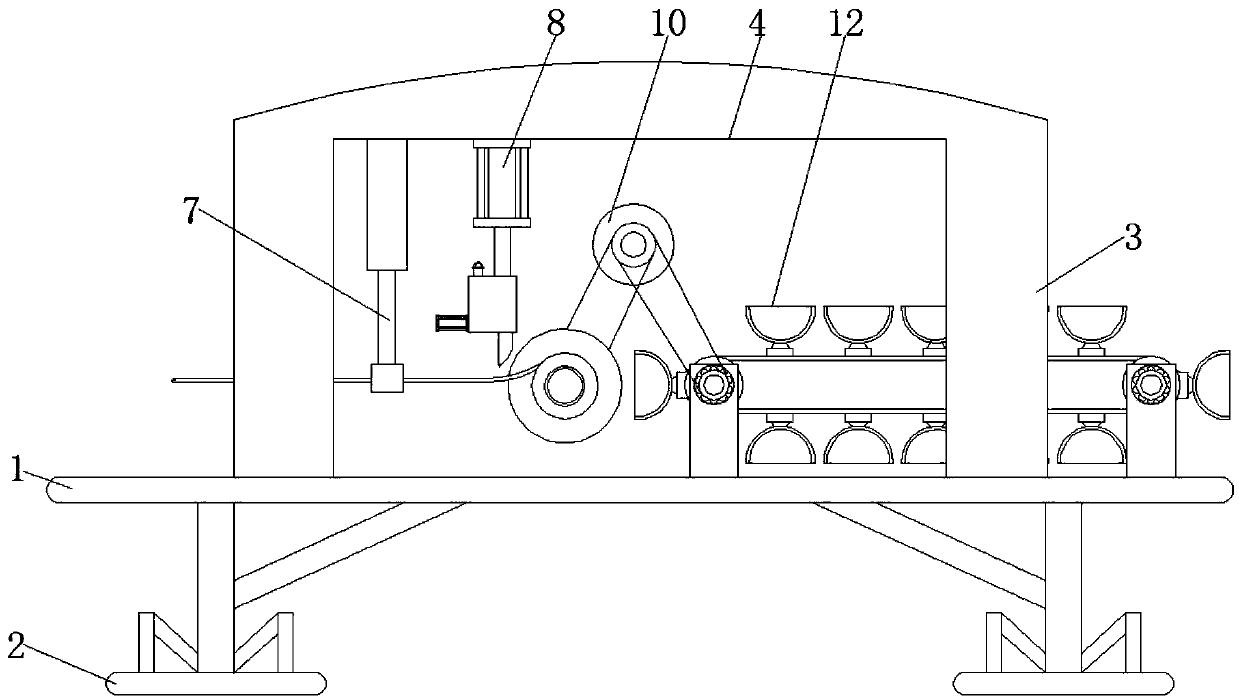

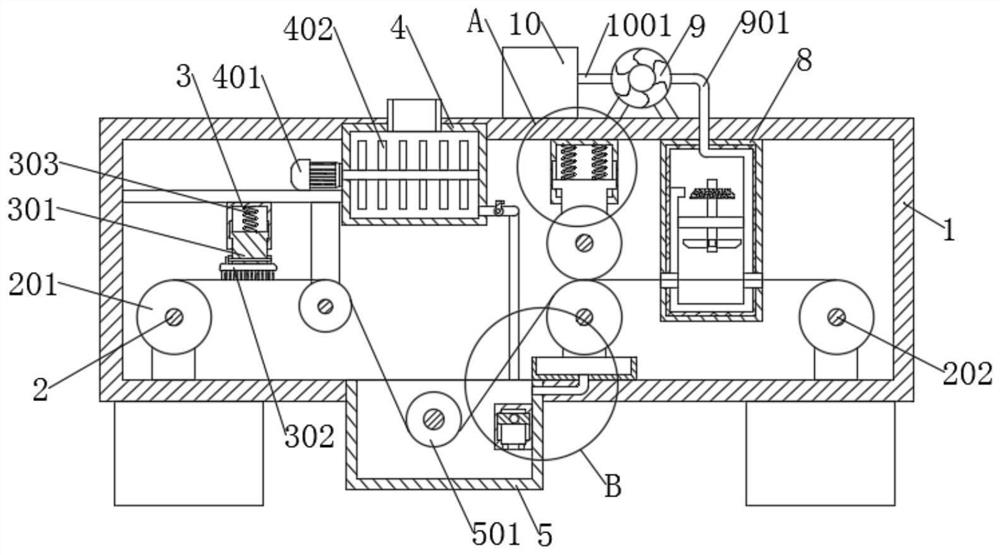

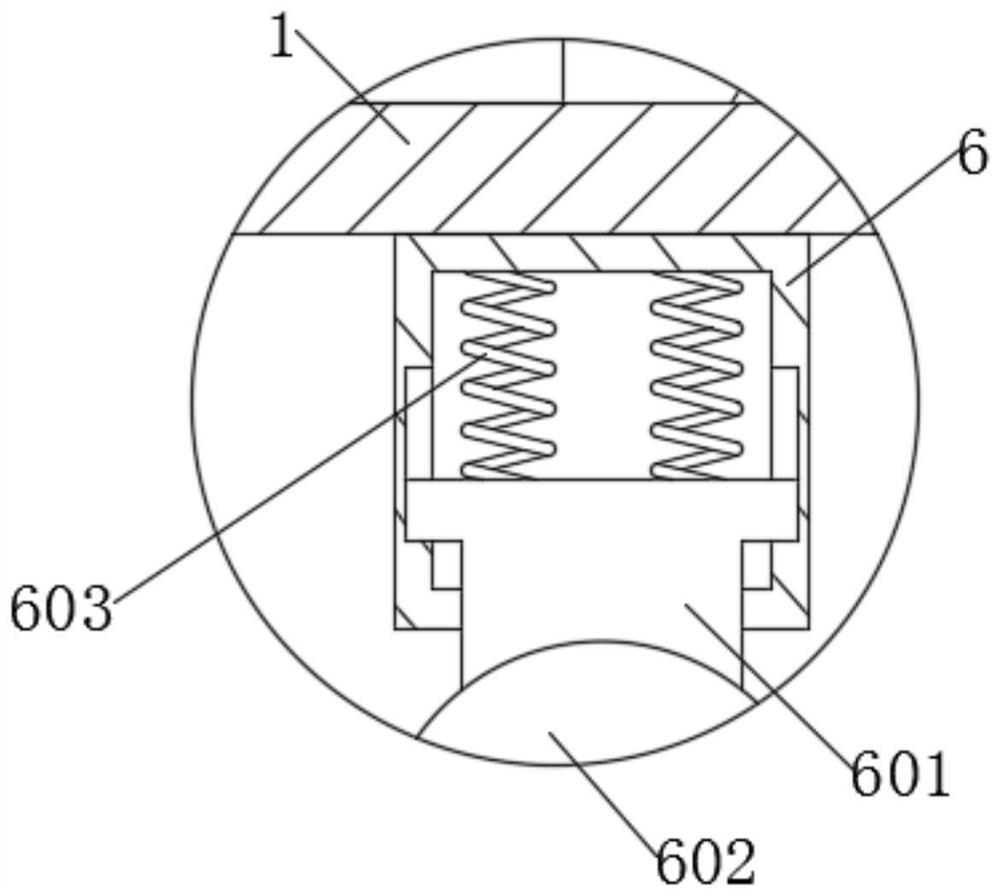

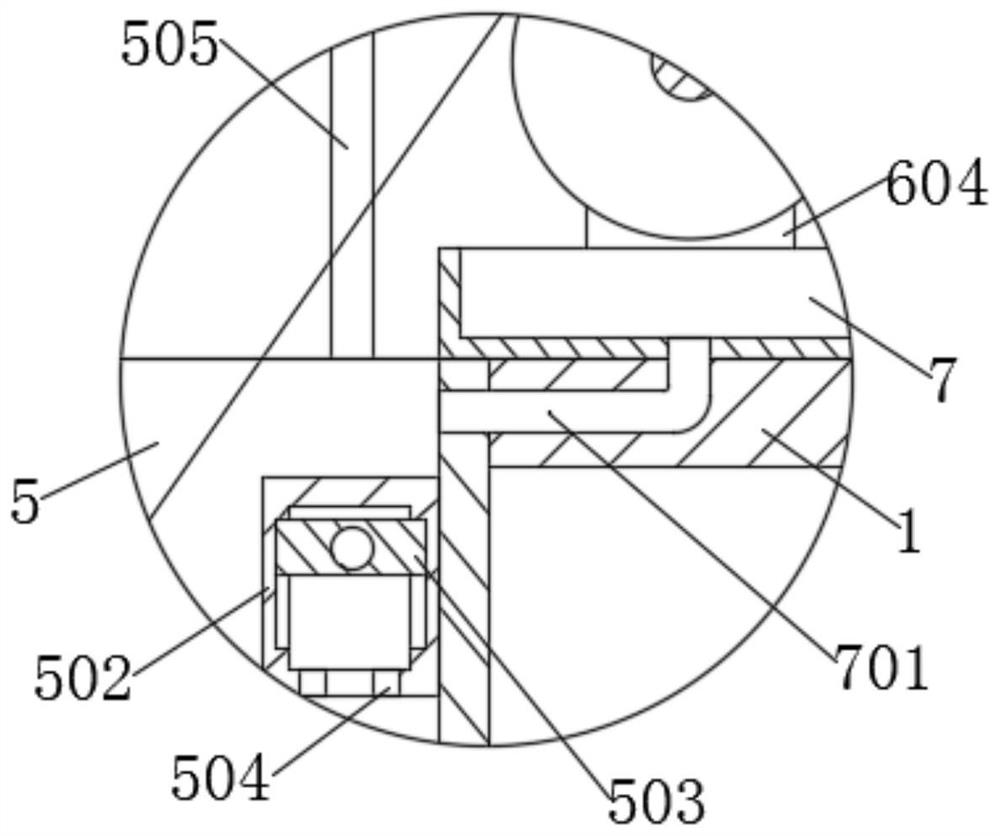

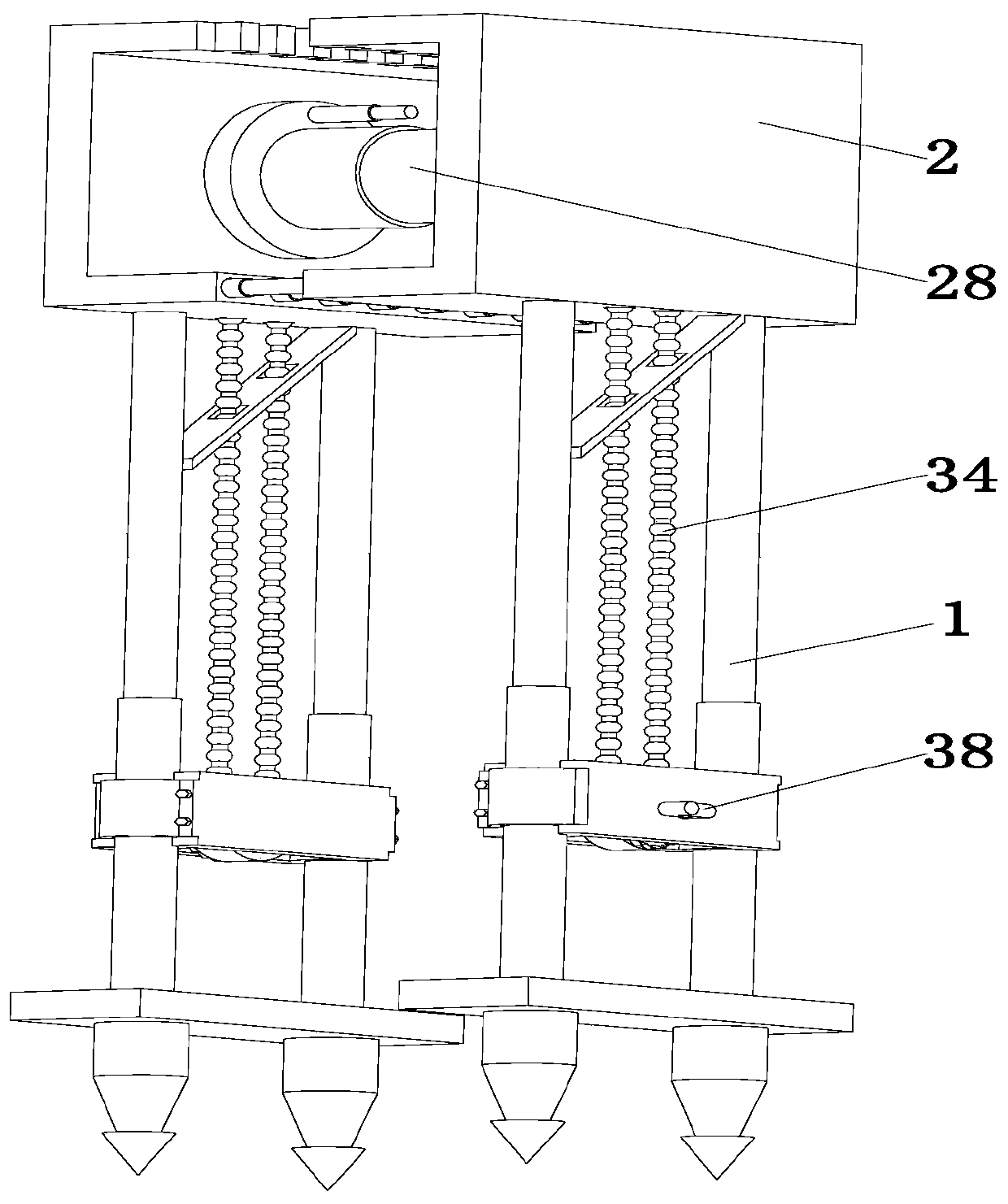

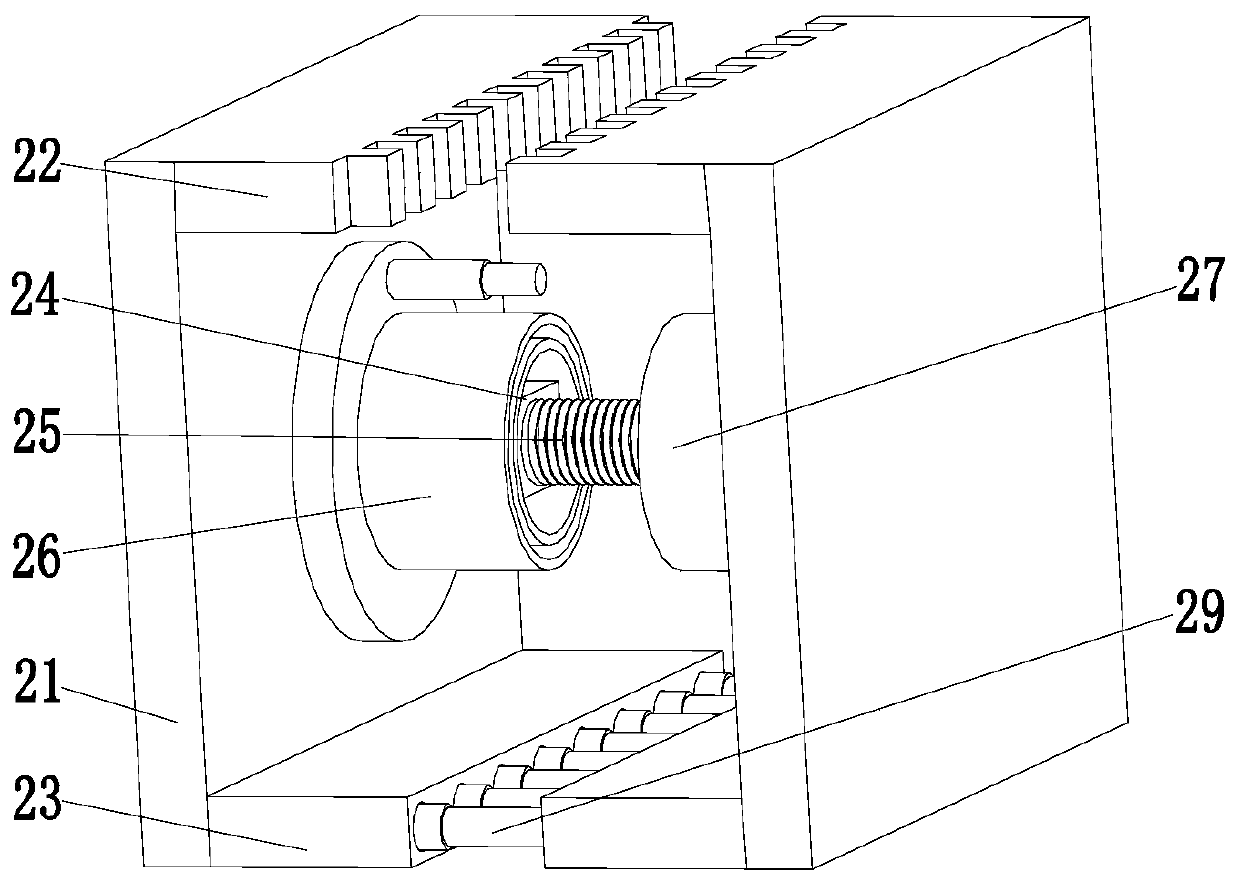

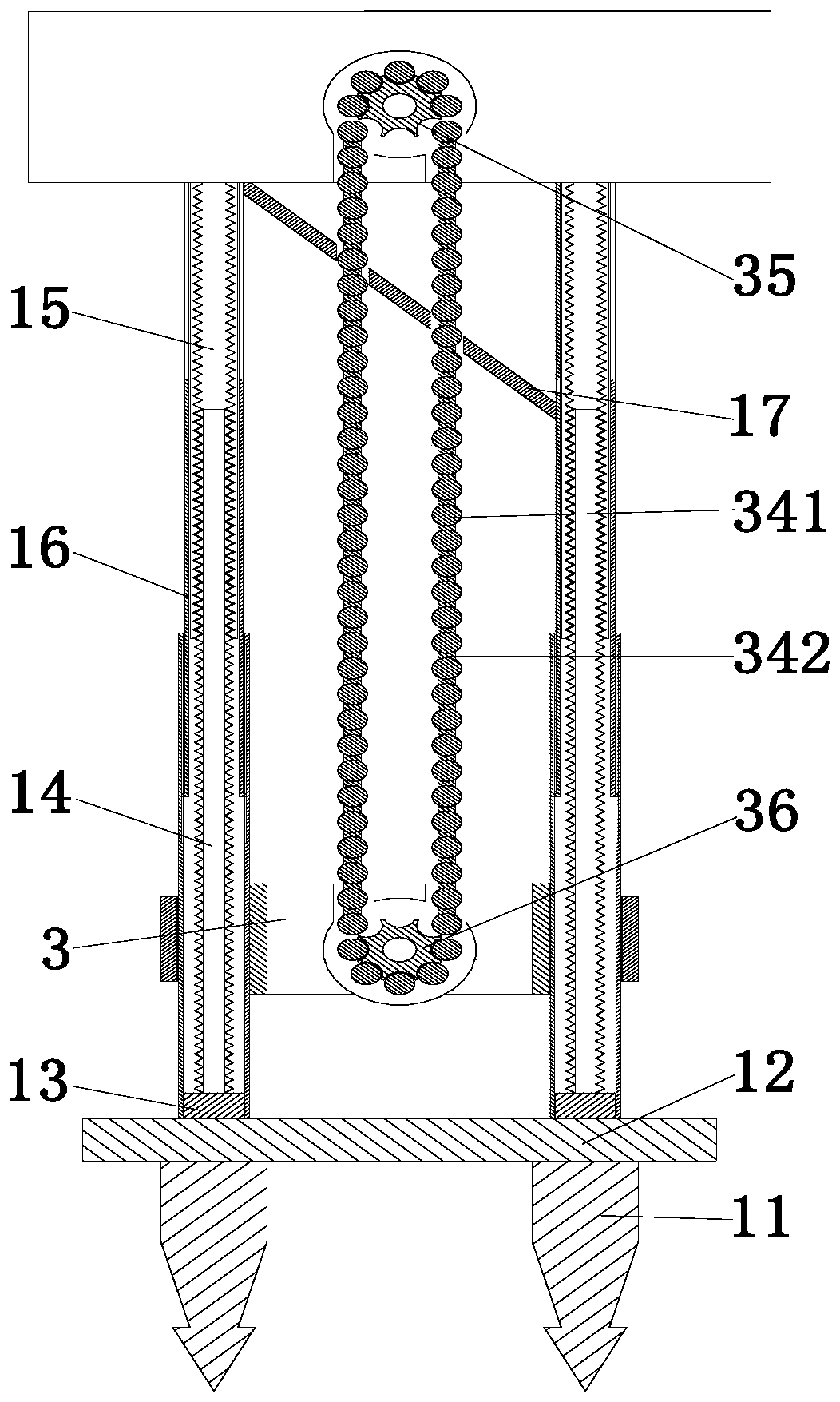

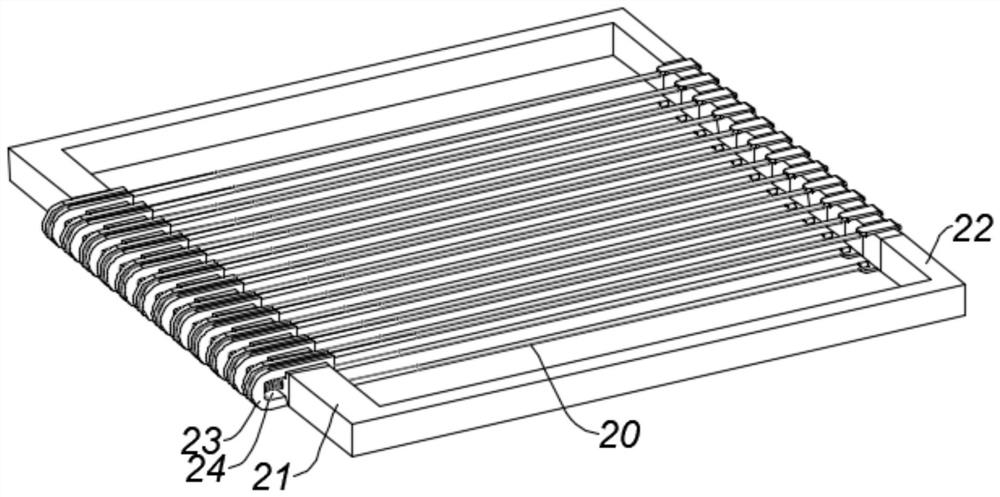

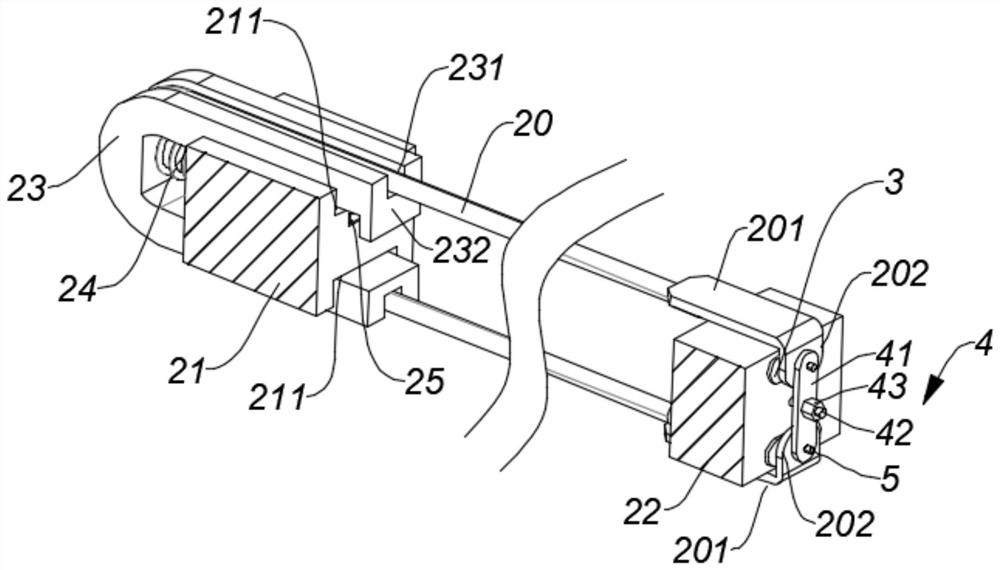

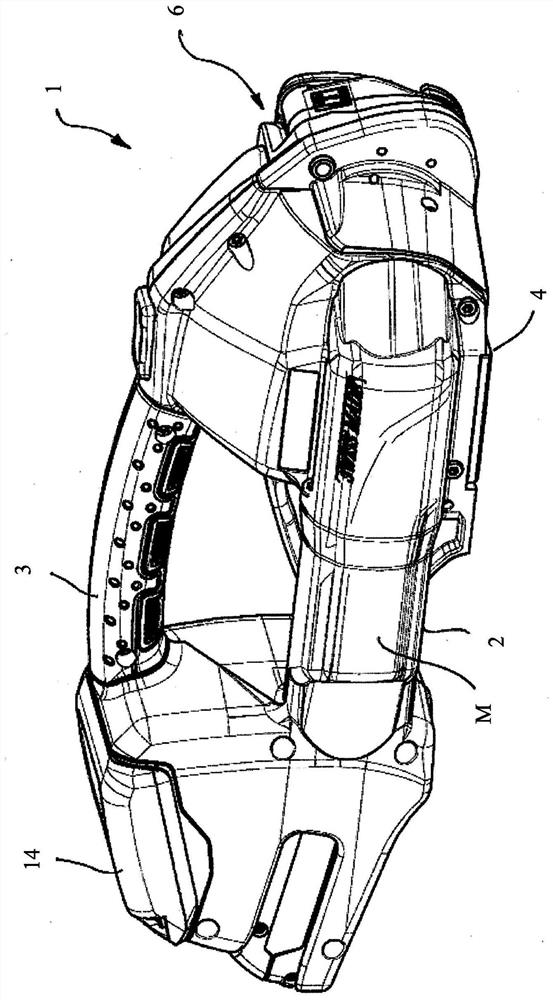

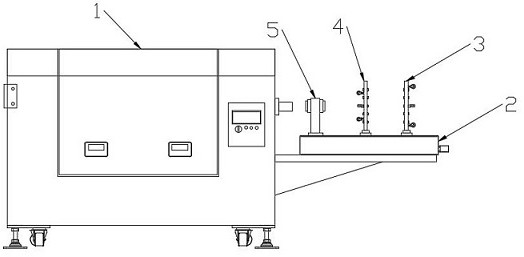

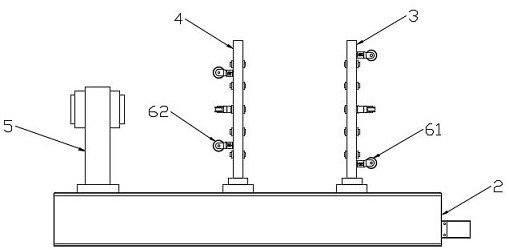

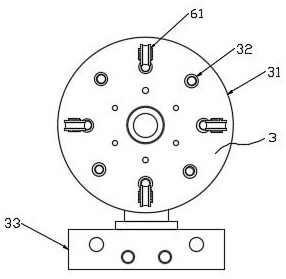

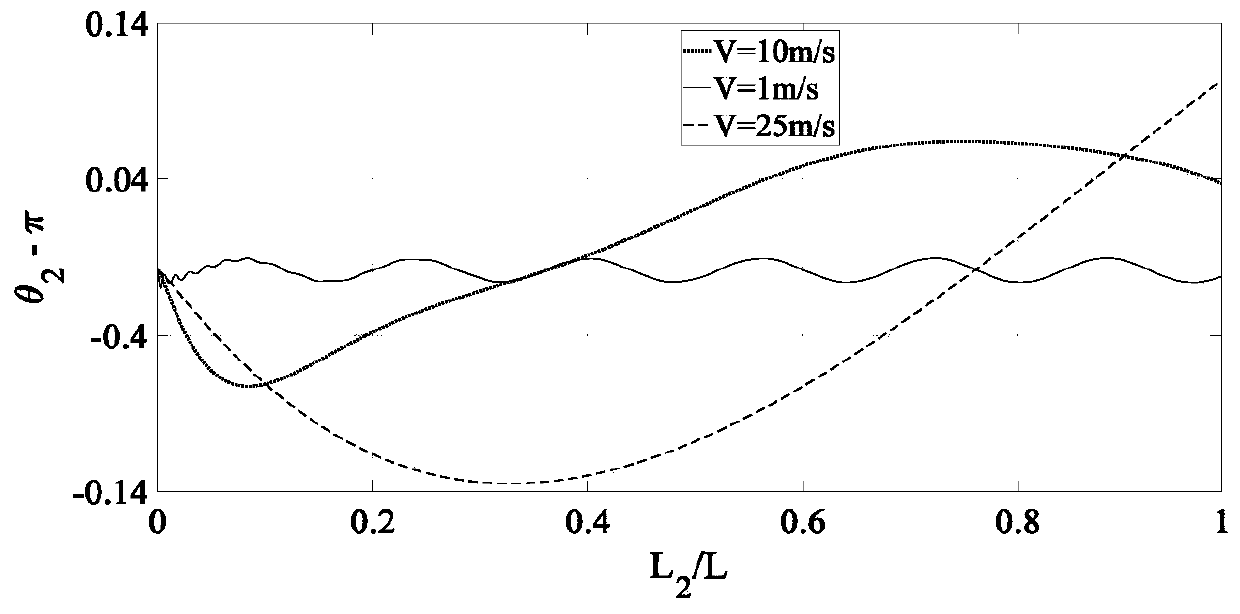

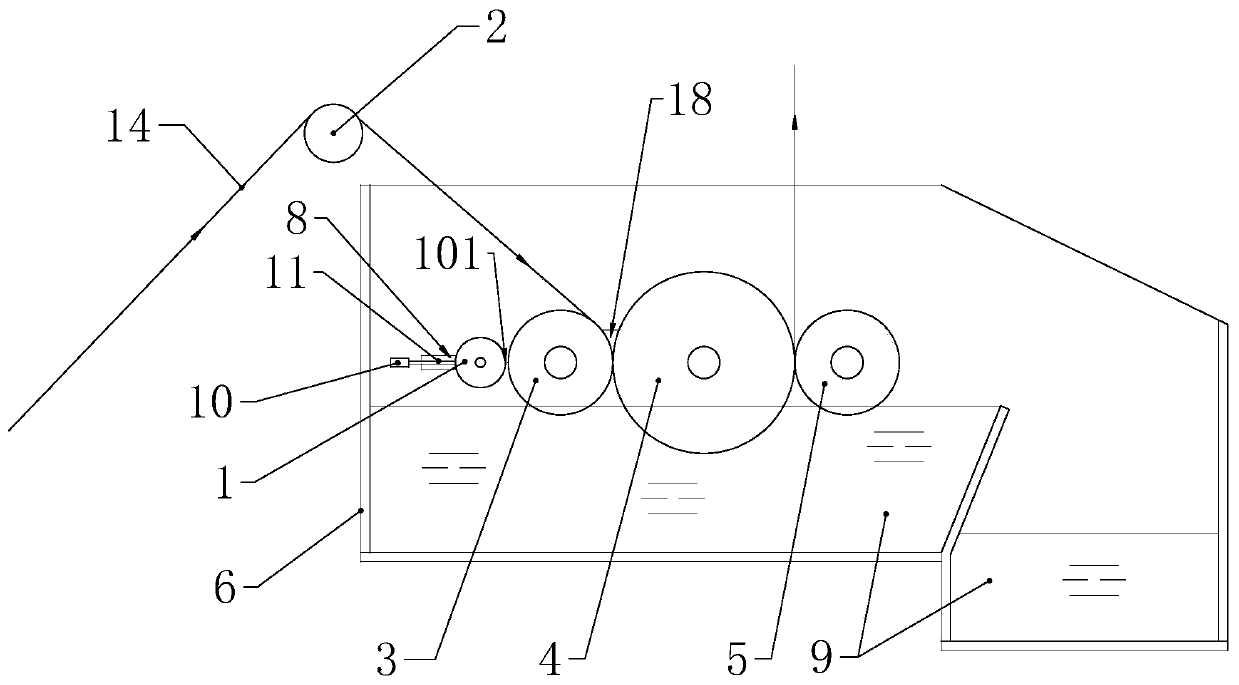

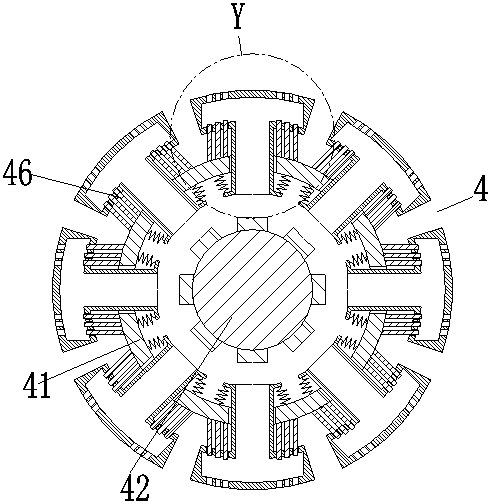

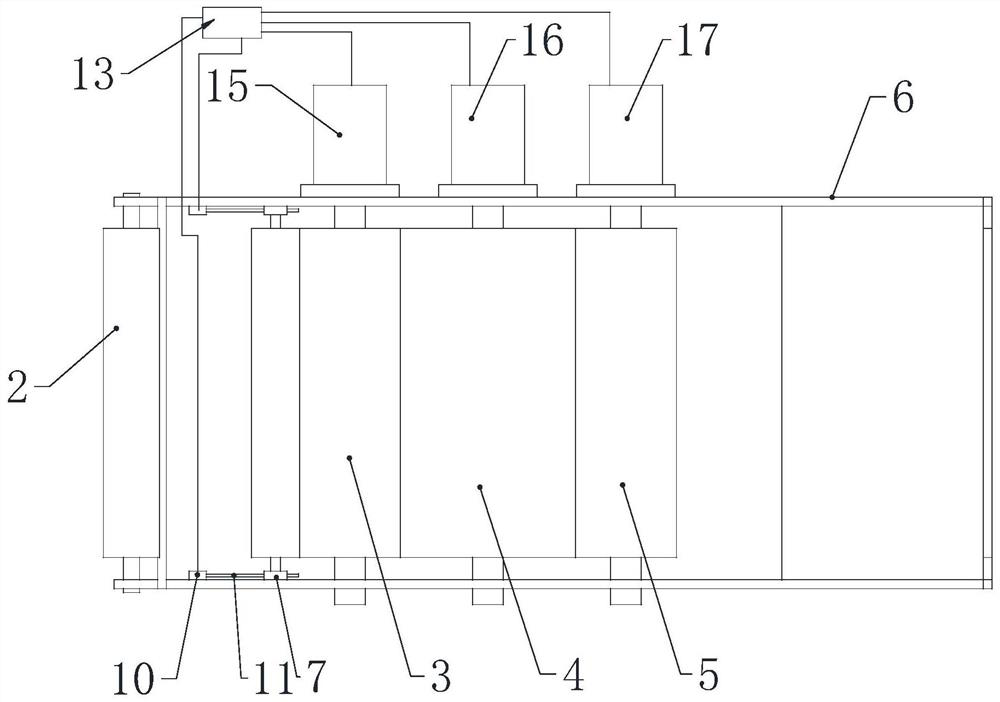

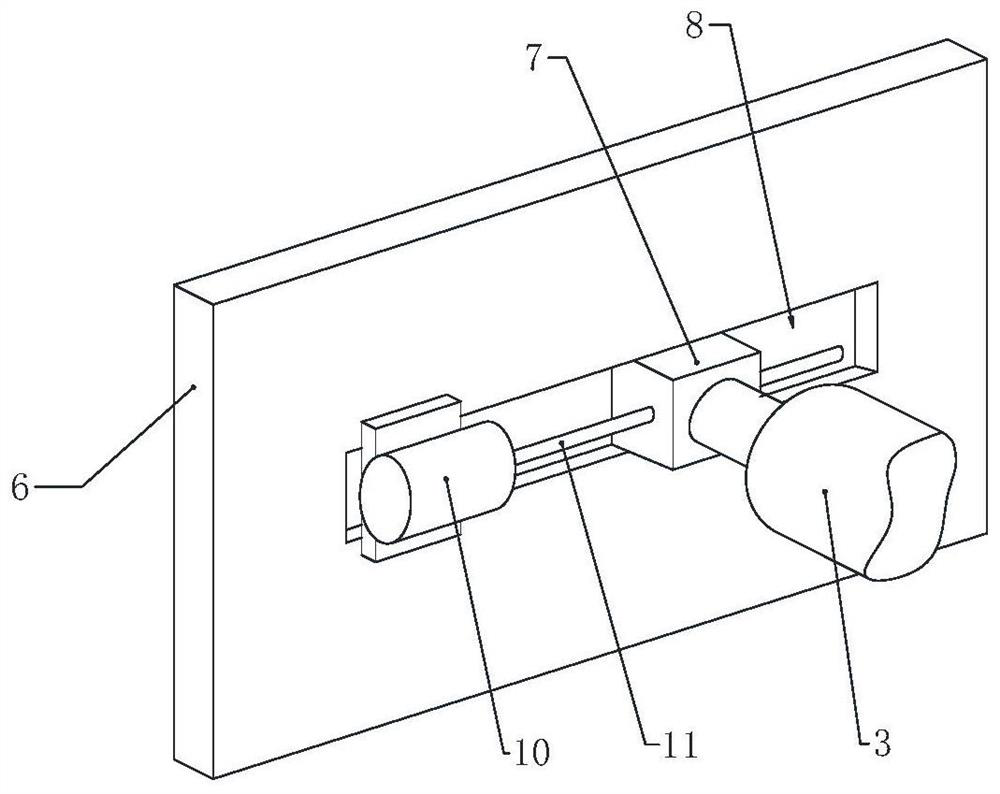

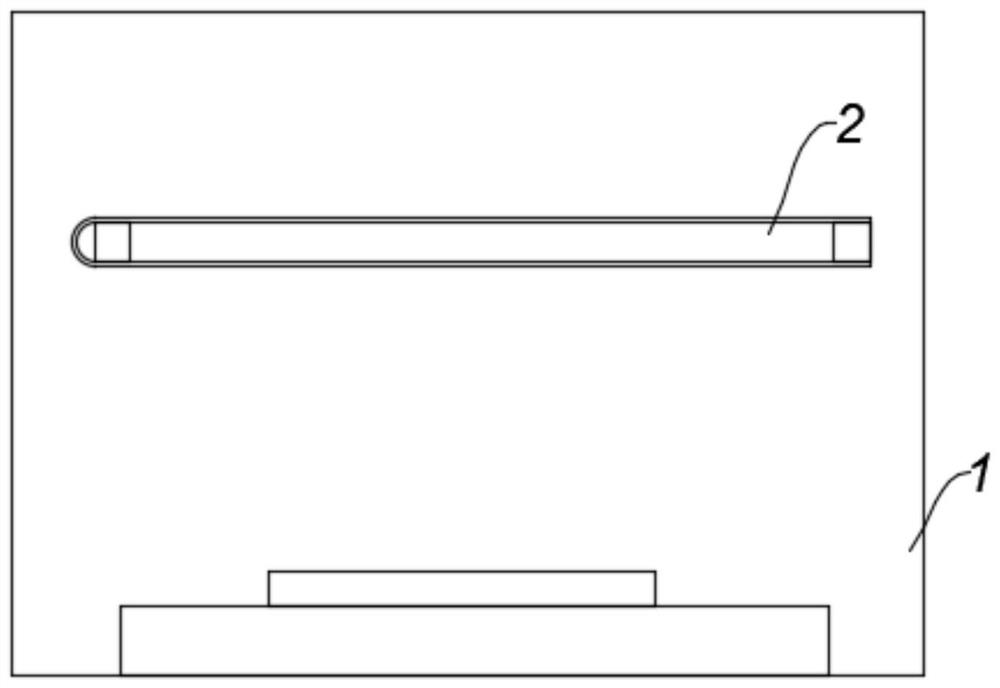

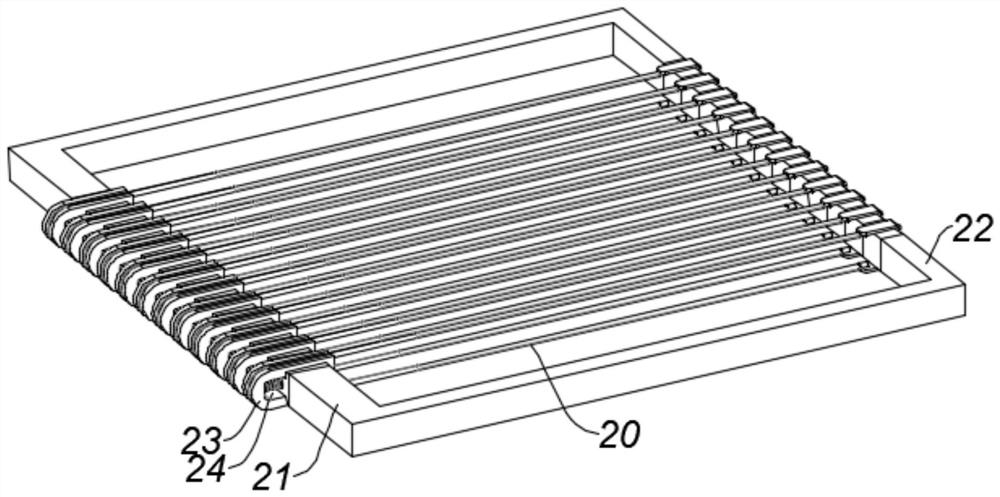

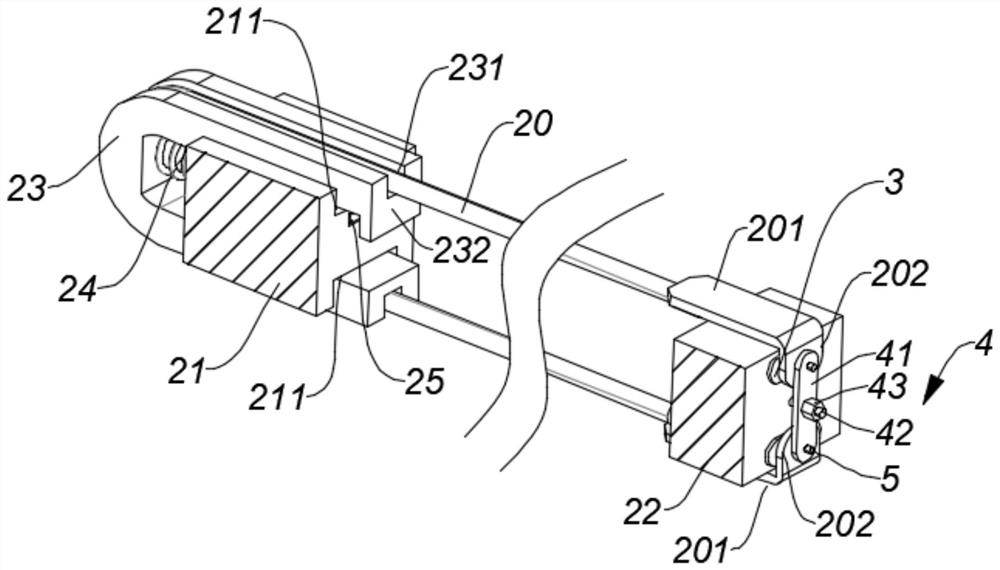

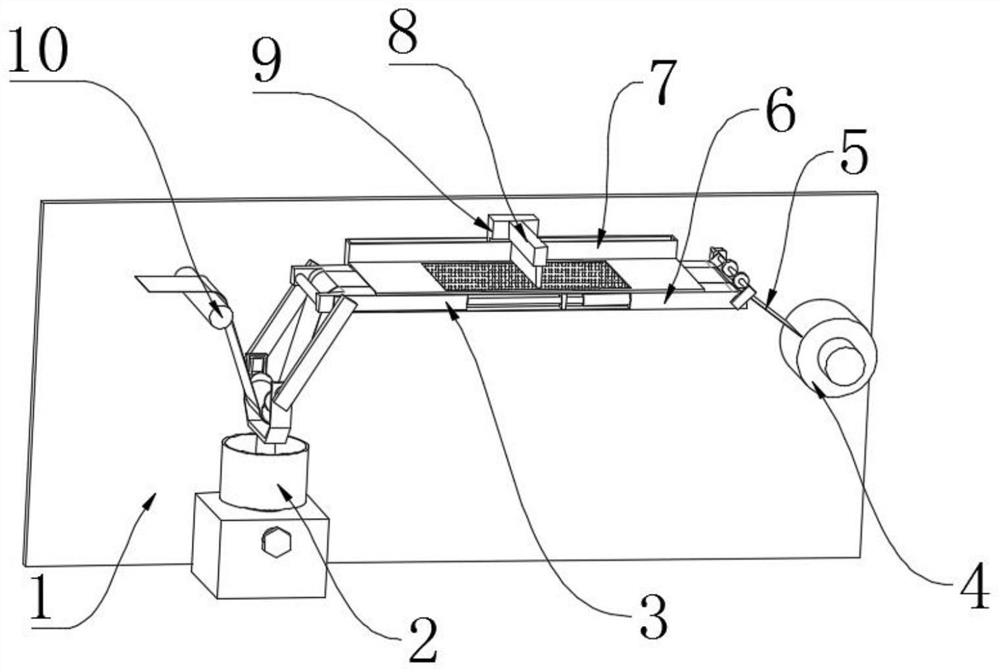

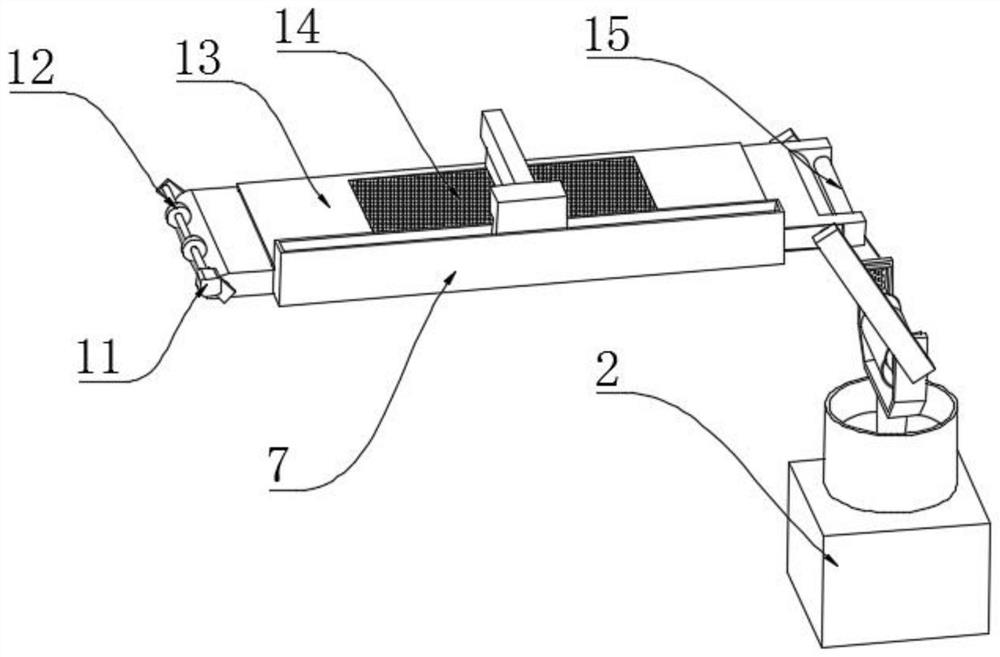

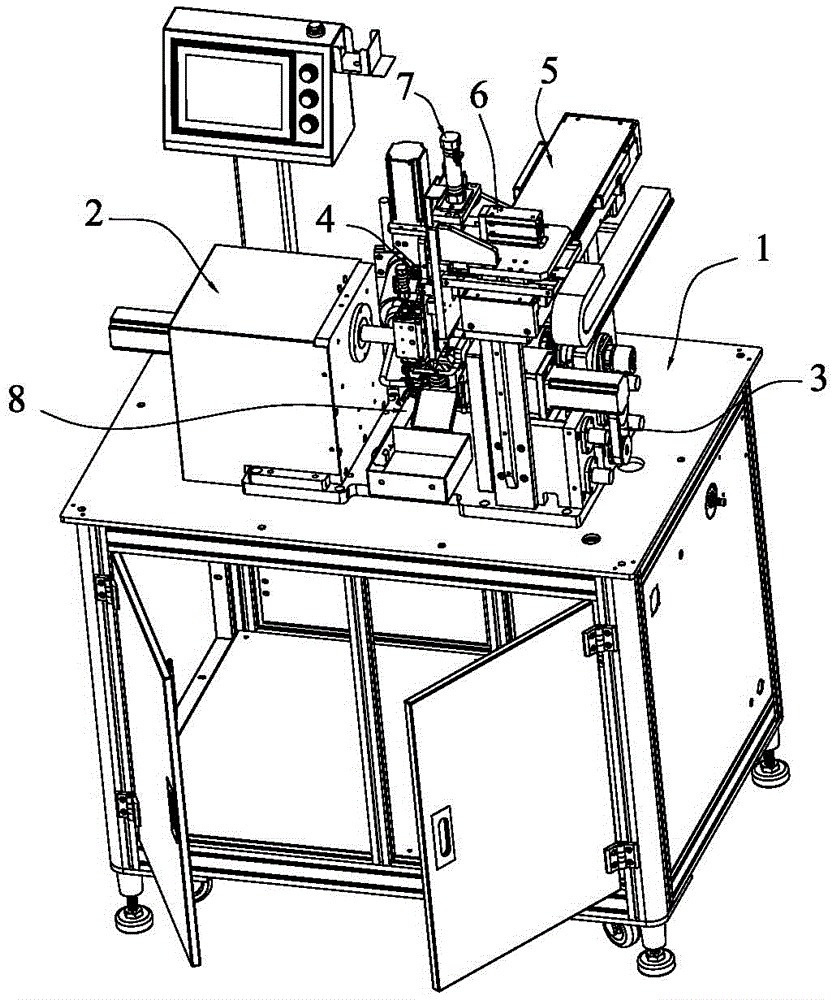

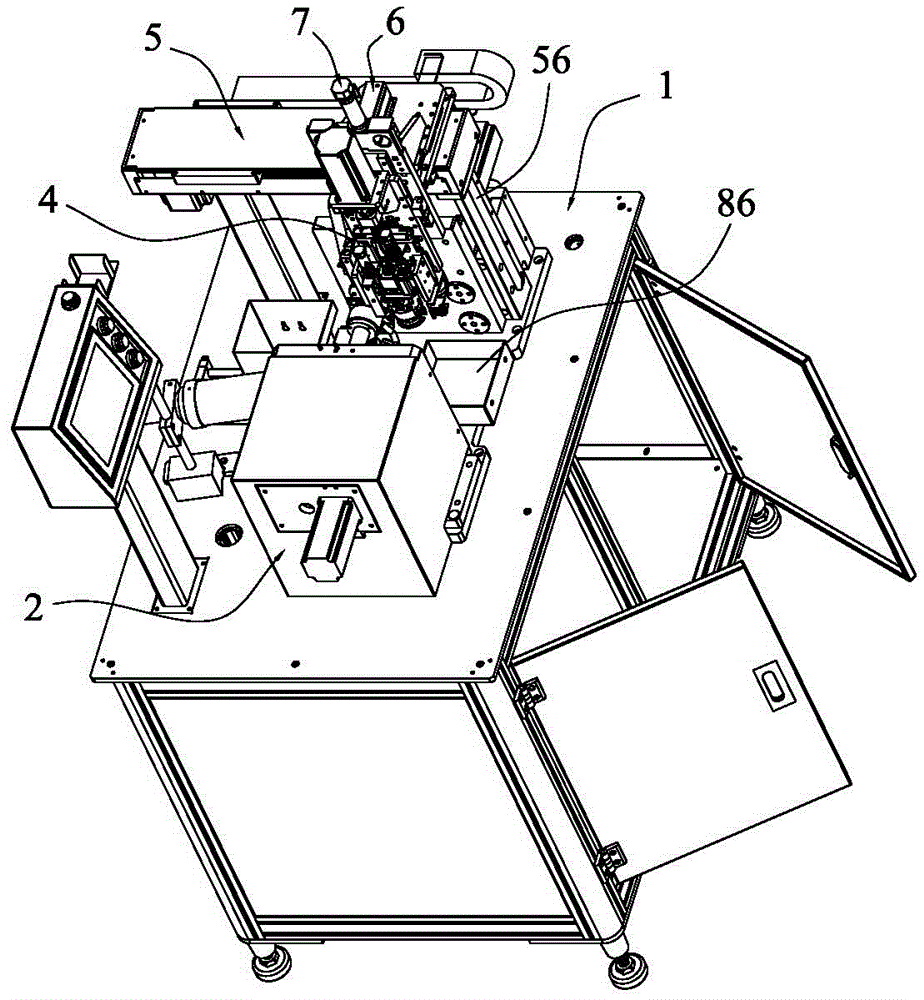

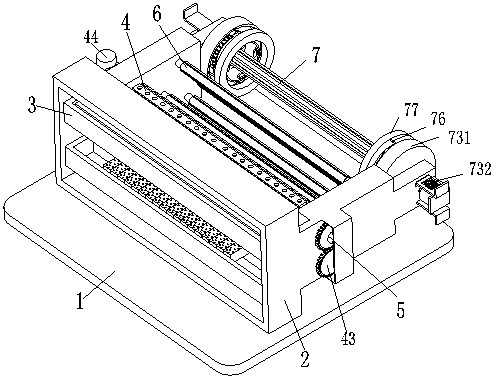

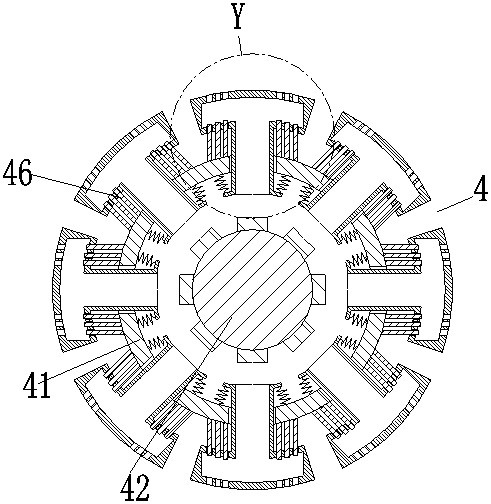

Full-automatic winding machine for wireless-charging coils

The invention discloses a full-automatic winding machine for wireless-charging coils. The full-automatic winding machine comprises a frame, a die head driving device, a wire arranging mechanism, a wire storing mechanism, a horizontal sliding mechanism, a longitudinal sliding mechanism, a vertical lifting and sliding mechanism and a discharging mechanism. The wire arranging mechanism is arranged on one side of the frame. The die head driving mechanism is arranged on the other side of the frame and is abutted against a die head of the wire arranging mechanism. The longitudinal sliding mechanism is arranged above the wire arranging mechanism through the horizontal sliding mechanism. The wire storing mechanism is arranged on the longitudinal sliding mechanism through the vertical lifting and sliding mechanism. The discharging mechanism is arranged between the wire arranging mechanism and the die head driving device. The full-automatic winding machine is ingenious and reasonable in design, smooth in operation, high in accuracy, high in working efficiency and good in winding quality; the die head of a split movable structure is arranged detachably, is convenient to mount and demount and has universality and interchangeability, and only replacement of proper die heads is needed for winding of different products, so that production cost is reduced, and production efficiency is improved; the full-automatic winding machine is applicable to winding of multilayer coils and wide in application range.

Owner:DONGGUAN ZHIGAN MACHINERY & ELECTRONICS TECHCO

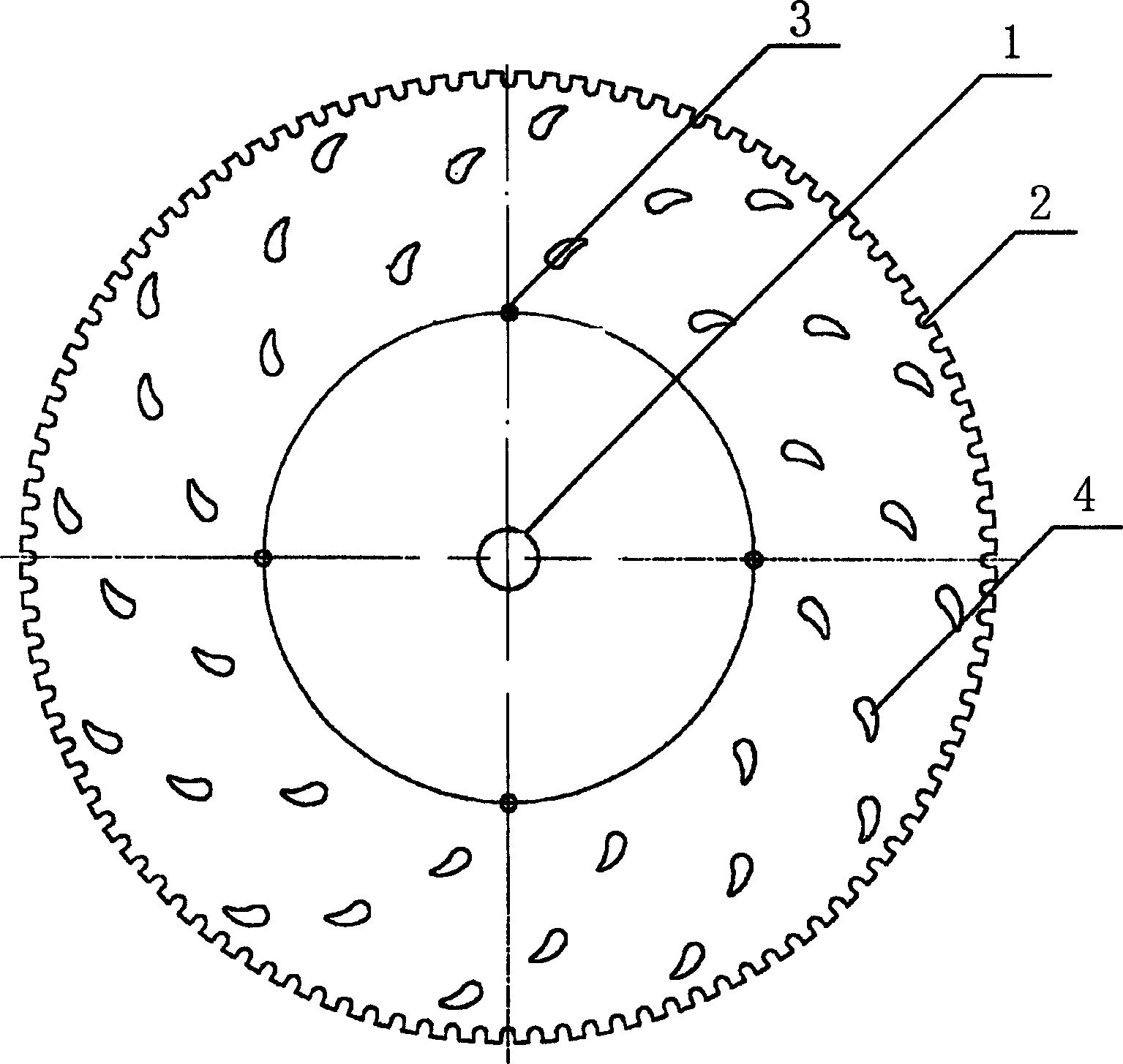

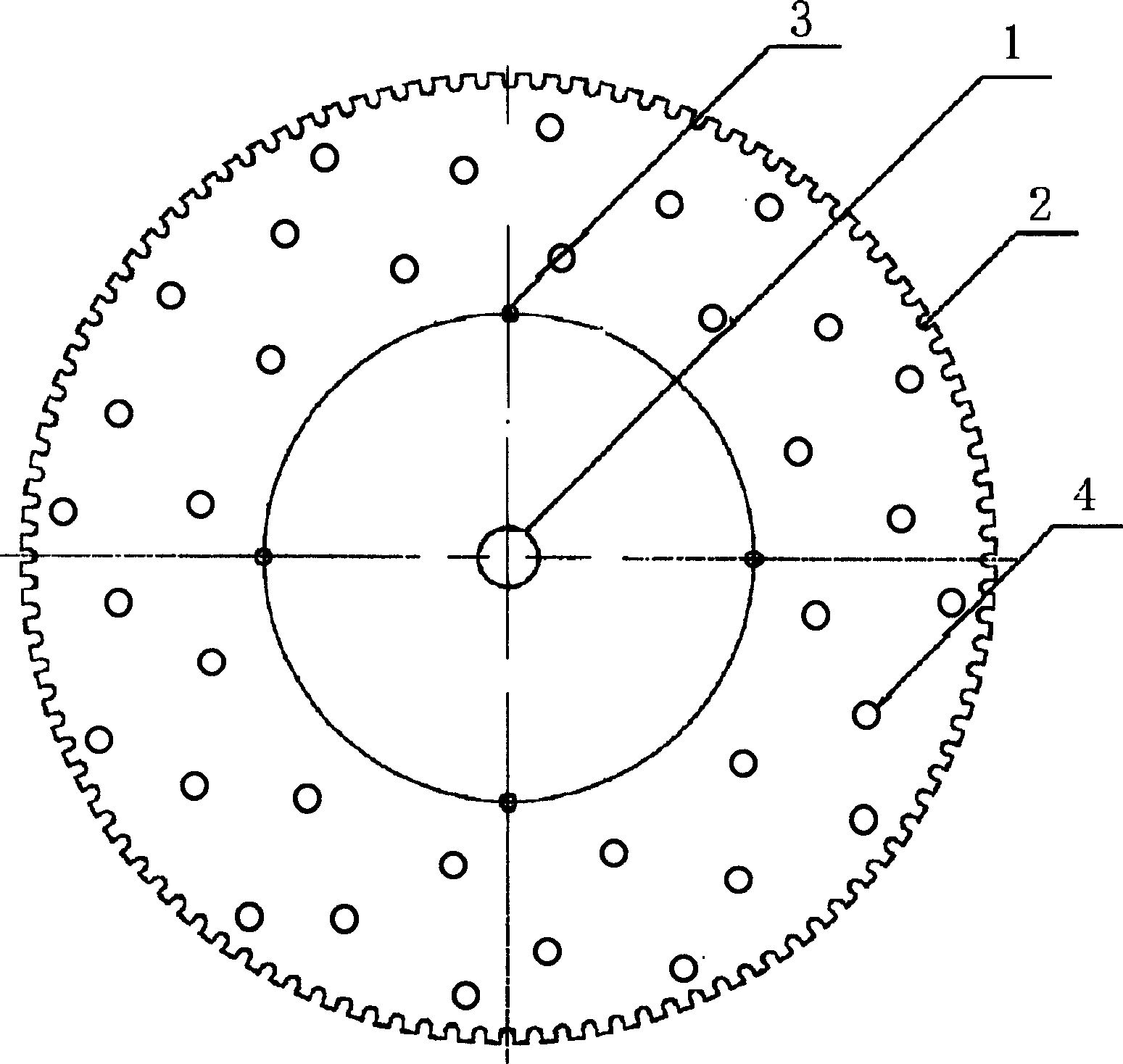

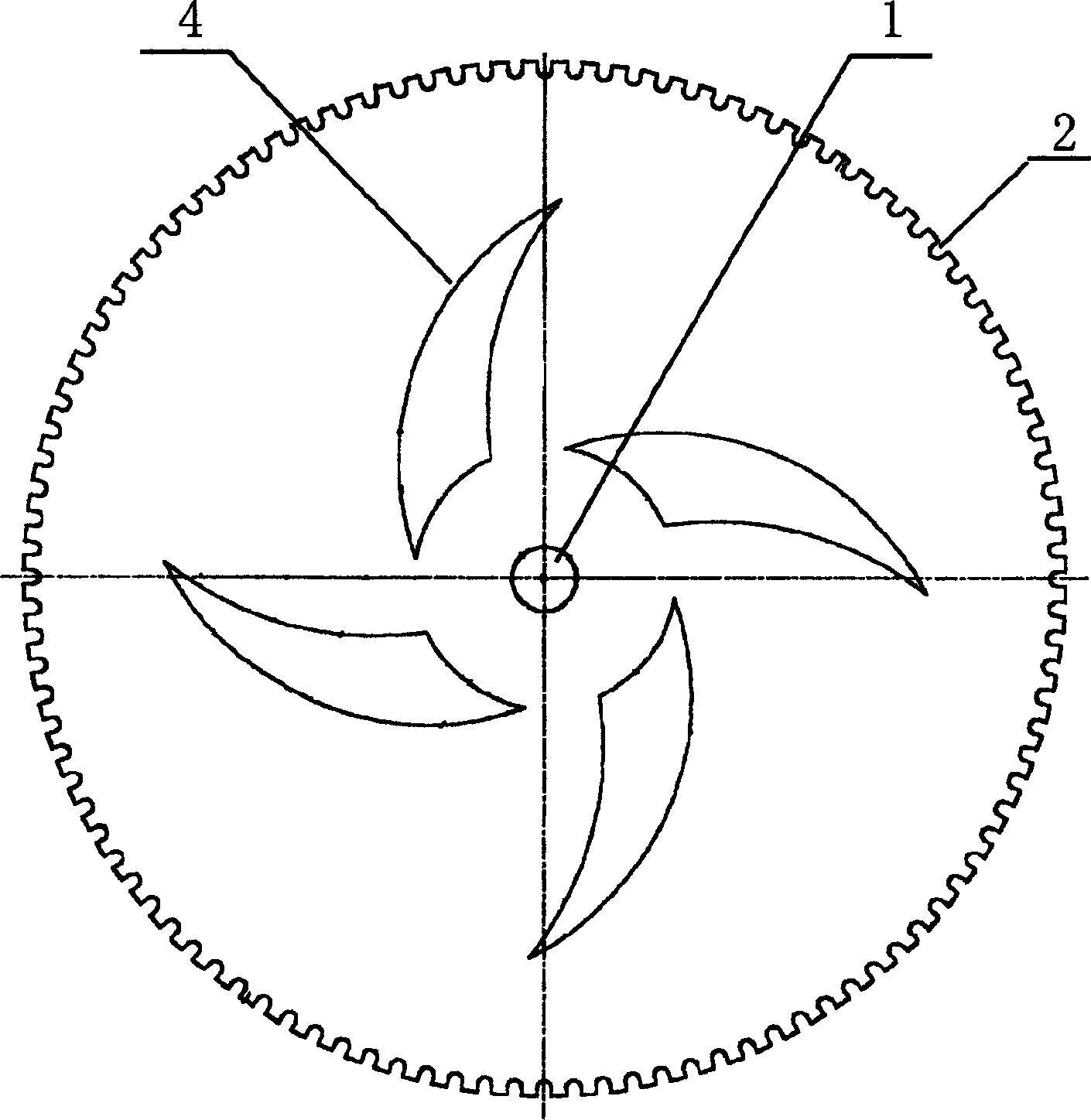

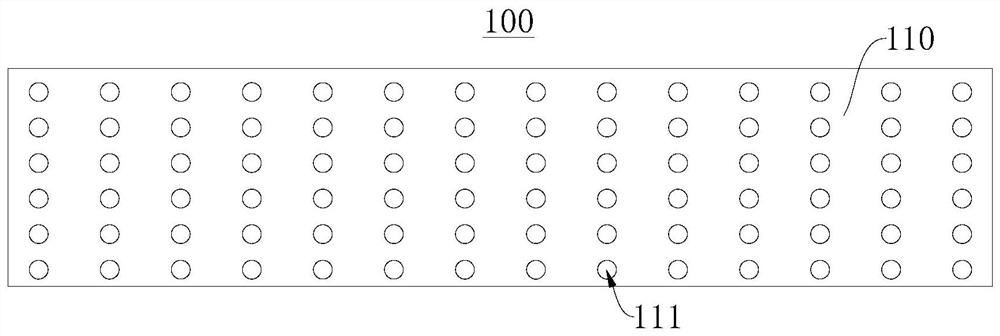

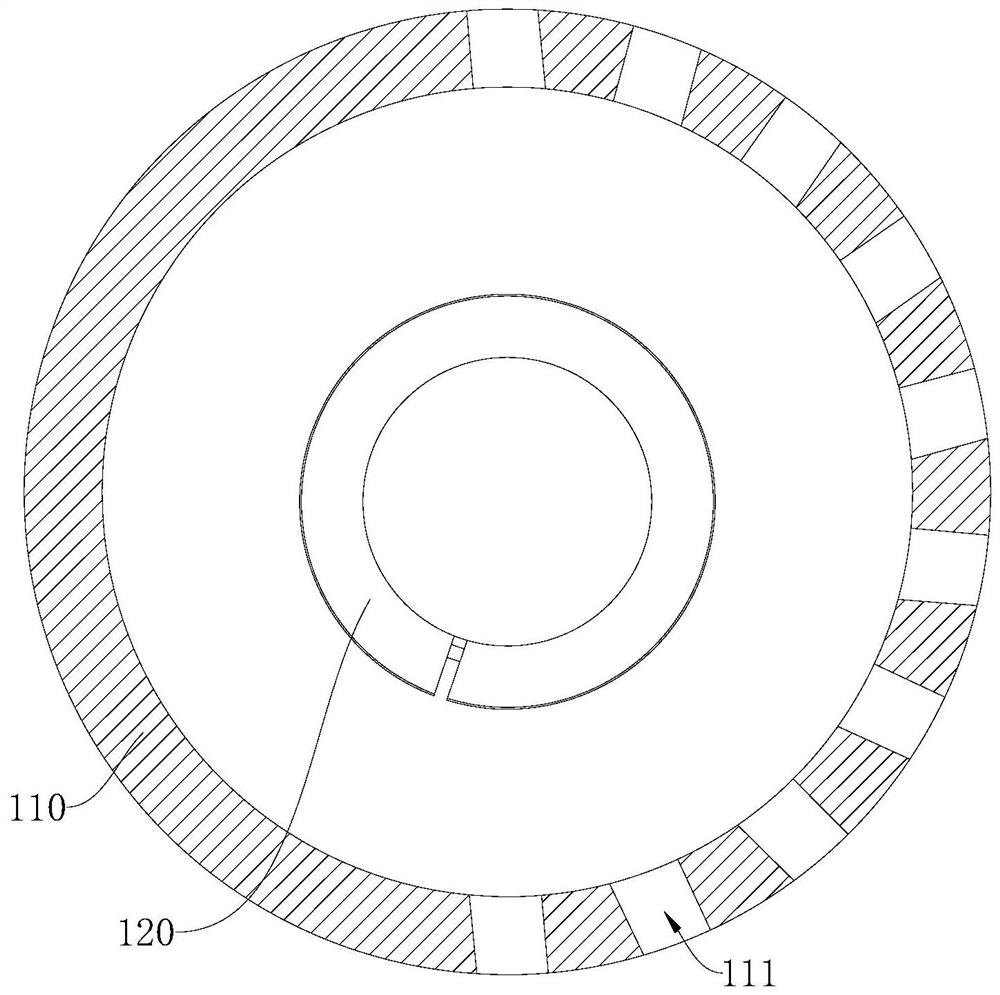

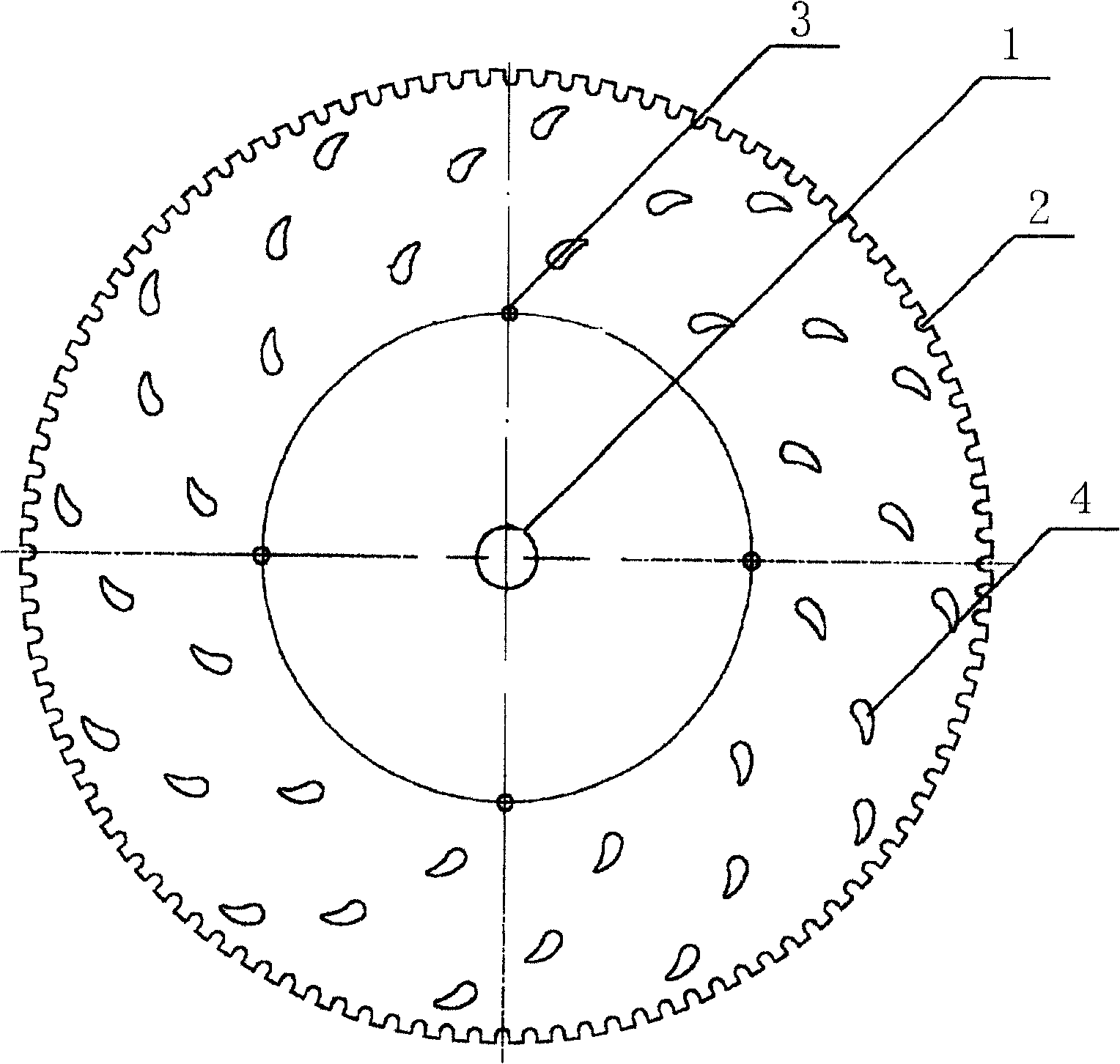

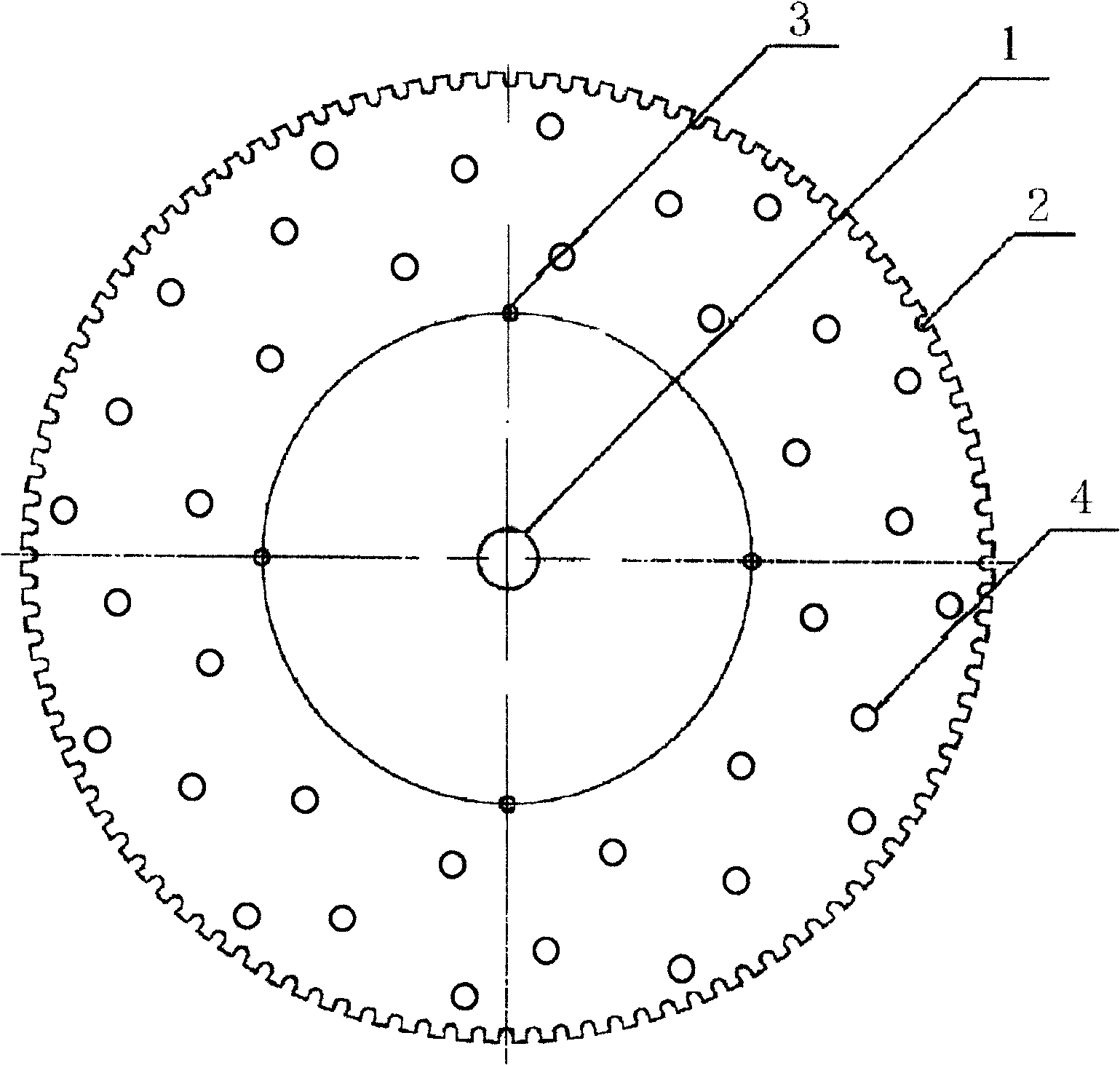

Saw web base body with hollowed holes

ActiveCN1544229AReduce frictionSmall cutting resistanceCircular sawsStone-like material working toolsEngineeringRadiation

The invention discloses a through hole saw blade basal body, there are central installation hole and processing locating hole, the outer edge of the basal body is made with water channel, and the through holes are uniformly distributed on the basal body. It reduces contact surface area, has small cutting resistance, effectively reduces noise, enhances heat radiation and cooling, and has simple process and lower fabrication cost.

Owner:HEIXUANFENG SAW IND

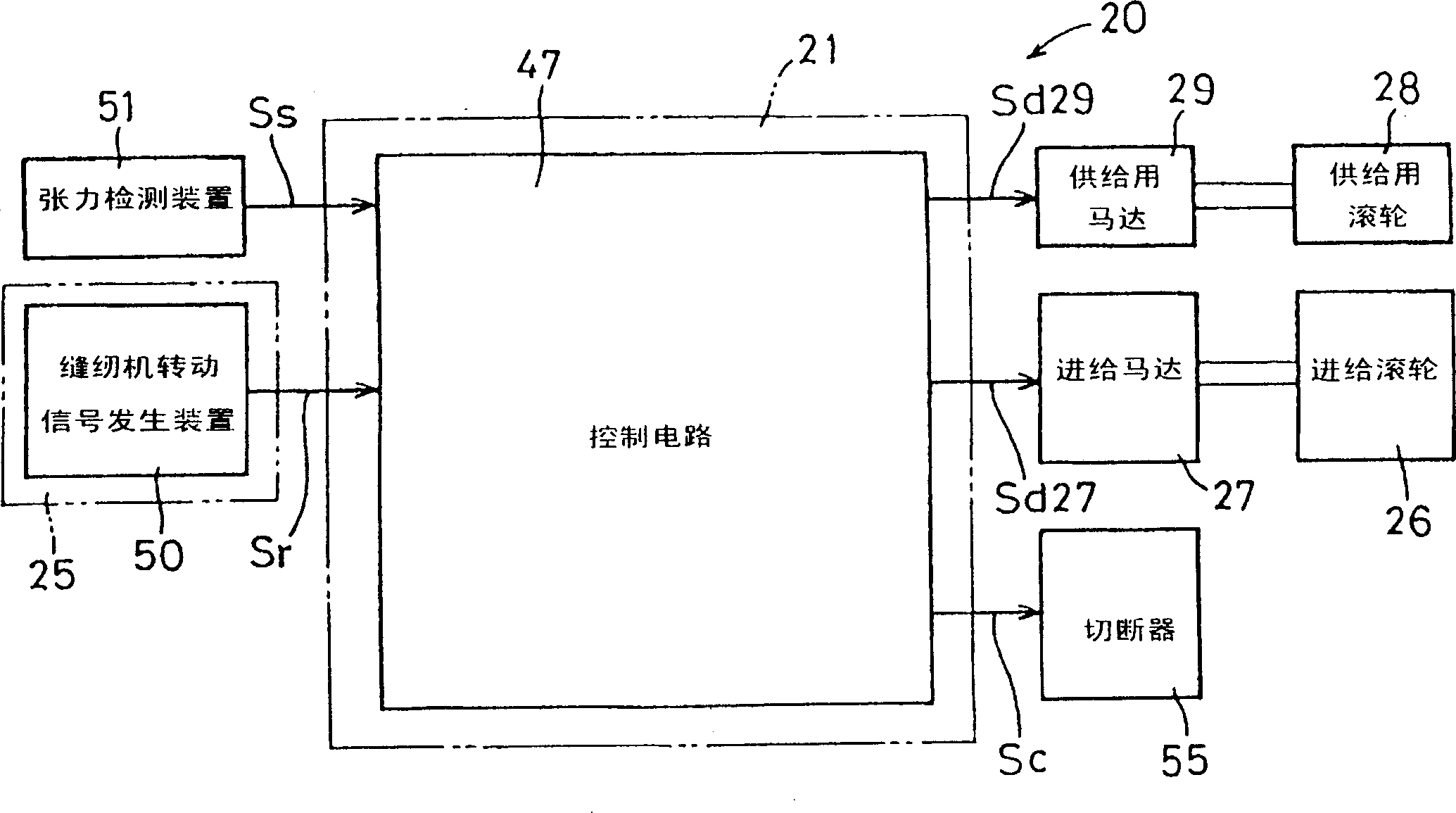

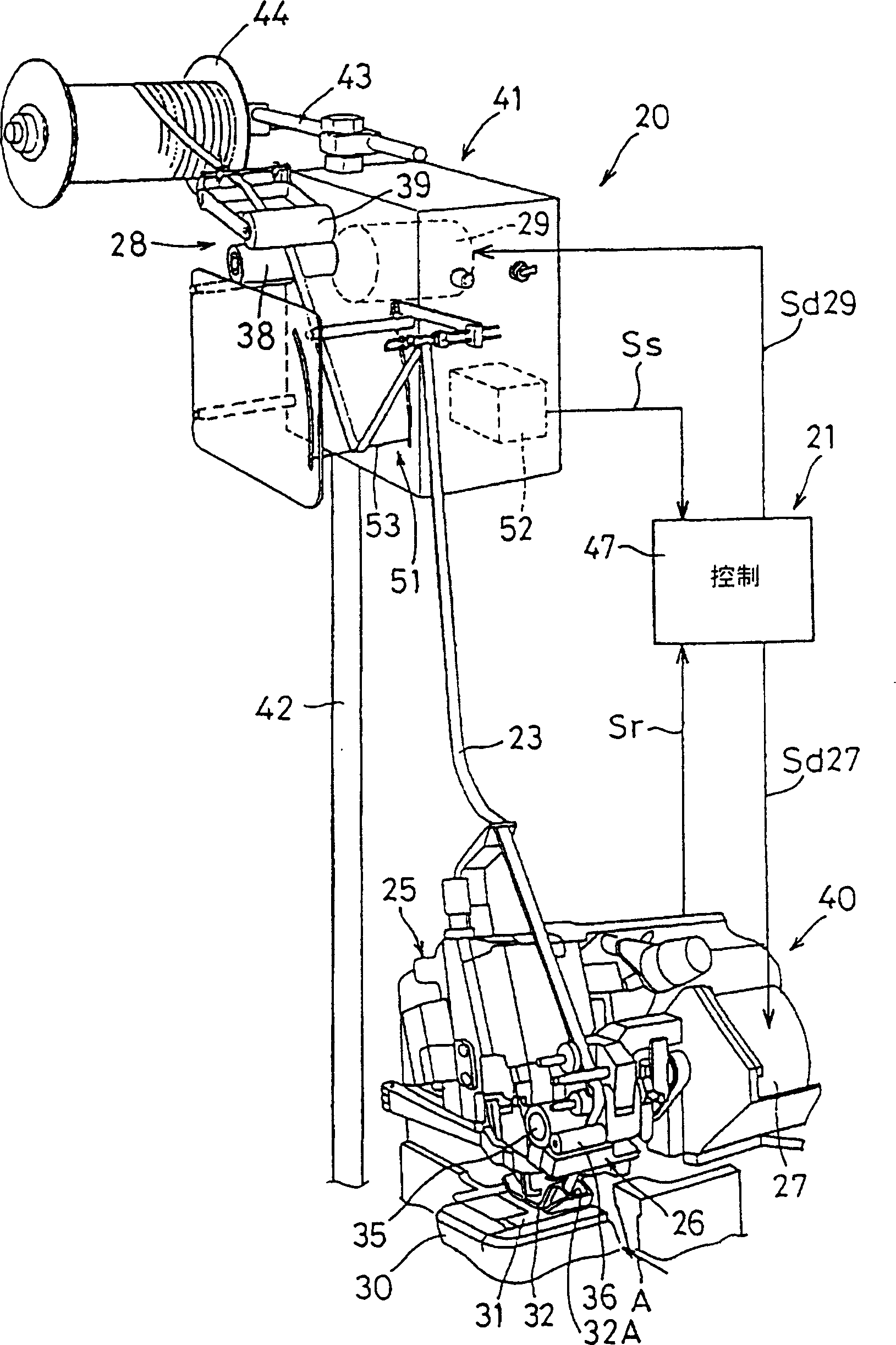

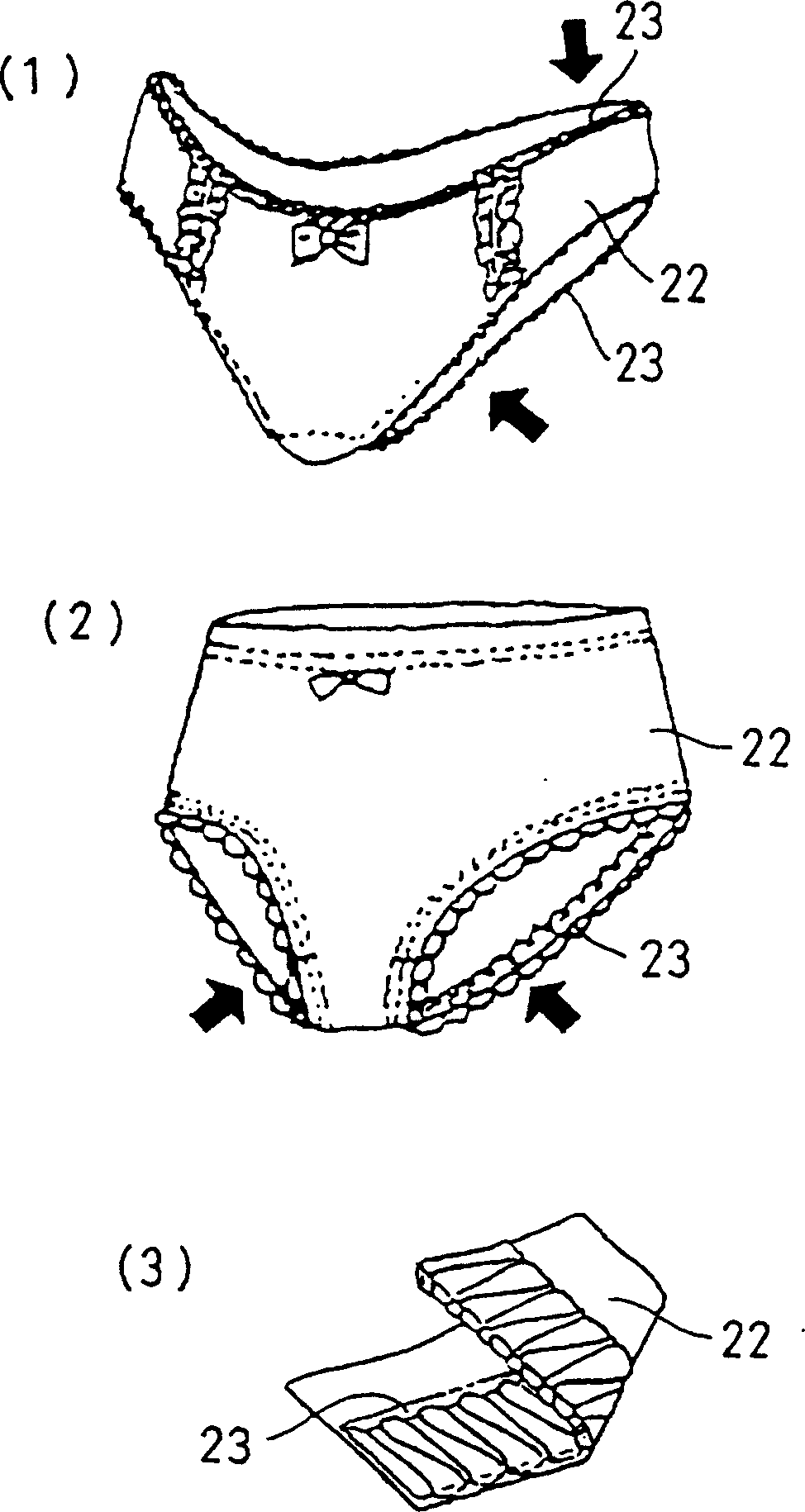

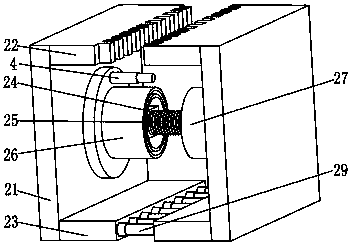

Controller of sewing device

InactiveCN1456729AAvoid changeAvoid entanglementWork-feeding meansSewing-machine control devicesEngineeringControl circuit

The invention provides a controller of sewing device, which is to make uniform the tension of a belt-shaped object sent into a sewing means, to prevent the enlargement of the size of a sewing machine and further to facilitate maintenance. Synchronously with the sewing movement of the sewing means 25, a sending-in driving means 27 and a supply driving means 29 are controlled by one control circuit 47. Therefore a sending-in means 26 and a supply drive means 28 can be controlled synchronously with the sewing movement, in correlation with each other. According to this constitution, it is possible to prevent a change in the tension of the belt-shaped object 23 between the sending-in means 26 and the supply means 28 due to the individual operations of the means 26 and 28, to prevent a change in the tension of the belt-shaped object 23 sent into the sewing means 25 due to the change in the tension between the means 26 and 28 and to maintain the tension to be uniform substantially.

Owner:YAMATO SEWING MASCH MFG CO LTD

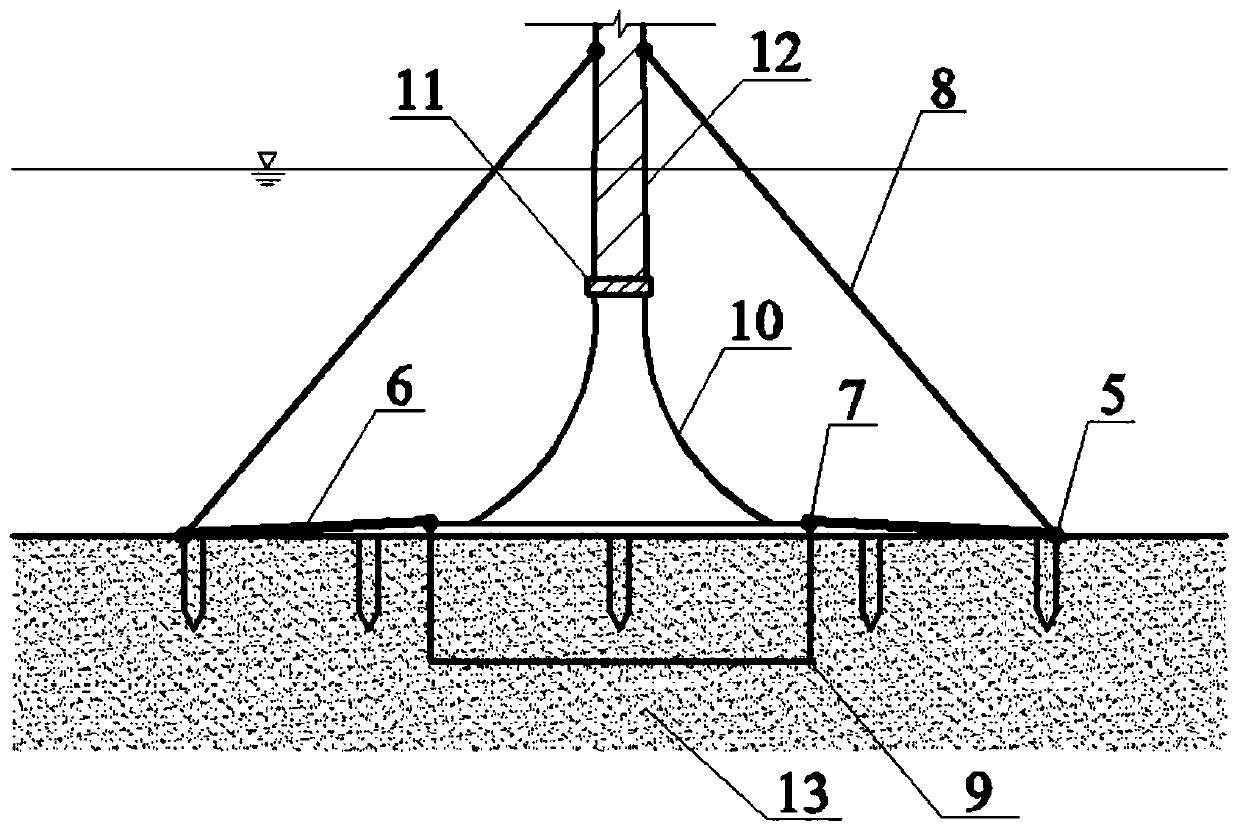

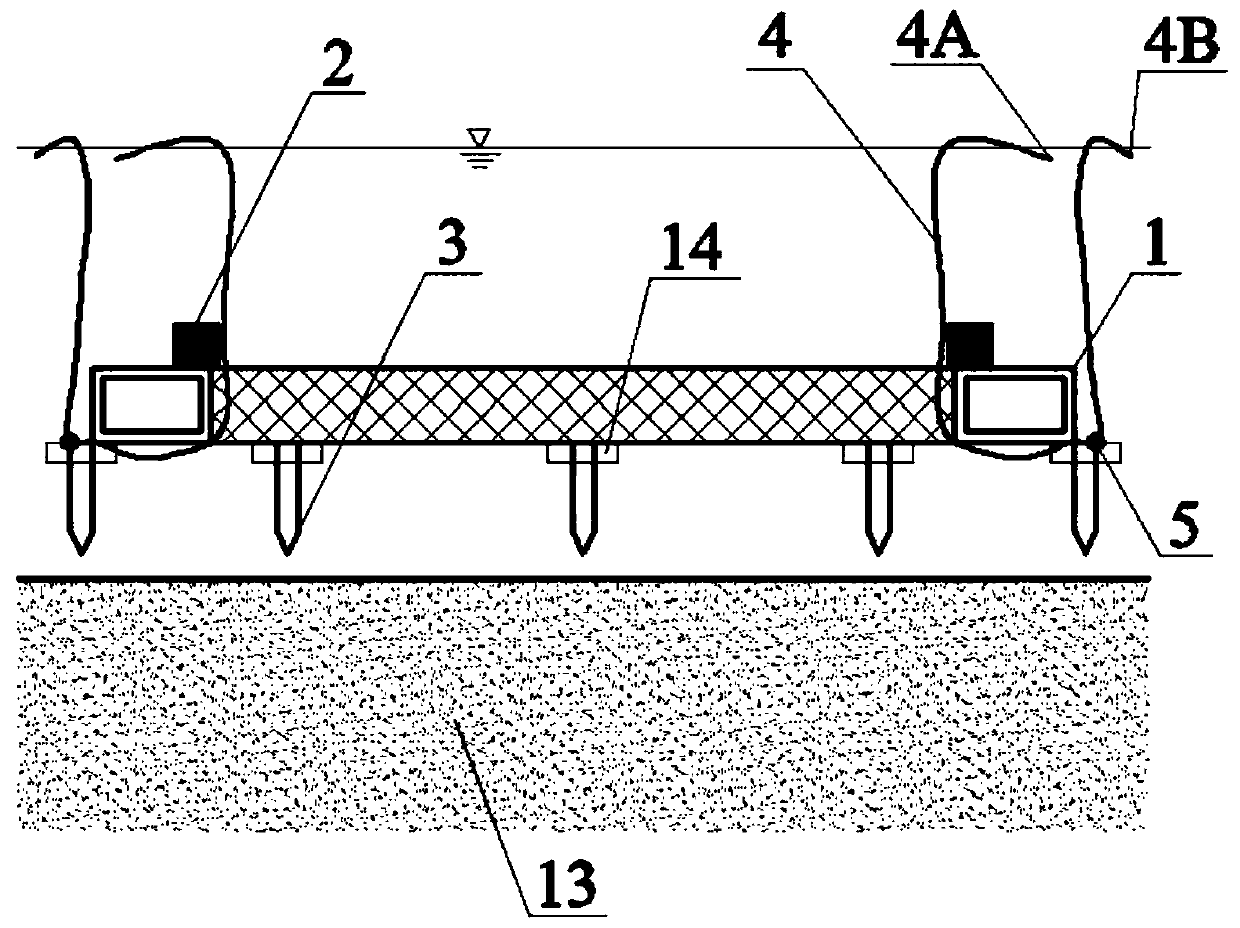

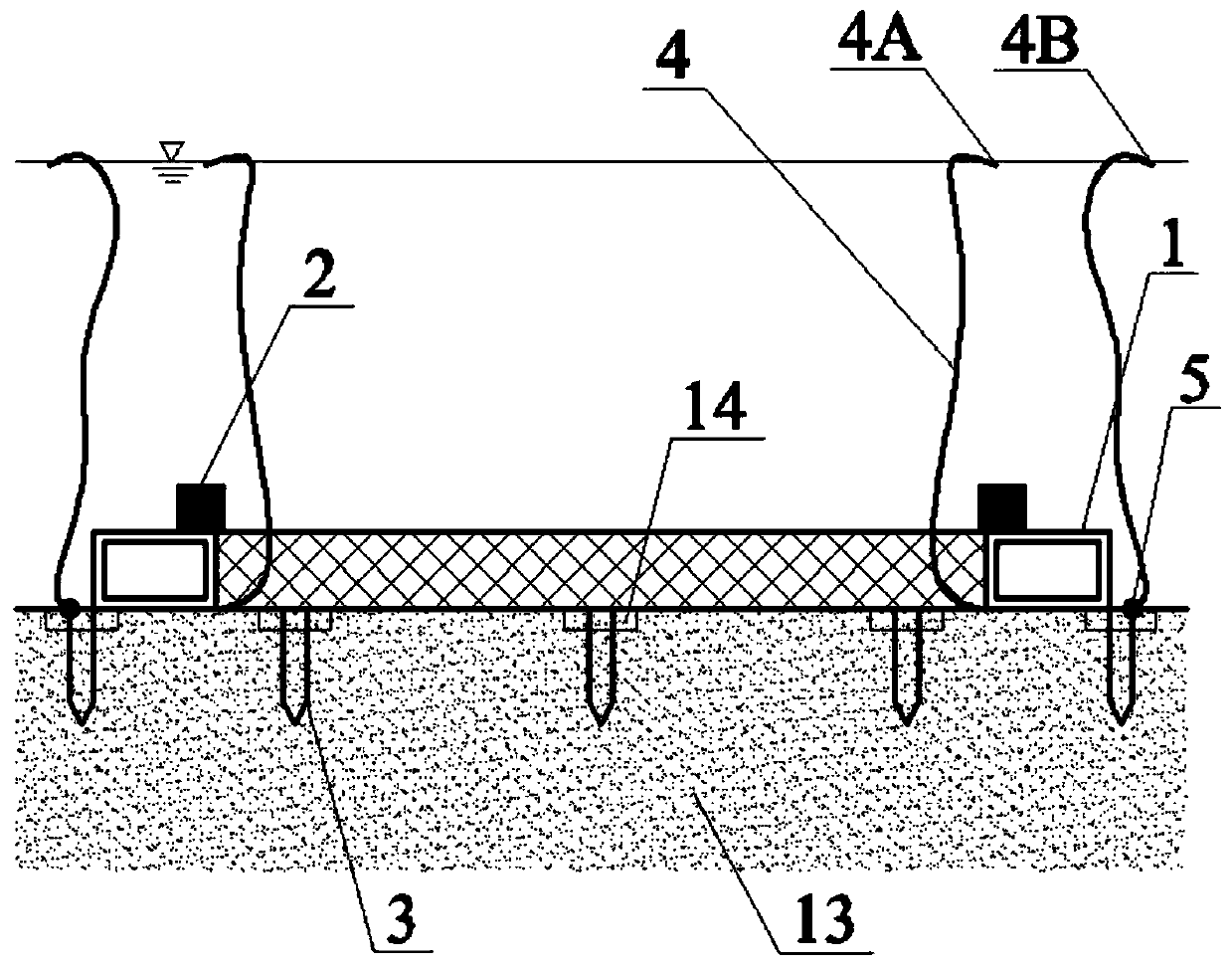

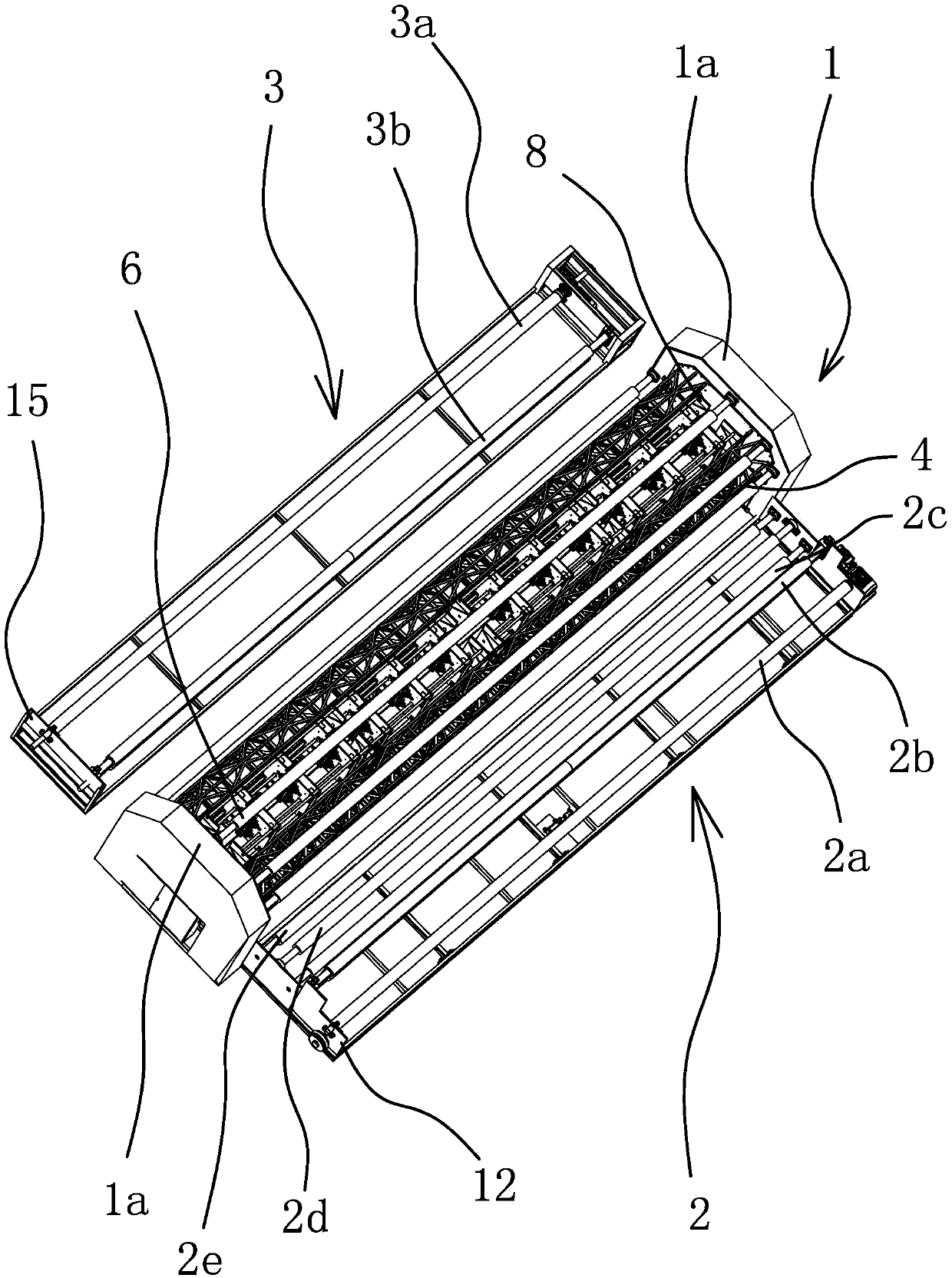

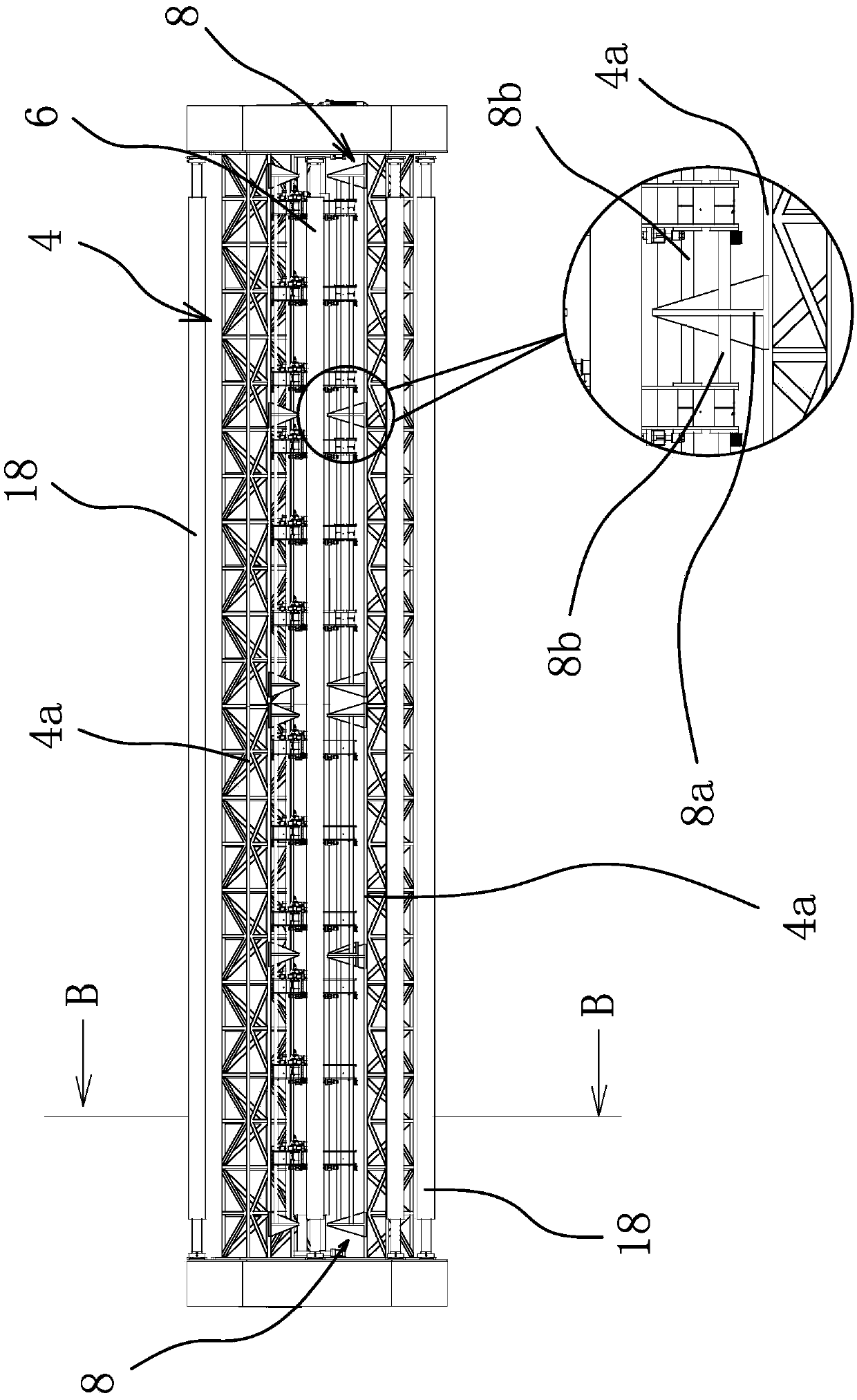

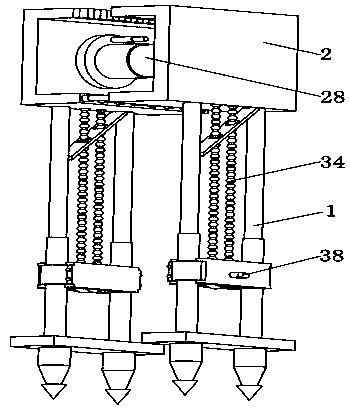

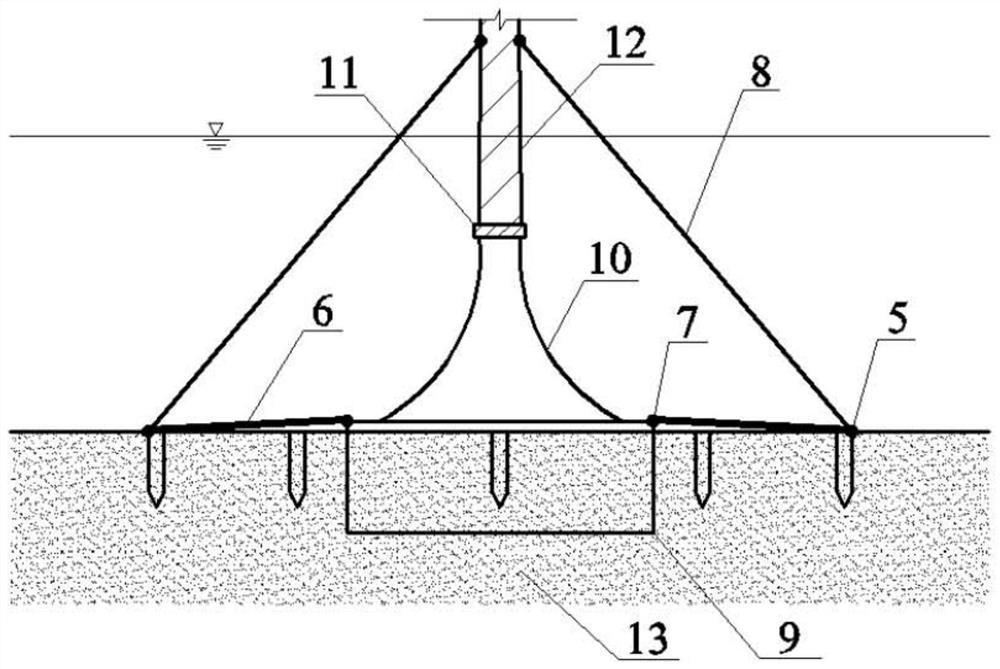

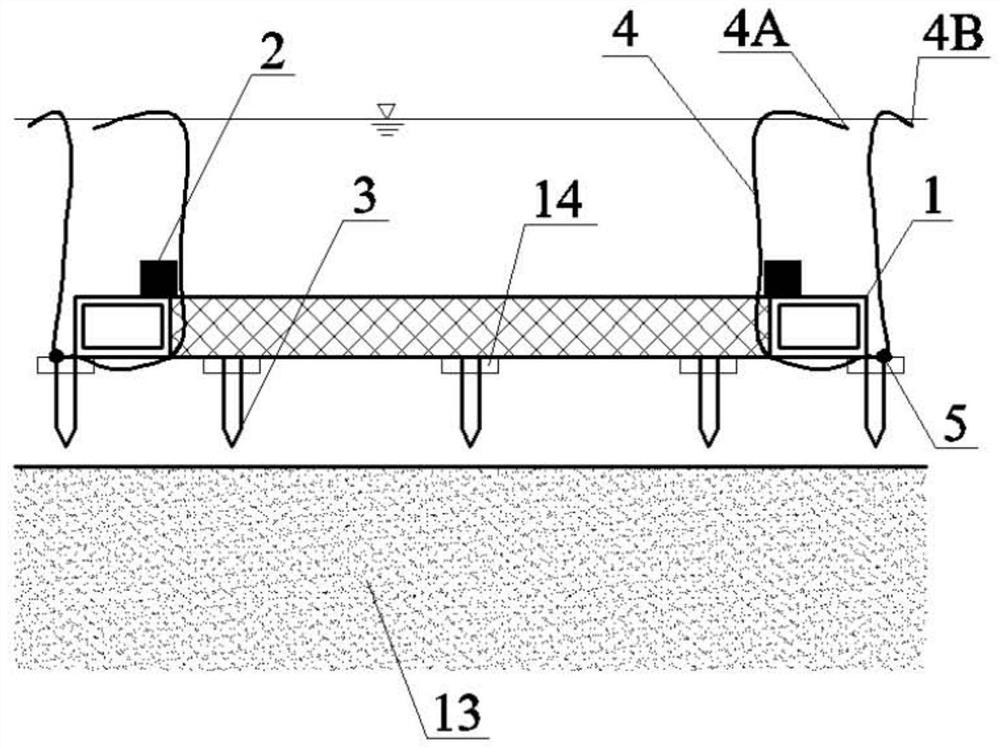

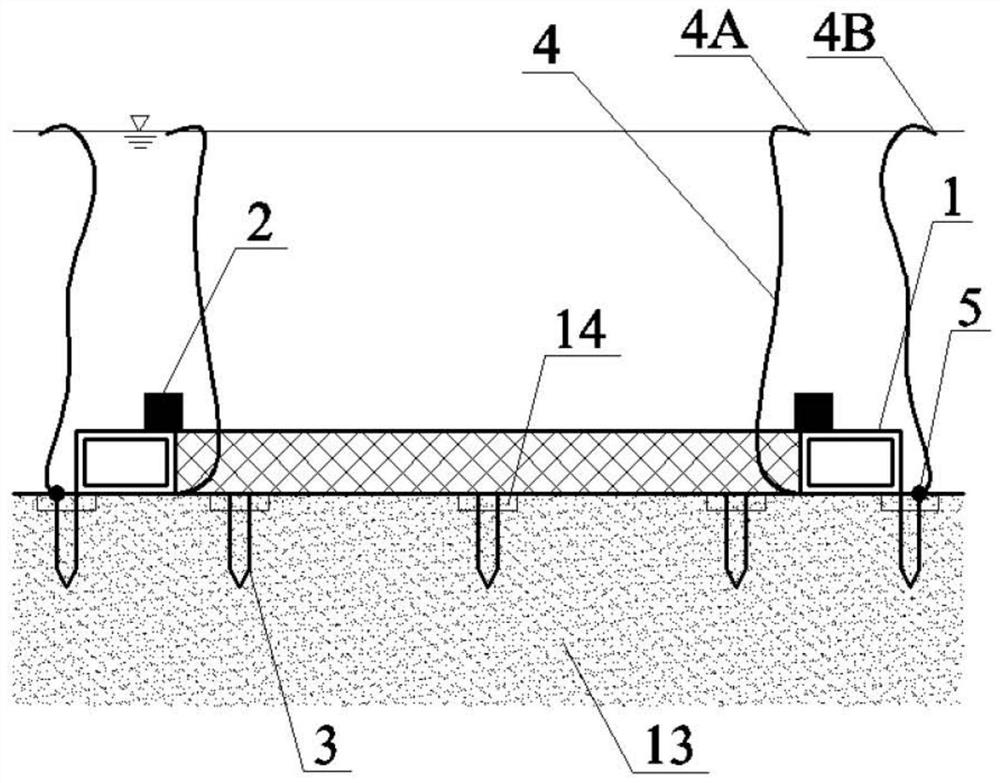

Offshore wind power foundation anti-scouring structure and construction method thereof

ActiveCN111535352ATension effectTensile reactionFoundation engineeringArchitectural engineeringOffshore wind power

The invention discloses an offshore wind power foundation anti-scouring structure and a construction method thereof. The offshore wind power foundation anti-scouring structure comprises a cylindricalfoundation arranged on a seabed and aligned to the seabed level, and a horn-shaped foundation transition section with the cross section decreasing from bottom to top is arranged on the top surface ofthe cylindrical foundation, a tower tube is fixedly arranged at the top of the foundation transition section through a flange plate, short piles pressed into the seabed are arranged at the periphery of the cylindrical foundation in the circumferential direction, second buckles are fixedly arranged at the intersections of connecting lines of each short pile pointing to the center of the cylindricalfoundation and the periphery of the cylindrical foundation, first buckles are fixedly arranged on the top sides of the short piles, annular covering films are laid between the second buckles and thefirst buckles, inner rings of the covering films are fixedly connected with the second buckles, and outer rings of the covering films are tightened by first cables arranged on the first buckles; the other ends of the first cables are fixedly connected to the tower tube. The invention aims to provide a fast, efficient and economical erosion protection method for the cylindrical foundation, and theoverall safety performance of the cylindrical foundation is improved.

Owner:TIANJIN UNIV

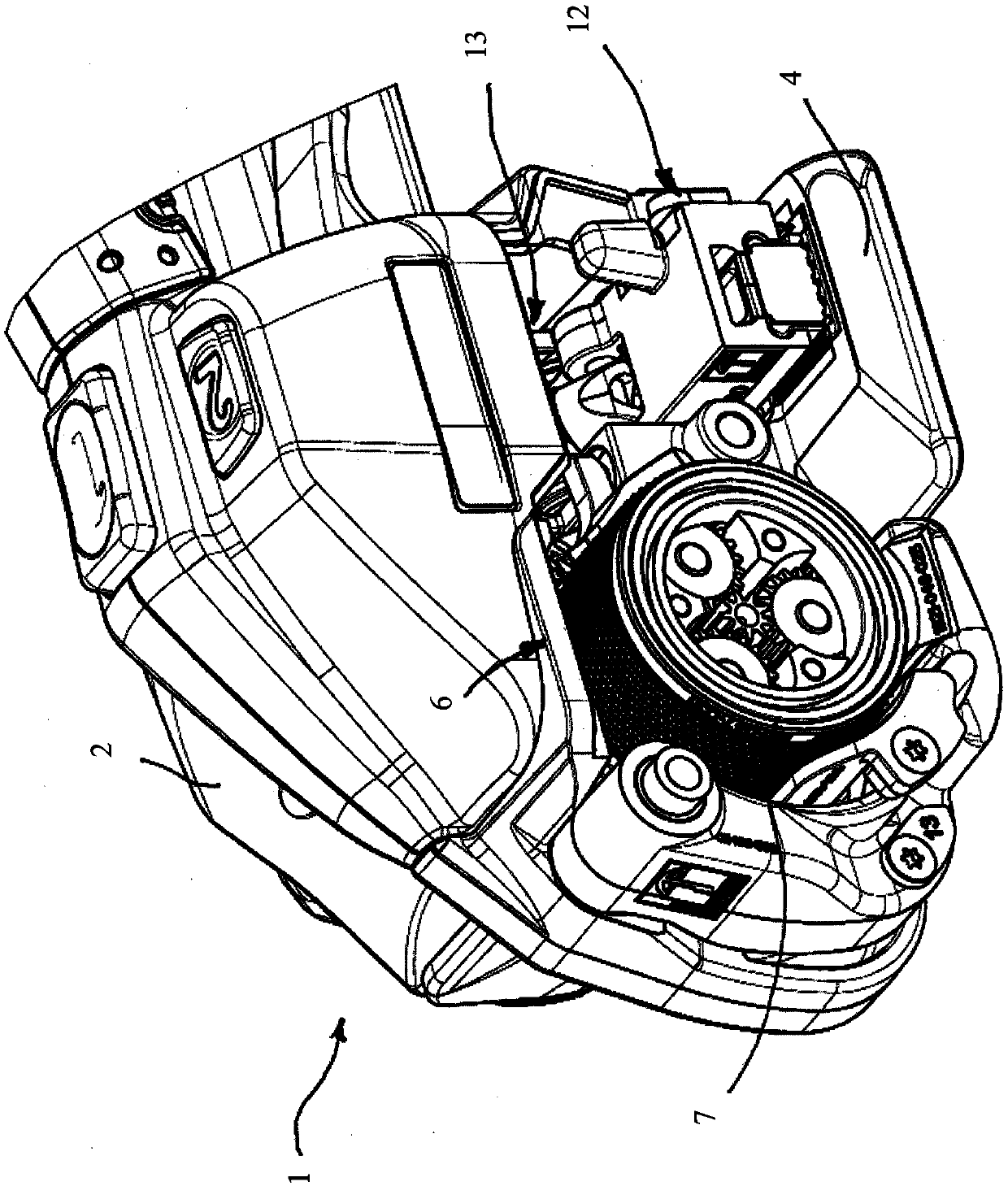

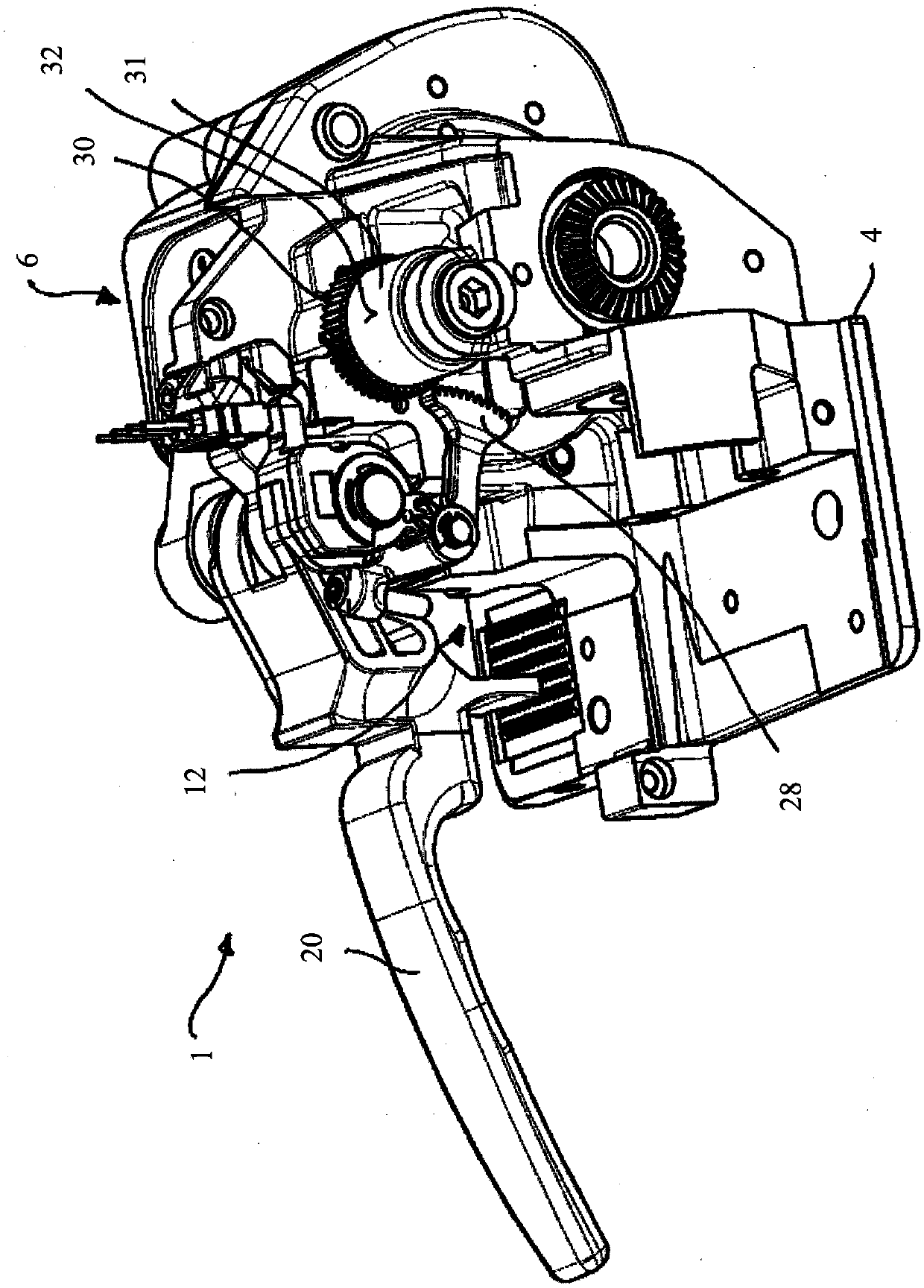

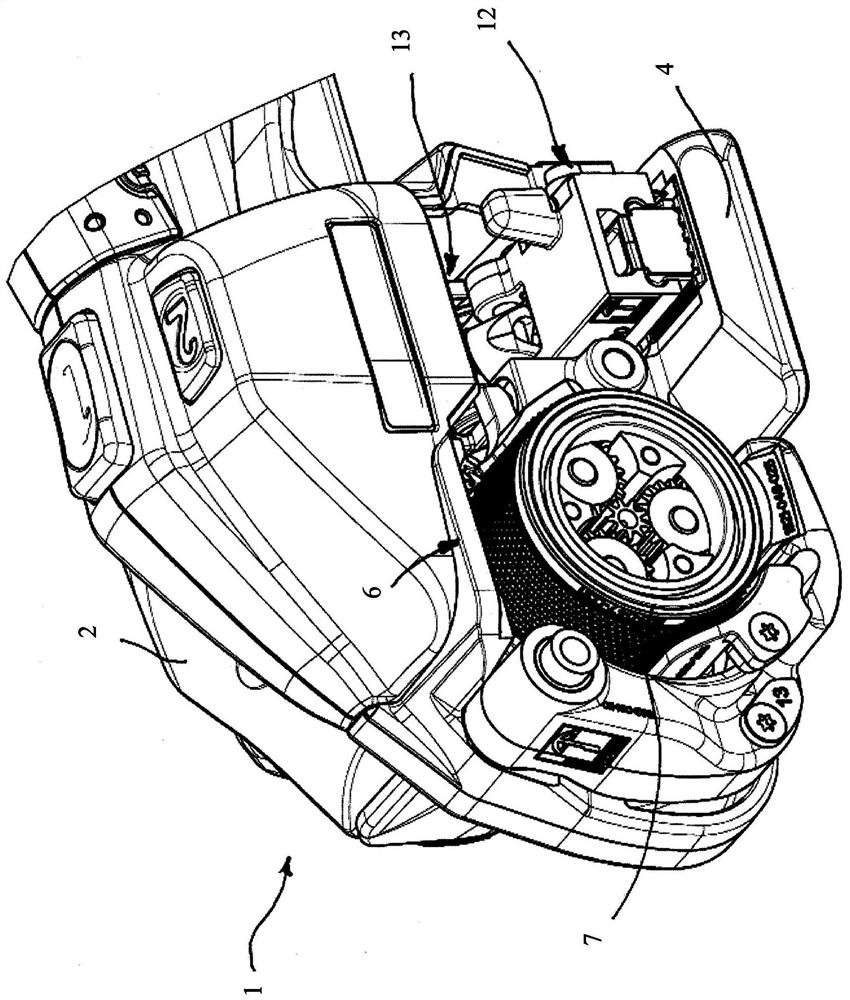

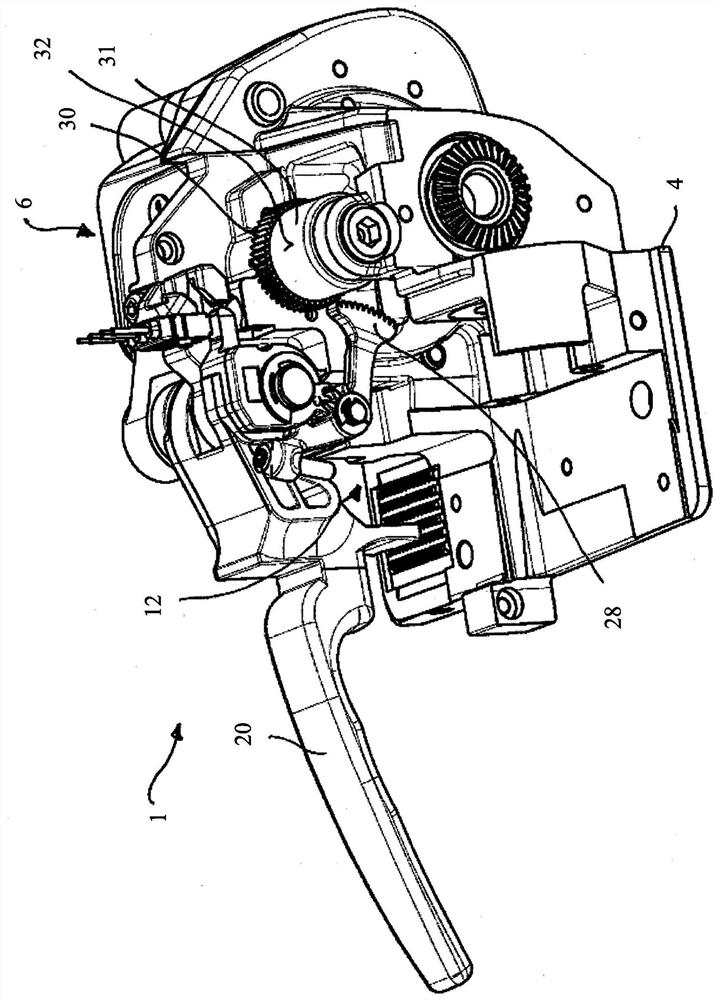

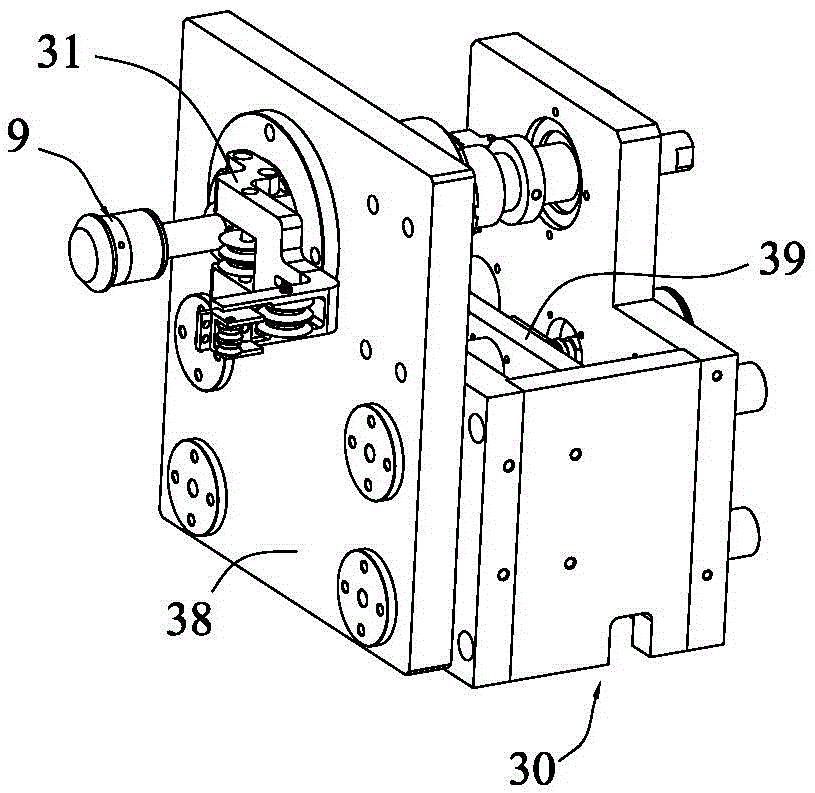

Strapping apparatus

ActiveCN109689505ATension effectAvoid sudden changesBinding material applicationBundling machine detailsClassical mechanicsStructural engineering

The invention discloses a strapping apparatus for strapping articles with a strapping band having a tensioning device for imparting a band tension to a loop of the strapping band, the tensioning device including a driveable tensioning element provided for engaging the strapping band to impart a band tension. The strapping apparatus including a connecting device for generating a permanent connection, in particular a welded connection, at two regions, situated one above the other, of the loop of the strapping band. The strapping apparatus is configured to achieve the release of the tensioning element from the strapping band reliably to avoid or reduce adverse characteristics attributed to the release of the tensioning device from the band.

Owner:SIGNODE IND GRP

Gaseous phase anti-rust paper winding equipment based on integral cutting and gluing

ActiveCN108677607AImprove buffering effectReduce tensionPaper/cardboardMetal working apparatusGas phasePulp and paper industry

The invention discloses gaseous phase anti-rust paper winding equipment based on integral cutting and gluing, and relates to the technical field of gaseous phase anti-rust paper processing equipment.The gaseous phase anti-rust paper winding equipment based on the integral cutting and gluing comprises a workbench, wherein two ends of the bottom surface of the workbench are fixedly provided with two supporting legs; the top surface of the workbench is welded with a box body; the front side of the box body is provided with a discharge hole; the bottom of the left side surface of the box body isprovided with a feeding hole. According to the gaseous phase anti-rust paper winding equipment based on the integral cutting and gluing, a buffer device, a cutting device, a gluing device, a winding device, a positioning device and a conveying device are cooperated, so that technical equipment for anti-rust paper processing has uniformity, so that the work efficiency of anti-rust paper processingcan be improved to a high degree, meanwhile, gluing after the anti-rust paper is cut can be conveniently finished so as to lighten the labor intensity of workers, and the practicality of the anti-rustpaper winding processing equipment is further improved.

Owner:MAANSHAN STEEL PACKAGING MATERIALS TECH CO LTD

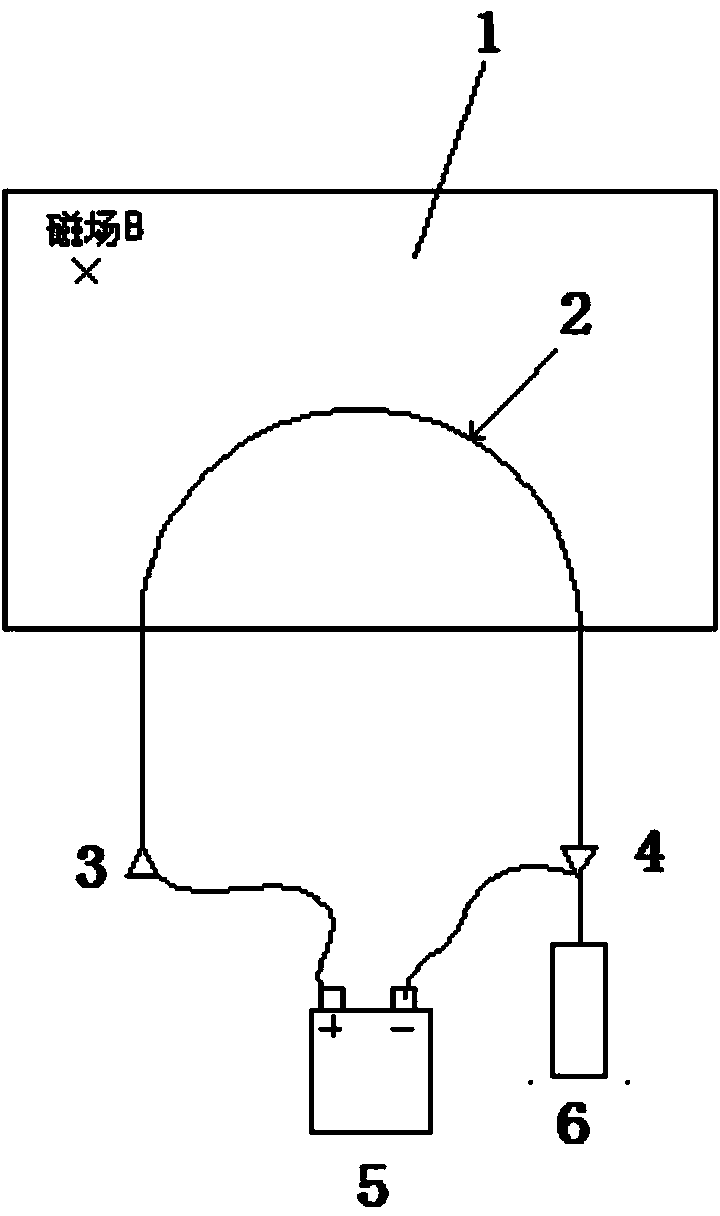

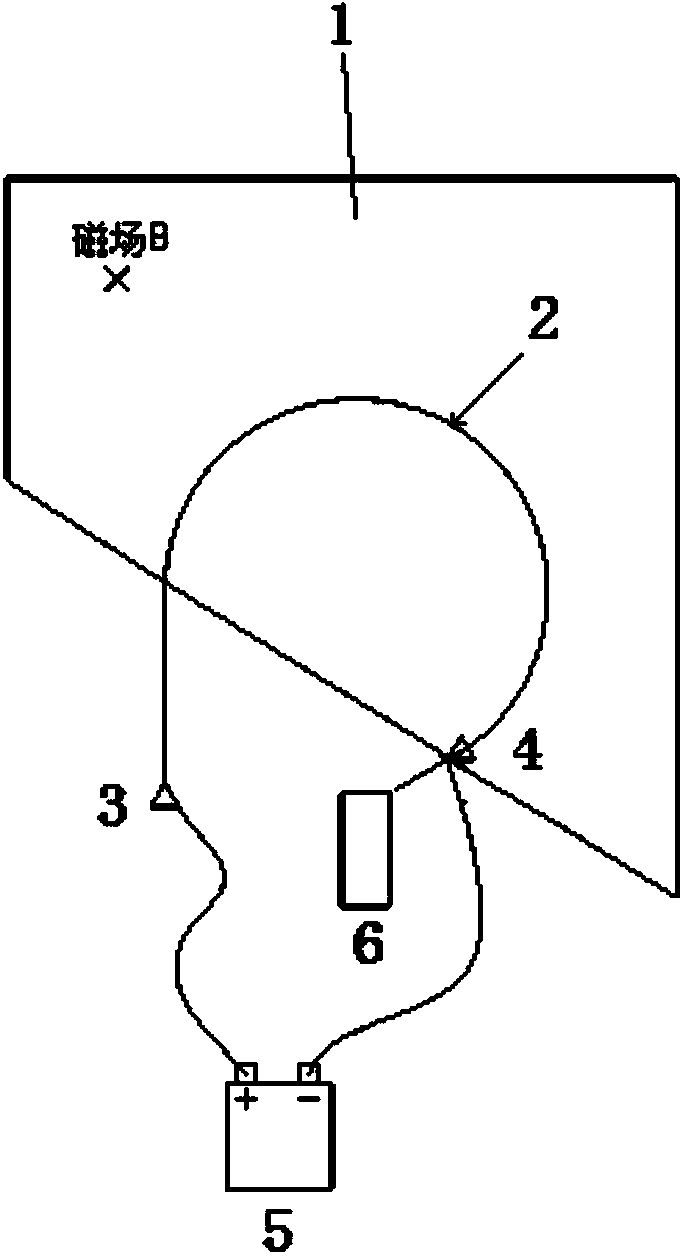

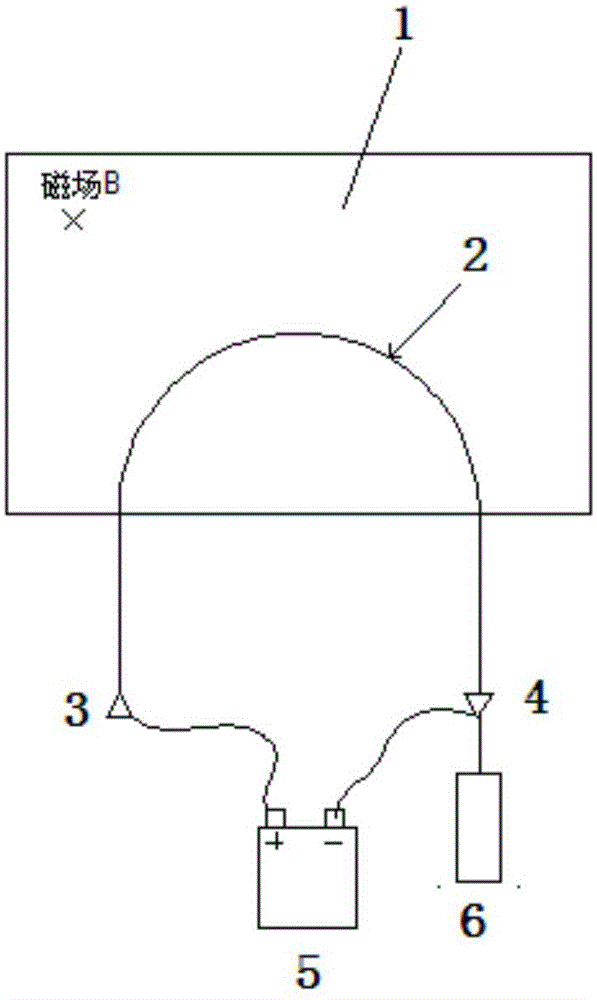

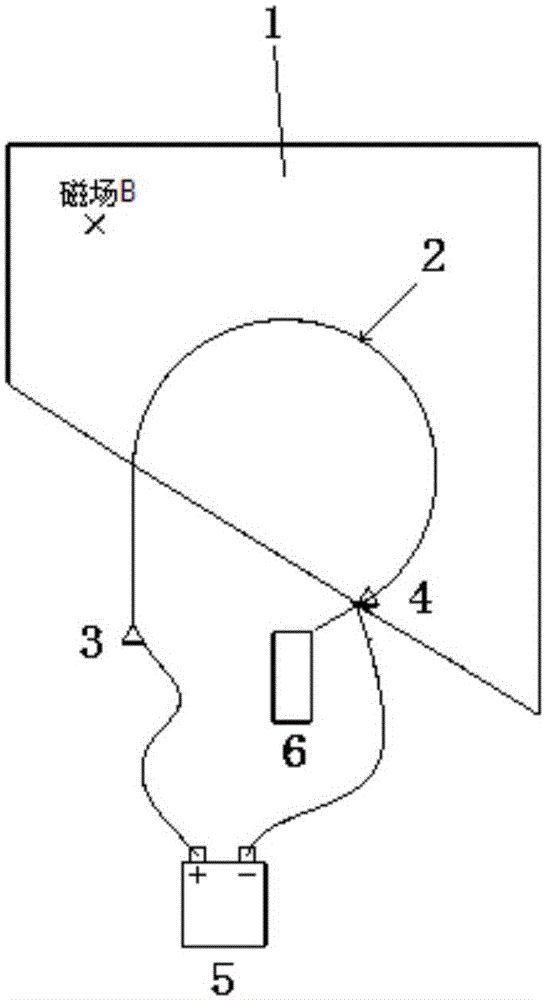

Method for simulating motion trajectory of charged particles in magnetic field

The invention discloses a method for simulating the motion trajectory of charged particles in a magnetic field. A movable supporting plane is placed in a horizontal plane perpendicular to the direction of the magnetic field so that required simulation equipment can be placed in the magnetic field conveniently; the two ends of a high-conductivity conductor wire are fixed to the movable supporting plane through a fixed supporting point and a sliding supporting point respectively; the positive electrode and the negative electrode of a direct-current constant-current power supply are connected to the high-conductivity conductor wire through the fixed supporting point and the sliding supporting point respectively; the direct-current constant-current power supply is turned on so that the high-conductivity conductor wire can acquire a current with a certain amplitude; the high-conductivity conductor wire will be unfolded in a certain arc shape; different shapes of the high-conductivity conductor wire in the magnetic field can be acquired by moving the sliding supporting point, and tension on the high-conductivity conductor wire can be read out through a tension meter; the momentum of the charged particles represented by the current-carrying high-conductivity conductor wire at the moment is calculated through the current and the tension. The method does not require real charged particles and thus is more convenient to apply and more flexible.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

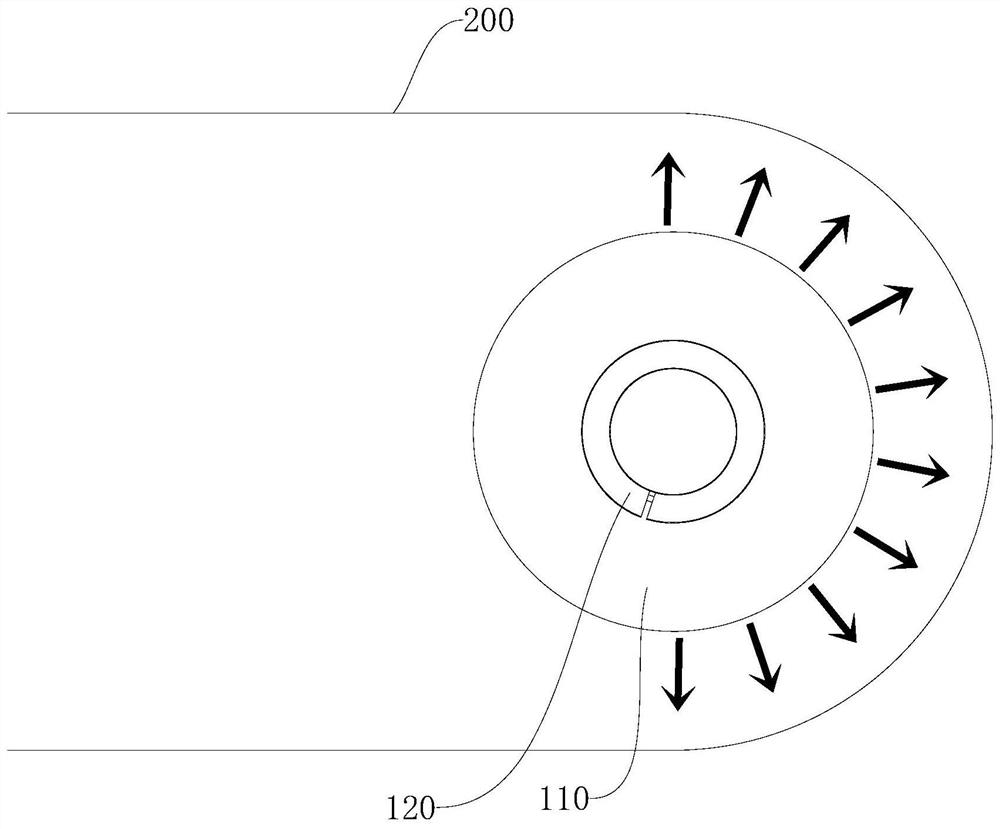

Airflow suspension device and lithium battery production equipment

PendingCN113335979ATension effectSimplify the tension control processFinal product manufactureElectrolyte accumulators manufactureThermodynamicsMechanical engineering

The invention discloses an airflow suspension device and lithium battery production equipment, and relates to the technical field of lithium battery production. The airflow suspension device comprises an outer shell and a fan. The fan is fixedly installed in the outer shell, a through hole is formed in the outer shell, and the fan is used for discharging air outwards through the through hole so that a strip can be suspended on the surface of the outer shell. Compared with the prior art, according to the airflow suspension device, the fan installed in the outer shell and the through hole formed in the outer shell are adopted, so that the influence on the tension of the strip can be avoided, a tension control process is simplified, the tension control precision is improved, the tension control delay is shortened, and the system response is accelerated.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

Drying device for polyester dyed elastic fabric production and drying method thereof

PendingCN113373620AReduce manual laborImprove work efficiencyMechanical cleaningPressure cleaningPolyesterPolymer science

The invention discloses a drying device for polyester dyed elastic fabric production and a drying method thereof, and belongs to the technical field of fabric processing equipment. The drying device for the polyester dyed elastic fabric production comprises a frame, a drying box provided with a drying bin, a heating device, a dyeing tank and a dyeing roller, a heat preservation layer is arranged between the drying bin and the drying box, and a heat conduction pipe is arranged in the heat preservation layer; the heating device is arranged on the frame and used for drying the cloth; the dyeing tank is arranged at the bottom of the frame; and the dyeing roller is rotationally connected into the dyeing tank. According to the drying device for the polyester dyed elastic fabric production, cloth can be uniformly dyed, when the dyeing liquid in the dyeing tank is lower than a limiting cylinder, the dyeing liquid can be automatically supplemented into the dyeing tank, the manual labor force is reduced, the working efficiency is improved, and redundant dyeing liquid on the dyed cloth can be extruded and cleaned; and meanwhile, the tensioning effect is achieved, the cloth is prevented from wrinkling in the drying process, and the drying effect on the cloth can be accelerated during drying.

Owner:吴江卓亮丝绸有限公司

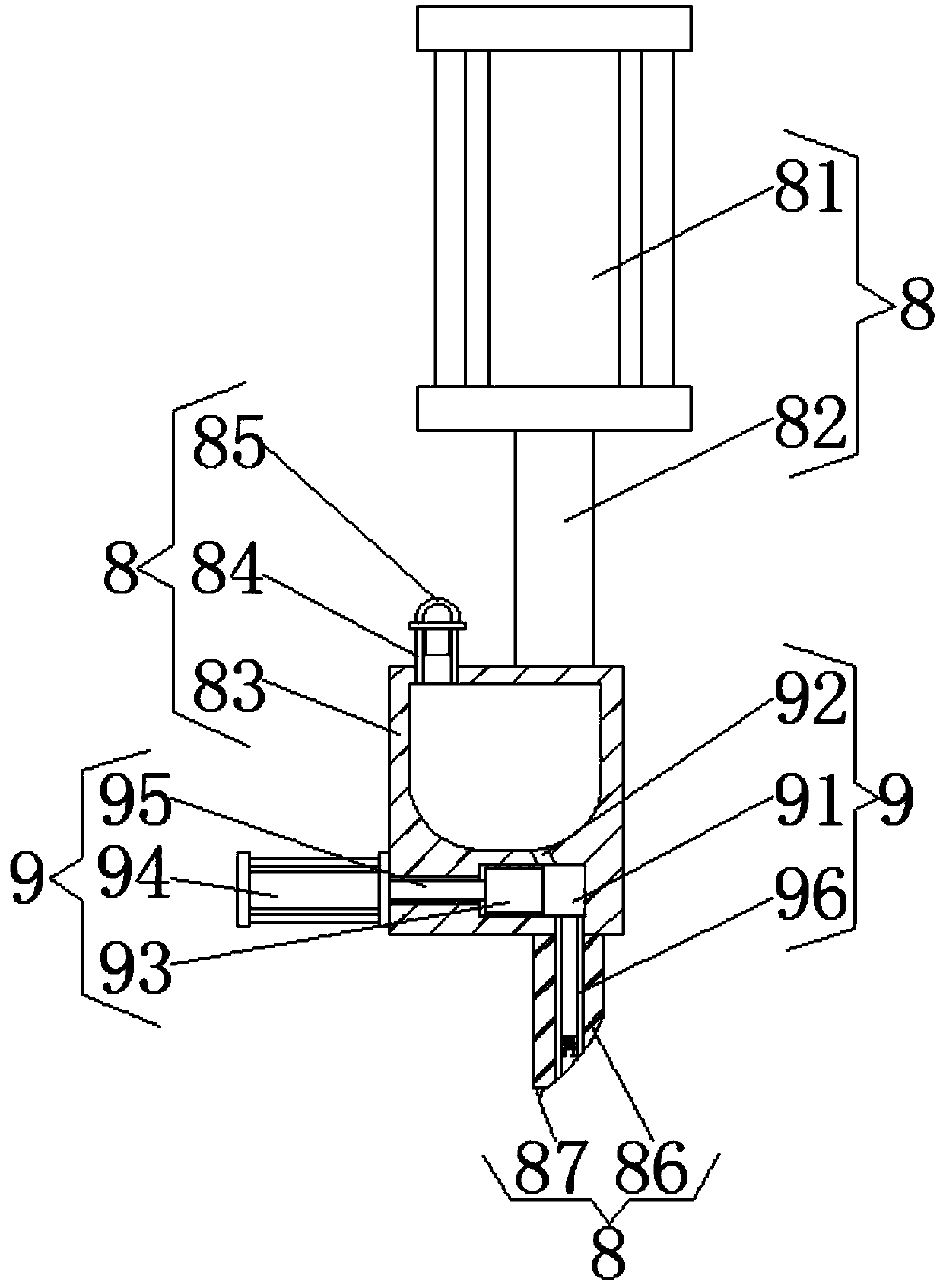

Portable wire harness tightening tool for electric power circuit laying

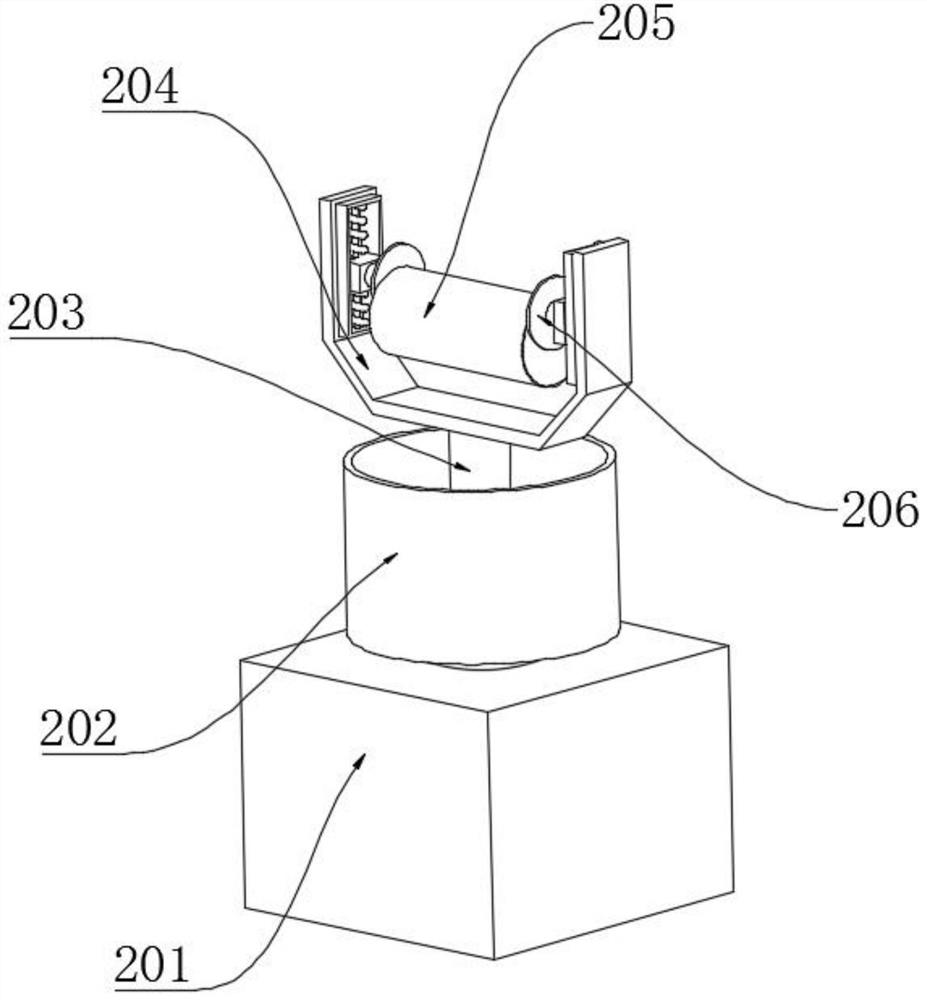

The invention relates to a portable wire harness tightening tool for electric power circuit laying. The portable wire harness tightening tool comprises a lifting device, a clamping device and a rotating device. The lifting device is installed at the lower end of the clamping device. The rotating device is installed at the lower end of the lifting device. The problems that when a drooping cable istightened, generally manual operation is needed, the cable cannot be too loose or too tight when tightened and needs to be tightened with great strength, the cable may be broken when being excessivelytightened, power transmission is affected, personal safety of an operator is greatly threatened, a traditional machine mechanically drives a winding roller through power to rotate so as to tighten the cable, a worker not only needs to straighten the cable by rotating a wheel in the operation process, but also needs to continuously prevent the wheel from rotating backwards with strength under thecounteracting force of the cable, and great inconvenience is brought to the worker can be solved.

Owner:STATE GRID CORP OF CHINA +1

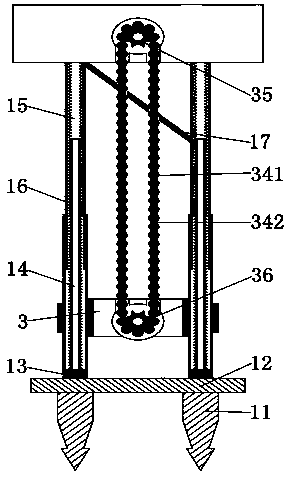

A kind of diamond processing equipment

ActiveCN113265643BAffect qualityTension effectChemical vapor deposition coatingEngineeringMechanical engineering

The present invention relates to the field of diamond technology, in particular, to a diamond processing equipment, including a vapor deposition furnace, and a hot wire mechanism installed in the vapor deposition furnace, the hot wire mechanism includes a carrier, and several The hot wire on the carrier, the carrier includes a first installation beam and a second installation beam arranged in parallel, the first installation beam is provided with a number of clips for the heating wire to bypass, wherein the clips are perpendicular to the The length direction of the first installation beam is slidably installed on the first installation beam; an elastic piece is arranged between the first installation beam and the clip, and the clip is always kept sliding to the outside of the first installation beam through the elastic piece Trend; the hot wire mechanism also includes a detection piece arranged on the first installation beam or clip, when the elastic piece returns to its original position, the detection piece is triggered and sends a signal feedback to the control center. The invention can play a reminder effect when the hot wire is blown.

Owner:杭州超然金刚石有限公司

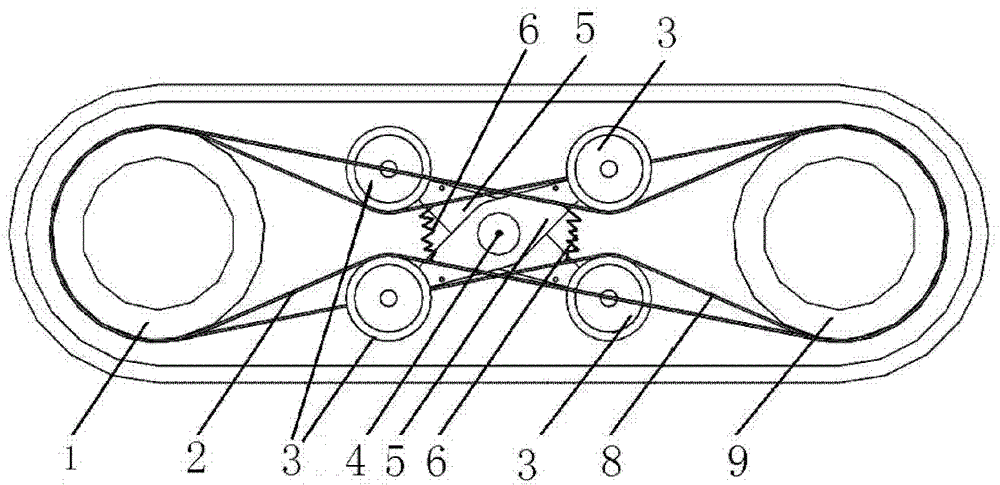

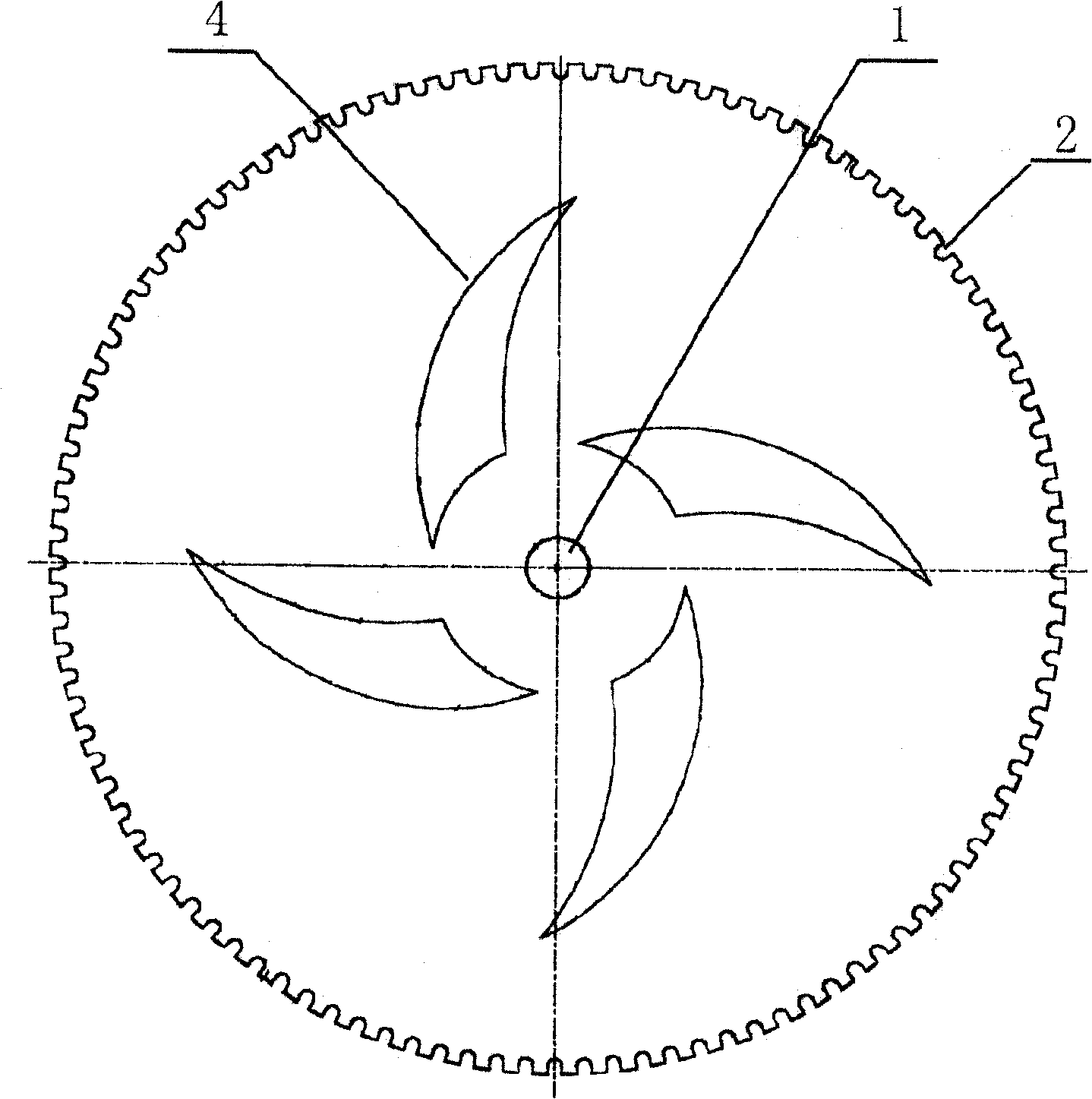

Pulley mechanism with tensioning mechanism

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Saw web base body with hollowed holes

InactiveCN100457414CReduce frictionReduce contact surfaceCircular sawsStone-like material working toolsWater channelHole saw

The invention discloses a through hole saw blade basal body, there are central installation hole and processing locating hole, the outer edge of the basal body is made with water channel, and the through holes are uniformly distributed on the basal body. It reduces contact surface area, has small cutting resistance, effectively reduces noise, enhances heat radiation and cooling, and has simple process and lower fabrication cost.

Owner:HEIXUANFENG SAW IND

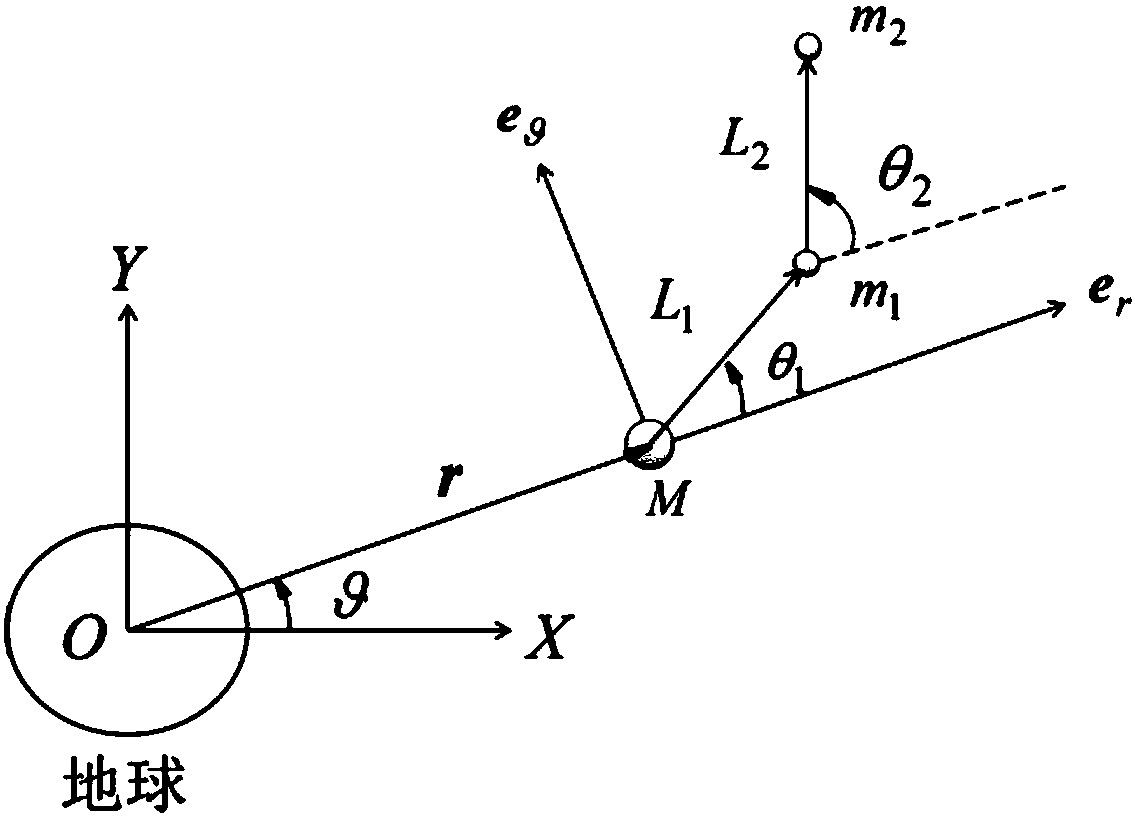

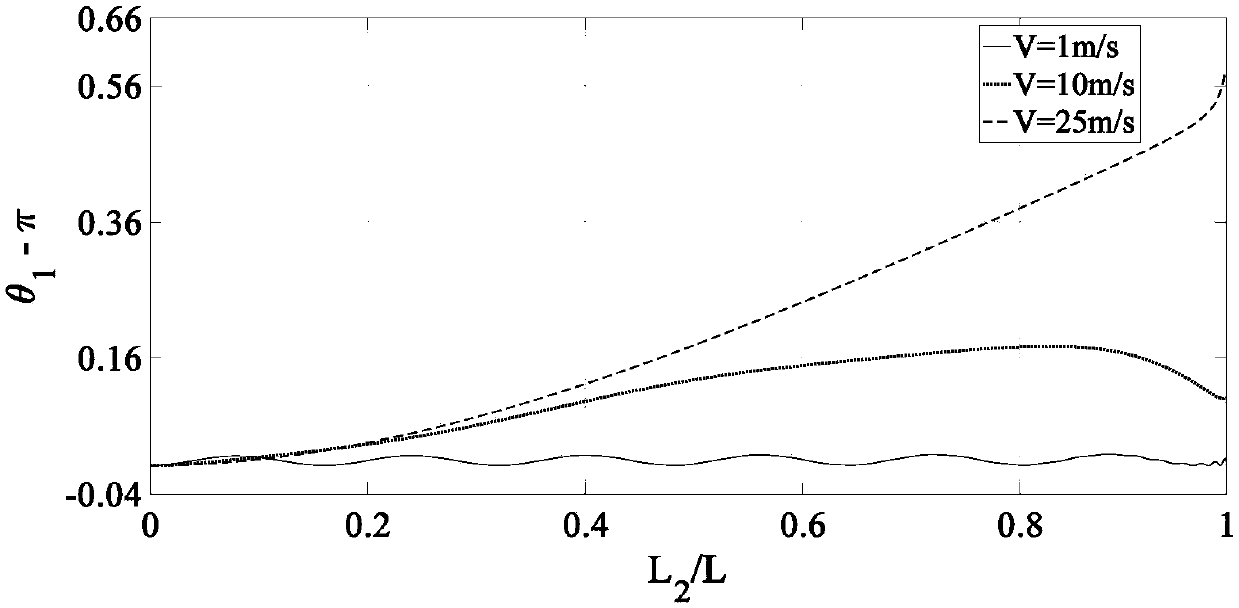

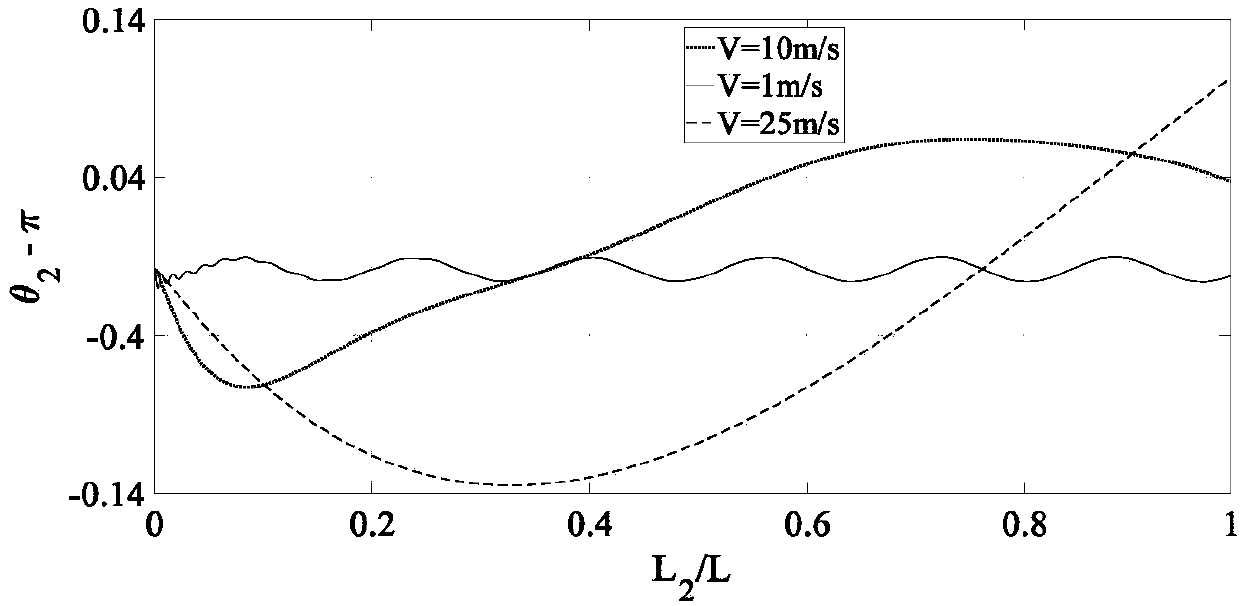

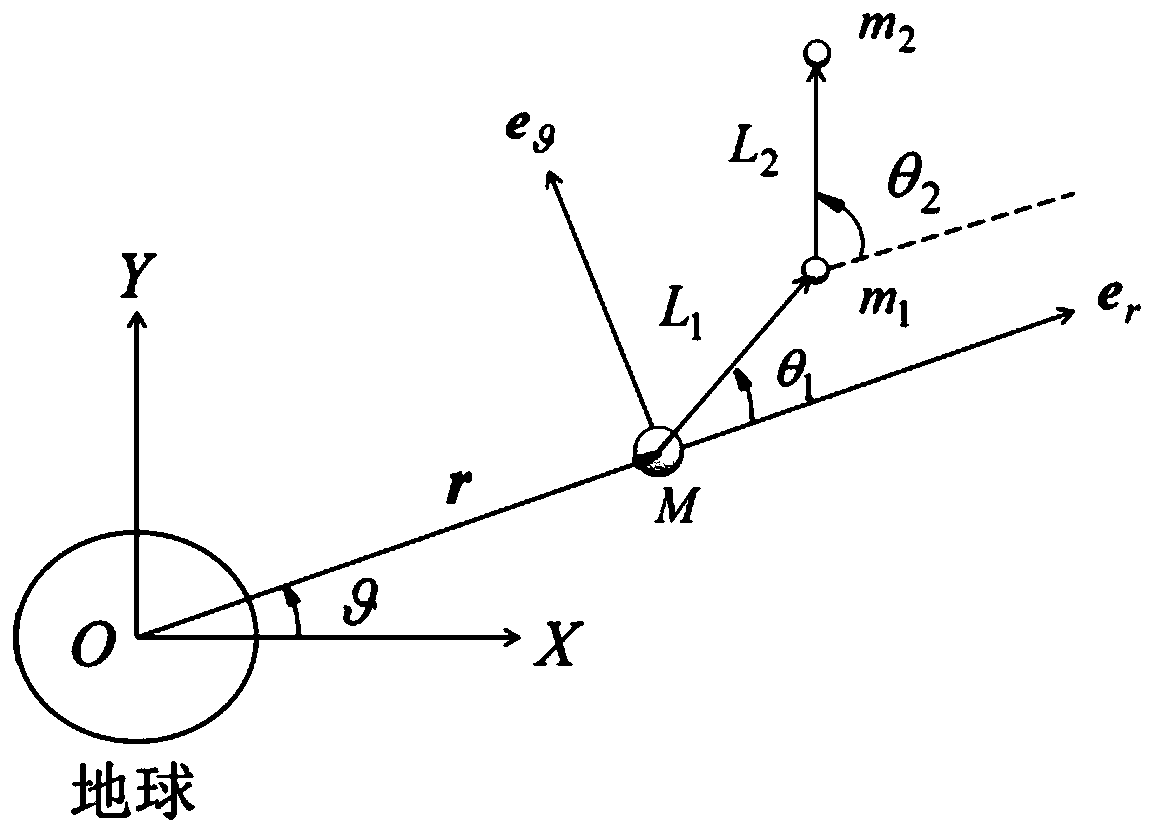

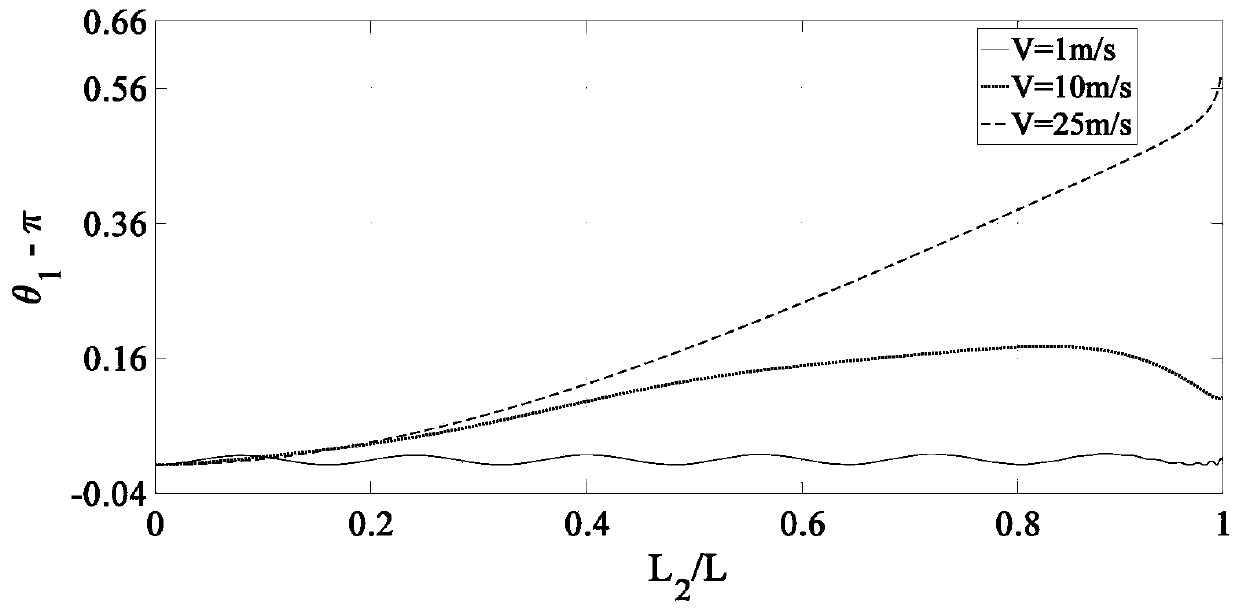

Method for predicting internal tension of tying ropes of elevator systems in local spaces

ActiveCN107688685ATension effectHigh precisionDesign optimisation/simulationSpecial data processing applicationsElevator systemActive force

The invention discloses a method for predicting internal tension of tying ropes of elevator systems in local spaces. The method includes steps that the elevator systems carry out planar movement in systems, mother stars are used as original points of moving coordinate systems of the systems, the mother stars are heavier than elevator cabins and operation spacecrafts, tracks of the mother stars areunaffected by movement of component stars, included angles between the tying ropes and Ox are represented as theta 1 and theta 2, the lengths of the portions, which are positioned between the motherstars and the elevator cabins, of the tying ropes are represented as L1, the lengths of the portions, which are positioned between the elevator cabins and the operation aircrafts, of the tying ropes are represented as L2, gravitation vectors of the elevator cabins m1 and gravitation vectors of the operation aircrafts m2 are represented as G1 and G2, and kinetic equations of elevator cabin bodies are established; inherent tension T0 of the tying ropes in the elevator systems in the local spaces is computed; tension generated by active force of the elevator cabins is obtained according to the kinetic equations of the elevator cabin bodies; the internal tension T1 and T2 of the corresponding tying ropes at the upper end and the lower end of each elevator system in the corresponding local spaces is computed. The method has the advantage that the internal tension of the tying ropes in the elevator systems in the local spaces can be predicted by the aid of the method.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

strapping equipment

ActiveCN109689505BTension effectAvoid sudden changesBinding material applicationBundling machine detailsStrappingConstruction engineering

The invention discloses a strapping device for bundling articles with a strapping strap, the strapping device has a tensioning device for imparting strap tension to a loop of the strapping, the tensioning device includes a drivable tensioning element, the tensioning device Elements are provided for engaging the strapping to impart tension to the strap. The strapping device comprises connecting means for producing a permanent connection, in particular a welded connection, at two regions of the loop of the strapping, one above the other. The strapping device is configured to reliably effect the release of the tensioning element from the strapping in order to avoid or reduce unfavorable characteristics caused by releasing the tensioning device from the strap.

Owner:SIGNODE IND GRP

High-speed stranding machine with stranding tension control function and working method of high-speed stranding machine

ActiveCN114551006AReduce tensionTension effectCable/conductor manufactureEngineeringStructural engineering

The invention discloses a high-speed stranding machine with a stranding tension control function, which comprises a stranding machine body, a bunching mechanism is arranged on one side of a fixed seat arranged on one side of the stranding machine body, a first branching mechanism and a second branching mechanism are arranged on the other side of the fixed seat, and the first branching mechanism and the second branching mechanism have the same structure; a plurality of first adjusting mechanisms and a plurality of second adjusting mechanisms used for adjusting tension are arranged on one side of the first wire separating mechanism and one side of the second wire separating mechanism respectively in an equal-radian mode. Through the first adjusting mechanism arranged on the first wire separating mechanism and the second adjusting mechanism arranged on the second wire separating mechanism, the extendable adjusting wheel on the first adjusting mechanism is used for finely adjusting the tension of the wire at the wire separating hole, so that the tension of each wire is kept balanced when the wire is fed; and a second adjusting mechanism on the second branching mechanism is used for adjusting the tension of the wire before twisting, so that the tension of the wire is balanced and the wire is uniformly paid off when the wire is twisted.

Owner:GUANGZHOU HONGHUI ELECTRICIAN & MACHINERY

A method for simulating the trajectory of charged particles in a magnetic field

The invention discloses a method for simulating the motion trajectory of charged particles in a magnetic field. A movable supporting plane is placed in a horizontal plane perpendicular to the direction of the magnetic field so that required simulation equipment can be placed in the magnetic field conveniently; the two ends of a high-conductivity conductor wire are fixed to the movable supporting plane through a fixed supporting point and a sliding supporting point respectively; the positive electrode and the negative electrode of a direct-current constant-current power supply are connected to the high-conductivity conductor wire through the fixed supporting point and the sliding supporting point respectively; the direct-current constant-current power supply is turned on so that the high-conductivity conductor wire can acquire a current with a certain amplitude; the high-conductivity conductor wire will be unfolded in a certain arc shape; different shapes of the high-conductivity conductor wire in the magnetic field can be acquired by moving the sliding supporting point, and tension on the high-conductivity conductor wire can be read out through a tension meter; the momentum of the charged particles represented by the current-carrying high-conductivity conductor wire at the moment is calculated through the current and the tension. The method does not require real charged particles and thus is more convenient to apply and more flexible.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

A Method for Predicting Internal Tension of Tether in Elevator System in Local Space

ActiveCN107688685BTension effectHigh precisionDesign optimisation/simulationSpecial data processing applicationsElevator systemClassical mechanics

The invention discloses a method for predicting internal tension of tying ropes of elevator systems in local spaces. The method includes steps that the elevator systems carry out planar movement in systems, mother stars are used as original points of moving coordinate systems of the systems, the mother stars are heavier than elevator cabins and operation spacecrafts, tracks of the mother stars areunaffected by movement of component stars, included angles between the tying ropes and Ox are represented as theta 1 and theta 2, the lengths of the portions, which are positioned between the motherstars and the elevator cabins, of the tying ropes are represented as L1, the lengths of the portions, which are positioned between the elevator cabins and the operation aircrafts, of the tying ropes are represented as L2, gravitation vectors of the elevator cabins m1 and gravitation vectors of the operation aircrafts m2 are represented as G1 and G2, and kinetic equations of elevator cabin bodies are established; inherent tension T0 of the tying ropes in the elevator systems in the local spaces is computed; tension generated by active force of the elevator cabins is obtained according to the kinetic equations of the elevator cabin bodies; the internal tension T1 and T2 of the corresponding tying ropes at the upper end and the lower end of each elevator system in the corresponding local spaces is computed. The method has the advantage that the internal tension of the tying ropes in the elevator systems in the local spaces can be predicted by the aid of the method.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

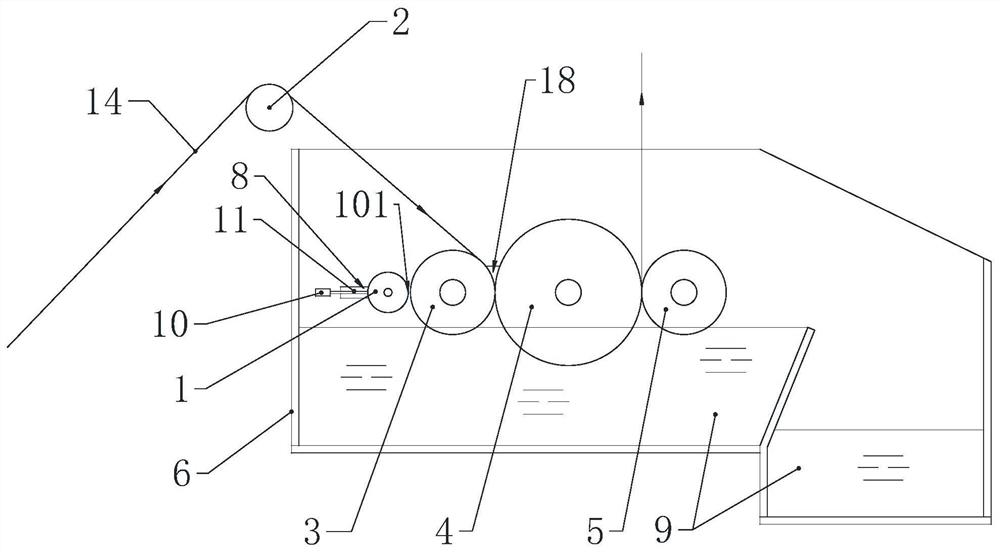

A thermal synthesis device with film

ActiveCN106903893BImprove stabilityStable tensionClimate change adaptationGreenhouse cultivationEngineeringSteel structures

The invention provides a thermal synthesis forming device of a belt film, belongs to the technical field of machinery, and solves the problem of poor thermal synthesis effect caused by low stability of the existing thermal synthesis forming device. The thermal synthesis forming device of the belt film comprises a stand, a conveying roller group and an output roller group, wherein the stand comprises two stand seats; the two stand seats are connected through a main cross beam group; the main cross beam group comprises at least two cross beams I consisting of steel structures; two ends of the cross beams I are respectively fixed on the two stand seats; thermal synthesis tool bars are further fixed on the cross beams I; an upper guide roller for reversing a thin film to vertically convey the thin film and a lower guide roller for reversely outputting the thin film subjected to thermal synthesis are further arranged between the two stand seats; two ends of the upper guide roller are respectively connected to the two stand seats and located above the main cross beam group; and two ends of the lower guide roller are respectively connected to the two stand seats and located below the main cross beam group. The thermal synthesis forming device of the belt film can realize stably continuous thermal synthesis forming of all portions of an ultrawide thin film, and is relatively good in forming effect.

Owner:BOEN SOLAR TECH

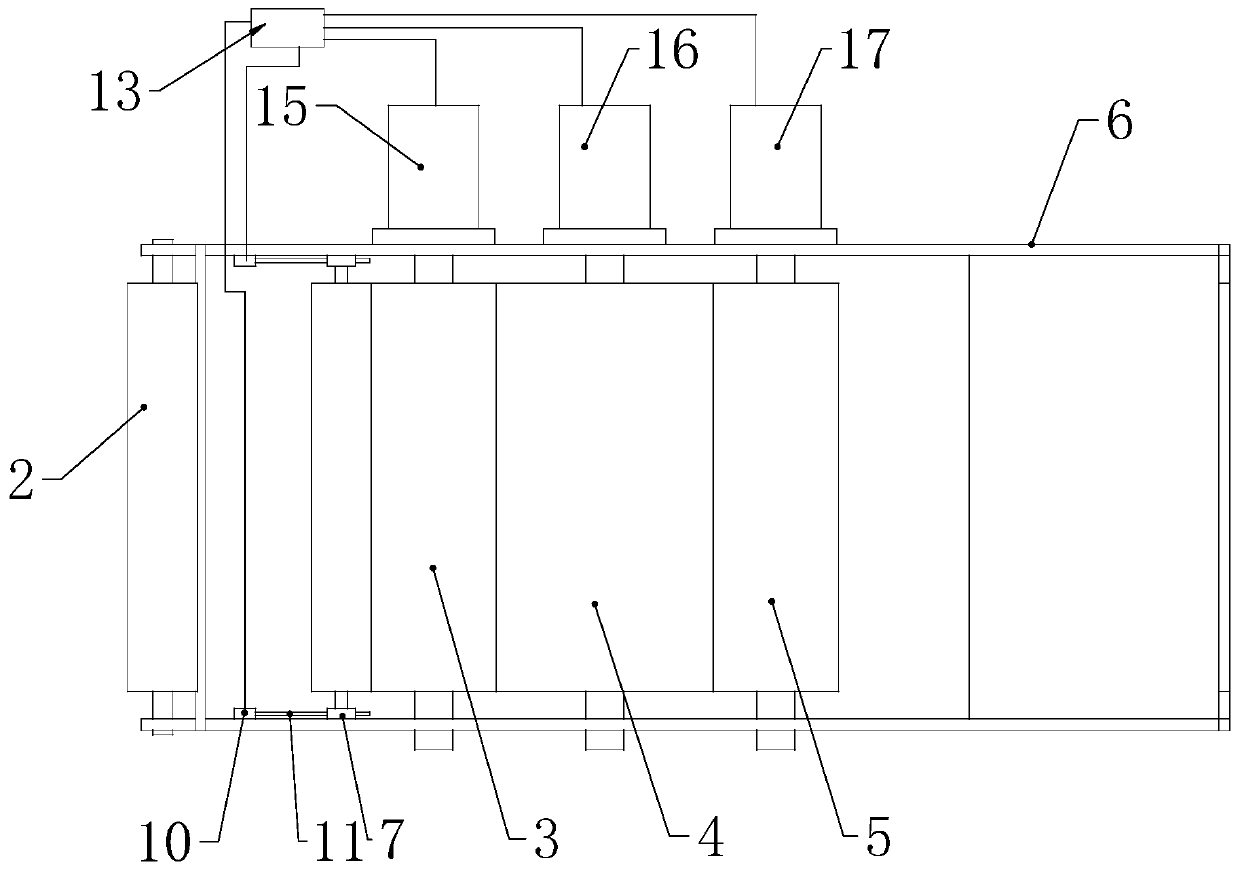

Sizing device

ActiveCN110629429ASizing rate guaranteeTension effectTextile treatment containersLiquid/gas/vapor removal by squeezing rollersYarnSlurry

The invention relates to a sizing device, comprising a feeding roll, a prepress roller, a sizing roller, a pressure-measuring roller and a size box; the prepress roller, the feeding roller and the pressure-measuring roller are rotationally mounted in the size box in parallel, the prepress roller is abutted against one side of the feeding roller, the pressure-measuring roller is abutted against theother side of the feeding roller, lower sides of the the prepress roller and the feeding roller are both soaked with size, and the feeding roller is arranged above the size box; a liquid-controller is arranged on the side, back to the feeding roller, of the prepress roller, has a liquid-control edge which is parallel to and close to the prepress roller, and is movably connected into the size box;and the spacing between the liquid-control edge and the prepress roller is adjustable. The yarn pre-sizing rate is adjusted by adjusting the spacing between the liquid-control edge and the prepress roll, so that the final sizing rate of yarn is adjusted. The yarn sizing rate adjusting manner is simple, without any influence to tension of yarn during adjusting, the yarn sizing rate is guaranteed,while external drawing to the yarn during sizing is eliminated to the utmost extent, and quality of the yarn is improved.

Owner:JIANGNAN UNIV

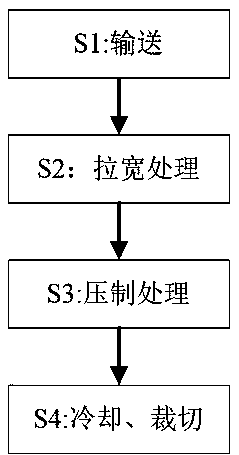

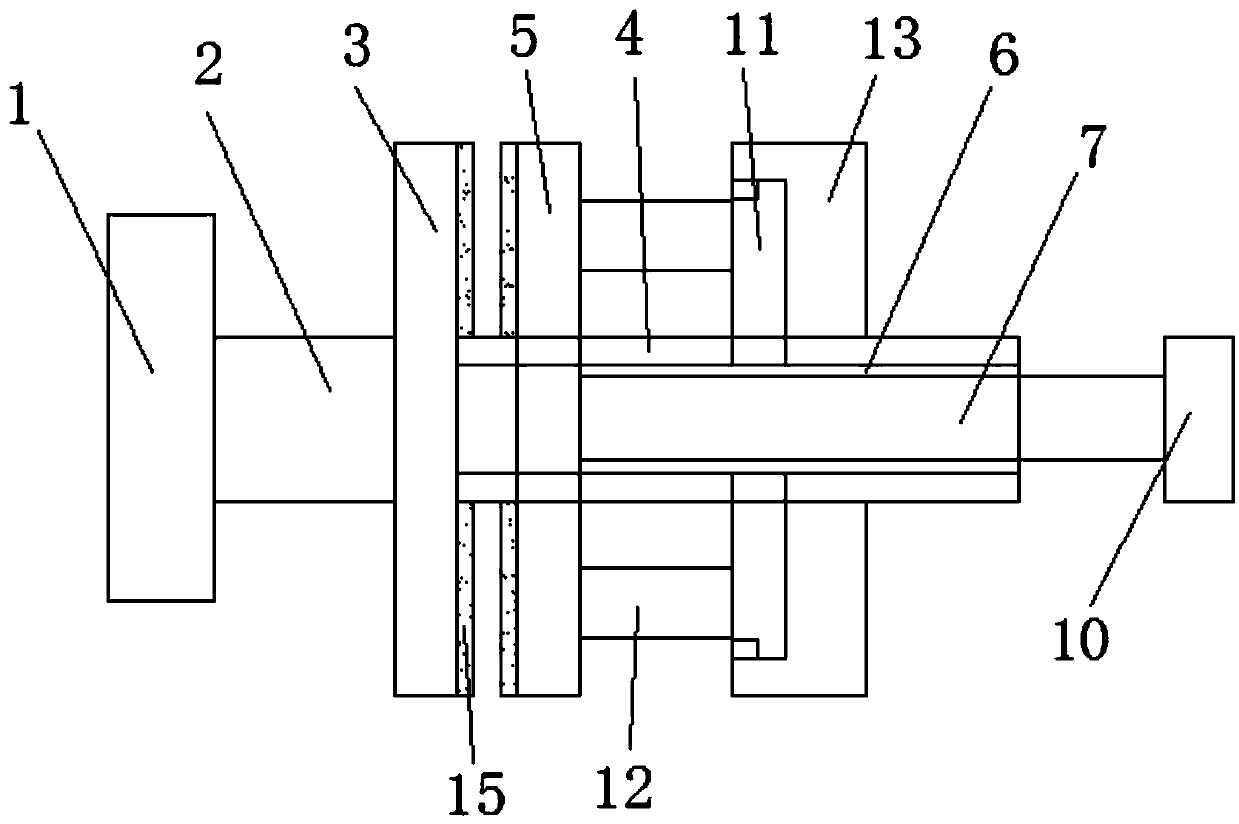

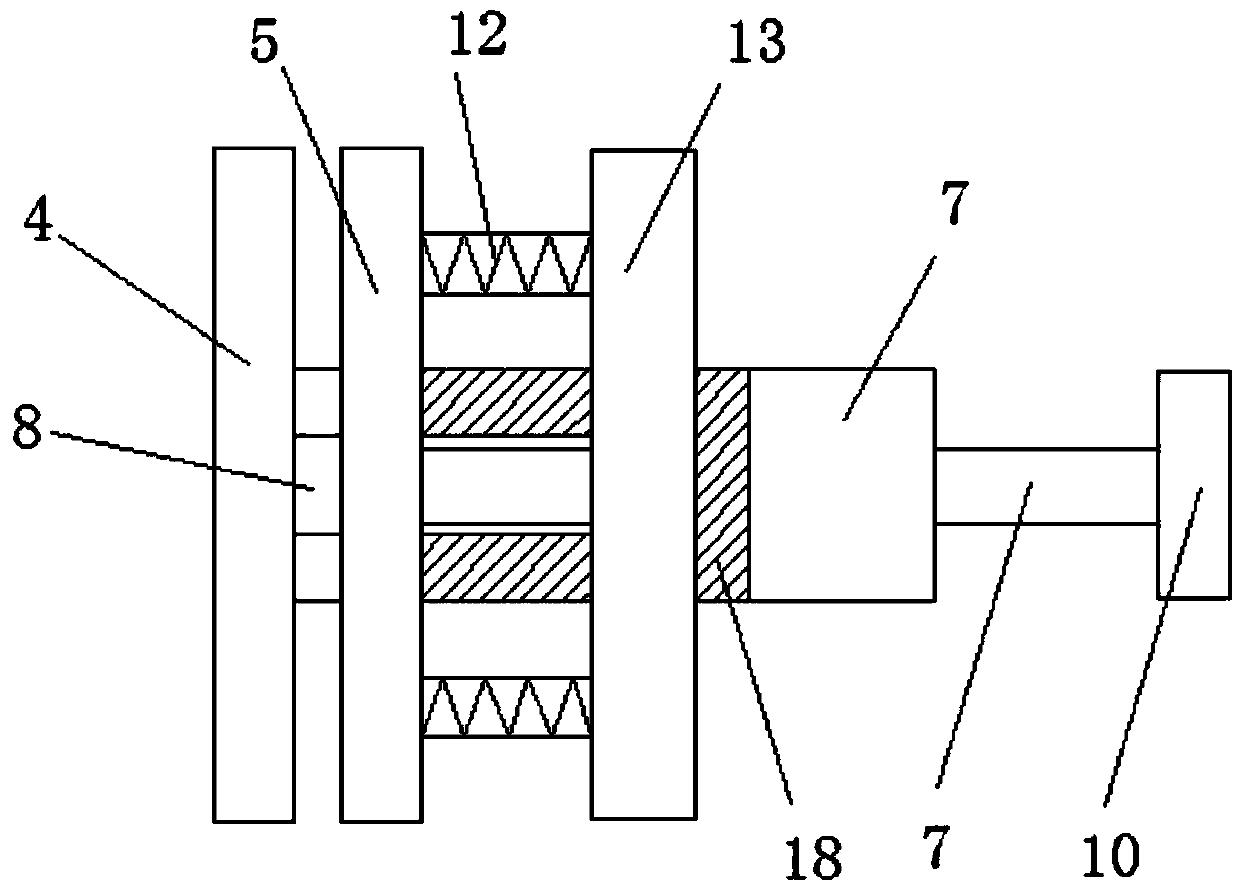

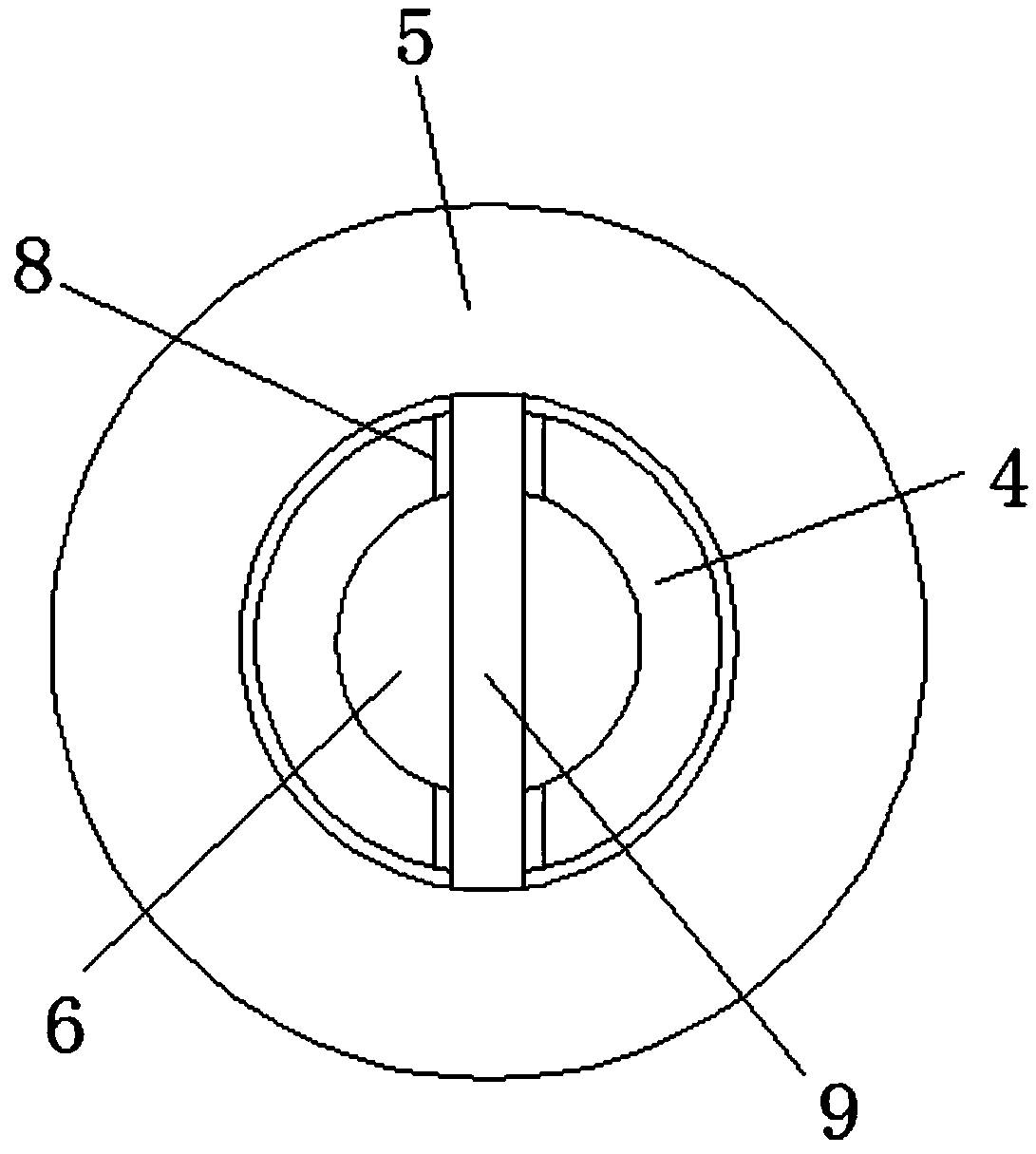

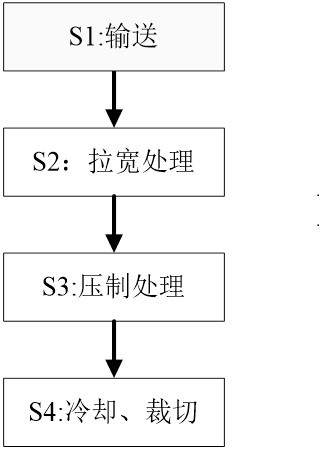

Plastic film production process

ActiveCN111231382AIncrease or decrease delivery routeReduce tensionFlat articlesBlow moldingElectric machinery

The invention provides a plastic film production process. According to the plastic film production process, a base plate, a mounting rack, two widening devices, two pressing devices, a driving motor,cooling rollers and a cutoff device are used in cooperation to complete operation. Through the plastic film production process, the problems that foam films formed by blow molding are different in thickness, it is hard to obtain the foam films with the uniform thickness through double rollers after one-time pressing, the blow molded foam films have a certain viscosity due to the temperature, the foam films can be still likely to adhere to common rollers when the common rollers conduct pressing on the foam films, the pressed foam films are pulled and torn by the rotating rollers accordingly, the shaped foam films are likely to get loose during transportation and can hardly be cut effectively, and the flatness of the edges of the cut foam films is reduced can be solved.

Owner:山东隆昌新材料科技股份有限公司

A sizing device

ActiveCN110629429BSizing rate guaranteeTension effectTextile treatment containersLiquid/gas/vapor removal by squeezing rollersControl engineeringYarn tension

The invention relates to a sizing device, comprising a feeding roll, a prepress roller, a sizing roller, a pressure-measuring roller and a size box; the prepress roller, the feeding roller and the pressure-measuring roller are rotationally mounted in the size box in parallel, the prepress roller is abutted against one side of the feeding roller, the pressure-measuring roller is abutted against theother side of the feeding roller, lower sides of the the prepress roller and the feeding roller are both soaked with size, and the feeding roller is arranged above the size box; a liquid-controller is arranged on the side, back to the feeding roller, of the prepress roller, has a liquid-control edge which is parallel to and close to the prepress roller, and is movably connected into the size box;and the spacing between the liquid-control edge and the prepress roller is adjustable. The yarn pre-sizing rate is adjusted by adjusting the spacing between the liquid-control edge and the prepress roll, so that the final sizing rate of yarn is adjusted. The yarn sizing rate adjusting manner is simple, without any influence to tension of yarn during adjusting, the yarn sizing rate is guaranteed,while external drawing to the yarn during sizing is eliminated to the utmost extent, and quality of the yarn is improved.

Owner:JIANGNAN UNIV

Diamond machining equipment

ActiveCN113265643AAffect qualityTension effectChemical vapor deposition coatingEngineeringStructural engineering

The invention relates to the technical field of diamonds, in particular to diamond machining equipment which includes a vapor deposition furnace and a hot wire mechanism arranged in the vapor deposition furnace, wherein the hot wire mechanism includes a bearing frame and a plurality of hot wires arranged on the bearing frame; the bearing frame includes a first mounting beam and a second mounting beam which are arranged in parallel, the first mounting beam is provided with a plurality of clamps around which the hot wires are wound, wherein the clamps are slidably mounted on the first mounting beam in a direction perpendicular to the length direction of the first mounting beam; an elastic element is arranged between the first mounting beam and each of the clamps, and the clamps always keep a trend of sliding towards the outer side of the first mounting beam through the elastic element; and the hot wire mechanism further includes a detection element arranged on the first mounting beam or the clamps, and when the elastic element restores to an initial position, the detection element is triggered to feed back signals to a control center. According to the invention, a reminding effect can be achieved when the hot wires are fused.

Owner:杭州超然金刚石有限公司

A convenient wire harness tightening tool for laying power lines

The invention relates to a portable wire harness tightening tool for electric power circuit laying. The portable wire harness tightening tool comprises a lifting device, a clamping device and a rotating device. The lifting device is installed at the lower end of the clamping device. The rotating device is installed at the lower end of the lifting device. The problems that when a drooping cable istightened, generally manual operation is needed, the cable cannot be too loose or too tight when tightened and needs to be tightened with great strength, the cable may be broken when being excessivelytightened, power transmission is affected, personal safety of an operator is greatly threatened, a traditional machine mechanically drives a winding roller through power to rotate so as to tighten the cable, a worker not only needs to straighten the cable by rotating a wheel in the operation process, but also needs to continuously prevent the wheel from rotating backwards with strength under thecounteracting force of the cable, and great inconvenience is brought to the worker can be solved.

Owner:STATE GRID CORP OF CHINA +1

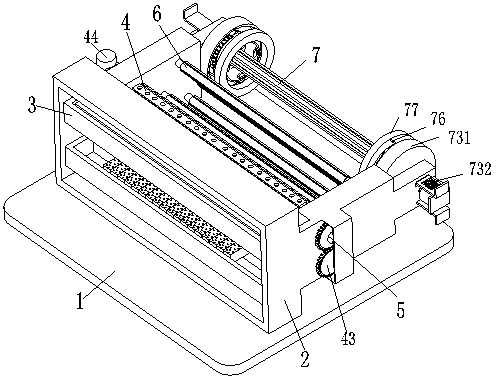

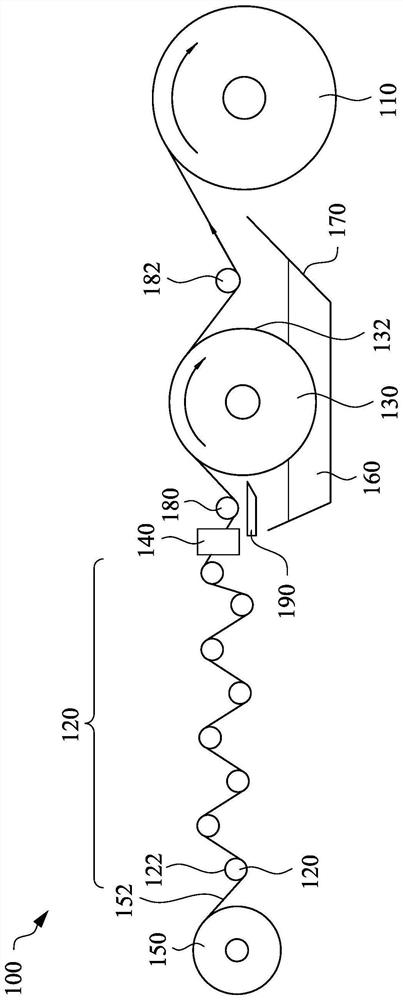

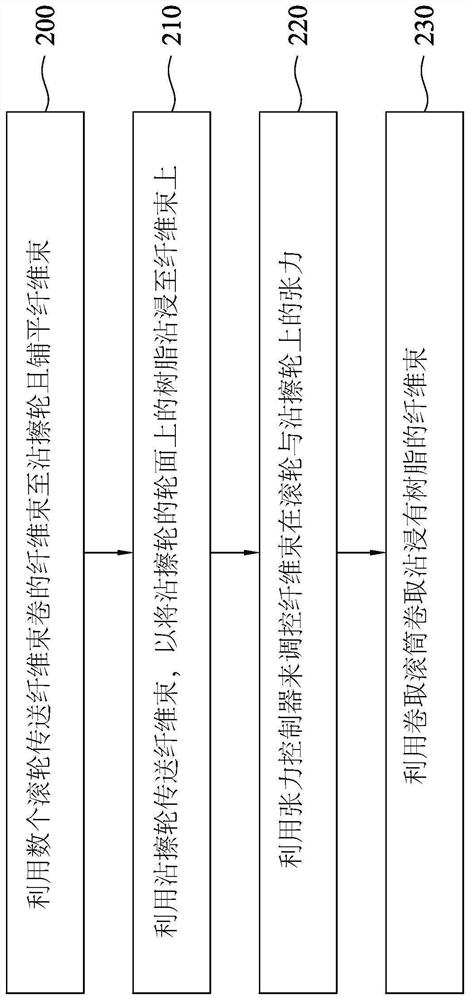

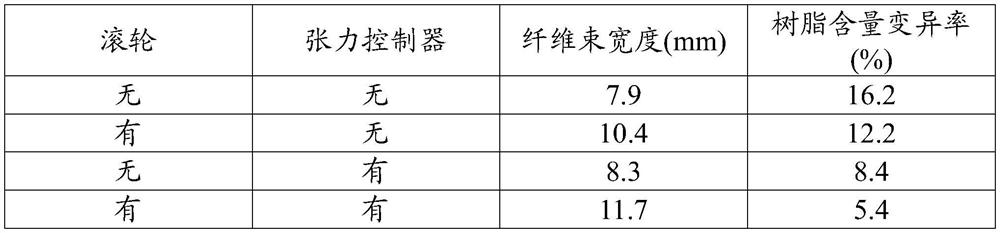

Manufacturing method and manufacturing equipment of prepreg

The invention relates to a manufacturing method and manufacturing equipment of prepreg. In the method, a plurality of rollers are used for conveying fiber bundles of a fiber bundle roll to a sticking and rubbing wheel and paving the fiber bundles. The rollers are sequentially arranged between the fiber bundle roll and the sticking and rubbing wheel and are separated from each other. And conveying the fiber bundle by using the sticking and rubbing wheel so as to dip the resin on the wheel surface of the sticking and rubbing wheel onto the fiber bundle. And when the roller and the sticking and rubbing wheel convey the fiber bundles, the tension controller is used for regulating and controlling the tension of the fiber bundles on the roller and the sticking and rubbing wheel. The fiber bundle impregnated with the resin is wound by a winding drum. The roller is used for conveying the fiber bundle, and the fiber bundle can be flattened and widened, so that the lug folding condition of the fiber bundle can be reduced, the width of the fiber bundle can be stabilized, the impregnation effect of the fiber bundle and resin can be improved, and the resin content variation rate of the prepreg can be effectively reduced. In addition, tension borne by the fiber bundles can be stabilized, and then the hairiness amount of the fibers can be reduced.

Owner:FORMOSA PLASTICS CORP

A kind of anti-scour structure for offshore wind power foundation and construction method thereof

The invention discloses an anti-scouring structure of an offshore wind power foundation and a construction method thereof. The trumpet-shaped foundation transition section is reduced from bottom to top. The top of the foundation transition section is fixed with a tower through a flange, and short piles pressed into the seabed are arranged around the cylindrical foundation, and each short pile points to the cylindrical foundation. The intersection of the line connecting the center of the circle and the circumference of the cylindrical foundation is fixed with a second cable buckle; the top side of the short pile is fixed with a first cable buckle, and a ring is laid between the second cable buckle and the first cable buckle. shaped coating; the inner ring of the coating is fixedly connected to the second cable buckle, and the outer ring of the coating is tightened by the first cable provided on the first cable buckle; the other end of the first cable is fixedly connected to the tower . The invention aims to provide a fast, efficient and economical erosion protection method for the cylindrical foundation, and improve the overall safety performance of the cylindrical foundation.

Owner:TIANJIN UNIV

Tension control device for flexographic printing and operation method of tension control device

PendingCN113860041AIncrease flexibilityImprove work efficiencyPrinting press partsWebs handlingFlexographyProcess engineering

The invention discloses a tension control device for flexographic printing and an operation method of the tension control device, and relates to the technical field of flexographic printing. The tension control device aims at solving the problem that the printing process is discontinuous due to the fact that a product needs to be fixed on a frosting plate when flexographic printing equipment is used for frosting the product. The device comprises a frosting rack, a tension buffering mechanism and a flexographic plate. The method comprises the following steps that the printed flexographic plate passes through a guide roller, penetrates through the tension buffering mechanism, a limiting connecting roller, a frosting plate and a rotating wheel and then is fixed to a winding connecting roller. The flexographic plate is frosted on the frosting table, the flexographic plate cannot move during frosting, printing of the flexographic plate is not stopped at the moment, tension control is conducted on the printed flexographic plate through the tension buffering mechanism, the situation that a large number of flexographic plates are gathered and fall down, and follow-up frosted conveying is affected is avoided, the tension of the flexographic plate is kept, and the flexibility of the device is improved; and the flexographic printing does not stop, so that the working efficiency is improved.

Owner:温州斯彩特印刷科技有限公司

Fully automatic wireless charging coil winding machine

The invention discloses a full-automatic winding machine for wireless-charging coils. The full-automatic winding machine comprises a frame, a die head driving device, a wire arranging mechanism, a wire storing mechanism, a horizontal sliding mechanism, a longitudinal sliding mechanism, a vertical lifting and sliding mechanism and a discharging mechanism. The wire arranging mechanism is arranged on one side of the frame. The die head driving mechanism is arranged on the other side of the frame and is abutted against a die head of the wire arranging mechanism. The longitudinal sliding mechanism is arranged above the wire arranging mechanism through the horizontal sliding mechanism. The wire storing mechanism is arranged on the longitudinal sliding mechanism through the vertical lifting and sliding mechanism. The discharging mechanism is arranged between the wire arranging mechanism and the die head driving device. The full-automatic winding machine is ingenious and reasonable in design, smooth in operation, high in accuracy, high in working efficiency and good in winding quality; the die head of a split movable structure is arranged detachably, is convenient to mount and demount and has universality and interchangeability, and only replacement of proper die heads is needed for winding of different products, so that production cost is reduced, and production efficiency is improved; the full-automatic winding machine is applicable to winding of multilayer coils and wide in application range.

Owner:DONGGUAN ZHIGAN MACHINERY & ELECTRONICS TECHCO

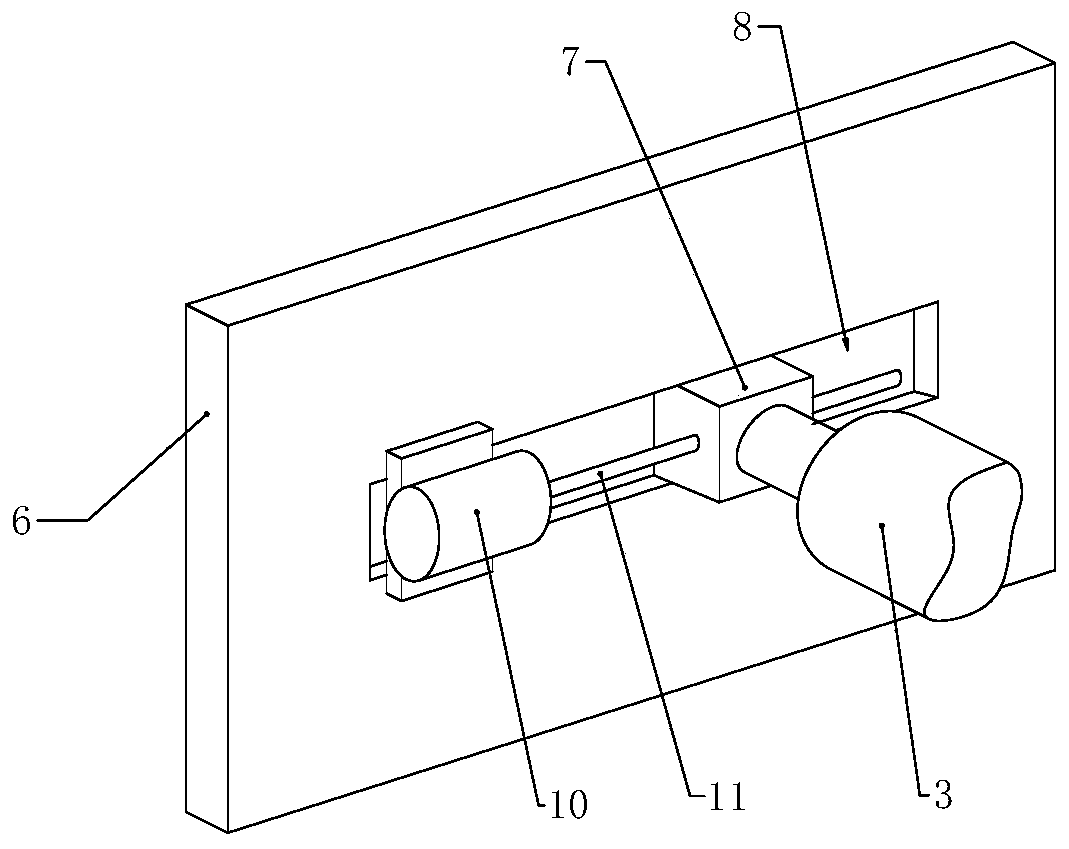

Tightener of sewing machine

PendingCN109537192AImprove regulation efficiencyTension effectTextiles and paperSewing machineControl force

The invention relates to a tightener of a sewing machine. The tightener comprises a mounting plate. A fixed bar is fixedly connected to the right side of the mounting plate, a fixed clamping plate isfixedly connected to the right side of the fixed bar, an adjusting rod is connected to the right side of the fixed clamping plate, a movable clamping plate is arranged on the outer side of the adjusting rod in a sleeving manner, a through hole is formed in an inner cavity of the adjusting rod, the drawing rod is arranged in the through hole, guide slots are symmetrically formed in the adjusting rod, a connecting rod is fixedly arranged in the movable clamping plate, the connecting rod penetrates through the guide slots, the left end of the drawing rod is connected to the connecting rod, the right end of the drawing rod extends out of the adjusting rod and is fixedly connected to a handle, a fastening plate is arranged on the right side of the movable clamping plate, the movable clamping plate is connected to the fastening plate through a spring, and the outside of the adjusting rodis sleeved with the fastening plate. The stability of the tightener to upper thread tension adjustment isimproved, the control force of the upper thread is enhanced, and meanwhile, the upper thread can be replaced without changing the tension of the tightener, so that the seam stitch is smooth and attractive.

Owner:吴江市宝鑫机械有限公司

A kind of plastic film production process

ActiveCN111231382BIncrease or decrease delivery routeReduce tensionFlat articlesBlow moldingElectric machinery

The invention provides a plastic film production process, which is completed by the cooperation of a bottom plate, a mounting frame, two stretching devices, two pressing devices, a driving motor, a cooling roller and a cutting device. The thickness of the film bubble is different, and it is difficult to press the thickness evenly by double-roller pressing, and because the blown film bubble has a certain viscosity due to the temperature, when ordinary rollers are used to press it, the two may appear to be rolled together. The situation is still sticky, which will cause the pressed film bubble to be pulled and torn by the rotating rollers. The shaped film bubble may be loose during transportation, and it is difficult to form an effective cutting when cutting it. , the flatness of the edge of the cut film bubble is reduced and other problems.

Owner:山东隆昌新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com